Home>Articles>What Co2 Pressure Should You Set For A Kegerator

Articles

What Co2 Pressure Should You Set For A Kegerator

Modified: March 1, 2024

Find out the ideal pressure for CO2 in your kegerator with articles covering tips and techniques for setting the perfect carbonation levels.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Are you a beer enthusiast who loves to enjoy a crisp, refreshing pint of draft beer from the comfort of your own home? If so, you may already be familiar with the concept of kegerators – those magical machines that refrigerate and dispense kegs of beer. But have you ever wondered what pressure you should set the CO2 at in a kegerator? This article aims to demystify the process and provide you with all the information you need to achieve the perfect pour.

Understanding CO2 Pressure in a Kegerator

Before we delve into the specifics of CO2 pressure, it’s essential to understand why it is crucial in a kegerator setup. CO2, or carbon dioxide, is the gas used to carbonate and dispense beer. When beer is kegged, it typically undergoes a process called force carbonation, where CO2 is applied under pressure to dissolve into the liquid. This results in the desired level of carbonation, ensuring a pleasant mouthfeel and a lively, effervescent beer.

The CO2 pressure in a kegerator serves two primary purposes: maintaining carbonation and dispensing the beer. The pressure in the keg keeps the carbonation level intact, preventing the beer from going flat. When you dispense the beer by pulling the tap handle, the pressure forces the beer out of the keg and into your glass, creating that perfect pint of draft beer.

Read more: How To Build A Co2 Kegerator

Factors to Consider when Setting CO2 Pressure

Several factors influence the ideal CO2 pressure for a kegerator setup. These factors include the beer style, desired carbonation level, temperature, and line length. Let’s explore each factor in detail:

1. Beer Style: Different beer styles have varying levels of carbonation. Beers like lagers generally have higher carbonation levels, while ales and stouts may have lower levels. It’s essential to consider the recommended carbonation level for the specific beer style you are kegging.

2. Desired Carbonation Level: Some beer enthusiasts prefer a higher level of carbonation, resulting in a crisp and bubbly beer, while others prefer a softer, smoother mouthfeel with lower carbonation. The desired carbonation level will impact the CO2 pressure setting.

3. Temperature: Temperature plays a crucial role in carbonation. Warmer temperatures can cause excess CO2 to be released from the beer, leading to over-carbonation. Colder temperatures can cause under-carbonation. It’s important to maintain a consistent and appropriate temperature for your kegerator.

…

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Introduction

If you’re a beer connoisseur or simply enjoy the taste of a cold glass of draft beer, then you might be familiar with kegerators. These convenient machines allow you to have your own personal tap system at home, dispensing fresh beer straight from a keg. However, to ensure a perfect pour and optimal carbonation, it’s important to understand the pressure settings for the CO2 in a kegerator.

Carbon dioxide, or CO2, is a crucial element in carbonating and dispensing beer. When beer is kegged, the process of force carbonation takes place. CO2 is applied under pressure, allowing it to dissolve into the beer and create the desired level of carbonation. The pressure in the kegerator not only helps maintain carbonation but also aids in dispensing the beer smoothly.

Setting the appropriate CO2 pressure in a kegerator is essential for achieving the perfect balance of carbonation and a satisfying pour. Too much pressure can result in over-carbonation, causing foamy, gushing beer. On the other hand, too little pressure can lead to flat, lifeless beer with barely any carbonation.

Several factors come into play when determining the ideal CO2 pressure for a kegerator setup. Beer style, desired carbonation level, temperature, and line length all contribute to finding the sweet spot.

Different beer styles have varying carbonation requirements. For instance, light, crisp lagers typically benefit from higher carbonation levels, while rich, malty stouts or smooth ales may call for less carbonation. It’s important to consider the recommended carbonation level for the specific beer style you wish to keg.

Your personal preference for carbonation also plays a role. Some beer enthusiasts enjoy a high level of carbonation, resulting in that exhilarating effervescence and a refreshing sensation on the palate. Others may prefer a softer mouthfeel with less carbonation. It’s crucial to strike the right balance based on your taste preferences.

Temperature is another critical factor in regulating CO2 pressure. Warmer temperatures can lead to excess CO2 being released, causing over-carbonation and potential foaming issues. Colder temperatures, on the other hand, may result in under-carbonation. Therefore, it’s vital to maintain a consistent and appropriate temperature within your kegerator.

In addition to beer style, carbonation preference, and temperature, the length of the beer line also affects CO2 pressure. A longer line requires higher pressure to overcome the resistance and deliver the beer smoothly. Conversely, a shorter line may require lower pressure to prevent excessive foaming.

Finding the optimal CO2 pressure for your kegerator may require some experimentation and fine-tuning. However, once you’ve discovered the perfect balance, you’ll be rewarded with beautifully carbonated beer and a delightful pouring experience.

In the following sections, we will delve deeper into each of these factors, providing insights and guidance on how to set the CO2 pressure for your kegerator based on different beer styles, desired carbonation levels, temperature considerations, and troubleshooting common issues.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Understanding CO2 Pressure in a Kegerator

Before we delve into the specifics of CO2 pressure, it’s essential to understand why it is crucial in a kegerator setup. CO2, or carbon dioxide, is the gas used to carbonate and dispense beer. When beer is kegged, it typically undergoes a process called force carbonation, where CO2 is applied under pressure to dissolve into the liquid. This results in the desired level of carbonation, ensuring a pleasant mouthfeel and a lively, effervescent beer.

The CO2 pressure in a kegerator serves two primary purposes: maintaining carbonation and dispensing the beer. The pressure in the keg keeps the carbonation level intact, preventing the beer from going flat. When you dispense the beer by pulling the tap handle, the pressure forces the beer out of the keg and into your glass, creating that perfect pint of draft beer.

To understand CO2 pressure in a kegerator, you need to familiarize yourself with two important terms: “head pressure” and “line pressure.”

Head pressure refers to the pressure inside the keg, specifically the space above the beer. It is the pressure that keeps the carbonation level consistent. By adjusting the head pressure, you can control the overall carbonation of your beer. Higher head pressure leads to increased carbonation, while lower head pressure results in reduced carbonation.

Line pressure, on the other hand, refers to the pressure required to push the beer from the keg to the tap. It is determined by factors such as line length, diameter, and the type of faucet or taps used. The line pressure should be adjusted to ensure a smooth and steady flow of beer without excessive foaming or splashing.

Maintaining the right balance between head pressure and line pressure is crucial for a perfect pour. Too much pressure can cause the beer to foam excessively, making it difficult to pour without a large head. Insufficient pressure may result in a slow, dribbling pour with no carbonation.

When setting the CO2 pressure in a kegerator, it’s important to strike a balance between head pressure and line pressure. This balance ensures that the beer remains appropriately carbonated while being dispensed at a consistent and controlled rate.

In the next sections, we will explore the various factors that influence the CO2 pressure setting in a kegerator. Understanding these factors will help you determine the ideal pressure for different beer styles, how to adjust the pressure for temperature changes, and how to troubleshoot common CO2 pressure issues.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Read more: How To Build A Co2 Kegerator

Factors to Consider when Setting CO2 Pressure

Several factors influence the ideal CO2 pressure for a kegerator setup. These factors include the beer style, desired carbonation level, temperature, and line length. Let’s explore each factor in detail:

1. Beer Style: Different beer styles have varying levels of carbonation. Beers like lagers generally have higher carbonation levels, while ales and stouts may have lower levels. It’s essential to consider the recommended carbonation level for the specific beer style you are kegging. Consult brewing references or guidelines to determine the appropriate carbonation range.

2. Desired Carbonation Level: Your personal preference for carbonation plays a significant role in determining the CO2 pressure. Some beer enthusiasts enjoy a high level of carbonation, which adds a sparkling and effervescent quality to the beer. Others may prefer a softer and smoother mouthfeel with lower carbonation. Consider your taste preferences and experiment with different pressure settings to achieve your desired carbonation level.

3. Temperature: Temperature is a crucial factor in carbonation. As temperature increases, the solubility of CO2 in beer decreases and excess gas is released, leading to over-pressurization. On the other hand, as temperature decreases, the solubility increases, and the beer can become under-carbonated. It’s important to maintain a consistent and appropriate temperature for your kegerator to ensure the desired carbonation level. Consult temperature charts for the specific style of beer you are kegging to determine the optimal temperature range.

4. Line Length and Diameter: The length and diameter of the beer lines in the kegerator also affect CO2 pressure. Longer lines will create more resistance, requiring higher pressure to push the beer through without excessive foaming. Shorter lines, on the other hand, may require lower pressure to prevent over-dispensing and flat beer. The line diameter also plays a role, with narrower lines creating more resistance and wider lines allowing for faster flow. It’s important to balance line length, diameter, and pressure to achieve a proper pour.

5. Pressure Relief Valves: Some kegerators are equipped with pressure relief valves, which help prevent over-pressurization. These valves automatically release excess pressure if it reaches a certain threshold, ensuring beer remains safely carbonated without causing kegs to burst or leak. Check if your kegerator has a pressure relief valve and set it to the recommended pressure to prevent accidents and maintain carbonation levels.

By considering these factors and making adjustments accordingly, you can set the CO2 pressure in your kegerator to achieve the perfect carbonation and pour for your beer style and personal preferences. Remember to document your pressure settings and make small adjustments as needed to fine-tune the carbonation level.

In the next sections, we will dive deeper into the recommended CO2 pressure ranges for different beer styles and explore how to adjust the pressure for temperature changes. Additionally, we will discuss common troubleshooting issues related to CO2 pressure and provide solutions to ensure a seamless kegerator experience.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Read more: Where To Get Co2 For A Kegerator

Ideal CO2 Pressure for Different Beer Styles

When it comes to setting the CO2 pressure in your kegerator, different beer styles have different carbonation requirements. Achieving the ideal carbonation level for each style enhances the overall flavor, aroma, and mouthfeel of the beer. Here are some general guidelines for the recommended CO2 pressure ranges for popular beer styles:

1. Lagers: Lagers are known for their crisp and refreshing qualities, which are enhanced by higher carbonation levels. Typically, lagers require CO2 pressures in the range of 12-15 psi (pounds per square inch) to achieve optimal carbonation.

2. Ales: Ales encompass a wide range of styles, including pale ales, IPAs, porters, and stouts. While the ideal carbonation level may vary within this category, a common range for ales is around 10-12 psi.

3. Wheat Beers: Wheat beers, such as hefeweizens and witbiers, often possess distinctive fruity and spicy characteristics. To showcase these flavors, wheat beers are typically carbonated at slightly higher pressures, ranging from 12-16 psi.

4. Belgian Styles: Belgian beers like saisons, dubbels, and tripels often have complex flavors and higher carbonation. CO2 pressures in the range of 14-18 psi are commonly used to achieve the effervescence that sets these styles apart.

5. Specialty Beers: Specialty and experimental beers might have unique carbonation requirements. It’s best to consult specific brewing references or guidelines provided by the brewery for these styles, as they may deviate from the general ranges mentioned above.

It’s worth noting that these guidelines are approximate starting points, and individual preferences may vary. Carbonation is a matter of personal taste, so don’t be afraid to experiment and adjust the CO2 pressure in small increments to find the ideal level for your favorite beer style.

Remember to consider temperature as well when setting the CO2 pressure, as temperature can affect carbonation. Warmer temperatures can cause carbon dioxide to escape more rapidly, leading to over-carbonation. Colder temperatures can result in under-carbonation. Always refer to temperature charts specific to your chosen beer style to ensure the appropriate temperature range for carbonation.

By understanding the recommended CO2 pressure ranges for different beer styles and maintaining the appropriate temperature, you can fine-tune the carbonation level and enjoy your favorite beers exactly as they were intended to be.

In the next section, we will explore how to adjust the CO2 pressure in response to temperature changes to maintain consistent carbonation and avoid over-carbonation or under-carbonation issues.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Adjusting CO2 Pressure for Temperature Changes

Temperature plays a crucial role in carbonation and therefore, in setting the CO2 pressure for a kegerator. Fluctuations in temperature can impact the amount of dissolved CO2 in the beer, leading to under-carbonation or over-carbonation. To maintain consistent carbonation levels despite temperature changes, it’s important to make adjustments to the CO2 pressure. Here’s how:

1. Understand the Temperature-Carbonation Relationship: As beer gets colder, it can hold more dissolved CO2. On the other hand, as beer gets warmer, the solubility of CO2 decreases, causing gas to escape from the beer. This means that a kegerator set at a colder temperature may require a higher CO2 pressure, while a warmer kegerator will need a lower CO2 pressure.

2. Use Temperature Charts as a Reference: Each beer style has a recommended temperature range for optimal carbonation. Refer to temperature charts specific to the beer style you are kegging to determine the ideal temperature. Make sure to set your kegerator’s temperature controller accordingly.

3. Adjust the CO2 Pressure Gradually: When your kegerator is at the desired temperature, adjust the CO2 pressure according to the following general guidelines:

– If your kegerator is colder than the desired temperature, decrease the CO2 pressure slightly. This helps prevent over-carbonation, as the cooler beer can hold more dissolved CO2.

– If your kegerator is warmer than the desired temperature, increase the CO2 pressure slightly. This compensates for the lower solubility of CO2 in warmer beer, preventing under-carbonation.

It’s important to make gradual adjustments to the CO2 pressure, as abrupt changes can cause imbalances and result in excessive foaming or flat beer. Make small adjustments, allow the system to settle, and then evaluate the impact on carbonation and pouring.

4. Periodically Check and Adjust: Regularly monitor the carbonation of your beer to ensure it remains within the desired range. Check the pour and observe the level of carbonation by examining the bubbles and head formation. If you find the carbonation level is not meeting your expectations, make further adjustments to the CO2 pressure as needed.

5. Document and Learn from Experience: Keep a record of the CO2 pressure settings and corresponding temperatures for each beer style. Over time, you’ll develop a better understanding of how different temperatures and CO2 pressures affect carbonation, allowing you to make more accurate adjustments in the future.

By adjusting the CO2 pressure in response to temperature changes, you can maintain consistent carbonation levels in your kegged beer. This ensures that regardless of the environmental conditions, you’ll enjoy a perfectly carbonated and delicious pint every time you pour.

In the next section, we will explore common troubleshooting tips for CO2 pressure issues that may arise in a kegerator setup.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Read more: How Adjust Co2 Kegerator

Troubleshooting CO2 Pressure Issues

While setting the CO2 pressure in your kegerator, you might encounter some common issues that affect the carbonation and pouring of your beer. Here are a few troubleshooting tips to help you address CO2 pressure issues:

1. Foamy Beer: Excessive foaming can be caused by a few factors:

– Overcarbonation: If your beer is consistently coming out foamy, it may be due to overcarbonation. Reduce the CO2 pressure slightly and allow time for the system to equalize. Check the carbonation levels periodically and make additional adjustments as needed.

– Temperature Too High: High temperatures can cause excessive foaming. Ensure that your kegerator is set to the appropriate temperature for the beer style you are serving. Lowering the temperature can help reduce excessive foaming.

– Dirty Beer Lines or Faucets: Beer lines and faucets can accumulate residue, leading to excessive foaming. Clean your lines regularly and ensure that all parts are properly sanitized.

2. Flat Beer: If your beer is lacking carbonation, there are a few potential causes:

– Undercarbonation: If your beer lacks bubbles and has a flat taste, it may be undercarbonated. Check the CO2 pressure and increase it slightly to achieve the desired carbonation level. Be sure to adjust the pressure gradually to prevent overcarbonation.

– Temperature Too Low: If your beer is being served at a very low temperature, it may lack carbonation. Increase the temperature slightly to allow the beer to absorb more CO2.

3. Inconsistent Pouring: If your beer pours inconsistently or has varying levels of carbonation in different glasses, consider the following:

– Line Length and Diameter: Unequal line length or diameter can cause variations in flow rate and carbonation levels. Ensure that all lines are of the same length and diameter for a consistent pour.

– Line Restrictions: Check for any obstructions or kinks in the beer lines that may be affecting the flow. Clear any blockages to ensure smooth pouring and consistent carbonation.

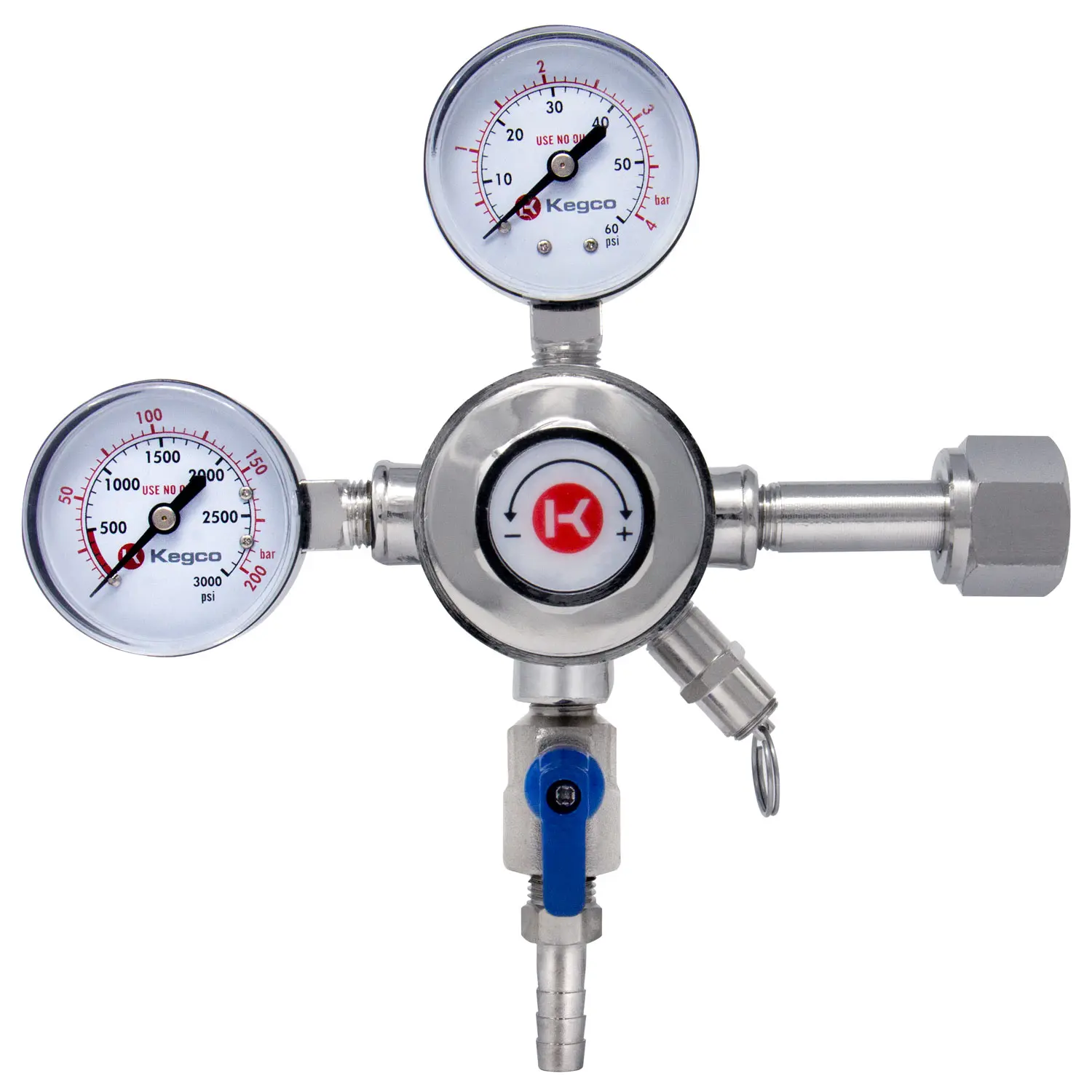

– Pressure Regulator: Faulty pressure regulators can result in inconsistent pressure output. Inspect and, if necessary, replace the pressure regulator to maintain a stable CO2 pressure.

Remember, troubleshooting CO2 pressure issues requires patience and experimentation. Make small adjustments and allow time for the system to stabilize before assessing the results. Keep track of the changes you make to help identify patterns and find the optimal CO2 pressure for your kegerator setup.

(Continued)

What Pressure Do You Set A The CO2 For A Kegerator

Conclusion

Setting the CO2 pressure in a kegerator is a fundamental aspect of achieving the perfect carbonation and pour for your beer. Understanding the factors that influence CO2 pressure, such as beer style, desired carbonation level, temperature, and line length, is crucial for an optimal kegerator setup.

By considering the recommended CO2 pressure ranges for different beer styles, you can enhance the flavors and aromas specific to each style. Experimentation and adjustments based on personal preferences will help you find the ideal carbonation level that suits your taste.

Temperature control is essential in maintaining consistent carbonation. Adjusting the CO2 pressure based on temperature changes will ensure that your beer remains properly carbonated, regardless of fluctuations in the environment.

When troubleshooting CO2 pressure issues, it’s important to address factors such as overcarbonation, temperature inconsistencies, dirty lines and faucets, line restrictions, and faulty pressure regulators. By addressing these issues, you can resolve problems related to excessive foaming, flat beer, or inconsistent pouring.

Keeping detailed records of CO2 pressure settings and the corresponding outcomes will help you refine your kegerator setup over time. With each adjustment, you’ll gain valuable insights and be able to achieve the perfect pour with confidence.

Ultimately, the goal of setting the CO2 pressure in a kegerator is to enhance your beer-drinking experience. Whether you’re enjoying a crisp lager, a hoppy IPA, or a rich stout, maintaining the ideal carbonation level will unlock the true potential of each beer style.

So, next time you take a sip of that perfectly poured draft beer from your kegerator, savor the flavors, and toast to the art of carbonation. Cheers!

Frequently Asked Questions about What Co2 Pressure Should You Set For A Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Co2 Pressure Should You Set For A Kegerator”