Articles

How To Tell If Electric Motor Is Bad

Modified: January 6, 2024

Learn how to determine if your electric motor is bad with these informative articles. Discover common signs and troubleshooting tips to save time and money.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

An electric motor is an essential component in many electrical devices, providing the power needed for various mechanical operations. From household appliances to industrial machinery, electric motors play a crucial role in our everyday lives. However, like any mechanical device, electric motors can experience wear and tear over time, leading to malfunctions or complete failure.

Recognizing the signs of a bad electric motor is crucial for prompt detection and resolution of issues. By being aware of these signs, you can take necessary action to repair or replace the motor, ensuring the smooth functioning of your devices and equipment.

In this article, we will discuss the common signs of a bad electric motor, testing methods to confirm its condition, and troubleshooting steps you can take to address any issues. So, let’s dive in and learn how to tell if an electric motor is bad.

Key Takeaways:

- Recognize signs of a bad electric motor such as unusual noise, excessive heat, or decreased performance. Conduct testing and troubleshoot to ensure safety and efficient operation of your electrical devices.

- Consider repair or replacement options based on the severity of motor issues. Consult professionals for complex repairs and weigh factors such as cost, efficiency, and operational requirements.

Signs of a Bad Electric Motor

There are several telltale signs that indicate a bad electric motor. By being attentive to these signs, you can quickly identify if your motor is experiencing problems. Here are some common signs to watch out for:

- Noisy operation: One of the most noticeable signs of a bad electric motor is unusual noise during operation. If you hear grinding, scraping, or rattling sounds coming from the motor, it may indicate a problem with the internal components.

- Excessive heat: Electric motors tend to generate heat during operation, but if you notice that the motor is getting excessively hot to the touch, it could be a sign of a problem. Overheating can result from various issues, such as a malfunctioning cooling system or excessive friction within the motor.

- Intermittent or no operation: If the electric motor fails to start or stops working intermittently, it may indicate an issue with the motor’s electrical connections, wiring, or internal components. This can occur due to loose connections, damaged wires, or worn-out brushes.

- Decreased performance: A decline in the motor’s performance, such as reduced speed or erratic movements, can indicate a problem. This could be due to worn or damaged bearings, faulty windings, or other internal issues affecting the motor’s efficiency.

- Burning smell: If you detect a burning smell emanating from the motor, it is a clear sign of trouble. It could suggest that the insulation or wiring inside the motor is overheating or burning, requiring immediate attention.

It’s important to note that these signs can vary depending on the type and size of the motor, as well as the specific application it is being used for. If you observe any of these signs, it is advisable to stop using the motor and proceed with testing and troubleshooting methods to determine the exact cause of the problem.

Testing the Electric Motor

Once you have identified potential signs of a bad electric motor, it’s essential to conduct testing to confirm its condition. Here are some methods you can use to test an electric motor:

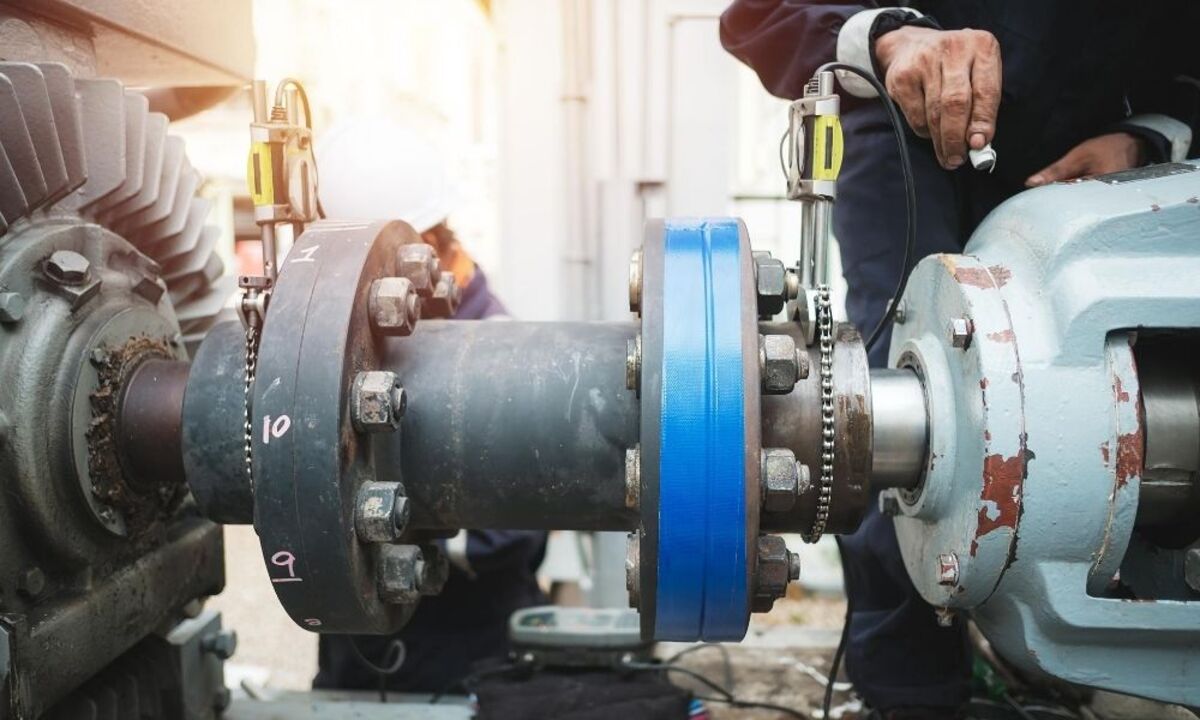

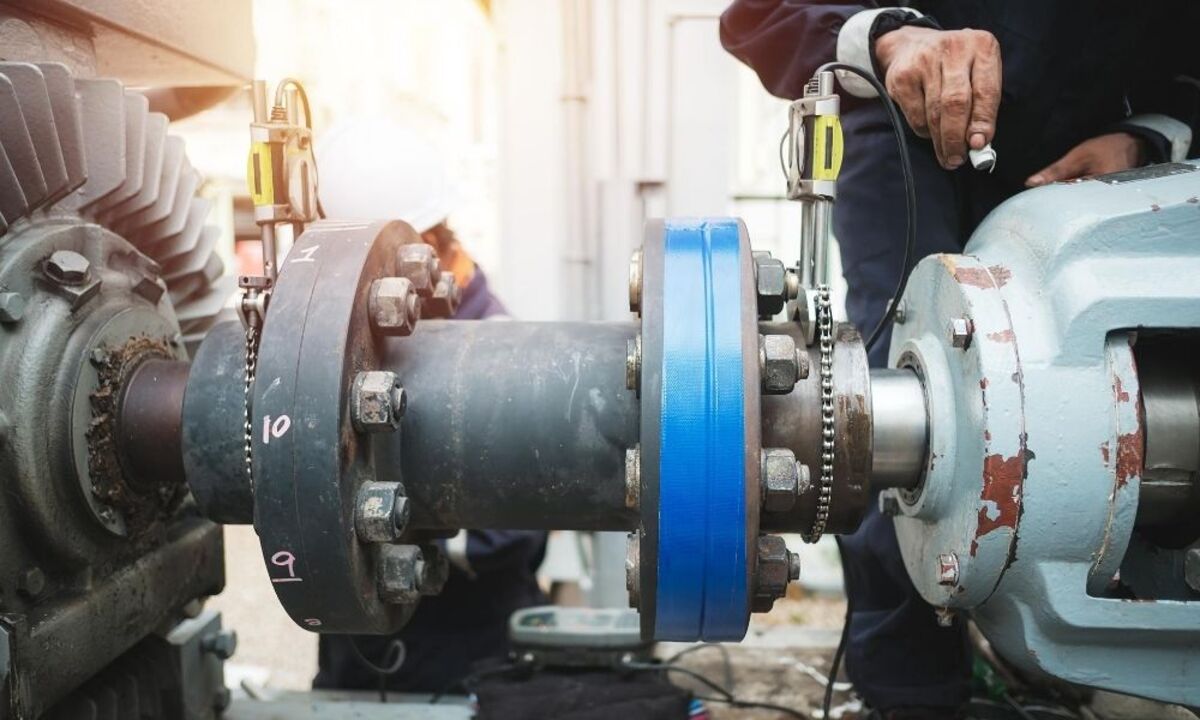

- Visual inspection: Begin by visually inspecting the motor for any visible signs of damage or wear. Look for loose connections, burnt wires, or any physical abnormalities that may indicate a problem.

- Motor resistance test: Using a multimeter, you can measure the resistance of the motor’s windings. This test helps identify any open or shorted circuits within the motor. Refer to the motor’s manufacturer manual or specifications to determine the correct resistance values.

- Motor continuity test: This test is used to check the continuity of the motor’s windings. By using a multimeter in continuity mode, you can determine if the windings are intact or if there are any breaks or interruptions.

- Motor load test: Depending on the application and availability of equipment, you may perform a load test to assess the motor’s performance under operating conditions. This test measures parameters such as current draw, speed, and torque, providing insight into the motor’s efficiency and behavior.

- Professional evaluation: If you are unsure about how to test the motor or suspect a severe problem, it is recommended to seek professional assistance. A qualified electrician or technician can perform a comprehensive evaluation and provide accurate diagnosis and recommendations.

During the testing process, it’s important to adhere to safety precautions and disconnect the motor from the power source to prevent any accidents or electrical shocks. If you are inexperienced or uncomfortable with electrical testing procedures, it’s best to seek professional help to avoid any further damage or injuries.

Once you have completed the testing and have a better understanding of the motor’s condition, you can move on to troubleshooting steps to address any issues that may have been identified.

If an electric motor is making unusual noises, running hot, or not starting at all, it may be a sign that the motor is bad and needs to be inspected or replaced.

Troubleshooting Steps

After conducting the necessary testing to determine the condition of your electric motor, it’s time to troubleshoot any issues that may have been identified. Here are some common troubleshooting steps you can take:

- Check the power supply: Ensure that the motor is receiving the proper voltage and that there are no issues with the power supply. Verify the circuit breaker, fuses, and wiring to eliminate any potential electrical problems.

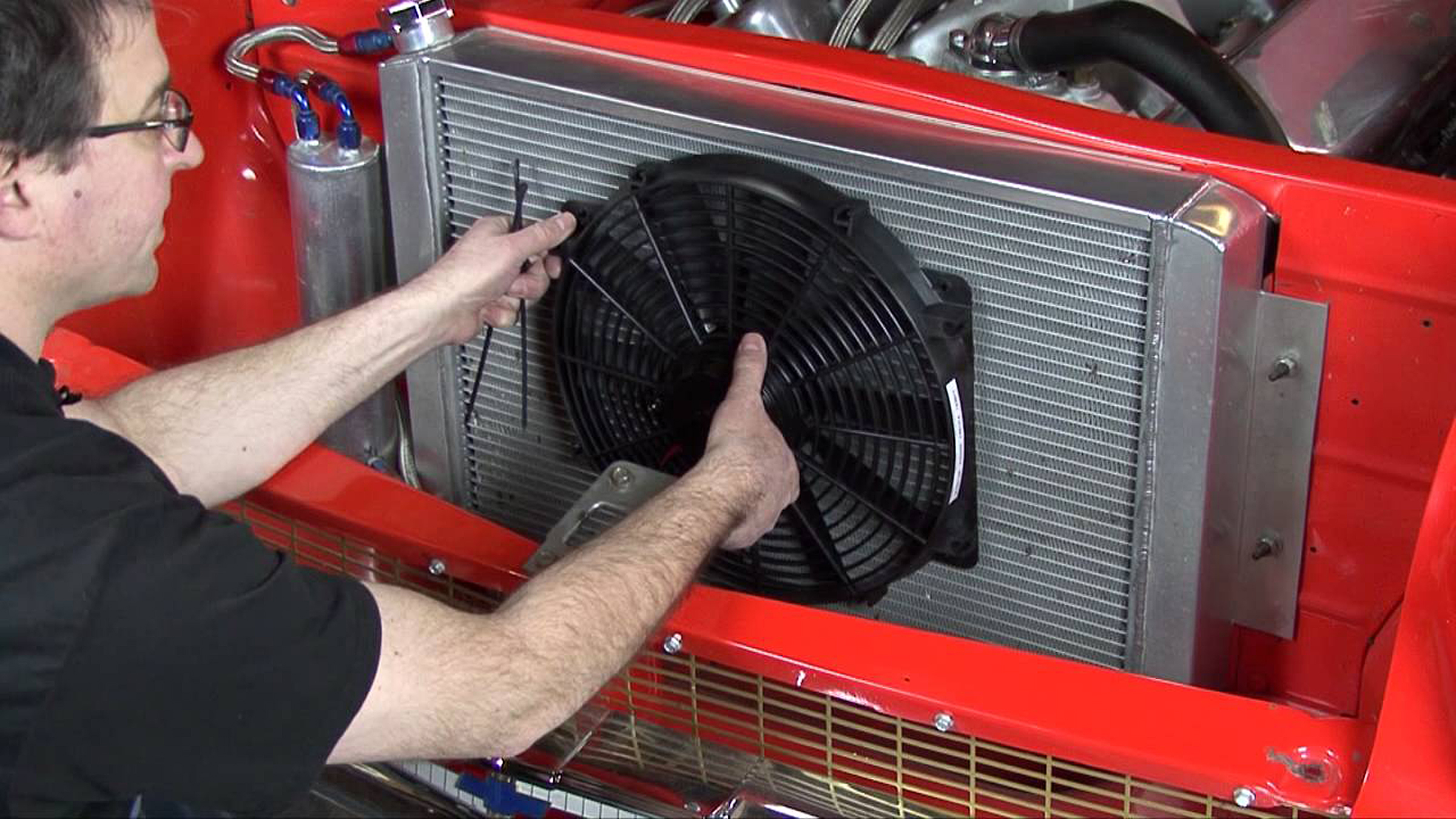

- Inspect and clean the motor: Remove any dirt, debris, or obstructions from the motor’s external components. Check for loose connections and tighten them as needed. Clean the cooling system, such as fans or vents, to prevent overheating.

- Replace faulty components: If specific components within the motor, such as worn-out brushes or damaged bearings, are identified as the problem, replace them accordingly. Be sure to use compatible replacement parts recommended by the motor manufacturer.

- Repair or rewind the windings: If the motor’s windings are found to be damaged, you may need to repair or rewind them. This process requires expertise and specialized equipment, so it is typically best left to professional motor repair services.

- Consider motor replacement: In some cases, it may be more cost-effective or practical to replace the entire motor rather than repairing it, especially if the motor is old, heavily worn, or if major internal components are damaged.

It’s important to follow the specific troubleshooting steps recommended by the motor manufacturer or seek guidance from a professional to ensure proper handling and resolution of the issues.

Remember that safety should be your top priority when troubleshooting or working with electrical components. Always disconnect the motor from the power source before performing any repairs or maintenance.

Repair or Replacement Options

When dealing with a bad electric motor, you have the option to either repair or replace it based on the severity of the issues and cost-effectiveness. Here are some considerations for repair and replacement:

- Repair: If the issues with the motor are minor or localized, repair can be a viable option. This involves fixing or replacing specific components, such as brushes, bearings, or windings, to restore the motor’s functionality. Repairing can be a cost-effective solution, particularly for motors with high-quality construction and expensive replacement costs.

- Professional repair services: If the motor requires complex repairs or rewinding of the windings, it is recommended to seek professional motor repair services. Specialized technicians have the expertise and equipment to diagnose and fix motor problems effectively. They can ensure the proper handling of delicate components and perform comprehensive testing before returning the motor to service.

- Replacement: In some cases, it may be more practical or cost-effective to replace the electric motor, especially if the motor is older, extensively worn, or has major internal damage. Additionally, if repairs are not feasible due to unavailability of replacement parts or high repair costs, replacement becomes the preferred choice.

- Consider efficiency and requirements: When deciding between repair and replacement, consider the energy efficiency of the motor. Older motors, especially those without energy-efficient ratings, may benefit from being replaced with newer, more efficient models. Additionally, reassess your operational requirements to ensure that the replacement motor meets your specific needs.

- Consultation with experts: If you are unsure about the best course of action, consult with motor manufacturers, electricians, or professionals in the industry. They can provide valuable insights and recommendations based on their experience and expertise.

Ultimately, the decision to repair or replace the electric motor depends on various factors such as the extent of damage, availability of replacement parts, cost considerations, and the motor’s age and efficiency. It’s essential to weigh these factors and make an informed decision that suits your specific circumstances.

Read more: How To Tell If Insulation Is Bad

Conclusion

Recognizing and addressing a bad electric motor is essential to ensure the proper functioning of electrical devices and equipment. By familiarizing yourself with the signs of a bad motor, conducting necessary testing, and following troubleshooting steps, you can efficiently diagnose and resolve any issues.

Remember, if you notice signs such as unusual noise, excessive heat, intermittent operation, decreased performance, or a burning smell, it may indicate a problem with the motor. Testing methods such as visual inspections, resistance and continuity tests, and load tests can help confirm the motor’s condition.

When troubleshooting, it’s important to check the power supply, inspect and clean the motor, replace faulty components, repair or rewind the windings if necessary, and consider the options for repair or replacement. Seeking professional assistance, especially for complex repairs or rewinding, can ensure the best outcomes.

Ultimately, the decision to repair or replace the motor depends on factors such as the extent of damage, cost-effectiveness, energy efficiency, and operational requirements. Consulting with experts in the field can provide valuable guidance in making an informed decision.

By being proactive in maintaining and addressing issues with electric motors, you can extend their lifespan, optimize performance, and avoid costly breakdowns or replacements. Regular inspections, preventive maintenance, and prompt attention to any signs of trouble can help keep your electric motors running smoothly.

Remember, safety should always be a priority when working with electrical devices. If you are unsure about any testing or repair procedures, it’s best to seek professional assistance to ensure your own safety and the proper handling of the equipment.

By following these guidelines, you can effectively determine if your electric motor is bad and take the necessary steps for repair or replacement, allowing you to continue enjoying the benefits of your electrical appliances and equipment.

Frequently Asked Questions about How To Tell If Electric Motor Is Bad

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Tell If Electric Motor Is Bad”