Articles

How To Make An Oil Filter Suppressor Adapter

Modified: December 7, 2023

Learn how to make an oil filter suppressor adapter with our comprehensive articles. Explore step-by-step instructions and expert tips for a successful project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of homemade suppressors, where resourcefulness and creativity combine to create a hassle-free and cost-effective means of silencing your firearm. In this article, we will guide you through the process of making an oil filter suppressor adapter, a popular and often inexpensive option for those looking to reduce the noise produced by their firearms.

A suppressor, also known as a silencer, is a device designed to reduce the sound and recoil of a firearm. While there are commercially available suppressors, they can be quite costly and require extensive paperwork and background checks to acquire legally. However, with the right knowledge and materials, you can make your own homemade suppressor.

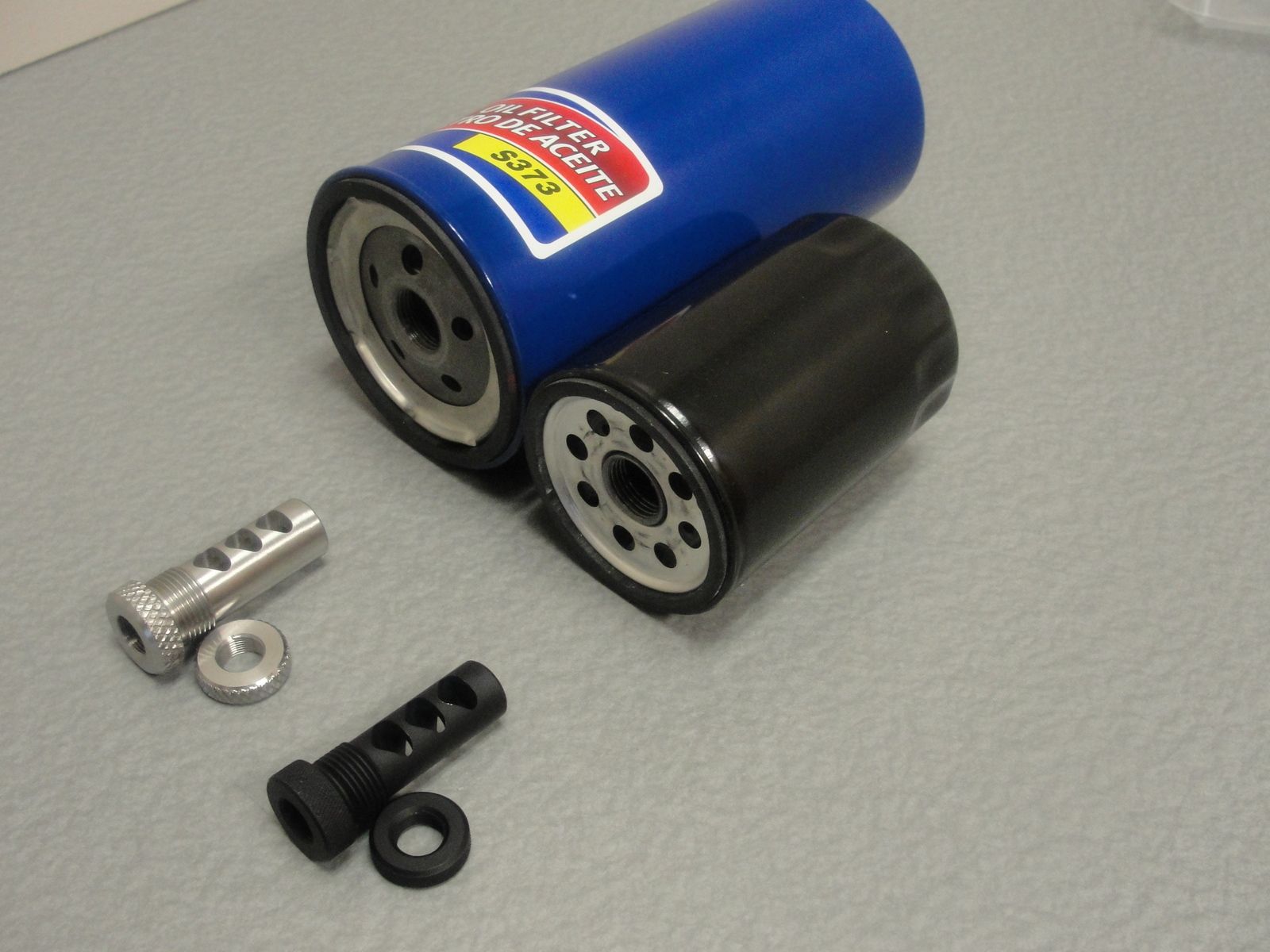

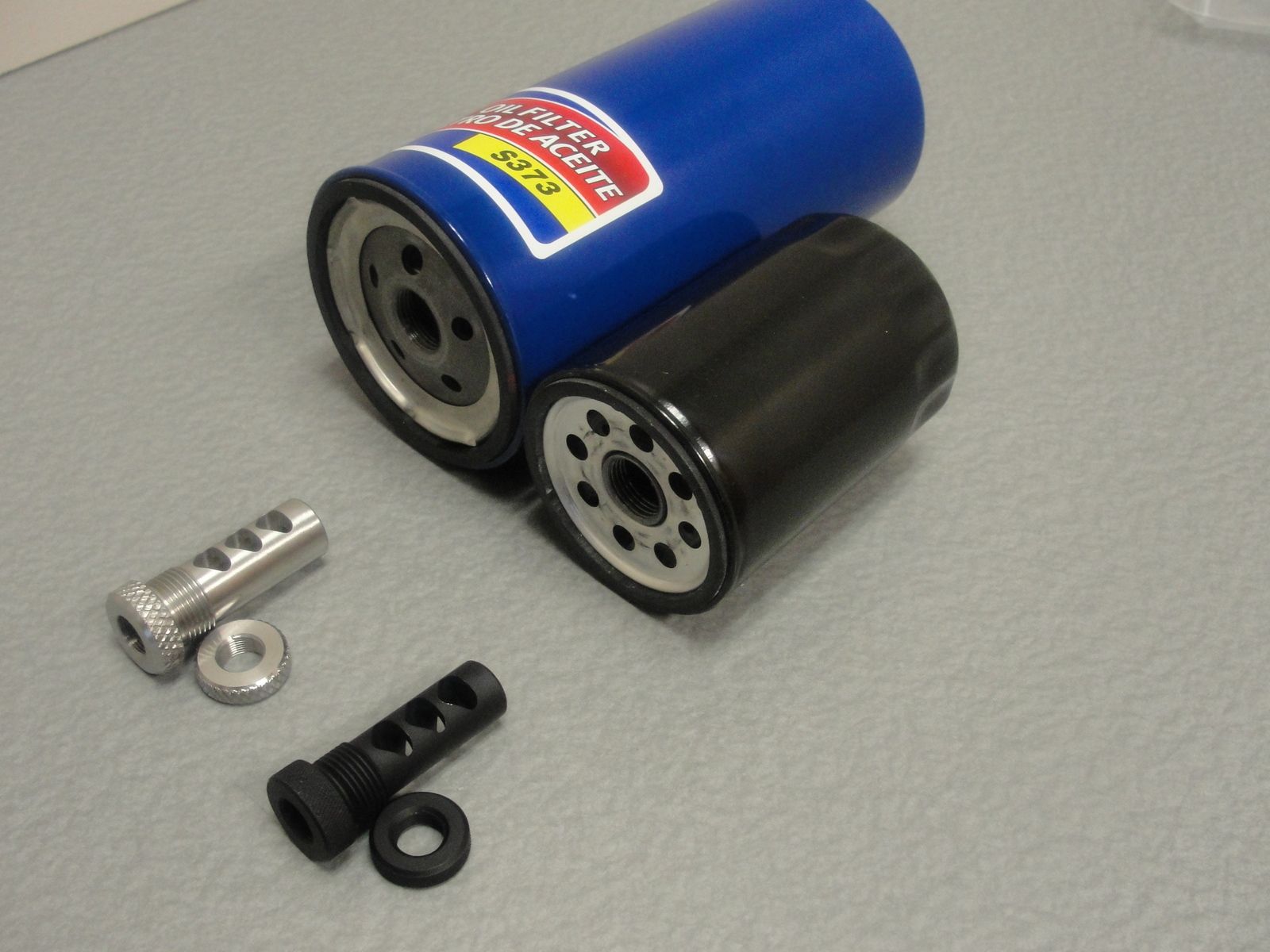

One of the most popular methods for creating a suppressor is by repurposing an oil filter and constructing an adapter to fit it onto the barrel of your firearm. Oil filters have similar internal structures to suppressors, making them a convenient choice for DIY enthusiasts.

Before we dive into the step-by-step process of making an oil filter suppressor adapter, it’s important to note that the legality of creating and using a homemade suppressor varies by country and state. Be sure to research and comply with all applicable laws before attempting this project.

Now that you’re aware of the legalities, let’s gather the materials needed for this project.

Key Takeaways:

- Create a cost-effective oil filter suppressor adapter to reduce firearm noise, but always prioritize safety and legality, and consult local laws before attempting this DIY project.

- Exercise caution and thorough testing when using homemade suppressors, as they may not match professional-grade performance. Prioritize safety, compliance, and responsible firearm usage at all times.

Read more: How To Make Thyme Oil

Materials Needed

Before you begin constructing your oil filter suppressor adapter, gather the following materials:

- Oil filter: Choose a high-quality oil filter that is compatible with your firearm. Look for a model that has a solid reputation for durability and reliability.

- Threaded adapter: You will need a threaded adapter that matches the threads on both the oil filter and the barrel of your firearm. Ensure that the adapter is made from sturdy material to withstand the pressure and stress of firing.

- Thread locker: To securely fasten the threaded adapter, use a thread locker to prevent it from loosening over time. This will ensure a tight and safe fit.

- Barrel wrench: A barrel wrench is necessary to remove the barrel of your firearm and attach the oil filter suppressor adapter. Be sure to have the correct size barrel wrench for your specific firearm.

- Solvent: It’s essential to have a solvent for cleaning and lubricating the oil filter suppressor adapter. Look for a solvent specifically designed for gun cleaning to maintain the performance and longevity of your firearm.

- Safety gear: Always prioritize safety when working with firearms. Wear protective gloves, safety glasses, and ear protection to protect yourself from any potential harm during the construction process.

Once you have gathered all the necessary materials, you’re ready to start the step-by-step process of constructing your oil filter suppressor adapter.

Step 1: Gather the Necessary Tools

Before diving into the construction process, ensure that you have the following tools on hand:

- Wrench set: You will need a wrench set with various sizes to dismantle the oil filter and attach the threaded adapter securely.

- Drill and drill bits: A drill is necessary for creating the necessary holes in the oil filter and the adapter.

- Vice grip or pliers: These tools will assist you in securely gripping and manipulating small parts during the construction process.

- File or sandpaper: A file or sandpaper can be used to remove any sharp edges or burrs from the drilled holes, ensuring a smooth and safe fit.

- Measuring tape or ruler: Accurate measurements are crucial for creating precise cuts and alignments throughout the process.

- Marker or pencil: Use a marker or pencil to mark the locations for drilling and cutting, ensuring precision and accuracy.

- Cleaning brushes: Various cleaning brushes will assist you in removing any debris or metallic shavings that may accumulate during the construction process.

- Shop towels or rags: Have plenty of shop towels or rags nearby to wipe away excess oil, solvent, or dirt.

Having these tools readily available will make the construction process smoother and more efficient. It’s important to ensure that all the tools are in good working condition and that you have a comfortable and well-lit workspace to carry out the construction.

Now that you have all the necessary tools, it’s time to move on to the next step: dismantling the oil filter.

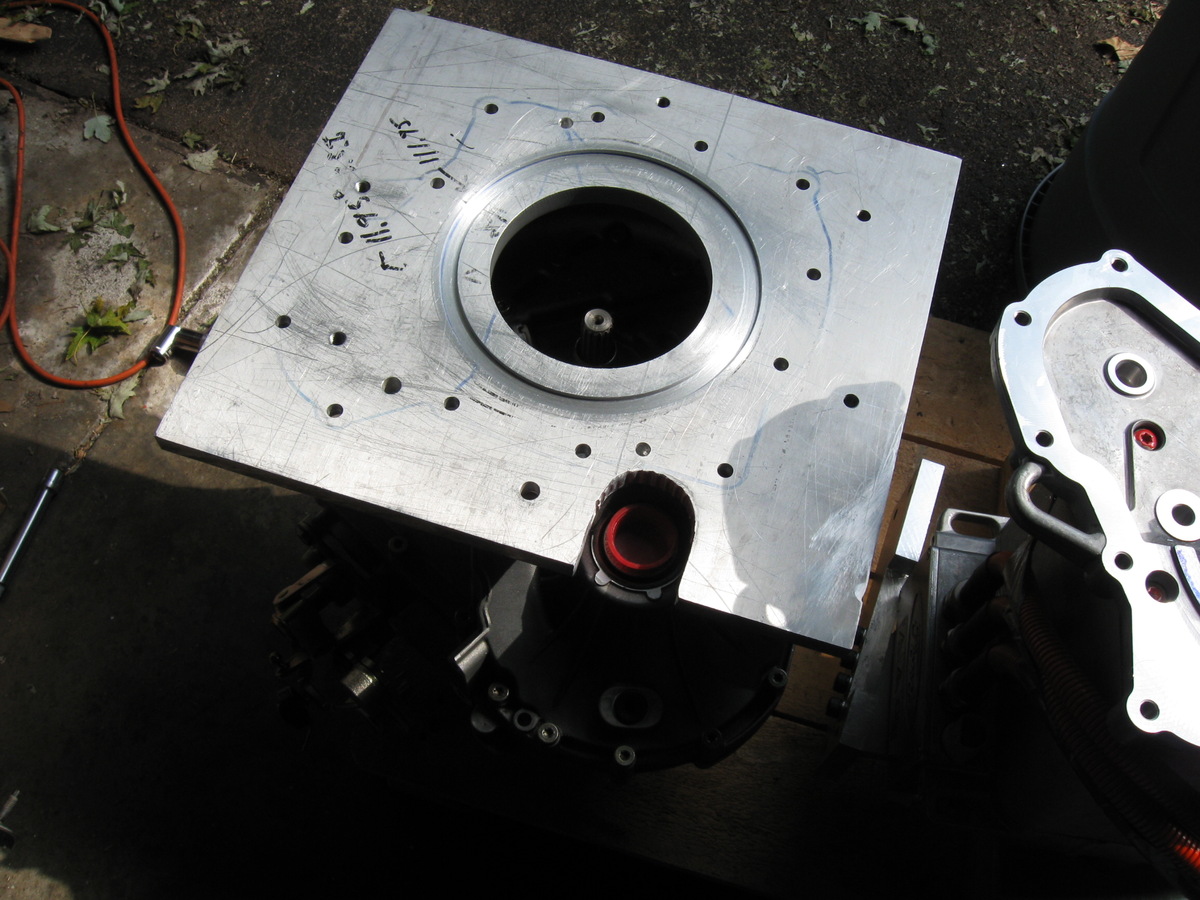

Step 2: Dismantle the Oil Filter

Now that you have gathered all the necessary tools, it’s time to begin the process of dismantling the oil filter. Follow these steps:

- Place the oil filter in a vice grip or use pliers to securely hold it in place. Ensure that it is stable and will not move during the dismantling process.

- Use a wrench to loosen the end cap of the oil filter. Turn it counterclockwise until it comes off, exposing the filter element and the threads inside the filter housing.

- Once the end cap is removed, carefully pull out the filter element from the housing. Take note of how it is assembled, as you will need to reassemble it in the same manner later.

- Inspect the filter element for any debris or contaminants. Clean it thoroughly using solvent and a cleaning brush, ensuring that it is free from dirt or residue that could affect the performance of your homemade suppressor.

- With the filter element removed, you can now examine the threads inside the filter housing. Remove any debris or residue that may be present using a cleaning brush or solvent. Ensure that the threads are clean and in good condition.

Dismantling the oil filter is an essential step in this process as it allows you to access the interior components for cleaning and preparation. Taking the time to clean and inspect the filter element and the filter housing ensures optimal performance and longevity of your homemade suppressor.

Once you have completed this step, you are ready to move on to preparing the oil filter suppressor adapter in the next step.

When making an oil filter suppressor adapter, ensure that the threads on the adapter match the threads on the oil filter and that it is securely attached to the firearm to prevent any potential safety hazards.

Step 3: Prepare the Oil Filter Suppressor Adapter

With the oil filter dismantled, it’s time to move on to preparing the oil filter suppressor adapter. Follow these steps:

- Take the threaded adapter and ensure that it fits correctly into the end cap of the oil filter. It should have the same threads as the filter housing to create a secure and tight connection.

- If the threaded adapter doesn’t fit perfectly into the end cap, you may need to make some adjustments. You can use a file or sandpaper to carefully remove material from the end cap, creating a larger opening for a proper fit. Take your time and keep checking the fit until it is snug.

- Attach the threaded adapter to the end cap of the oil filter. Apply a thread locker to the threads of the adapter to ensure a secure connection that won’t loosen during use. Follow the manufacturer’s instructions for the specific thread locker you are using.

- Use a wrench to tighten the threaded adapter onto the end cap. Ensure that it is securely fastened, but be careful not to overtighten, as this may damage the threads or strip them.

Once you have prepared the oil filter suppressor adapter, it’s essential to double-check the fit and alignment with the oil filter housing. The adapter should fit snugly into the housing and align perfectly with the threads.

Take a moment to inspect the adapter and ensure that there are no sharp edges or burrs that could interfere with the assembly or pose a safety risk. If necessary, use a file or sandpaper to smooth out any rough edges.

Now that you have successfully prepared the oil filter suppressor adapter, it’s time to move on to the next step: attaching the adapter to the oil filter.

Read more: How To Make An Oil Diffuser

Step 4: Attach the Adapter to the Oil Filter

Now that you have prepared the oil filter suppressor adapter, it’s time to attach it to the oil filter. Follow these steps:

- Take the oil filter housing and ensure that it is clean and free from any debris or residue. Wipe it down with a clean cloth or paper towel to ensure a smooth surface.

- Apply a thin layer of thread locker to the threads on the oil filter housing. This will help secure the adapter in place and prevent it from loosening during use.

- Insert the threaded adapter into the housing, making sure to align it properly with the threads. Use a wrench to tighten the adapter, ensuring a snug and secure fit. Be careful not to overtighten, as this could damage the threads or strip them.

- Inspect the assembly to ensure that the adapter is properly attached to the oil filter housing. Verify that the connection is tight and that there are no visible gaps or misalignments.

It’s essential to ensure that the adapter is securely attached to the oil filter housing to prevent any potential safety hazards or malfunction during firearm usage. Take your time during this step and ensure a proper fit.

Now that you have successfully attached the adapter to the oil filter, it’s time to move on to the final step: testing the suppressor.

Step 5: Test the Suppressor

With the oil filter suppressor adapter securely attached to the oil filter, it’s time to put it to the test. Follow these steps as you test your homemade suppressor:

- Ensure that you are in a safe and legal shooting environment. Follow all local laws and regulations regarding firearm usage and noise reduction devices.

- Attach the assembled oil filter suppressor to the barrel of your firearm, ensuring a proper fit and alignment.

- Load your firearm with appropriate ammunition and take aim at a safe target downrange.

- Fire a few rounds to test the effectiveness of the suppressor. Pay attention to the reduction in noise and recoil compared to shooting without the suppressor.

- Observe and evaluate the performance of your homemade suppressor. Take note of any improvements in noise reduction and recoil management. Keep in mind that the level of suppression may vary depending on factors such as the type of ammunition used and the specific firearm.

During the testing process, it’s important to pay close attention to the performance of your homemade suppressor. Ensure that it functions safely and effectively, providing the desired level of noise reduction without compromising the reliability or accuracy of your firearm.

It’s worth noting that further modifications or adjustments may be necessary to fine-tune the performance of your homemade suppressor. Experiment with different configurations and setups to achieve the desired results, always prioritizing safety and compliance with local laws and regulations.

Remember, the construction and use of homemade suppressors can have legal implications, and it is your responsibility to ensure compliance with all relevant laws and regulations. Always consult local authorities and seek professional advice regarding the legality and proper usage of homemade suppressors in your jurisdiction.

With thorough testing complete, you can now conclude the process of making an oil filter suppressor adapter.

Conclusion

Congratulations! You have successfully completed the process of making an oil filter suppressor adapter. Through resourcefulness and creativity, you’ve created a cost-effective and accessible option for reducing the noise produced by your firearm. However, before proceeding any further, it’s crucial to emphasize the importance of understanding and complying with all applicable laws and regulations regarding the construction and use of suppressors in your area.

Creating a homemade suppressor requires careful consideration of safety, legality, and proper usage. It’s vital to understand that homemade suppressors may not provide the same level of performance and reliability as commercially available ones. Thus, it’s essential to conduct thorough testing and evaluation to ensure your homemade suppressor functions safely and effectively.

Remember, the primary purpose of a suppressor is to reduce the sound and recoil produced by a firearm. While homemade suppressors can offer some degree of noise reduction, they may not match the performance and quality of professional-grade suppressors. It’s essential to manage your expectations and prioritize safety at all times.

As you continue your journey in the world of firearms and firearm accessories, always stay informed and up-to-date on the laws and regulations governing suppressor construction and usage. Consult with local authorities and seek professional guidance regarding the legality and proper use of homemade suppressors in your jurisdiction.

We hope that this article has provided you with valuable insights and guidance on the process of making an oil filter suppressor adapter. Remember to exercise caution, responsibility, and proper firearm safety practices throughout the construction and usage of your homemade suppressor. Enjoy your shooting experiences and have fun exploring the world of DIY firearm accessories!

Frequently Asked Questions about How To Make An Oil Filter Suppressor Adapter

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make An Oil Filter Suppressor Adapter”