Articles

How Do Pressure Washer Pumps Work

Modified: January 6, 2024

Learn how pressure washer pumps work in this informative article. Explore the inner workings of these powerful machines and discover their various applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A pressure washer is a powerful tool that uses high-pressure water to clean a variety of surfaces. Whether it’s removing dirt from driveways, cleaning deck stains, or blasting away grime from outdoor furniture, pressure washers deliver impressive cleaning results. At the heart of every pressure washer is the pump, responsible for generating the high-pressure water that makes these machines so effective.

In this article, we will take a closer look at how pressure washer pumps work. We’ll explore the components of a pressure washer pump, understand its working principle, and discuss maintenance and troubleshooting tips to keep your pressure washer running smoothly.

So, let’s dive into the fascinating world of pressure washer pumps and uncover the secrets behind their cleaning prowess.

Key Takeaways:

- Pressure washer pumps use components like plunger, check valves, and pressure relief valve to generate high-pressure water. Understanding their functions helps troubleshoot issues and maintain optimal cleaning performance.

- Regular maintenance, such as cleaning, lubrication, and inspection of seals, is crucial for prolonging the life of pressure washer pumps. Troubleshooting techniques and safety precautions ensure reliable and efficient cleaning results.

Read more: How Do I Know If My Water Pump Is Working?

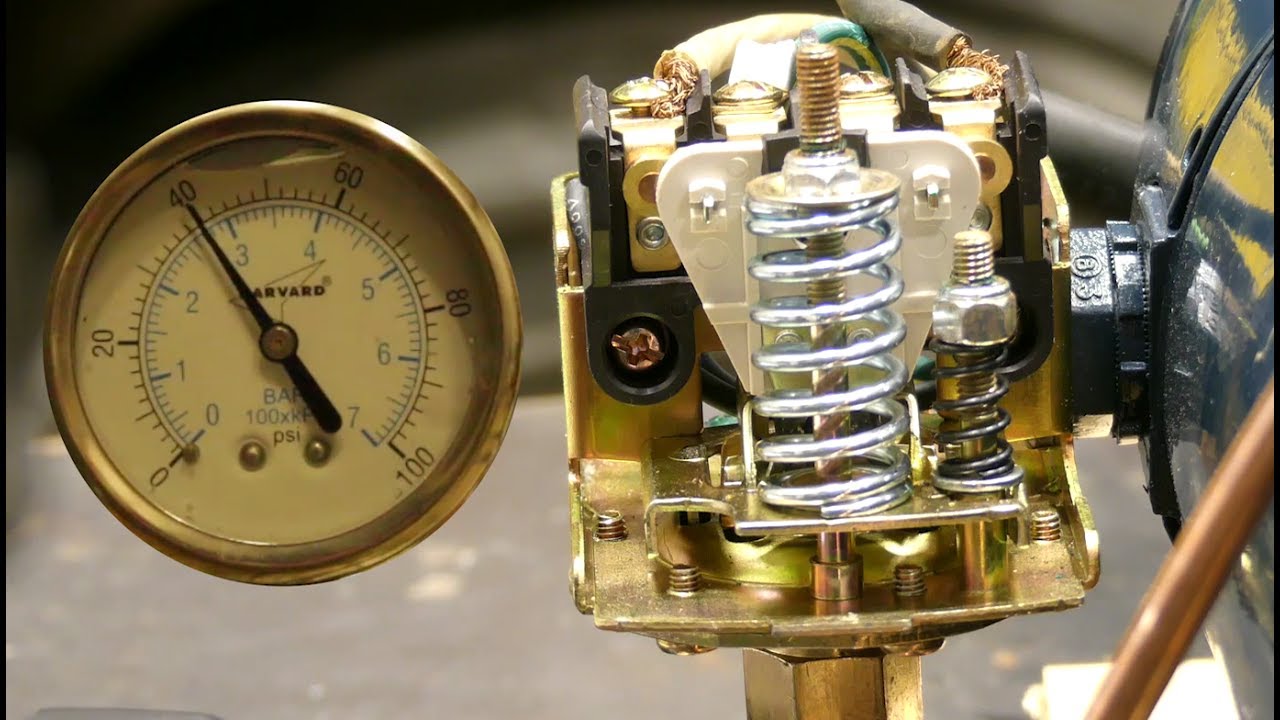

Components of a Pressure Washer Pump

A pressure washer pump is a complex machinery with several key components working together to generate high-pressure water. Understanding these components will give you a better insight into how the pump functions.

1. Inlet Valve: The inlet valve is responsible for drawing water from an external source, such as a garden hose or a water tank. It allows water to enter the pump for pressurization.

2. Plunger or Piston: The plunger (or piston) is the main component that creates pressure within the pump. It moves back and forth, propelled by an engine or motor, to compress water and generate high pressure.

3. Check Valves: Check valves ensure that water flows in one direction within the pump. They open and close to regulate the flow, preventing water from backflowing.

4. Seals and O-rings: Seals and O-rings are crucial for maintaining a tight seal between various components of the pump. They prevent leaks and ensure that water flows smoothly through the system.

5. Pressure Relief Valve: The pressure relief valve regulates the maximum pressure that the pump can generate. It releases excess pressure to prevent damage or injury in case the pressure exceeds safe levels.

6. Connecting Rod: The connecting rod transfers motion from the engine or motor to the plunger, creating the reciprocating motion that generates pressure.

These are the main components of a pressure washer pump, working in harmony to create the high-pressure water that effectively cleans various surfaces. Understanding their functions will help you troubleshoot any issues and perform regular maintenance to keep the pump in optimal condition.

Working Principle of Pressure Washer Pumps

The working principle of a pressure washer pump revolves around converting the incoming water flow into a high-pressure stream. Let’s delve into the step-by-step process of how pressure washer pumps work.

1. Water Intake: The first step in the process is the intake of water. The pump’s inlet valve opens, allowing water to enter the pump from an external source such as a garden hose or water tank.

2. Pressure Creation: Once inside the pump, the water is pressurized. This is accomplished through the reciprocating motion of the plunger or piston. As the plunger moves back and forth, it creates pressure by compressing the water against the closed check valve.

3. One-Way Flow: The check valves play a crucial role in ensuring that water flows in one direction only. When the plunger moves forward, the inlet check valve closes to prevent backflow, while the outlet check valve opens to allow water to move towards the high-pressure side of the pump.

4. Pressure Regulation: As the pressure builds up, it is essential to regulate it to prevent excessive pressure that may damage the pump or the surfaces being cleaned. The pressure relief valve helps maintain the desired pressure by releasing any excess pressure beyond safe levels.

5. High-Pressure Water Delivery: Once the water reaches the desired pressure, it is delivered through the outlet of the pump, ready to tackle tough dirt and grime. The high-pressure stream generated by the pump effectively blasts away dirt and debris from surfaces.

By following this working principle, pressure washer pumps are able to generate the high-pressure water required for effective cleaning. With their ability to create a powerful stream, pressure washer pumps provide a versatile cleaning solution for a wide range of applications.

Water Intake and Pressure Generation

The process of water intake and pressure generation is a crucial aspect of how pressure washer pumps function. Let’s explore this process in more detail:

1. Water Intake: The water intake is the initial step in the pressure generation process. The pressure washer pump draws water from an external source, such as a garden hose or water tank, through its inlet valve. It is important to ensure a steady and sufficient water supply for the pump to operate optimally.

2. Water Filtration: Before entering the pump, it is essential to filter the water to remove any debris or particles that could potentially clog or damage the internal components of the pump. Many pressure washers include a filter or strainer at the inlet to ensure clean water enters the pump.

3. Pressure Generation: Once inside the pump, the water is pressurized using the plunger or piston. The engine or motor-powered mechanism drives the reciprocating motion of the plunger, which compresses the water against a closed check valve. As the plunger moves back and forth, it generates pressure within the pump.

4. Check Valve Operation: The check valves of the pressure washer pump play a crucial role in regulating the flow of water and maintaining the generated pressure. When the plunger moves forward, it closes the inlet check valve to prevent backflow and opens the outlet check valve to allow water to move towards the high-pressure side of the pump.

5. Pressure Regulation: To ensure safe operation, pressure washer pumps feature a pressure relief valve. This valve is designed to release excess pressure if it exceeds the pump’s designated maximum limit. The pressure relief valve helps protect the pump and other components from damage and ensures safe operation.

By properly managing the water intake and effectively generating pressure, pressure washer pumps are able to deliver high-pressure water streams that are highly effective for cleaning various surfaces. It’s important to ensure a steady water supply and perform regular maintenance to keep the pump running smoothly and efficiently.

When using a pressure washer pump, always ensure that the water supply is clean and free of debris to prevent clogging and damage to the pump. Regular maintenance and cleaning of the pump will also prolong its lifespan.

High-Pressure Water Delivery

Once the pressure washer pump has generated the desired pressure, it is time for the high-pressure water delivery. This process involves directing the pressurized water towards the surface to be cleaned. Let’s explore the steps involved in high-pressure water delivery:

1. Nozzle Selection: The nozzle plays a crucial role in determining the characteristics of the high-pressure water stream. Different nozzles have different spray patterns and pressures. The nozzle should be selected based on the cleaning task at hand, whether it’s a narrow jet for tough stains or a wider spray for larger surfaces.

2. Trigger Operation: Most pressure washers have a trigger-operated spray gun. When the trigger is pulled, it allows the pressurized water to flow from the pump through the hose and out of the nozzle. Releasing the trigger stops the flow of water.

3. Water Stream Impact: The high-pressure water stream generated by the pressure washer pump has significant impact and force. This force is what effectively removes dirt, grime, and other contaminants from various surfaces. The user can control the pressure by adjusting the distance between the nozzle and the surface being cleaned.

4. Cleaning Efficiency: The high pressure of the water stream combined with the appropriate nozzle creates a powerful cleaning force. It is important to remember that certain surfaces, such as delicate wood or paint, may require lower pressure to prevent damage. Adjusting the pressure and nozzle accordingly ensures optimal cleaning efficiency without causing harm.

5. Water Conservation: High-pressure water delivery also helps conserve water. The forceful stream allows for thorough cleaning with less water usage compared to traditional methods. This is especially beneficial during drought conditions or when water conservation is essential.

By effectively delivering high-pressure water streams, pressure washer pumps offer a versatile and efficient cleaning solution for a wide range of surfaces. However, it’s important to use the appropriate nozzle, adjust the pressure as needed, and follow safety guidelines to achieve the best cleaning results without causing any damage.

Pump Maintenance and Troubleshooting

To keep your pressure washer pump in optimal condition and ensure its longevity, regular maintenance is essential. Additionally, understanding common troubleshooting techniques can help you address any issues that may arise. Let’s explore some important maintenance tips and troubleshooting steps for pressure washer pumps:

1. Regular Cleaning: After each use, flush out the pump system by running clean water through it. This helps remove any dirt or debris that may have accumulated during the cleaning process. Regular cleaning prevents clogs and ensures smooth operation.

2. Lubrication: Check and lubricate the pump’s moving parts, including the plunger or piston, as recommended by the manufacturer. Proper lubrication reduces friction, enhances performance, and prevents premature wear and tear.

3. Inspect Seals and O-rings: Regularly check the seals and O-rings for any signs of damage or leaks. Replace any damaged components to ensure a tight seal and prevent water leakage.

4. Water Supply: Ensure a steady water supply to the pressure washer pump. Check the inlet screen regularly to clean out any debris that may hinder water flow. Proper water supply is crucial for optimal pump performance.

5. Pressure Adjustment: Use the pressure adjustment mechanism on your pressure washer to match the pressure to the specific cleaning task. Using excessive pressure for the task at hand can strain the pump and cause damage.

6. Troubleshooting: If you encounter any issues with your pressure washer pump, there are a few common troubleshooting steps you can take. Check for clogs in the inlet or outlet, inspect hoses and fittings for leaks, and make sure all connections are secure. Consult the manufacturer’s manual or contact customer support for specific troubleshooting steps related to your pressure washer model.

Remember, safety is paramount when working with pressure washer pumps. Always follow the manufacturer’s guidelines, wear appropriate protective gear, and disconnect the power source before performing any maintenance or troubleshooting tasks.

By following these maintenance tips and troubleshooting techniques, you can prolong the life of your pressure washer pump and ensure its reliable performance for years to come.

Conclusion

Pressure washer pumps are the heart of these powerful cleaning machines, responsible for generating the high-pressure water streams that effectively remove dirt, grime, and debris from various surfaces. Understanding the components and working principle of pressure washer pumps allows us to appreciate their capabilities and maintain them properly.

By ensuring regular maintenance such as cleaning, lubrication, and inspection of seals, we can keep the pump in optimal condition, ensuring its longevity and performance. Troubleshooting techniques help address common issues, ensuring that the pressure washer pump continues to function smoothly.

With the ability to adjust and regulate pressure, pressure washer pumps offer versatility in cleaning different surfaces. Whether it’s cleaning driveways, decks, vehicles, or outdoor furniture, pressure washer pumps deliver impressive cleaning results.

However, it’s important to remember to follow safety guidelines and use the appropriate nozzle and pressure settings for each cleaning task to prevent damage to surfaces and ensure personal safety.

In conclusion, pressure washer pumps are essential components that power these cleaning machines, providing high-pressure water streams for efficient cleaning. By understanding how they work, performing regular maintenance, and troubleshooting as needed, we can maximize the performance and longevity of our pressure washer pumps, ensuring they remain reliable and effective tools for years to come.

So, next time you power up your pressure washer, take a moment to appreciate the incredible technology behind the pump that makes it all possible. Happy cleaning!

Frequently Asked Questions about How Do Pressure Washer Pumps Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Do Pressure Washer Pumps Work”