Articles

How To Reverse An Electric Motor Rotation

Modified: December 7, 2023

Learn how to reverse the rotation of an electric motor in a few simple steps. Read our informative articles to gain valuable insights and knowledge.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

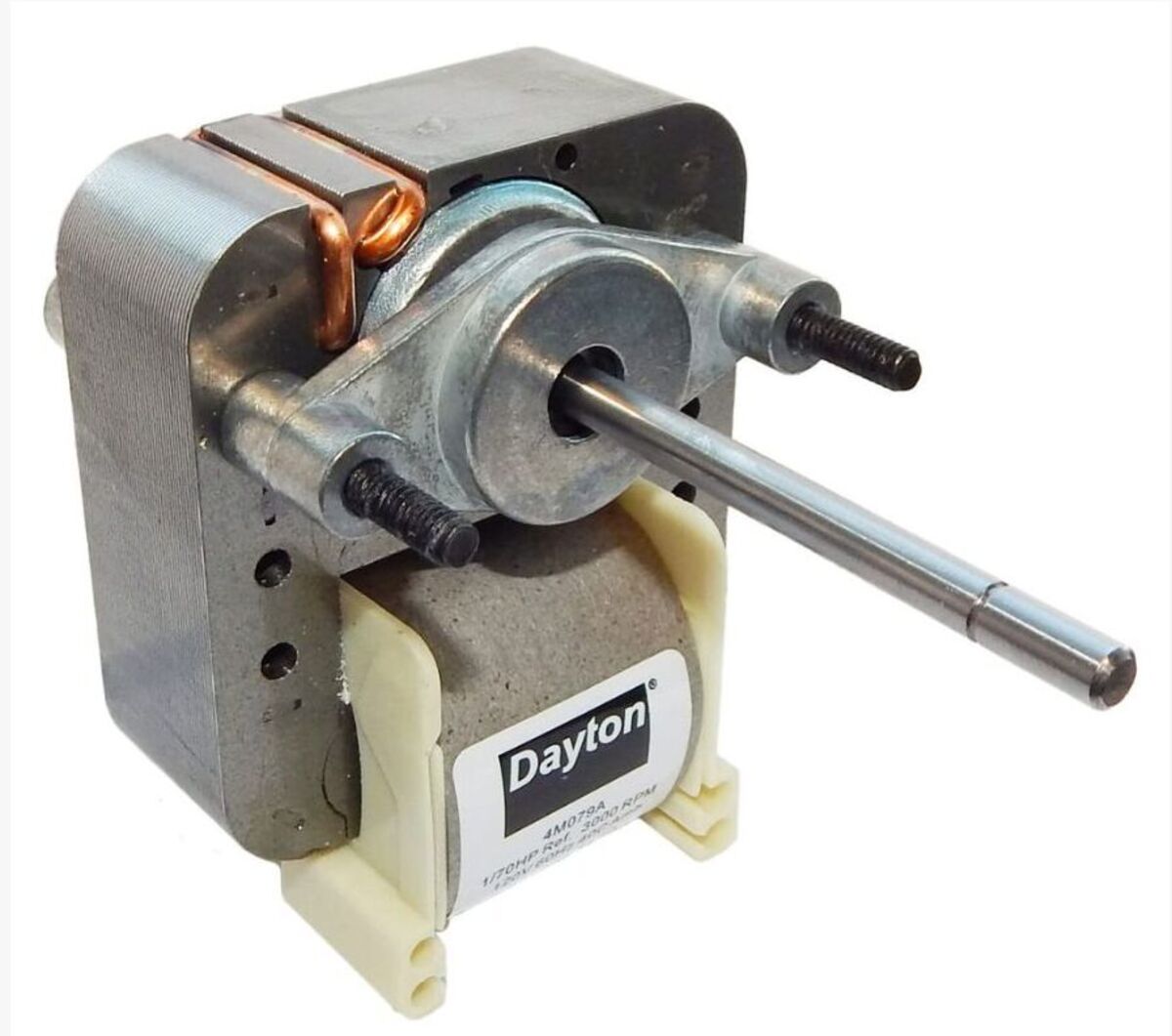

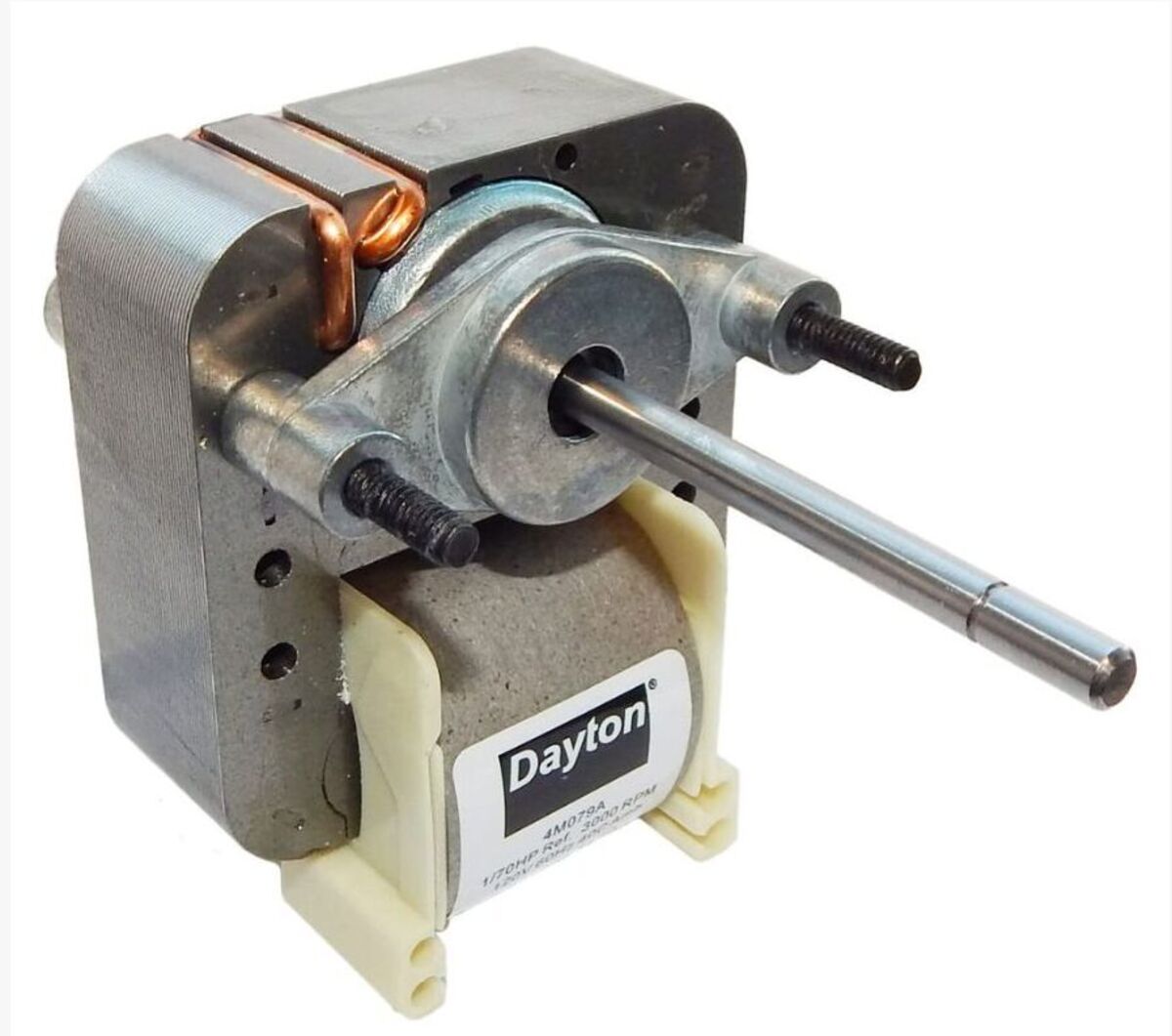

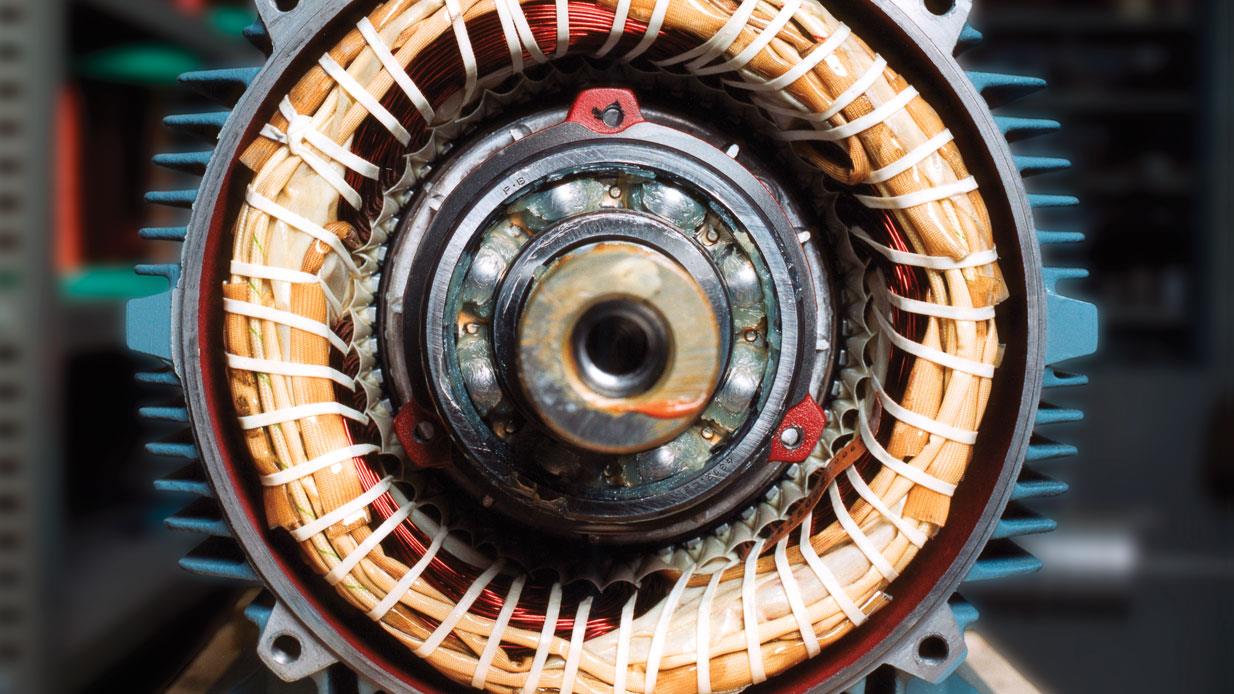

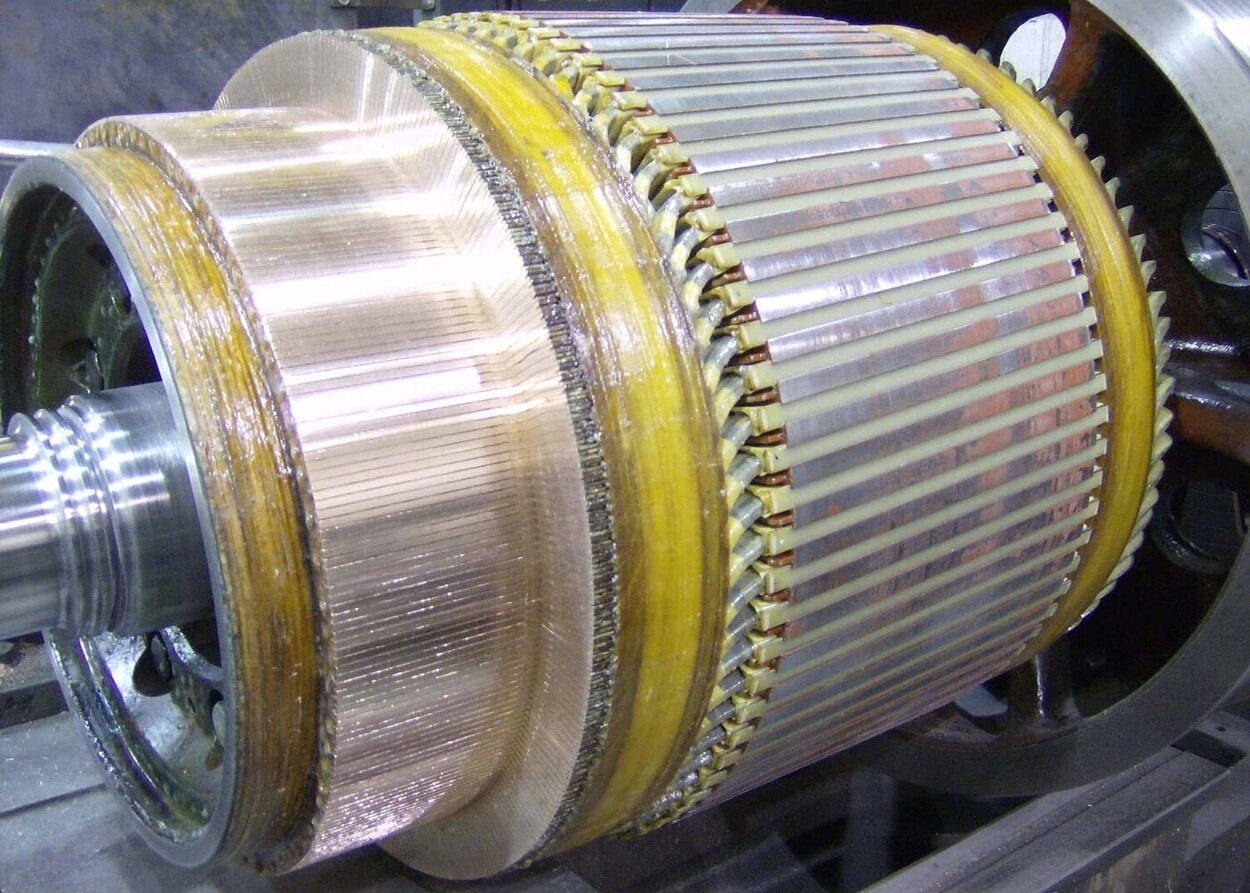

Electric motors play a crucial role in various applications, from industrial machinery to household appliances. However, there may be instances where you need to reverse the rotation of an electric motor. Whether it is due to a wiring mistake, a need to change the direction of a mechanical system, or any other reason, understanding how to reverse an electric motor rotation is valuable knowledge.

In this article, we will explore the common reasons for needing to reverse electric motor rotation, discuss the different methods available, and guide you through the steps to accomplish this task.

Reversing the rotation of an electric motor can have a significant impact on the performance and functionality of the system it powers. By understanding how to reverse the rotation, you can troubleshoot issues, optimize operations, and ensure the smooth operation of your equipment.

So, let’s dive in and explore the world of reversing electric motor rotation!

Key Takeaways:

- Reversing the rotation of an electric motor is crucial for troubleshooting, optimizing functionality, and ensuring compatibility with various systems. Understanding the five methods available provides valuable tools for accomplishing this task.

- Whether it’s swapping electrical leads, reversing power supply polarity, using a reversing switch, modifying wiring, or utilizing a motor reversing module, each method offers unique advantages and suitability based on the specific motor and its configuration. By carefully following the steps outlined for each method and considering the motor’s documentation, you can confidently reverse the rotation of your electric motor.

Read more: How To Wire A Reversible Electric Motor

Common Reasons for Needing to Reverse Electric Motor Rotation

There can be various reasons why you might need to reverse the rotation of an electric motor. Let’s take a look at some of the most common scenarios:

- Mechanical System Reversal: In some applications, such as conveyor belts, fans, or pumps, changing the direction of rotation may be necessary to accommodate changes in the workflow or to optimize the functionality of the system. Reversing the motor rotation allows for seamless operation without the need for complex mechanical modifications.

- Miswiring or Incorrect Initial Setup: Sometimes, during installation or maintenance, the electrical leads of the motor may have been accidentally swapped, resulting in the incorrect rotation direction. In such cases, reversing the rotation becomes essential to ensure proper operation and prevent potential damage to the equipment.

- Troubleshooting and Testing: Reversing the rotation can be a crucial diagnostic step when troubleshooting motor-related issues. By temporarily changing the rotation direction, you can identify problems such as faulty bearings, improper alignment, or mechanical obstructions that may be affecting the motor’s performance.

- Compatibility with Existing Systems: When integrating new equipment into an existing setup, it’s important to ensure compatibility. Reversing the motor rotation allows you to align the new equipment with the existing system, minimizing the need for extensive rewiring or modifications.

- Operational Requirements: Some applications, such as winches or cranes, require the ability to change the direction of rotation on-demand to perform specific tasks effectively. By being able to reverse the motor rotation, operators can enhance operational flexibility and improve overall productivity.

Whatever the reason may be, understanding how to reverse the rotation of an electric motor is a valuable skill for anyone working with electrical systems. Fortunately, there are several methods available to accomplish this task. In the next section, we will explore these methods in more detail.

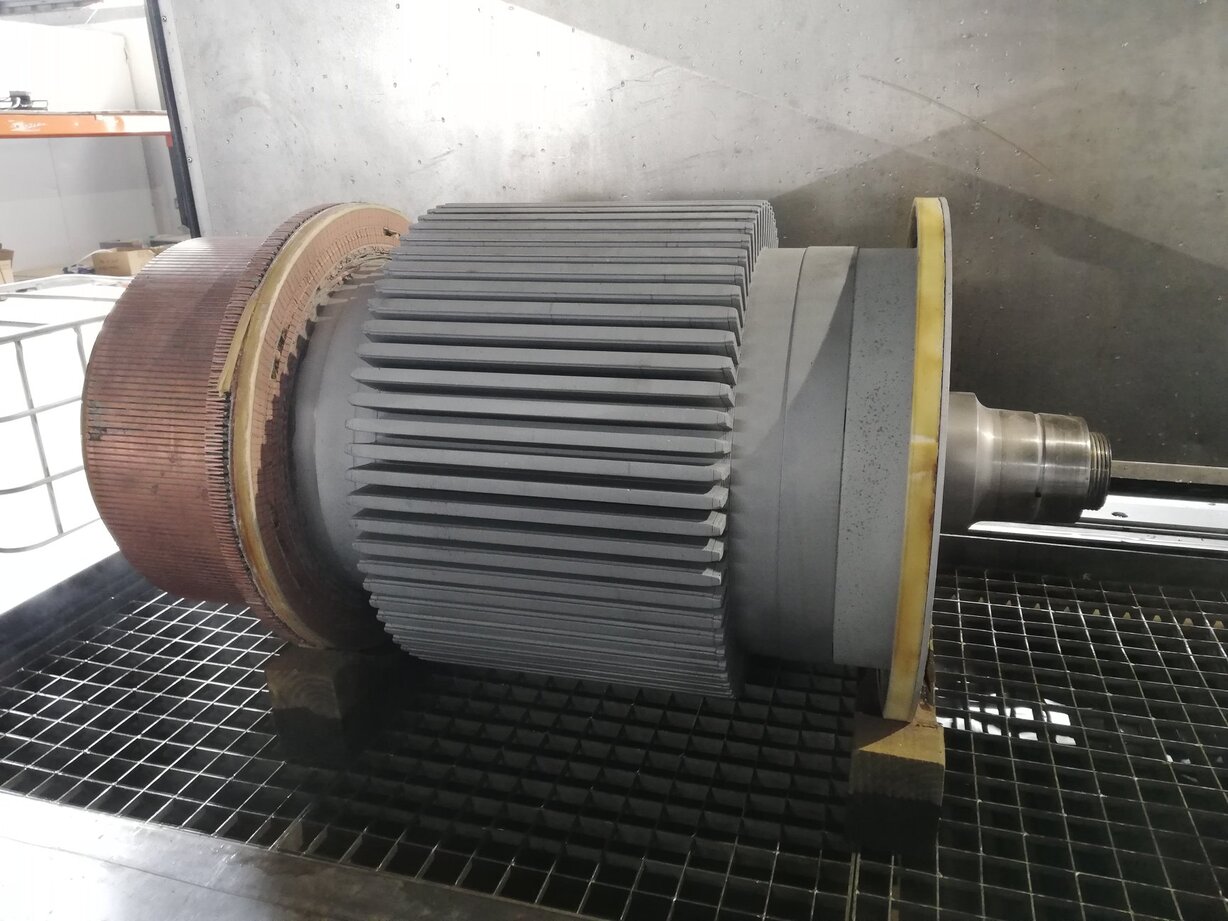

Understanding Motor Rotation Direction

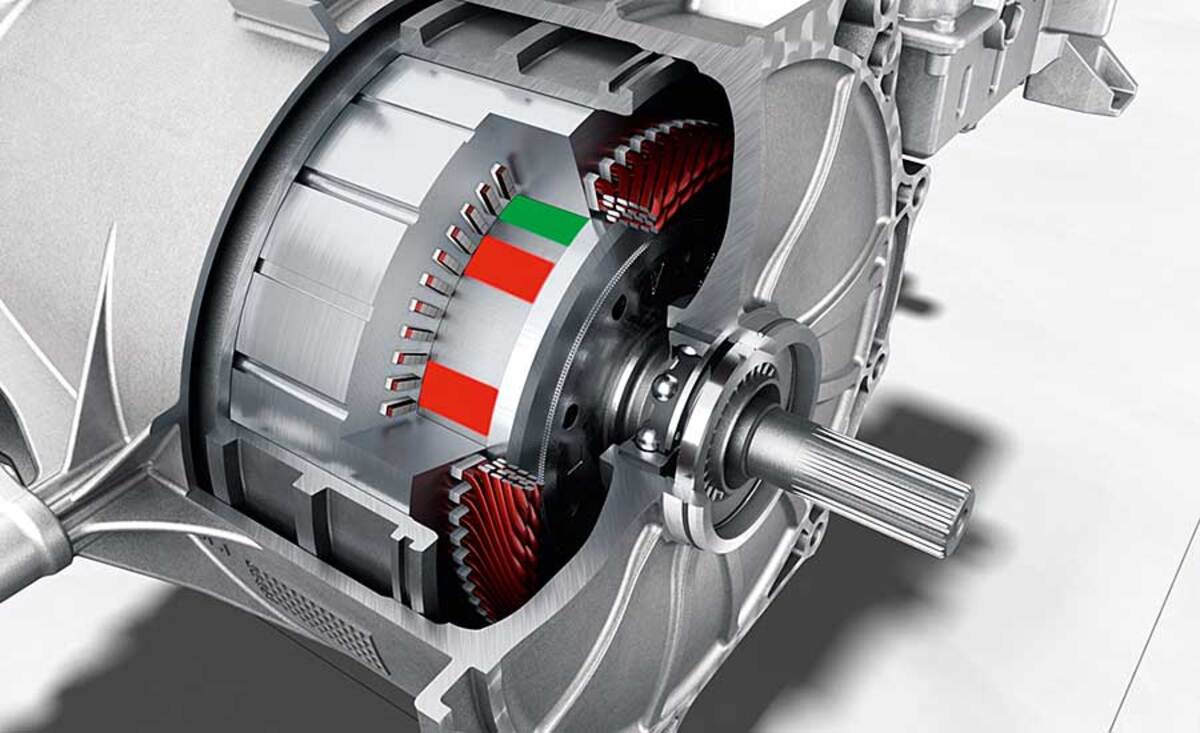

Before we dive into the methods of reversing electric motor rotation, it’s essential to understand how motor rotation direction is determined. Electric motors have a predetermined rotation direction, which is typically indicated by an arrow or label on the motor casing. The two primary rotation directions are clockwise (CW) and counterclockwise (CCW).

The direction of rotation is defined from the perspective of the motor’s shaft. When looking at the motor shaft from the front or the output side, a clockwise rotation means that the shaft will spin in a clockwise direction, while a counterclockwise rotation means the shaft will spin in the opposite direction.

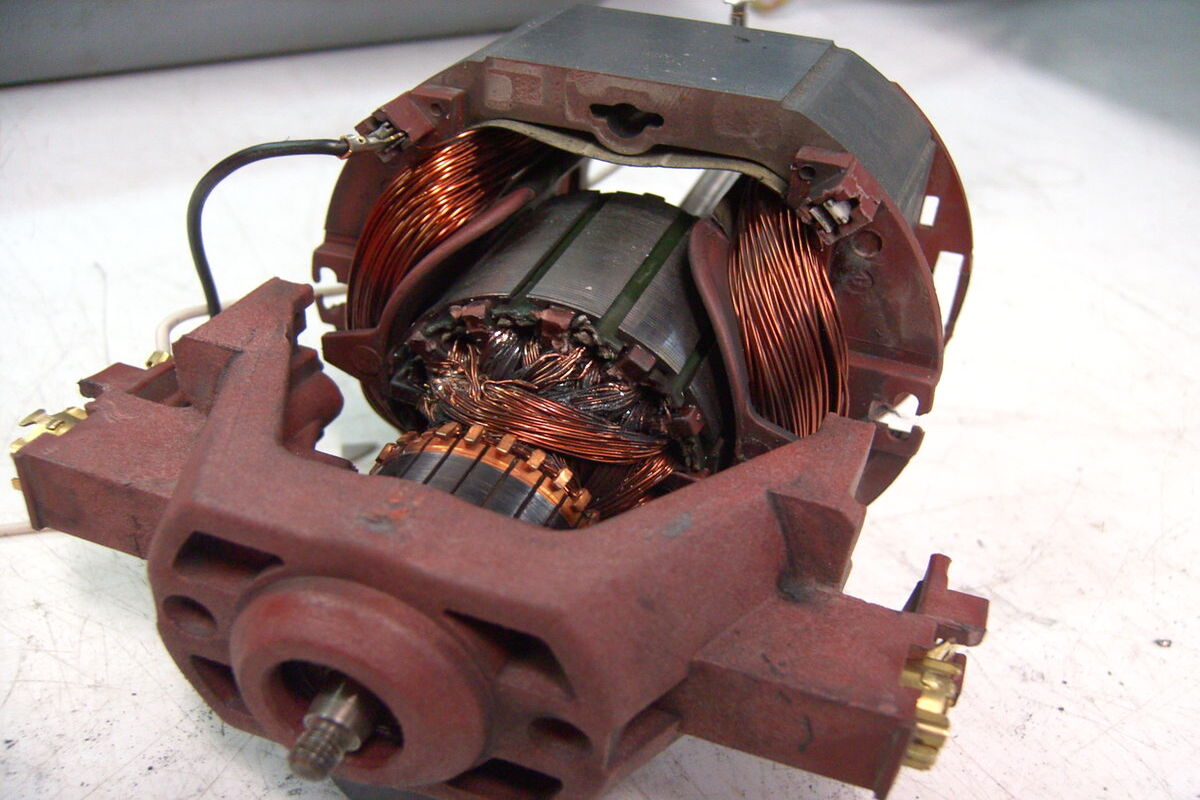

It’s important to note that the direction of rotation is not arbitrary; it is determined by the motor’s internal design and wiring configuration. Reversing the rotation of an electric motor involves altering this configuration to change the flow of electric current through the winding coils and thus the resulting magnetic field orientation.

When attempting to reverse the rotation, it’s crucial to have a clear understanding of the motor’s original rotation direction. This information can typically be found in the motor’s documentation or by referring to the manufacturer’s specifications.

Alternatively, you can visually inspect the motor for any directional indicators. If no indicators are present, you may need to rely on other cues, such as the motor’s cooling fan direction or the rotation of the machine it is connected to (if applicable), to determine the original rotation direction.

Once you have determined the motor’s original rotation direction, you can proceed with selecting the most suitable method for reversing the rotation. In the following section, we will explore several methods that can be used to reverse the rotation of an electric motor.

Methods for Reversing Electric Motor Rotation

Reversing the rotation of an electric motor can be accomplished through various methods. The most appropriate method depends on the specific motor and its wiring configuration. Here are five common methods that you can use to reverse electric motor rotation:

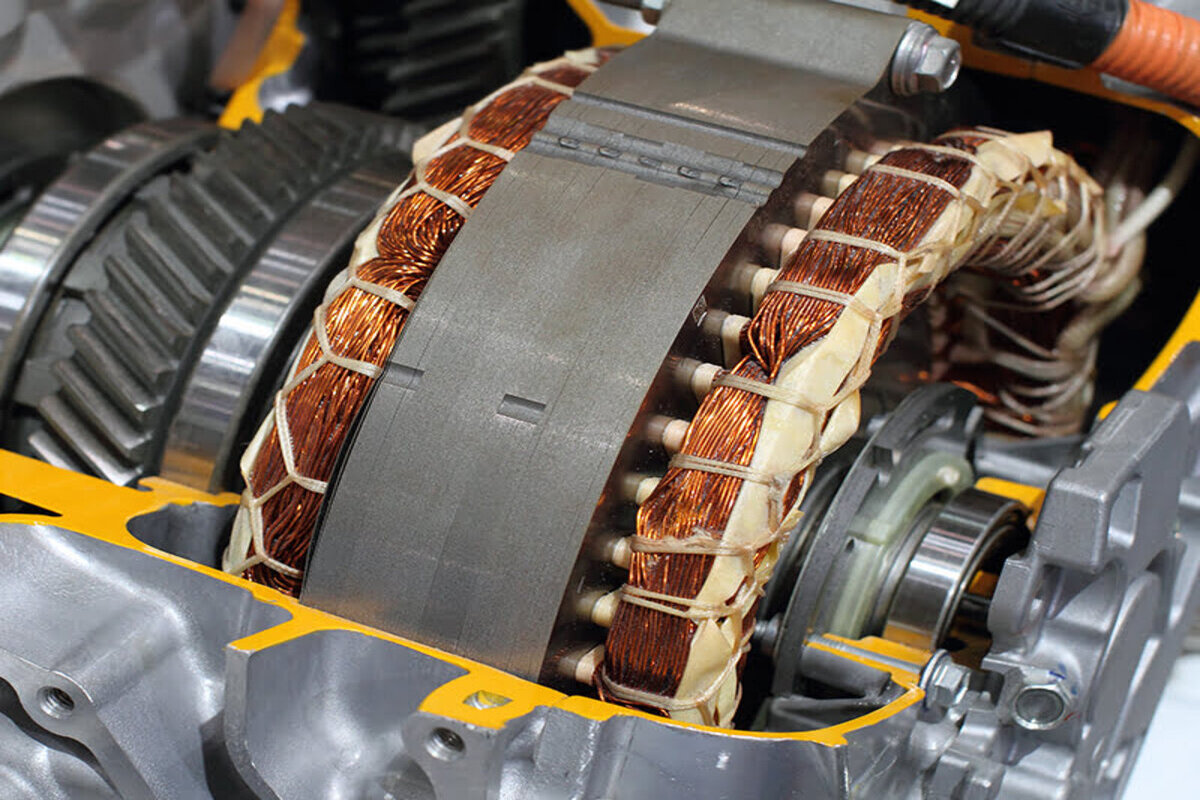

- Method 1: Swapping the Electrical Leads: This method involves interchanging the connections of any two motor leads. By swapping the electrical leads, you effectively reverse the flow of current through the motor windings, resulting in a change in the magnetic field orientation and rotation direction. Keep in mind that this method applies to motors with a single set of winding coils.

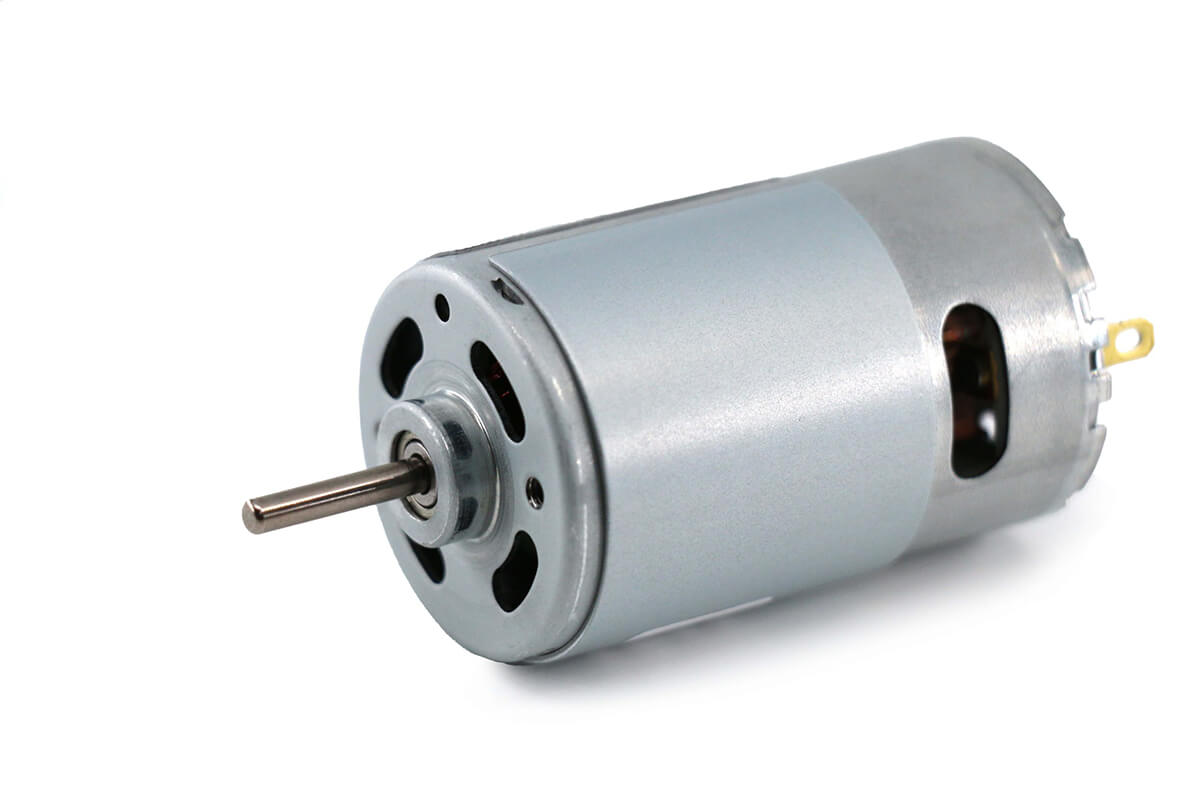

- Method 2: Reversing the Polarity of the Power Supply: In this method, the polarity of the power supply is reversed by swapping the positive and negative leads. By doing so, the direction of current flow through the motor windings is reversed, leading to a change in the rotation direction. This method is applicable to motors with a permanent magnet component.

- Method 3: Using a Reversing Switch or Controller: Some motors come with built-in reversing switches or controllers. These devices allow for quick and convenient reversal of the motor rotation. By activating the reversing switch or controller, the electrical circuit is altered, changing the current flow through the motor windings and reversing the rotation direction.

- Method 4: Modifying the Motor Wiring Configuration: For more complex motor configurations, such as those with multi-speed or multi-voltage capabilities, modifying the motor wiring configuration may be necessary. This method involves reconfiguring the wiring connections, typically through the use of a wiring diagram provided by the manufacturer, to achieve the desired rotation direction.

- Method 5: Using a Motor Reversing Module: Motor reversing modules are external devices that facilitate the reversing of motor rotation. These modules are designed to handle the electrical complexities involved in reversing the motor direction and provide a convenient solution for motors that do not have built-in reversing capabilities. They typically operate by switching the motor leads electronically to achieve the desired rotation direction.

It’s important to note that not all methods are applicable to every motor type or configuration. Therefore, it’s essential to consult the motor’s documentation or seek professional advice to determine the most suitable method for your specific motor.

Now that we have discussed the various methods available, we can dive deeper into each method in the following sections, providing step-by-step instructions on how to execute them successfully.

Method 1: Swapping the Electrical Leads

One of the simplest methods to reverse the rotation of an electric motor is by swapping the electrical leads. This method is applicable to motors with a single set of winding coils and does not require any additional components or modifications.

Here are the steps to reverse the rotation using this method:

- Disconnect the Power: Before making any changes to the motor’s electrical connections, always ensure that the power supply to the motor is turned off and properly disconnected to avoid any electrical accidents.

- Identify the Motor Leads: On the motor, locate the electrical leads. These leads are typically color-coded or labeled for easy identification. Note the original connections or take a picture for reference.

- Swap the Leads: Carefully disconnect any two motor leads and swap their positions. For example, if the original connection is A-B-C, disconnect and reconnect it as B-A-C. This simple swap reverses the flow of current through the motor windings, resulting in a change in the rotation direction. Ensure that the connections are secure and properly tightened.

- Test the Motor: Once the leads are swapped, it’s time to test the motor to ensure the rotation direction has been reversed successfully. Connect the power supply and turn it on. Observe the motor’s rotation and verify that it rotates in the desired direction. If the rotation is still incorrect, double-check the leads’ connections and make any necessary adjustments.

- Secure the Connections: Once you have verified that the motor is rotating in the correct direction, secure the electrical connections using appropriate terminal screws or connectors. Ensure that all connections are tight and properly insulated to prevent any electrical issues.

It’s important to note that this method only applies to motors with a single set of winding coils. If your motor has multiple winding configurations or you are unsure about the wiring setup, it is recommended to consult the motor’s documentation or seek professional assistance.

Now that you understand how to reverse the rotation using the basic method of swapping electrical leads, you can move on to explore additional methods for reversing electric motor rotation.

To reverse the rotation of an electric motor, simply swap the connections of the two power leads. This will change the direction of the magnetic field and reverse the motor’s rotation.

Method 2: Reversing the Polarity of the Power Supply

Another method to reverse the rotation of an electric motor is by reversing the polarity of the power supply. This method is applicable to motors with a permanent magnet component and involves swapping the positive and negative leads of the power source.

Here are the steps to reverse the rotation using this method:

- Disconnect the Power: Before making any changes to the motor or power supply, ensure that the power source is turned off and properly disconnected to prevent any electrical accidents.

- Identify the Power Leads: Identify the positive (+) and negative (-) leads of the power supply or power source. Note their positions or take a picture for reference.

- Swap the Power Leads: Carefully disconnect the positive (+) and negative (-) leads of the power source. Swap their positions, connecting the positive (+) lead to the terminal that was previously connected to the negative (-) lead, and vice versa.

- Connect the Motor: Reconnect the power supply leads to the motor, ensuring that the positive (+) lead is connected to the motor’s positive terminal and the negative (-) lead is connected to the motor’s negative terminal.

- Test the Motor: Once the power leads are swapped and the connections are secure, turn on the power supply and observe the motor’s rotation. It should now rotate in the opposite direction from its original rotation. If the rotation is still incorrect, double-check the power connections and make any necessary adjustments.

- Secure the Connections: After verifying that the motor is rotating in the desired direction, secure all electrical connections, ensuring that they are tight and properly insulated.

It’s important to note that this method is only applicable to motors with a permanent magnet component. If your motor does not have a permanent magnet or you are unsure about its configuration, it is recommended to consult the motor’s documentation or seek professional advice.

Now that you understand how to reverse the rotation using the method of reversing the polarity of the power supply, you can explore other methods for reversing electric motor rotation and choose the most suitable one for your specific motor.

Method 3: Using a Reversing Switch or Controller

Using a reversing switch or controller is another convenient method for reversing the rotation of an electric motor. This method is applicable to motors that come equipped with built-in reversing capabilities or those that can be retrofitted with a reversing switch or controller.

Here are the steps to reverse the rotation using this method:

- Disconnect the Power: Before making any changes to the motor or the reversing switch/controller, ensure that the power supply is turned off and properly disconnected to avoid any electrical accidents.

- Identify the Reversing Switch/Controller: Locate the reversing switch or controller on the motor. This may be a physical switch, a dial, or a digital control panel, depending on the motor’s design.

- Activate the Reversing Switch/Controller: Follow the instructions provided in the motor’s documentation to activate the reversing switch or controller. This typically involves flipping a switch, turning a dial, or selecting the appropriate option on a control panel.

- Test the Motor: Once the reversing switch or controller is activated, turn on the power supply and observe the motor’s rotation. It should now rotate in the opposite direction from its original rotation. If the rotation is still incorrect, double-check the switch/controller settings and make any necessary adjustments.

- Secure the Connections: After verifying that the motor is rotating in the desired direction, ensure that all electrical connections are secure, tight, and properly insulated to prevent any electrical issues.

Using a reversing switch or controller offers a convenient way to reverse the rotation of a motor without the need for complex wiring modifications or additional components. However, not all motors come with built-in reversing capabilities. If your motor does not have a reversing switch or controller, you may need to explore other methods or consider using an external reversing module.

Now that you understand how to reverse the rotation using a reversing switch or controller, you can explore additional methods for reversing electric motor rotation, allowing you to choose the most suitable one for your specific motor.

Method 4: Modifying the Motor Wiring Configuration

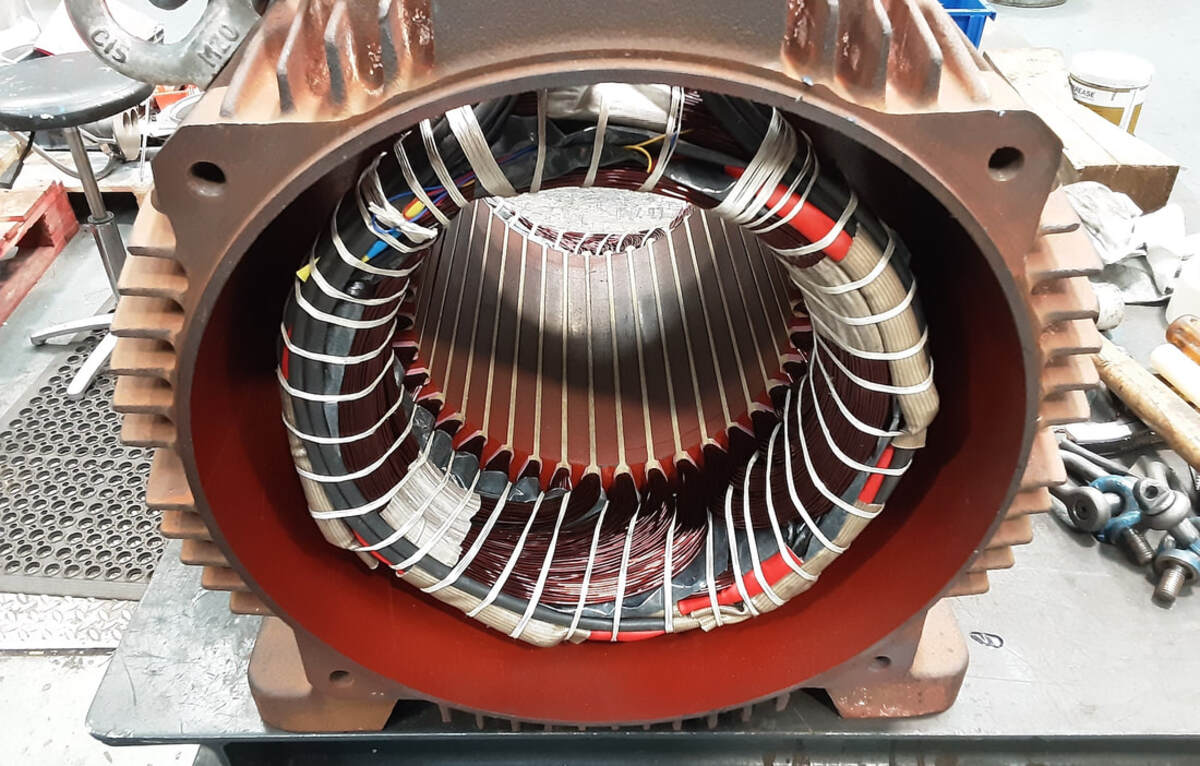

In certain cases, where motors have complex configurations, such as multiple speeds or voltages, modifying the motor’s wiring configuration might be necessary to reverse its rotation. This method involves reconfiguring the wiring connections, typically using a wiring diagram provided by the manufacturer.

Here are the steps to reverse the rotation using this method:

- Disconnect the Power: Before making any changes to the motor’s wiring, ensure that the power supply is turned off and properly disconnected to prevent any electrical accidents.

- Consult the Wiring Diagram: Refer to the motor’s documentation or wiring diagram provided by the manufacturer. It should outline the specific wiring connections required to achieve the desired rotation direction.

- Identify and Modify the Wiring Connections: Identify the necessary wiring connections that need to be modified to reverse the rotation. You may need to disconnect specific wires or rearrange their positions according to the wiring diagram’s instructions.

- Reconnect the Wires: Once you have made the necessary modifications to the wiring connections, carefully reconnect the wires based on the new configuration outlined in the wiring diagram. Make sure that all connections are secure and properly tightened.

- Test the Motor: With the wiring connections modified and secured, turn on the power supply and observe the motor’s rotation. It should now rotate in the opposite direction from its original rotation. If the rotation is still incorrect, double-check the wiring connections against the provided diagram and make any necessary adjustments.

- Secure the Connections: After verifying that the motor is rotating in the desired direction, secure all electrical connections, ensuring that they are tight and properly insulated to prevent any electrical issues.

Modifying the motor’s wiring configuration requires careful adherence to the provided wiring diagram. If you are not confident in your ability to execute this method correctly, it is advisable to seek professional assistance or guidance.

Now that you understand how to reverse the rotation by modifying the motor’s wiring configuration, you can explore additional methods for reversing electric motor rotation to find the most suitable one for your specific motor.

Method 5: Using a Motor Reversing Module

In situations where motors do not have built-in reversing capabilities, or if you prefer a more convenient solution, using a motor reversing module is an effective method to reverse the rotation of an electric motor. These modules are external devices designed specifically to handle the complexities involved in reversing motor rotation.

Here are the steps to reverse the rotation using a motor reversing module:

- Disconnect the Power: Before making any changes to the motor or the motor reversing module, ensure that the power supply is turned off and properly disconnected to prevent any electrical accidents.

- Select a Motor Reversing Module: Choose a motor reversing module that is compatible with your motor’s specifications. Consider factors such as voltage, current capacity, and the appropriate type of module for your motor type.

- Follow the Module Instructions: Read and follow the instructions provided by the manufacturer of the motor reversing module. Each module may have specific wiring instructions or setup procedures, so it is essential to carefully adhere to the guidelines outlined in the module’s documentation.

- Connect the Motor and Power Supply to the Module: Make the necessary wiring connections between the motor, power supply, and the motor reversing module. These connections will depend on the specific module’s design and instructions.

- Activate the Reversing Function: Once the motor and power supply are properly connected, activate the reversing function on the motor reversing module. This can typically be done through a switch, button, or controller provided by the module.

- Test the Motor: Turn on the power supply and observe the motor’s rotation. The motor should now rotate in the opposite direction from its original rotation. If the rotation is still incorrect, double-check the module’s settings and the wiring connections to ensure they are correct.

- Secure the Connections: After verifying that the motor is rotating in the desired direction, secure all electrical connections, ensuring that they are tight and properly insulated to prevent any electrical issues.

Utilizing a motor reversing module provides a convenient and reliable way to reverse the rotation of an electric motor. It eliminates the need for complex wiring modifications and simplifies the process of reversing motor rotation.

It’s important to note that motor reversing modules are available in various configurations, so it is crucial to select a module suitable for your motor’s specifications and follow the manufacturer’s instructions for optimal performance.

Now that you understand how to reverse the rotation using a motor reversing module, you can explore the different methods for reversing electric motor rotation and choose the most suitable one for your specific motor.

Conclusion

Reversing the rotation of an electric motor is a valuable skill to have, as it allows you to troubleshoot issues, optimize functionality, and ensure compatibility with your systems. Whether you need to reverse the motor rotation due to a wiring mistake, a need for mechanical system reversal, or operational requirements, understanding the various methods available provides you with the tools to accomplish this task.

In this article, we explored the common reasons for needing to reverse electric motor rotation and learned about five methods to achieve this reverse rotation. These methods include swapping the electrical leads, reversing the polarity of the power supply, using a reversing switch or controller, modifying the motor wiring configuration, and utilizing a motor reversing module.

Each method has its advantages and suitability based on the specific motor and its configuration. By carefully following the steps outlined for each method and considering the motor’s documentation, you can confidently reverse the rotation of your electric motor.

Remember to take necessary precautions by disconnecting the power supply before making any changes to the motor or its wiring. Additionally, it is always recommended to consult the motor’s documentation or seek professional assistance if you are unsure about the wiring or the appropriate method for your motor.

By understanding how to reverse electric motor rotation, you can troubleshoot issues, adapt to changing requirements, and ensure optimal performance in a wide range of applications. With the knowledge gained from this article, you are well-equipped to tackle challenges related to motor rotation direction and unlock the full potential of your electric motor.

Frequently Asked Questions about How To Reverse An Electric Motor Rotation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Reverse An Electric Motor Rotation”