Articles

How To Check Static Pressure In HVAC

Modified: February 28, 2024

Looking for helpful articles on how to check static pressure in HVAC systems? Explore our comprehensive guides and expert tips to ensure optimal performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on how to check static pressure in HVAC systems. As a homeowner or HVAC professional, it is essential to understand and monitor static pressure to ensure optimal performance and energy efficiency of your heating and cooling system.

Static pressure refers to the force exerted by the air as it moves through the ductwork of an HVAC system. It is measured in units of inches of water column (in. WC), which represents the amount of pressure needed to lift a column of water.

Monitoring static pressure is crucial because it can indicate potential issues such as clogged filters, obstructions in the ductwork, or problems with the blower or fan motor. By regularly checking static pressure, you can identify these issues early on and take necessary actions to address them.

In this article, we will walk you through the step-by-step process of checking static pressure in your HVAC system. But before we dive into the procedure, let’s understand why static pressure is so important in HVAC systems.

Key Takeaways:

- Regularly checking static pressure in your HVAC system is crucial for identifying potential issues and optimizing performance, energy efficiency, and indoor comfort.

- Measuring static pressure at supply and return grilles, comparing readings, and addressing any issues ensures efficient HVAC system operation and comfortable indoor environments.

Read more: How To Check HVAC Compressor

What is Static Pressure in HVAC

Static pressure is the force exerted by the air within an HVAC system as it moves through the ductwork. It is referred to as “static” because it represents the pressure of the air when it is not in motion, i.e., when no fans or blowers are operating.

Static pressure is measured in inches of water column (in. WC), which indicates the amount of pressure required to lift a column of water. It is typically measured at two points in the HVAC system: the supply grille, where conditioned air is delivered into the living space, and the return grille, where air is pulled back into the system to be conditioned.

The static pressure in an HVAC system is influenced by several factors, including the size and layout of the ductwork, the condition of the air filters, the efficiency of the blower or fan motor, and any obstructions or restrictions in the airflow path.

There are two types of static pressure that are commonly measured:

- Supply Static Pressure: This is the measurement of the air pressure at the supply grille when the system is operating. It indicates the resistance to airflow in the supply ductwork.

- Return Static Pressure: This is the measurement of the air pressure at the return grille when the system is operating. It indicates the resistance to airflow in the return ductwork, including the air filters.

Both supply and return static pressures are important because they provide valuable information about the performance and efficiency of the HVAC system. Monitoring static pressure helps HVAC professionals and homeowners identify any potential issues that may be hindering proper airflow and overall system performance.

High static pressure readings may indicate problems such as clogged filters, duct obstructions, closed dampers, or undersized ductwork. On the other hand, low static pressure readings may suggest issues such as leaking ducts, improper blower speed settings, or oversized ductwork.

By regularly checking static pressure, HVAC professionals and homeowners can diagnose problems early on and make necessary adjustments or repairs to optimize system performance, energy efficiency, and indoor comfort.

Importance of Checking Static Pressure

Checking static pressure in your HVAC system is crucial for several reasons. Let’s explore the importance of monitoring static pressure and understanding its implications for overall system performance.

1. Energy Efficiency: Proper airflow is essential for your HVAC system to operate efficiently. When there are high levels of static pressure, it means the system has to work harder to move the air through the ductwork. This increased workload results in higher energy consumption and reduced efficiency. By monitoring static pressure, you can identify and address any issues that may be causing excessive pressure and optimize the airflow for improved energy efficiency.

2. System Performance: Excessive static pressure can negatively impact the performance of your HVAC system. It can lead to uneven cooling or heating, reduced airflow to certain areas of your home, increased noise levels, and even equipment failure. By regularly checking static pressure, you can detect and rectify any problems that may be affecting the performance of your system, ensuring consistent and reliable operation.

3. Indoor Comfort: Proper airflow plays a vital role in maintaining indoor comfort. When static pressure is too high, your HVAC system may struggle to deliver conditioned air evenly throughout your home, resulting in hot or cold spots. By monitoring static pressure and addressing any issues, you can ensure that your HVAC system provides optimal comfort to every room in your home.

4. Preventing Damage: High static pressure can put excessive strain on your HVAC system’s components, such as the blower motor and air conditioning coils. This increased stress can lead to premature wear and damage, requiring costly repairs or replacements. By regularly checking static pressure and taking corrective measures, you can help prevent potential damage to your HVAC system, extending its lifespan and saving on repair costs.

5. Energy Savings: When your HVAC system is operating with optimal static pressure, it consumes less energy and operates more efficiently. By identifying and correcting any issues that may be causing high static pressure, you can reduce energy waste and potentially lower your utility bills.

Overall, checking static pressure is essential for maintaining the efficiency, performance, and longevity of your HVAC system. It allows you to identify and address any issues that may be affecting airflow and ensures optimal indoor comfort for you and your family.

Equipment and Tools Needed

Before you begin checking the static pressure in your HVAC system, it’s important to gather all the necessary equipment and tools. Here’s a list of items you’ll need:

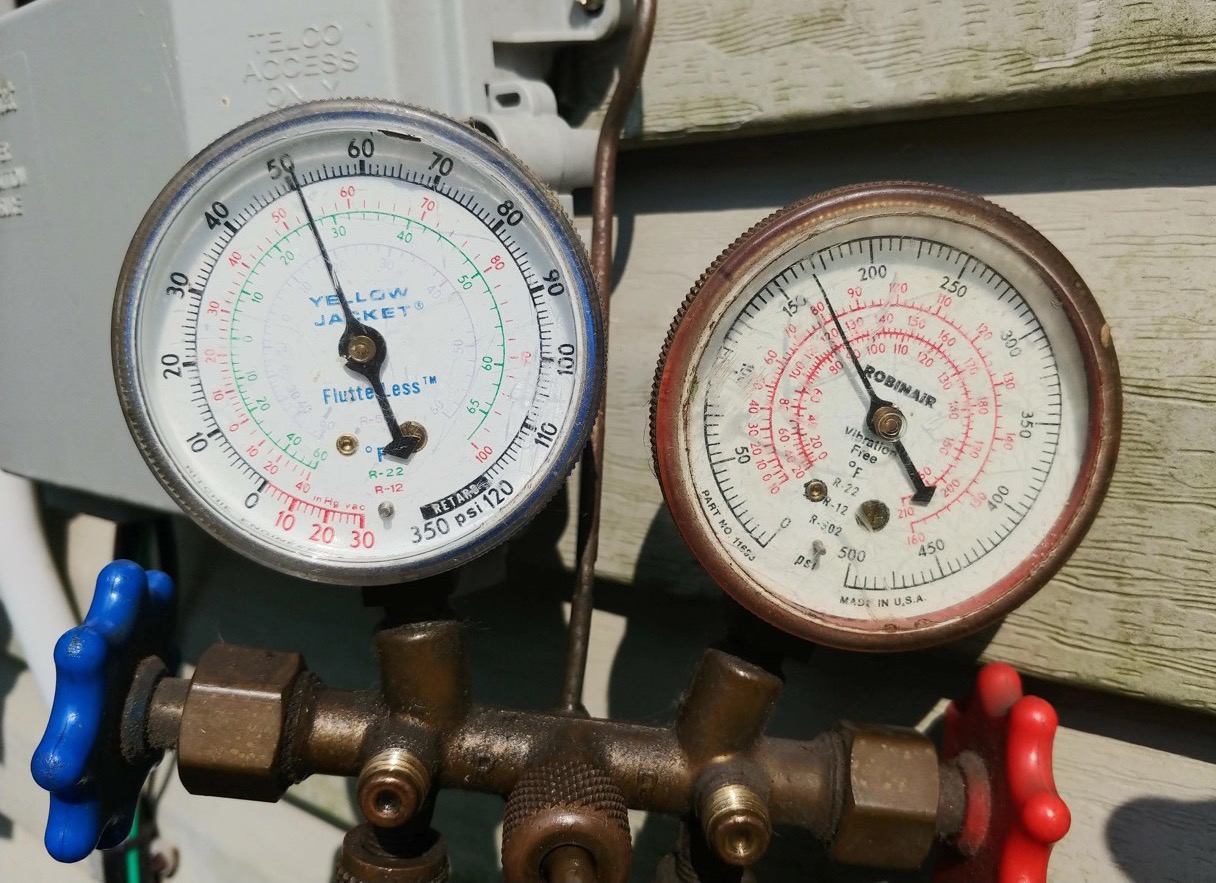

- Manometer: A manometer is a device used to measure the static pressure in the HVAC system. There are various types of manometers available, such as digital manometers or inclined manometers. Choose one that is suitable for your needs and budget.

- Tubing: Tubing is used to connect the manometer to the supply and return grilles. Make sure you have enough tubing to reach the grilles from where you’ll be taking the measurements.

- Tape Measure: A tape measure is essential for measuring the distance between the supply and return grilles. Accurate measurements are important for determining the proper static pressure readings.

- Notebook and Pen: Keeping a notebook and pen handy will allow you to record the static pressure readings at each grille for future reference and comparison.

- Protective Gear: It’s always a good idea to wear protective gear, such as gloves and safety glasses, when working with HVAC systems. This protects you from any potential hazards and ensures your safety.

- Flashlight: A flashlight can be helpful for illuminating dimly lit areas around the grilles, especially if they are located in tight or hard-to-reach spaces.

It’s important to note that the specific equipment and tools you’ll need may vary depending on the type and design of your HVAC system. Refer to the manufacturer’s guidelines or consult with a professional if you’re unsure about the requirements for your particular system.

Once you have gathered all the necessary equipment, you’re ready to proceed with checking the static pressure in your HVAC system. The next section will guide you through the step-by-step process to ensure accurate measurements and proper analysis of the readings.

Step 1: Turn off the HVAC System

Before you start measuring the static pressure in your HVAC system, it is essential to ensure the system is turned off. This step is crucial for your safety and for accurate pressure readings.

Follow these steps to turn off your HVAC system:

- Locate the main control panel for your HVAC system. It is typically found near the indoor unit or in a utility room.

- Open the control panel and look for the main power switch or circuit breaker that supplies electricity to the HVAC system.

- Turn off the main power switch or flip the circuit breaker to the “off” position. This will cut off the power supply to the HVAC system, ensuring there is no electricity running through the system during the static pressure measurement.

- For an added layer of safety, you may want to place a lock or tag on the main power switch or circuit breaker to prevent accidental activation of the system while you are working on it.

Once you have turned off the HVAC system and ensured its power supply is disconnected, you can proceed to the next step of measuring the static pressure at the supply and return grilles.

Note: It’s important to remember that working with HVAC systems involves electricity and other potential hazards. If you are unsure or uncomfortable with performing these steps, it is recommended to seek assistance from a professional HVAC technician who has the necessary experience and expertise to handle the task safely.

Read more: What Is Fan Static Pressure

Step 2: Locate the Supply and Return Grilles

Once you have turned off the HVAC system, the next step is to locate the supply and return grilles. These grilles are important access points where you will measure the static pressure. Here’s how to find them:

- Supply Grilles: Supply grilles are vents or registers through which conditioned air is delivered into the living space. Typically, they are located on walls, ceilings, or floors. Take a walk around your home and look for these grilles. They often have slatted covers or louvers that can be adjusted to control the airflow.

- Return Grilles: Return grilles, on the other hand, are larger vents through which air is pulled back into the HVAC system to be conditioned. They are usually located on walls or ceilings and may have a filter behind them. Look for larger grilles with minimal or no adjustable louvers.

- If you have difficulty finding the supply and return grilles, consult the HVAC system’s installation manual or contact a professional who can assist you in locating them. It is important to identify the correct grilles for accurate static pressure measurement.

Once you have located the supply and return grilles, you are ready to proceed to the next step of measuring the static pressure at these points. This step will help you assess the system’s airflow and potential issues that may affect its performance.

Please note that the locations of supply and return grilles may vary depending on your home’s layout and HVAC system design. The steps provided here are general guidelines, and it’s important to refer to your specific HVAC system’s documentation for precise information.

When checking static pressure in HVAC systems, make sure to use a manometer to measure the pressure at the supply and return ducts. This will help you identify any potential airflow issues.

Step 3: Measure the Static Pressure at the Supply Grille

Now that you have located the supply grille, it’s time to measure the static pressure at this point. By measuring the static pressure at the supply grille, you can determine the resistance to airflow in the supply ductwork. Here’s how to do it:

- Prepare your manometer and tubing. Ensure that the manometer is calibrated correctly and ready for use. Connect one end of the tubing to the pressure port on the manometer.

- Take the other end of the tubing and attach it to the supply grille. Ensure a secure connection is made with no air leaks.

- Once the tubing is properly connected, position the manometer in a convenient location. Make sure it’s easily visible for reading the pressure.

- Turn on the HVAC system. The fan should be set to run but not in heating or cooling mode. This ensures that the blower is operating without actually conditioning the air.

- Allow the system to run for a few minutes to stabilize the airflow. This will ensure accurate static pressure reading.

- Observe the manometer and note the static pressure reading. It’s important to wait for the pressure reading to stabilize before recording it.

- Record the static pressure reading in your notebook. Note the date and time of the measurement for future reference.

Measuring the static pressure at the supply grille provides valuable information about the resistance to airflow in the supply ductwork. It helps identify potential issues like duct obstructions or undersized ductwork. Make sure to repeat this step multiple times to ensure consistency in the readings.

Once you have obtained the static pressure at the supply grille, you can move on to the next step of measuring the static pressure at the return grille. This will give you a comprehensive understanding of the overall static pressure in your HVAC system.

Step 4: Measure the Static Pressure at the Return Grille

After measuring the static pressure at the supply grille, it’s important to measure the static pressure at the return grille. This step helps you assess the resistance to airflow in the return ductwork, including the air filters. Here’s how to do it:

- Ensure that the manometer and tubing are still connected from the previous step. If not, reattach the tubing to the pressure port on the manometer.

- Detach the tubing from the supply grille and carefully connect it to the return grille. Ensure a secure connection without any air leaks.

- Position the manometer in a convenient location where you can easily observe and read the static pressure.

- Turn on the HVAC system again, ensuring that the fan is running but the system is not in heating or cooling mode.

- Allow the system to run for a few minutes to stabilize the airflow, ensuring accurate static pressure reading at the return grille.

- Observe the manometer and note the static pressure reading once it has stabilized.

- Record the static pressure reading in your notebook, along with the date and time of measurement.

Measuring the static pressure at the return grille provides crucial information about the resistance to airflow in the return ductwork and the condition of the air filters. It helps identify potential issues like clogged filters or leaking ducts, which can impact the performance of your HVAC system. Remember to repeat this step multiple times to ensure consistency in the readings.

By measuring the static pressures at both the supply and return grilles, you can compare the readings and gain insights into the overall static pressure in your HVAC system. This information will help you identify any issues and make necessary adjustments to optimize the airflow and ensure efficient system operation.

Now that you have obtained the static pressure readings at both grilles, it’s time to compare them in the next step.

Step 5: Compare the Readings

After measuring the static pressures at the supply and return grilles, it’s time to compare the readings. Comparing the static pressure readings will give you insights into the overall performance of your HVAC system and potential issues that may need to be addressed. Here’s how to compare the readings:

- Refer to your recorded static pressure readings at the supply and return grilles.

- Compare the readings to determine the pressure difference between the supply and return grilles.

- A positive pressure difference (higher static pressure at the supply grille) indicates a higher resistance to airflow in the supply ductwork. This could be due to factors such as clogged filters, undersized ductwork, or obstructions in the supply ducts.

- A negative pressure difference (higher static pressure at the return grille) suggests a higher resistance to airflow in the return ductwork. This could be due to factors such as clogged filters, leaking ducts, or improper return grille sizing.

- Take note of the pressure readings and the pressure difference between the supply and return grilles. Significant differences in static pressure may indicate potential issues that need to be addressed.

- If the pressure difference is within an acceptable range (usually specified by the HVAC system manufacturer), it indicates a balanced airflow and proper system performance.

- If the pressure difference is too high or too low, it suggests a need for further investigation and potential adjustments or repairs to optimize the system’s airflow.

Comparing the static pressure readings is a crucial step in evaluating the performance of your HVAC system. It helps identify potential issues in the supply or return ductwork that may affect the efficiency and comfort of your home. If you notice significant deviations or have concerns about the pressure difference, it is advisable to consult with an HVAC professional for a more in-depth evaluation and appropriate solutions.

Now that you have compared the static pressure readings, it’s time to move on to the next step of identifying and addressing any issues that may have been identified.

Read more: How To Check For Mold In HVAC System

Step 6: Identify and Address any Issues

After comparing the static pressure readings and noting any significant pressure differences, it’s time to identify and address any issues that may have been identified. Here’s how to proceed:

- Review your notes and the static pressure readings from both the supply and return grilles.

- If the pressure difference is within an acceptable range, it indicates balanced airflow and proper system performance. In this case, no further action is required, and you can proceed with routine maintenance and filter changes as recommended by the HVAC system manufacturer.

- If the pressure difference is too high or too low, it suggests that there may be issues affecting the airflow in the HVAC system. Some common issues include clogged filters, duct obstructions, closed dampers, undersized ductwork, improper blower motor speed settings, or leaking ducts.

- Begin troubleshooting by checking the air filters. If they are dirty or clogged, replace them with clean ones. Dirty filters restrict airflow and can cause higher static pressure readings. Regularly changing or cleaning the filters is essential to maintain optimal performance.

- Inspect the ductwork for any obstructions, such as debris, collapsed sections, or ductwork disconnected at joints. If you notice any issues, clean or repair the ducts as necessary. Consider contacting a professional HVAC technician if you are unsure or uncomfortable with the inspection and repair process.

- Ensure that all dampers throughout the ductwork are fully open and not restricting airflow.

- Check the blower motor speed settings. If the blower is operating at an incorrect speed, it can result in imbalanced airflow and higher static pressure. Consult the HVAC system’s documentation or seek guidance from a professional to adjust the blower motor speed if necessary.

- If you suspect leaking ducts, inspect them visually for any visible signs of air leakage. Seal any gaps or leaks using duct tape or mastic sealant. For more significant leaks, it is recommended to consult with an HVAC professional for proper sealing and repair.

- Record any actions taken to address the static pressure issues in your notebook for future reference.

- Re-measure the static pressure after addressing the identified issues to assess the impact on the system’s performance. Ensure that the pressure readings have improved and are within an acceptable range.

Identifying and addressing any issues affecting the static pressure in your HVAC system is essential to ensure efficient system operation and optimal comfort. Regular maintenance and attention to airflow issues will help maintain the performance and longevity of your HVAC system.

If you are unsure or uncomfortable with troubleshooting or making repairs yourself, it’s always recommended to consult with a professional HVAC technician. They have the knowledge and expertise to diagnose and resolve any issues related to system airflow and static pressure.

By following these steps and addressing any identified issues, you can optimize the performance of your HVAC system and enjoy comfortable indoor environments with improved energy efficiency.

With the completion of Step 6, you have successfully measured, compared, and identified any issues related to static pressure in your HVAC system. By taking appropriate actions, you can ensure the proper functioning of your system and enjoy the benefits of optimal airflow and comfort.

Remember, regular monitoring of static pressure and performing routine maintenance will help keep your HVAC system running efficiently for years to come.

By following these steps and making necessary adjustments or repairs, you can optimize the performance of your HVAC system, improve energy efficiency, and maintain comfortable indoor environments.

Conclusion

Checking the static pressure in your HVAC system is a crucial step in ensuring optimal performance, energy efficiency, and comfort. By monitoring static pressure, you can identify potential issues that may be affecting airflow, such as clogged filters, duct obstructions, or undersized ductwork. Regularly measuring static pressure allows you to address these issues early on and take necessary actions to optimize your HVAC system.

In this comprehensive guide, we have walked you through the step-by-step process of checking static pressure in your HVAC system. We discussed what static pressure is and why it is important to monitor it. We also provided a detailed breakdown of the equipment and tools needed for the task.

We guided you through each step, including turning off the HVAC system, locating the supply and return grilles, and measuring the static pressure at both points. We emphasized the importance of comparing the readings to identify any pressure differences that may indicate potential issues. Lastly, we encouraged you to address these issues promptly to ensure efficient system operation.

Remember, if you are unsure or uncomfortable with any step of the process or need assistance, it is always recommended to consult with a professional HVAC technician. They have the expertise and experience to diagnose and resolve any issues with your HVAC system.

Regularly checking the static pressure in your HVAC system, along with routine maintenance and filter changes, will help optimize performance, improve energy efficiency, and maintain comfortable indoor environments. By taking the time to monitor and address static pressure, you can ensure that your HVAC system is running at its best, providing you and your family with reliable heating and cooling year-round.

Thank you for reading our guide on how to check static pressure in HVAC systems. We hope that you found this information helpful and that it enables you to maintain a well-functioning and efficient HVAC system in your home or business.

Frequently Asked Questions about How To Check Static Pressure In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Check Static Pressure In HVAC”