Articles

How Accurate Is A Laser Level

Modified: February 22, 2024

Discover the accuracy of laser levels in this informative article. Learn how these tools can help you achieve precise measurements in your projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

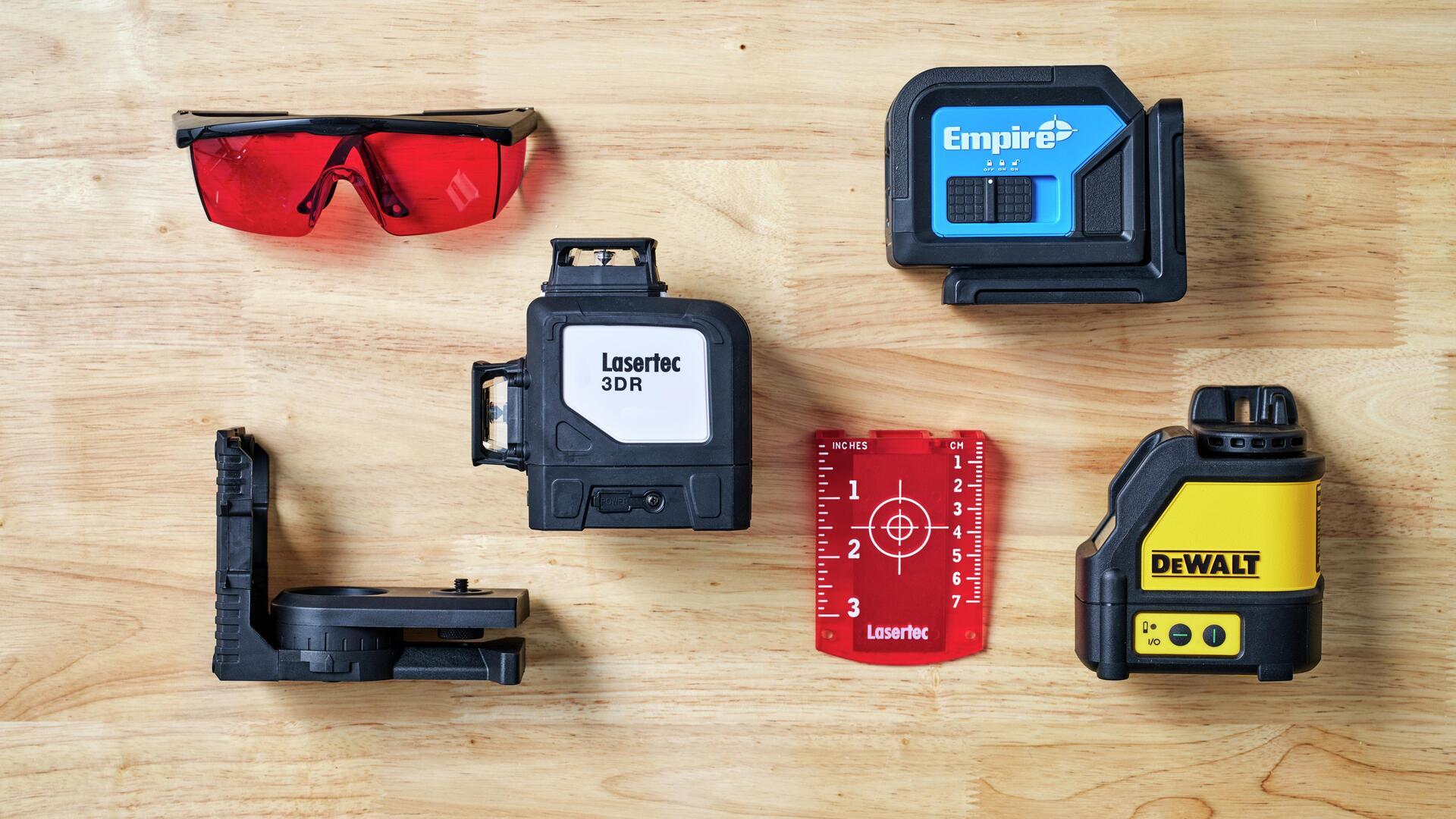

A laser level is a versatile tool that has revolutionized the construction and home improvement industry. From aligning and leveling surfaces to creating precise measurements, laser levels have become an essential part of any project that requires accuracy. However, the question remains – just how accurate is a laser level?

In order to understand the accuracy of a laser level, it is important to delve into how it works and the factors that can influence its precision. Factors such as calibration and maintenance also play a significant role in ensuring the accuracy of a laser level. Additionally, testing the accuracy of a laser level is crucial to determine its reliability in various applications.

This article aims to shed light on the accuracy of a laser level and the factors that can affect its precision. Whether you are a construction professional or a DIY enthusiast, understanding the limitations and nuances of a laser level’s accuracy can help you make informed decisions and achieve better results in your projects.

Key Takeaways:

- Laser levels provide highly accurate measurements, but factors like ambient lighting, surface reflectivity, and user error can affect their precision. Regular calibration, maintenance, and testing are crucial for ensuring reliable results in construction and home improvement projects.

- Using a single laser level throughout a project ensures consistency, accuracy, and efficiency. It simplifies the process, reduces complexity, and promotes better collaboration, ultimately leading to superior outcomes in construction and home improvement tasks.

Read more: How To Level A Laser Level Tripod

How Does a Laser Level Work?

A laser level operates on a simple yet ingenious principle – it emits a laser beam that creates a perfectly straight reference line or dot. This line or dot serves as a guide for aligning or leveling surfaces, ensuring precise measurements and accurate positioning.

Inside a laser level, there are various components that work together to create the laser beam. The key components include a laser diode, a leveling mechanism, a beam splitter, and a prism or lens system.

The laser diode is the heart of the laser level. When an electric current is applied to the diode, it emits a highly concentrated beam of light. This beam is then directed towards the leveling mechanism, which ensures that it is perfectly level and unaffected by external factors such as vibrations or movements.

Once the beam is level, it passes through a beam splitter, which divides the beam into two parts – the reference beam and the projection beam. The reference beam is directed towards a prism or lens system that helps create a visible laser line or dot on the target surface.

The laser emission from a laser level can either be in the form of a line or a dot, depending on the type of laser level. Line lasers emit a straight line, making them ideal for tasks that require alignment and leveling over a long distance. Dot lasers emit a single point, which is useful for tasks that require precise spot referencing.

Overall, the intricate combination of these components allows a laser level to create a highly accurate and visible reference line or dot. This makes it an invaluable tool for a wide range of applications, including installing fixtures, laying tiles, framing walls, and hanging shelves.

Factors Affecting Accuracy

While laser levels are designed to provide accurate measurements, there are several factors that can affect their precision. It is important to be aware of these factors in order to ensure the highest level of accuracy in your projects:

- Quality of the Laser Level: The quality of the laser level itself plays a crucial role in its accuracy. Higher-quality laser levels tend to have more precise components and better calibration, resulting in more accurate measurements.

- Ambient Lighting Conditions: The ambient lighting conditions in your work area can impact the visibility of the laser beam. Bright or direct sunlight can overpower the laser beam, making it difficult to see. It is best to use a laser level in a well-lit or dimly lit environment for optimal accuracy.

- Distance to Target: The distance between the laser level and the target surface can impact accuracy. Most laser levels have a maximum range within which they can provide accurate measurements. Beyond that range, the laser beam may begin to diverge and lose its precision.

- Surface Reflectivity: The reflectivity of the target surface can affect the accuracy of the laser level. Highly reflective surfaces, such as glass or polished metal, can cause the laser beam to bounce back and create inaccuracies in the measurements. It is advisable to use a target surface with a matte finish for improved accuracy.

- Temperature and Environmental Conditions: Extreme temperatures or severe environmental conditions can impact the performance of a laser level. Changes in temperature can cause the internal components of the laser level to expand or contract, affecting its calibration and accuracy. It is important to follow the manufacturer’s guidelines regarding operating temperature ranges for optimal performance.

- User Error: Perhaps one of the most common factors affecting accuracy is user error. Improper leveling, incorrect positioning, or misalignment of the laser level can introduce errors into the measurements. It is essential to carefully read and follow the instructions provided by the manufacturer to ensure accurate results.

By understanding and mitigating these factors, you can significantly improve the accuracy of your laser level measurements. Remember to choose a high-quality laser level, work in appropriate lighting conditions, consider the distance and surface reflectivity, and adhere to proper calibration and usage techniques.

Calibration and Maintenance

Calibration and regular maintenance are essential for ensuring the accuracy and reliability of a laser level. Here are some key aspects to consider:

Calibration: Laser levels should be calibrated periodically to maintain their accuracy. Calibration involves adjusting the internal components of the laser level to ensure that it is level and aligned correctly. Some laser levels come with built-in self-calibration features, while others may require manual calibration using specialized tools. It is important to follow the manufacturer’s instructions for calibration to ensure accurate measurements.

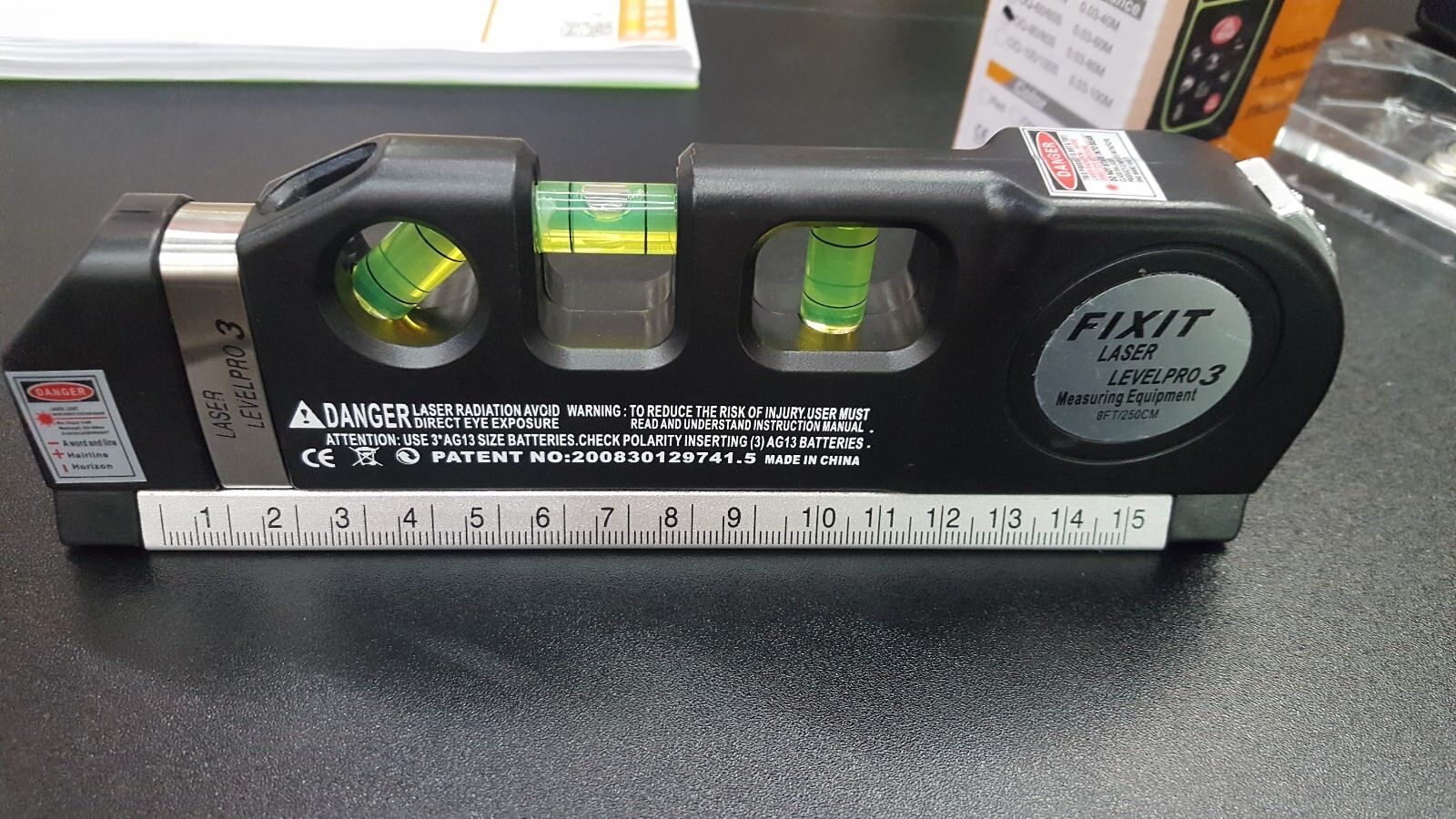

Leveling Mechanism: The leveling mechanism of a laser level plays a critical role in its accuracy. It is important to keep the leveling mechanism clean and free from debris or obstructions. Regularly check for any signs of wear or damage and replace any worn-out components if necessary. Additionally, make sure to use the built-in leveling vials or other leveling indicators to ensure that the laser level is perfectly level before use.

Battery Life: Laser levels typically operate on batteries, so it is important to monitor and maintain battery life for optimal performance. Replace batteries as needed and consider using high-quality, long-lasting batteries to avoid sudden power loss during critical measurements.

Cleaning and Storage: Regularly clean the laser level’s lenses, beam splitter, and other optical components to ensure clear and accurate laser emission. Use a soft, lint-free cloth to remove any dirt, dust, or smudges. When not in use, store the laser level in a protective case or pouch to prevent damage from dust, moisture, or accidental impacts.

Manufacturer’s Recommendations: Always consult the manufacturer’s instructions and guidelines for specific maintenance requirements and recommendations for your laser level model. They may provide additional tips and advice on how to keep your laser level in optimal condition and maximize its accuracy.

By taking the time to calibrate and maintain your laser level, you can ensure that it consistently delivers accurate and reliable measurements. Regular maintenance not only improves the accuracy of the laser level but also extends its overall lifespan, saving you time and money in the long run.

When using a laser level, always ensure that it is placed on a stable surface and that the laser beam is not obstructed by any objects. This will help to ensure the accuracy of the level.

Testing the Accuracy of a Laser Level

Testing the accuracy of a laser level is crucial to determine its reliability and ensure precise measurements in your projects. Here are some methods to test the accuracy of a laser level:

Static Test: Use a target plate or a wall-mounted target to measure the height or distance of the laser line at different points. Ensure that the laser level is stable and secure during the test. Compare the measured values with the intended measurements to check for any discrepancies. This test is particularly useful for verifying the horizontal or vertical alignment of the laser level.

Rotational Test: For rotary laser levels, perform a rotational test by mounting the laser level on a tripod and rotating it 360 degrees. Use a target plate or receiver at various intervals to measure the height or distance of the laser beam. Compare the readings to ensure that the laser level maintains consistency and accuracy throughout its rotation.

Horizontal and Vertical Verification: Place the laser level on a flat, stable surface and project a horizontal and vertical line onto a target surface. Measure the distance from the laser line to the target surface at various points to verify its accuracy. This test helps ensure that the laser level maintains a straight and accurate line over a specific distance.

Collimation Test: A collimation test assesses the parallel alignment of the laser beam. Place the laser level on a stable surface and project the beam onto a distant target. Measure the distance between the beam at different points to determine if it remains parallel. Any significant deviation may indicate a need for realignment or calibration.

Quality Control Certification: Some laser level manufacturers offer quality control certifications or calibration certificates for their products. These certifications provide assurance that the laser level has been tested and calibrated according to industry standards. Consider purchasing laser levels that come with such certifications for added peace of mind regarding accuracy.

It is important to note that the accuracy of a laser level may slightly vary depending on the brand, model, and price range. Always consult the manufacturer’s specifications for the expected accuracy levels of your specific laser level.

Regularly testing and verifying the accuracy of your laser level helps maintain its performance and ensures that your measurements are precise. By incorporating these testing methods into your routine, you can identify any potential inaccuracies early on and take appropriate measures to rectify them.

Read more: How To Calibrate Laser Level

Common Errors and Limitations

While laser levels are highly accurate tools, it is important to be aware of their common errors and limitations in order to use them effectively and avoid any potential inaccuracies:

Beam Divergence: Laser beams are not perfectly collimated and can slightly diverge as the distance increases. This divergence can lead to a wider laser line or a larger spot size, reducing the precision of measurements over longer distances. It is important to consider the maximum range and accuracy limitations of your laser level when working on projects that require measurements over extended distances.

Ambient Interference: Laser beams can be affected by ambient interference, such as dust particles, fog, or smoke. These environmental factors can scatter the laser beam, making it less visible or distorting its shape. It is best to work in clean and clear conditions to minimize the impact of ambient interference on the accuracy of the laser level.

Uneven Surfaces: Laser levels rely on reflecting the laser beam off a surface to create a reference line or dot. If the surface is uneven or rough, the reflected beam may not accurately represent the true level or alignment. It is important to consider the surface conditions and make necessary adjustments when working on uneven surfaces. Alternatively, using a target plate or receiver can help capture and measure the laser beam accurately.

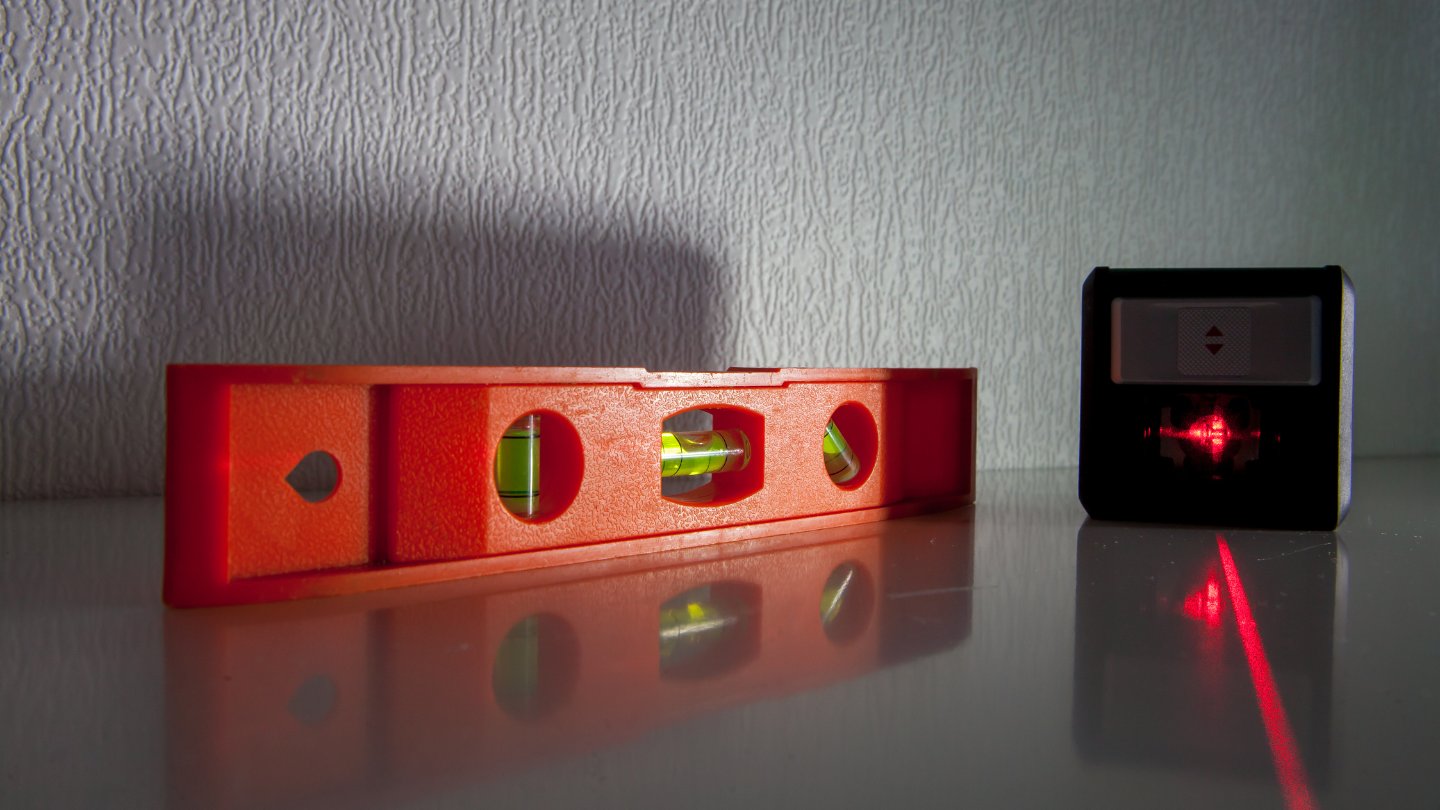

Mounting Stability: Proper mounting and stability are crucial for maintaining accuracy. If the laser level is not securely mounted or experiences vibrations or movement during operation, it can lead to inconsistent measurements. Ensure that your laser level is securely attached to a stable tripod or mounting bracket to minimize any potential errors caused by instability.

Human Error: Human error can introduce inaccuracies when using a laser level. Incorrect leveling, improper positioning, or misreading the measurements can all lead to errors in alignment or measurements. It is important to carefully follow the instructions provided by the manufacturer and double-check your work to minimize human-related inaccuracies.

Battery Life: Low battery power can affect the performance of a laser level and result in reduced accuracy. Always ensure that the batteries are adequately charged or replace them with fresh batteries to maintain optimal performance and accuracy.

By understanding the limitations and possible errors associated with laser levels, you can take proactive measures to mitigate them and maximize the accuracy of your measurements. Adhering to proper usage techniques, considering the environment and surface conditions, and regularly calibrating and maintaining your laser level will help you achieve the best possible results in your projects.

Importance of Using a Single Level

When working with a laser level, it is crucial to use a single level for your project. This means using one laser level throughout the entire task rather than relying on multiple levels or different reference points. Here’s why using a single level is important:

Consistency and Accuracy: Using a single level ensures consistency and accuracy in your measurements. Different laser levels may have slight variations in their calibration and accuracy, which can lead to discrepancies when trying to align or level surfaces. By using a single level, you can maintain consistent measurements and eliminate potential errors caused by using multiple devices.

Time and Efficiency: Using a single level saves time and increases efficiency. Instead of recalibrating or adjusting multiple levels, you can rely on one device for all your leveling and alignment needs. This streamlines the process and allows you to work more efficiently, reducing the risk of errors and delays in your project.

Reduced Complexity: Working with multiple levels can introduce complexity and confusion. Each level may have different features, controls, and settings, which can lead to user errors and inconsistencies in measurements. By using a single level, you can simplify the task at hand and focus on achieving accurate and precise results without the added complexity.

Cost-Effectiveness: Investing in a high-quality, reliable laser level is more cost-effective than purchasing multiple levels for different tasks. A single level that meets your specific project requirements can be used for a variety of applications, eliminating the need for additional tools and reducing overall costs.

Consolidated Documentation: Using a single level helps consolidate your project documentation. With a single level, you can easily refer to a single set of measurements and reference points, making it easier to track progress, troubleshoot issues, and communicate with clients or team members.

Workflow and Collaboration: When working as a team, using a single level ensures better coordination and collaboration. Everyone can refer to the same level and trust the accuracy of the measurements. This promotes smoother workflow, reduces confusion, and enhances teamwork on the job site.

Overall, using a single level provides numerous benefits in terms of consistency, accuracy, efficiency, simplicity, cost-effectiveness, documentation, and collaboration. It simplifies the process, ensures reliable measurements, and helps you achieve the desired outcomes in your projects more effectively.

Conclusion

A laser level is an invaluable tool for achieving accuracy and precision in construction and home improvement projects. By understanding the intricacies of a laser level’s accuracy and the factors that can affect it, you can make more informed decisions and achieve better results.

We explored how a laser level works, utilizing laser beams to create straight reference lines or dots. We discussed the factors that can impact accuracy, including the quality of the laser level itself, ambient lighting conditions, distance to the target, surface reflectivity, temperature, and user error.

Calibration and regular maintenance are essential for maximizing the accuracy of a laser level. Proper calibration and leveling mechanisms, as well as ensuring battery life and keeping the tool clean, can contribute to maintaining its accuracy over time.

We also discussed various methods for testing the accuracy of a laser level, such as static tests, rotational tests, horizontal and vertical verification, collimation tests, and the availability of quality control certifications from manufacturers.

It is important to be aware of the common errors and limitations associated with laser levels, such as beam divergence, ambient interference, uneven surfaces, mounting stability, and human error. Understanding these limitations allows you to minimize potential inaccuracies and improve the reliability of your measurements.

Lastly, we emphasized the importance of using a single level throughout your project to ensure consistency, accuracy, time and cost efficiency, reduced complexity, consolidated documentation, and improved workflow and collaboration.

By considering these factors, performing regular maintenance and calibration, and using a single level, you can maximize the accuracy of your laser level and achieve superior results in your construction or home improvement projects.

In conclusion, a laser level is a powerful tool that can significantly enhance your workmanship and precision. Understanding its accuracy and limitations empowers you to make informed decisions and deliver exceptional results in your projects.

Frequently Asked Questions about How Accurate Is A Laser Level

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Accurate Is A Laser Level”