Articles

How Long Does A Co2 Tank Last On A Kegerator

Modified: February 27, 2024

Discover how long a CO2 tank can last on a kegerator with this informative article. Learn about factors that affect its lifespan and maximize your beer enjoyment.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of kegerators, where you can enjoy your favorite draft beer in the comfort of your home. One essential component of a kegerator is the CO2 tank, which is responsible for carbonating and dispensing the beer. But have you ever wondered how long a CO2 tank lasts on a kegerator?

In this article, we will delve into the factors that affect the duration of a CO2 tank, and provide some tips on maximizing its lifespan. So whether you’re a seasoned kegerator enthusiast or just starting out, read on to learn more about the fascinating world of CO2 tanks.

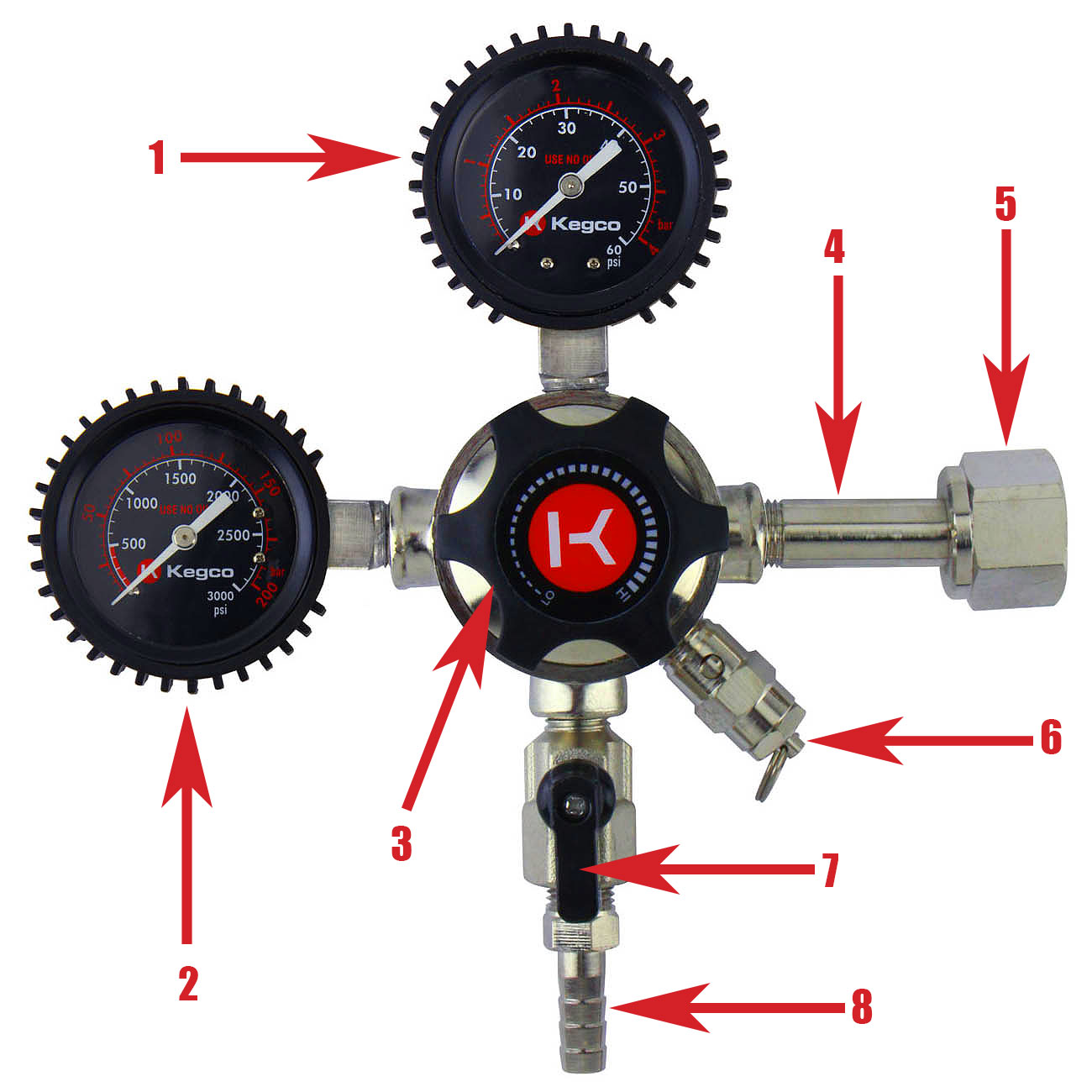

Before we jump into the details, let’s first understand what a CO2 tank is and how it works. CO2 tanks are cylinders that store carbon dioxide gas under high pressure. They connect to the keg through a regulator, which controls the release of CO2 into the keg and maintains the desired carbonation level.

The duration of a CO2 tank on a kegerator depends on various factors, including the size of the tank, the CO2 consumption rate, temperature and pressure, and the type of kegerator system. Let’s explore each of these factors in more detail.

Key Takeaways:

- Choose the right size CO2 tank based on your keg consumption and availability of refills. Optimizing CO2 consumption rate and maintaining proper temperature and pressure can extend the lifespan of your tank.

- Regularly inspect for leaks, clean beer lines, and avoid overfilling your keg to maximize CO2 tank lifespan. Consider having a spare CO2 tank on hand for uninterrupted beer pouring.

Understanding CO2 Tanks

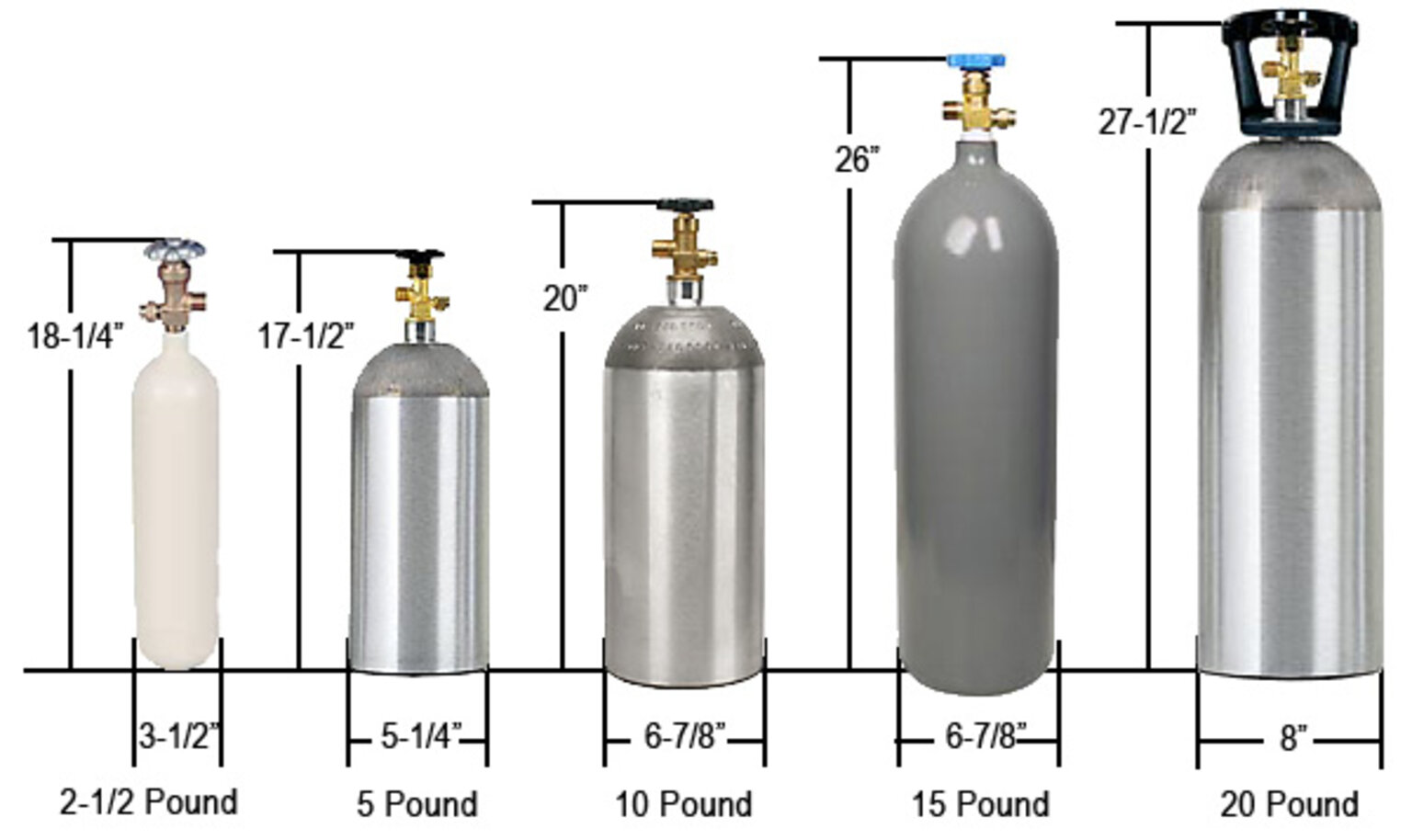

CO2 tanks are available in different sizes, commonly ranging from 2.5 pounds to 20 pounds. The larger the tank size, the more CO2 it can hold and the longer it will last. When selecting a CO2 tank for your kegerator, consider your needs and the frequency of use. A larger tank may be more suitable if you frequently host gatherings or have multiple kegs.

CO2 consumption rate is another crucial factor to understand. It refers to the amount of CO2 used per pour. The consumption rate can vary depending on factors such as the length of beer lines, the level of carbonation desired, and the beer pressure setting. Generally, a standard pour consumes around 0.5 to 1.5 ounces of CO2.

The temperature and pressure inside the kegerator can impact the lifespan of a CO2 tank. Cold temperatures can cause the CO2 to contract, slowing down the release of gas. On the other hand, warm temperatures can increase the pressure, causing the CO2 to be used up more quickly. It’s important to maintain an optimal temperature range for both the keg and the CO2 tank to ensure efficient carbonation and dispensing.

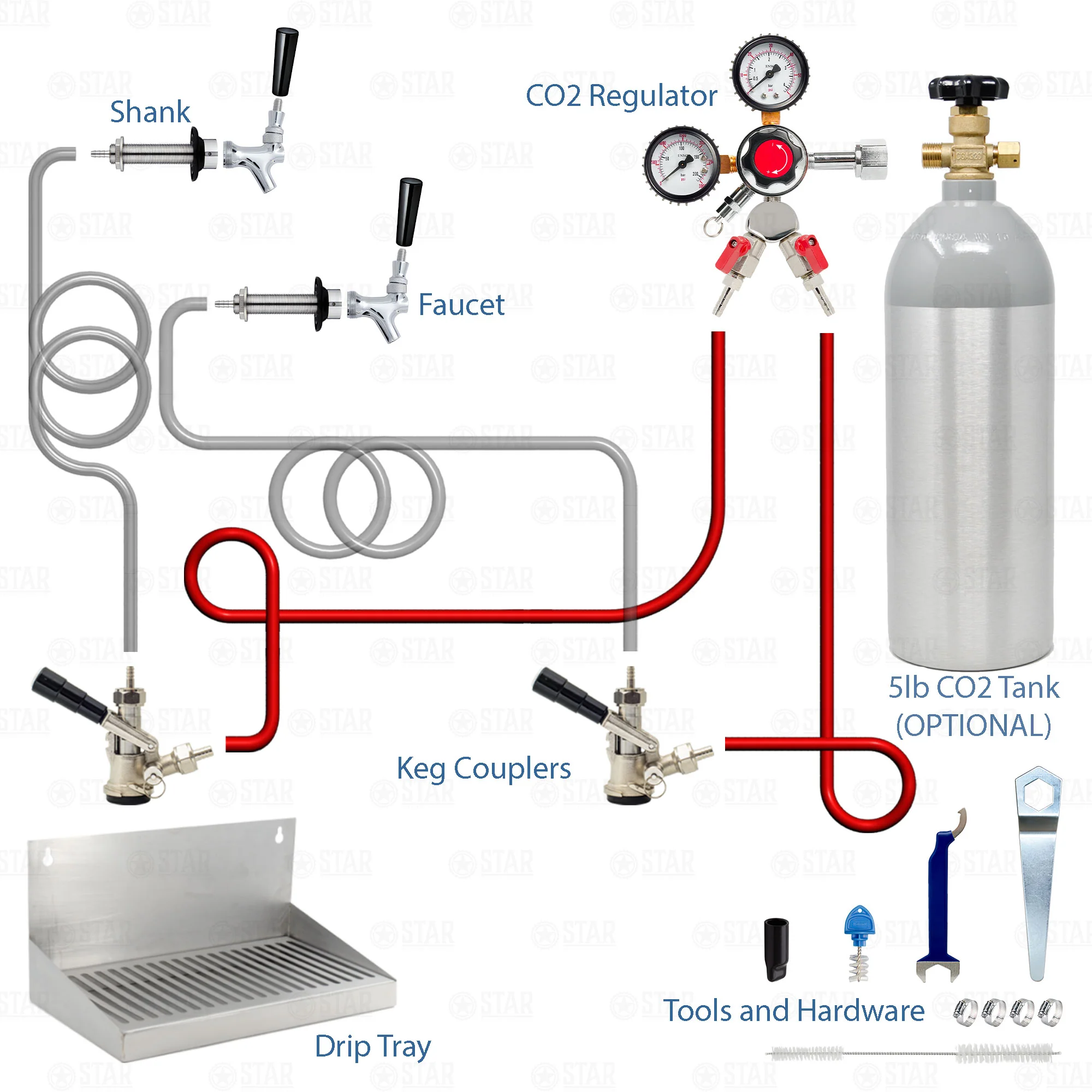

The type of kegerator system also plays a role in CO2 tank duration. There are two common types of systems: single-keg and dual-keg. In a single-keg system, the CO2 is only used for carbonating and dispensing one keg. In a dual-keg system, the CO2 is divided between two kegs. The dual-keg system may require more CO2, as it serves multiple kegs simultaneously.

Now that we understand the basics of CO2 tanks and the factors that affect their duration, let’s explore some tips to maximize the lifespan of your CO2 tank.

Factors Affecting CO2 Tank Duration

Several factors can impact the duration of a CO2 tank on a kegerator. It’s important to consider these factors to ensure you have a consistent supply of CO2 for your beer enjoyment. Let’s take a closer look at each of these factors:

The Size of the CO2 Tank

The size of the CO2 tank is a significant factor in determining its duration. Larger tanks, such as 10 or 20-pound tanks, can last much longer compared to smaller tanks like 2.5 or 5-pound ones. The size you choose will depend on your usage frequency and the number of kegs you plan to dispense.

CO2 Consumption Rate

The rate at which you consume CO2 will vary based on factors such as the length of beer lines, desired carbonation level, and beer pressure. A longer beer line will increase the resistance and decrease the flow rate, reducing CO2 consumption. It’s essential to strike a balance between maintaining carbonation levels and minimizing CO2 usage.

Read more: How To Change Co2 Tank In Kegerator

Temperature and Pressure

The temperature and pressure inside the kegerator can directly impact the CO2 tank’s lifespan. Cold temperatures can cause the CO2 to contract, slowing down its release and extending the tank’s duration. Conversely, warmer temperatures can increase the pressure, leading to faster CO2 consumption. It’s crucial to regulate the temperature within the optimal range for both the keg and the CO2 tank.

Type of Kegerator System

The type of kegerator system you have can affect CO2 consumption. A single-keg system uses CO2 only for one keg, while a dual-keg system distributes CO2 between two kegs. A dual-keg system will require more CO2, as it serves multiple kegs simultaneously. It’s important to consider your specific kegerator setup when estimating CO2 usage.

By understanding these factors and considering them when using your kegerator, you can maximize the duration of your CO2 tank and ensure you have a constant supply of carbonated beer. In the next section, we will provide some tips to help you extend the lifespan of your CO2 tank.

The Size of the CO2 Tank

The size of the CO2 tank is an important factor to consider when determining how long it will last on a kegerator. CO2 tanks come in various sizes, typically ranging from 2.5 pounds to 20 pounds. The size you choose will depend on your specific needs and usage requirements.

Smaller CO2 tanks, such as the 2.5 or 5-pound options, are commonly used for home kegerators or setups with limited space. These tanks are more compact and easier to handle, but they do have a shorter duration. On average, a 2.5-pound CO2 tank can last for around 2-4 full kegs, while a 5-pound tank can last for approximately 4-8 full kegs.

Larger CO2 tanks, such as the 10 or 20-pound options, are often preferred by those who have higher keg consumption or frequently entertain guests. These bigger tanks have a larger capacity and can last significantly longer. A 10-pound CO2 tank can provide around 16-20 full kegs, while a 20-pound tank can last for approximately 32-40 full kegs.

When choosing the size of your CO2 tank, it’s important to consider your usage patterns and frequency. If you’re an occasional beer enthusiast or have limited keg consumption, a smaller tank may be sufficient. However, if you frequently enjoy draft beer at home, host parties, or have multiple kegs on rotation, a larger tank would be a more practical choice.

Another factor to consider is the availability of CO2 tank refills or exchanges in your area. Smaller tanks are often more widely available for exchanges, making it easier to replenish your supply. Larger tanks may require less frequent refills, but it’s important to ensure that refill or exchange services are readily accessible to avoid any inconvenience or downtime when you run out of CO2.

Ultimately, the size of the CO2 tank you choose for your kegerator will depend on your specific needs, keg consumption, and availability of refills or exchanges. It’s always a good idea to calculate your usage and consider any future scenarios where you may have increased demand. This way, you can ensure that you have an adequate supply of CO2 to keep pouring draft beer from your kegerator for an extended period.

In the next sections, we will explore other factors that can affect the duration of a CO2 tank on a kegerator, including the CO2 consumption rate, temperature and pressure, and the type of kegerator system.

CO2 Consumption Rate

The CO2 consumption rate is a crucial factor that determines how quickly a CO2 tank is depleted on a kegerator. It refers to the amount of CO2 used per pour and can vary depending on several factors.

One of the primary factors influencing the CO2 consumption rate is the length of the beer lines. Longer beer lines result in more resistance to the flow of beer and therefore require more CO2 pressure to maintain the desired carbonation levels. As a result, the CO2 consumption rate tends to be higher with longer beer lines compared to shorter ones.

The desired carbonation level also affects the CO2 consumption rate. If you prefer a higher level of carbonation in your beer, the kegerator system will need to dispense more CO2 into the keg to achieve and maintain that carbonation. Conversely, if you prefer a lower level of carbonation, the CO2 consumption rate will be lower.

The beer pressure setting on the regulator also plays a role in the CO2 consumption rate. Higher pressure settings require more CO2 to be dispensed into the keg, resulting in a faster depletion of the CO2 tank. It’s important to find the right balance and adjust the pressure setting to match your desired carbonation level without unnecessarily increasing the CO2 consumption rate.

It’s worth noting that the CO2 consumption rate can vary between different types of beers. Beers with higher carbonation levels, such as certain styles of lagers or sparkling ales, may require more CO2 than beers with lower carbonation levels, such as stouts or porters. Understanding the specific carbonation needs of the beer you are dispensing can help you estimate and manage the CO2 consumption rate more effectively.

To optimize the CO2 consumption rate and maximize the lifespan of your CO2 tank, it’s advisable to regularly monitor the carbonation levels of your beer and make adjustments as needed. Conducting periodic checks and maintenance on your kegerator system, including cleaning the beer lines and ensuring proper seals, can also help maintain an efficient CO2 consumption rate.

In the next section, we will explore how temperature and pressure can impact the duration of a CO2 tank on a kegerator.

Read more: Where To Fill A Kegerator Co2 Tank

Temperature and Pressure

The temperature and pressure inside the kegerator can significantly affect the duration of a CO2 tank on a kegerator. It’s essential to understand how these factors interact and how they impact CO2 consumption.

Temperature plays a crucial role in the carbonation process and can affect the lifespan of a CO2 tank. Cold temperatures cause gases, including CO2, to contract. As a result, the release of CO2 slows down, leading to a more efficient use of the gas and extending the duration of the CO2 tank. It is recommended to keep the kegerator at a temperature range of 36-40°F (2-4°C) to maximize CO2 tank lifespan.

On the other hand, warm temperatures can accelerate the release of CO2, resulting in faster depletion of the CO2 tank. Higher temperatures increase the pressure inside the kegerator, causing more CO2 to be dispensed into the keg. It’s crucial to maintain proper temperature control to prevent excessive CO2 consumption and ensure a consistent and enjoyable pouring experience.

It’s important to note that temperature fluctuations can also impact CO2 consumption. Rapid temperature changes or inconsistent temperature control can lead to variations in carbonation levels, which may require additional adjustments and CO2 usage. It’s best to maintain a stable and controlled temperature environment for the kegerator to optimize CO2 usage and avoid unnecessary wastage.

Pressure is another critical factor to consider. The pressure setting on the regulator determines the amount of CO2 that is dispensed into the keg. Higher pressure settings require more CO2 and can lead to faster depletion of the CO2 tank. It’s advisable to set the pressure to the recommended level based on the specific beer style and carbonation level desired. Fine-tuning the pressure setting can help optimize CO2 usage and extend the duration of the CO2 tank.

Regularly monitoring the temperature and pressure inside the kegerator is essential for maintaining optimal carbonation levels and maximizing CO2 tank lifespan. Having a reliable thermometer and pressure gauge can assist in keeping track of these variables and making adjustments as needed.

In the next section, we will discuss how the type of kegerator system can impact the duration of a CO2 tank.

Type of Kegerator System

The type of kegerator system you have can also affect the duration of a CO2 tank. There are typically two common types: single-keg systems and dual-keg systems.

In a single-keg system, the CO2 is used solely for carbonating and dispensing one keg. This type of system is ideal for those who typically have one keg at a time or have limited space. Since the CO2 is only serving a single keg, the consumption rate tends to be lower, resulting in a longer duration for the CO2 tank. It’s important to note that if you have a larger keg or frequently dispense larger quantities of beer, the CO2 consumption rate can increase accordingly.

A dual-keg system, as the name suggests, is designed to accommodate two kegs simultaneously. This type of system requires the CO2 to be split between the two kegs, meaning that more CO2 is generally required. The CO2 usage in a dual-keg system is often higher compared to a single-keg system, resulting in a shorter duration for the CO2 tank. If you frequently have multiple kegs on rotation or like the convenience of having two different beers available, a dual-keg system may be the right choice for you.

It’s important to consider your specific needs and usage patterns when choosing the type of kegerator system. If you have a single-keg system but find yourself frequently running out of CO2, it may be worth considering upgrading to a dual-keg system to accommodate your demands adequately.

Additionally, it’s essential to ensure that your kegerator system is properly calibrated and adjusted. A well-maintained system ensures efficient use of CO2 and minimizes any potential leaks that can lead to unnecessary CO2 depletion. Regularly inspect your system, including the connections, hoses, and regulator, to detect and address any issues promptly.

By understanding the type of kegerator system you have and its impact on CO2 consumption, you can make informed decisions about your CO2 tank and plan accordingly for refills or exchanges. Owning the appropriate type of kegerator system for your needs will allow you to enjoy draft beer consistently while efficiently utilizing your CO2 resources.

Next, we will provide some practical tips to help you maximize the lifespan of your CO2 tank.

Tips to Maximize CO2 Tank Lifespan

Maximizing the lifespan of your CO2 tank is essential to ensure a constant supply of carbonated beer from your kegerator. By following these tips, you can make the most out of your CO2 tank and prolong its duration:

1. Optimize Your CO2 Consumption:

Pay attention to the CO2 consumption rate by adjusting factors such as the length of beer lines, carbonation levels, and beer pressure settings. Finding the right balance will help minimize CO2 usage without compromising the quality of your beer.

Read more: What Size Co2 Tank Does A Kegerator Use

2. Maintain Proper Temperature and Pressure:

Keep your kegerator at a consistent temperature within the recommended range to ensure efficient carbonation and slow down CO2 consumption. Additionally, set the pressure on the regulator to the appropriate level based on your beer style and desired carbonation, preventing excessive CO2 usage.

3. Regularly Inspect for Leaks:

Perform routine inspections of all connections, hoses, and the regulator for any potential leaks. Even a small leak can significantly deplete your CO2 tank over time. Fix any leaks promptly to preserve your CO2 resources.

4. Clean Beer Lines Regularly:

Regularly clean your beer lines to prevent any build-up or blockages that can interfere with the flow of beer. This will help maintain optimal carbonation levels and reduce the need for excessive CO2 usage.

5. Don’t Overfill Your Keg:

Avoid overfilling your keg, as excess foam can cause CO2 to be released rapidly. This can result in faster CO2 depletion. Properly fill the keg, leaving enough headspace to allow for carbonation without excessive foam creation.

6. Use the Right Size CO2 Tank:

Choose a CO2 tank size that suits your needs and keg consumption. Assess how often you use the kegerator and consider investing in a larger tank if you frequently entertain or have multiple kegs on rotation. This will reduce the frequency of refills or exchanges.

7. Keep Spare CO2 Tanks on Hand:

Consider having a spare CO2 tank available to avoid any interruption in your beer pouring. This allows you to switch to the backup tank while getting the empty one refilled or exchanged without having to wait.

By implementing these tips, you can optimize your CO2 usage and extend the lifespan of your CO2 tank. This ensures a consistent supply of carbonated beer for a longer period, enhancing your kegerator experience.

Let’s wrap up our discussion in the next section.

Conclusion

Understanding how long a CO2 tank lasts on a kegerator is essential for every beer enthusiast and kegerator owner. The duration of a CO2 tank can be influenced by various factors, including the size of the tank, CO2 consumption rate, temperature and pressure, and the type of kegerator system.

Choosing the right size CO2 tank based on your usage frequency and keg consumption is crucial. Larger tanks generally last longer, but it’s essential to consider the availability of refills or exchanges in your area. Monitoring and optimizing your CO2 consumption rate by adjusting factors such as beer line length, carbonation levels, and pressure settings can help extend the lifespan of your tank.

Maintaining proper temperature and pressure inside the kegerator is key to minimizing CO2 usage. Regular inspections for leaks, cleaning of beer lines, and avoiding overfilling your keg are also important steps to maximize the lifespan of your CO2 tank. Additionally, having a spare CO2 tank on hand can ensure a continuous supply of carbonated beer without any interruptions.

By following these tips and understanding the factors that affect CO2 tank duration, you can enjoy a consistent supply of draft beer from your kegerator for an extended period.

So, whether you’re a seasoned kegerator enthusiast or just starting out, use these insights to make the most out of your CO2 tank and enhance your home beer pouring experience. Cheers!

Frequently Asked Questions about How Long Does A Co2 Tank Last On A Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Does A Co2 Tank Last On A Kegerator”