Articles

How To Laser Level A Field

Modified: January 6, 2024

Learn how to laser level a field with our informative articles. Discover expert tips and techniques for achieving an even and precise surface.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

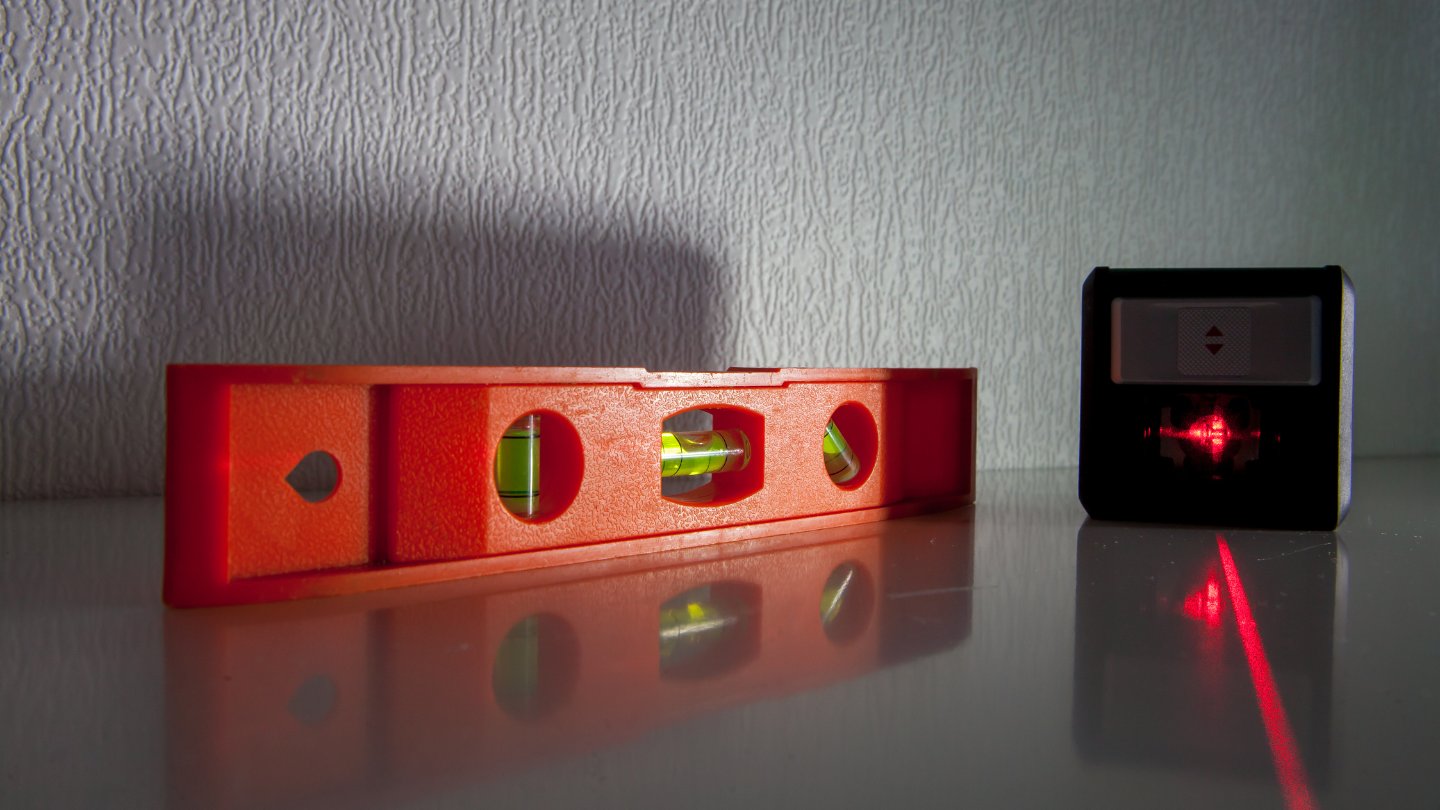

Leveling a field is an essential task when it comes to various outdoor projects and activities. Whether you’re planning to build a sports field, prepare a garden plot, or construct a patio, achieving a level surface is crucial for optimal performance and aesthetics. While manual leveling methods can be time-consuming and tedious, using a laser level can significantly simplify the process, providing accurate and precise results.

In this article, we will guide you through the step-by-step process of laser leveling a field. From gathering the necessary tools and equipment to making adjustments and completing the leveling process, we will cover each stage to ensure you achieve a perfectly level field.

Before we dive into the detailed steps, let’s briefly explore what a laser level is and why it is the preferred tool for field leveling. A laser level is a device that emits a beam of light to create a level reference line or point. It is commonly used in construction and landscaping to ensure accurate measurements and alignments. Unlike traditional leveling techniques that rely on manual tools like spirit levels, a laser level provides a more efficient and precise solution.

By using a laser level for field leveling, you not only save time and effort but also increase the accuracy of the leveling process. This is especially important when it comes to projects that require a high degree of precision, such as installing irrigation systems or constructing playing surfaces for sports activities.

Now that we understand the importance of laser leveling and its advantages, let’s move on to the first step: gathering the necessary tools and equipment.

Key Takeaways:

- Laser leveling a field is a precise and efficient process that saves time and ensures a high degree of accuracy, making it ideal for various outdoor projects and activities.

- Proper preparation, calibration, and periodic checking are crucial for achieving a level surface, ensuring accurate measurements and addressing any inconsistencies.

Read more: How To Laser Level A Baseball Field

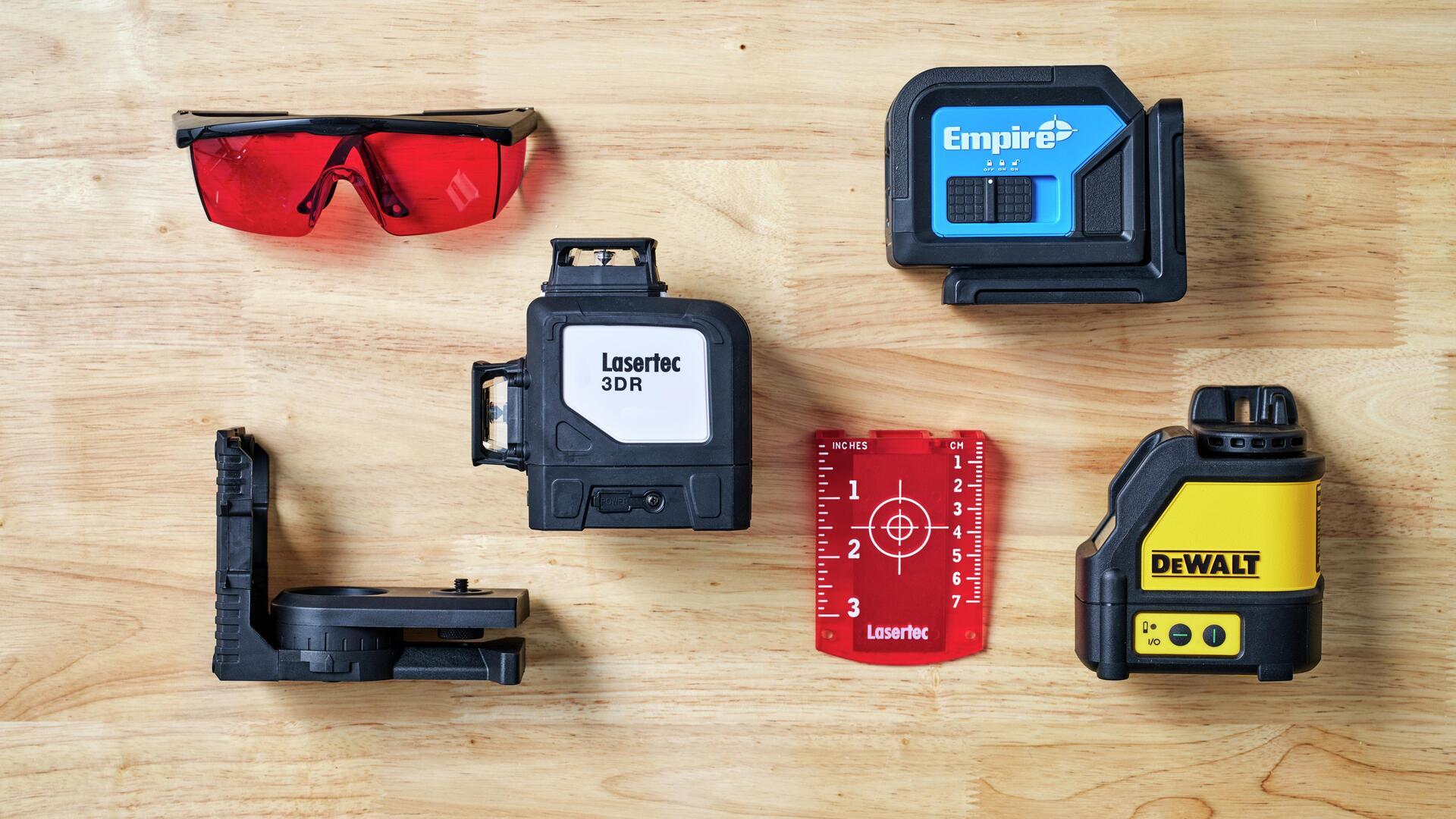

Step 1: Gather the necessary tools and equipment

Before you begin the laser leveling process, it’s crucial to gather all the necessary tools and equipment to ensure a smooth and efficient operation. Here is a list of items you will need:

- Laser level: This is the main tool you will need for the leveling process. Make sure to choose a laser level with a rotating beam function and a receiver for outdoor use. The laser level should also come with a tripod for stability.

- Receiver: A receiver is essential for outdoor leveling as it allows you to detect the laser beam even under bright sunlight. Make sure the receiver is compatible with the laser level you have or purchase a receiver that is specifically designed for your model.

- Measuring tape: A measuring tape is necessary to take accurate measurements and mark reference points on the field.

- Pegs and string: These will be used to mark reference lines and create a grid pattern for leveling.

- Total station: A total station is an advanced surveying instrument that combines the functions of a theodolite and an electronic distance meter. It is used for accurate measurements and data collection during the leveling process.

- Safety equipment: Ensure you have safety goggles, gloves, and appropriate footwear to protect yourself during the leveling process.

Once you have gathered all the necessary tools and equipment, you are ready to move on to the next step: preparing the field for leveling.

Step 2: Prepare the field for leveling

Before you can begin the laser leveling process, it is important to properly prepare the field to ensure accurate and effective results. Here are the steps to follow:

- Clear the field: Remove any obstacles, such as rocks, debris, or vegetation, from the field. Clearing the field will provide a clean and even surface for leveling.

- Mark the boundary: Use pegs and string to mark the boundary of the area you want to level. This will help you visualize the extent of the leveling process and ensure that you stay within the designated area.

- Remove high spots: Identify any high spots or uneven areas in the field and mark them for later adjustment. This will allow you to focus on leveling these specific areas during the leveling process.

- Water the field: If the field is dry or has compacted soil, it is recommended to water it thoroughly a day or two before leveling. This will help soften the soil and make it easier to level.

- Check for drainage: Ensure that the field has proper drainage by examining the slope and any existing drainage systems. If necessary, adjust the slope or install additional drainage to prevent water pooling after the leveling process.

- Take preliminary measurements: Use a measuring tape to take preliminary measurements at different points across the field. This will give you an idea of the current elevation variations and help you determine the extent of leveling required.

By following these steps and properly preparing the field, you will create an ideal foundation for the laser leveling process. Now that the field is ready, it’s time to move on to the next step: setting up the laser level.

Step 3: Set up the laser level

Setting up the laser level correctly is crucial to ensure accurate and reliable results. Follow these steps to set up your laser level:

- Choose a level location: Select a stable and level location near the field where you can set up the laser level and tripod. This will serve as your base station for the leveling process.

- Install the batteries: Check the power requirements of your laser level and ensure it has fresh batteries or is adequately charged. Install the batteries according to the manufacturer’s instructions.

- Mount the laser level: Attach the laser level to the tripod securely. Make sure it is stable and level by adjusting the tripod legs as needed. Use a bubble level or built-in leveling mechanisms on the tripod to ensure accuracy.

- Turn on the laser level: Once the laser level is securely mounted, turn it on and allow it to initialize. Some laser levels may require a few moments to stabilize and establish a level reference.

- Aim the laser level: Adjust the position of the laser level and tripod so that the laser beam points towards the field and aligns with your intended leveling area. Use the fine adjustment controls on the tripod or laser level to ensure precision.

- Secure the laser level: Once you have aimed the laser level correctly, tighten any securing mechanisms or locks on the tripod to ensure that the laser level remains fixed in position throughout the leveling process.

By following these steps, you will ensure that your laser level is set up properly and ready to deliver accurate measurements and leveling references. With the laser level ready, it’s time to move on to the next step: calibrating the laser level.

Step 4: Calibrate the laser level

Calibrating the laser level is an essential step to ensure accurate measurements and precise leveling. Follow these steps to calibrate your laser level:

- Check the levelness: Use a bubble level or the built-in leveling mechanisms on the laser level to ensure that it is perfectly level on the tripod. Make any necessary adjustments to achieve a level position.

- Stabilize the laser level: Allow the laser level to stabilize before proceeding with the calibration process. This ensures that the internal components settle properly and provide accurate readings.

- Set up calibration targets: Place the calibration targets or known height reference points across the field at various locations. These can be stakes with marked heights or other objects with known elevations.

- Start the calibration process: Activate the calibration mode on your laser level. Follow the manufacturer’s instructions to enter the calibration process, which typically involves aligning the laser beam with the calibration targets or reference points.

- Adjust the laser level: Use the adjustment screws or knobs on the laser level to align the laser beam with each calibration target. Make incremental adjustments until the laser beam is hitting the targets at the correct elevations.

- Verify the calibration: After aligning the laser beam with all calibration targets, check multiple points on the field to confirm that the laser level is providing accurate readings. Use a measuring tape to compare the elevation measurements with the laser level’s indicated elevation.

Calibrating the laser level is crucial for obtaining accurate and reliable measurements during the leveling process. By properly aligning the laser beam with calibration targets and verifying the readings, you can ensure precise leveling results. With the laser level calibrated, let’s move on to the next step: beginning the leveling process.

When laser leveling a field, make sure to calibrate the laser level properly before use to ensure accurate and precise results.

Read more: How To Level A Laser Level Tripod

Step 5: Begin the leveling process

With the laser level set up and calibrated, you’re now ready to begin the actual leveling process. Follow these steps to start leveling the field:

- Identify the starting point: Choose a starting point on the field where you will begin the leveling process. This can be one of the corners or a central point, depending on the size and shape of the field.

- Set up reference lines: Use pegs and string to create reference lines across the field. These lines will serve as guides for the leveling process. Ideally, you should create a grid pattern with evenly spaced reference lines.

- Measure the initial elevation: Use the laser level and receiver to measure the initial elevation at the starting point. Adjust the receiver’s height until it aligns with the laser beam, and take note of the elevation reading.

- Move along the reference lines: Move along each reference line systematically, taking elevation measurements at regular intervals. Adjust the receiver’s height as needed to align with the laser beam and record the elevation readings.

- Mark high and low spots: As you measure the elevation across the field, mark any high or low spots that deviate significantly from the desired level. These areas will require additional attention during the leveling process.

- Repeat the process: Repeat the elevation measurement process for each reference line until you have covered the entire field. Make precise and accurate measurements to ensure uniformity in leveling.

By following these steps, you will gradually level the field by measuring and adjusting the elevation along the reference lines. This will help create a more even and consistent surface. Remember to take note of any high or low spots for adjustment in the next step. As you continue with the leveling process, periodically check the level to ensure accuracy and make necessary adjustments. Let’s move on to the next step: checking the level periodically.

Step 6: Check the level periodically

As you progress through the leveling process, it’s important to periodically check the level to ensure the accuracy and effectiveness of your work. Follow these steps to check the level periodically:

- Select checking points: Choose specific points across the field where you will check the level. These points should be representative of different areas and elevations on the field.

- Place the receiver: Position the receiver at each checking point and adjust its height until it aligns with the laser beam emitted by the laser level.

- Take elevation readings: Record the elevation readings indicated by the receiver at each checking point. Compare these readings to the desired level or the initially measured reference elevation.

- Identify deviations: Analyze the collected elevation readings and identify any significant deviations from the desired level. These deviations may indicate areas that require further adjustment or attention during the leveling process.

- Make necessary adjustments: If you observe any deviations from the desired level, make the necessary adjustments to correct them. This may involve adding or removing soil, compacting the ground, or making changes to the drainage system.

- Re-check periodically: After making adjustments, re-check the level at the same checking points to ensure that the desired level has been achieved. Repeat this process as you continue to level the field.

By periodically checking the level during the leveling process, you can identify and address any deviations or inconsistencies. This helps ensure a more precise and accurate leveling outcome. Don’t hesitate to make necessary adjustments and re-check the level as needed to achieve the desired results. Now, let’s move on to the next step: making necessary adjustments.

Step 7: Make necessary adjustments

During the laser leveling process, it is common to encounter areas that require adjustment to achieve the desired level. Follow these steps to make necessary adjustments:

- Identify areas for adjustment: Refer to the measurements and observations made during the leveling and periodic checking processes. Identify areas that deviate significantly from the desired level or have noticeable unevenness.

- Address low spots: If you have identified low spots on the field, where the elevation is below the desired level, you can add soil or fill to raise the surface. Use a shovel or other suitable tools to evenly distribute the soil, then compact it to ensure stability and a level surface.

- Correct high spots: For areas with high spots, where the elevation is above the desired level, remove excess soil or material. Use a shovel or other appropriate tools to carefully scrape away the excess material, ensuring that the final surface is even and matches the desired level.

- Adjust drainage: If there are issues with water pooling or inadequate drainage, make the necessary adjustments to ensure proper water flow. This may involve altering the slope of the field or installing additional drainage systems.

- Re-measure after adjustments: Once adjustments have been made, re-measure the elevation at the adjusted areas to verify that the desired level has been achieved. Make any final fine-tuning adjustments if needed.

It’s important to ensure that all adjustments are made gradually and carefully to maintain the integrity and stability of the field. Take your time and double-check the levelness after each adjustment to achieve a uniformly leveled surface.

Now that you have made the necessary adjustments to level the field, let’s move on to the final step: completing the leveling process.

Step 8: Complete the leveling process

Congratulations! You’ve reached the final step of the laser leveling process. Follow these steps to complete the leveling process:

- Review the entire field: Take a final walk or survey of the entire field to ensure that all areas have been properly leveled and any adjustments have been made.

- Check for uniformity: Evaluate the overall levelness of the field. Look for any noticeable unevenness, ridges, or depressions that may require additional attention.

- Take final elevation measurements: Use the laser level and receiver to measure the elevation at multiple points across the field. Compare these measurements to the desired level or the initial reference elevation to confirm that the leveling process has been successful.

- Make final adjustments if necessary: If you detect any remaining areas that are not at the desired level, make the required adjustments as you have done previously. Pay attention to small details to ensure a consistent and level surface.

- Document the leveling process: Record the final measurements, adjustments made, and any notable observations during the leveling process. This documentation will serve as a reference for future maintenance or modifications to the field.

- Clean up and restore the field: Remove any temporary markings, pegs, or strings used during the leveling process. Clean up the field by removing debris or excess soil to restore it to its desired state.

With these final steps, you have successfully completed the laser leveling process! You can now enjoy a level and evenly surfaced field that is ready for various outdoor projects or activities.

Remember to regularly monitor the field after the leveling process, especially after heavy rainfall or usage, to ensure that it remains in an optimal condition. This may involve periodic maintenance and re-leveling if necessary.

Thank you for following this step-by-step guide on laser leveling a field. We hope this article has provided you with valuable insights and practical instructions to achieve a perfectly leveled field. Happy leveling!

Read more: How To Calibrate Laser Level

Conclusion

Laser leveling a field is a precise and efficient process that allows you to achieve a perfectly leveled surface for various outdoor projects and activities. By following the step-by-step guide outlined in this article, you can ensure accurate measurements and precise adjustments, resulting in an even and uniform field.

We began by discussing the importance of laser leveling and its advantages over traditional leveling methods. The use of a laser level simplifies the process, saves time, and ensures a high degree of accuracy, making it an ideal tool for field leveling.

We then covered the essential steps in the laser leveling process, starting with gathering the necessary tools and equipment. Proper preparation of the field, including clearing obstacles and marking boundaries, was emphasized to ensure a clean and even surface.

The significance of setting up and calibrating the laser level was highlighted next. We explained the importance of leveling the laser level itself and aligning it with calibration targets to obtain accurate readings throughout the leveling process.

With the laser level properly set up and calibrated, we moved on to the actual leveling process. This involved measuring elevations along reference lines, identifying deviations, and making necessary adjustments to achieve a level surface.

Periodically checking the level and making adjustments as needed were emphasized to maintain accuracy and address any inconsistencies that may arise during the leveling process.

Lastly, we discussed the final steps in completing the leveling process, including reviewing the entire field, taking final elevation measurements, making any last-minute adjustments, documenting the process, and restoring the field to its desired state.

By following these steps and paying attention to detail, you can successfully laser level a field and create an ideal foundation for various projects and activities. Remember to regularly monitor the field after the leveling process to ensure its long-term integrity and functionality.

We hope this comprehensive guide has provided you with valuable insights and practical instructions for laser leveling a field. Whether you’re preparing a sports field, constructing a garden, or building a patio, a leveled surface will enhance performance and aesthetics, contributing to the success of your project. Happy leveling!

Frequently Asked Questions about How To Laser Level A Field

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Laser Level A Field”