Articles

How To Scrap A Electric Motor

Modified: December 7, 2023

Learn the step-by-step process of scrapping an electric motor with our comprehensive articles. Gain valuable insights and tips to maximize your earnings.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

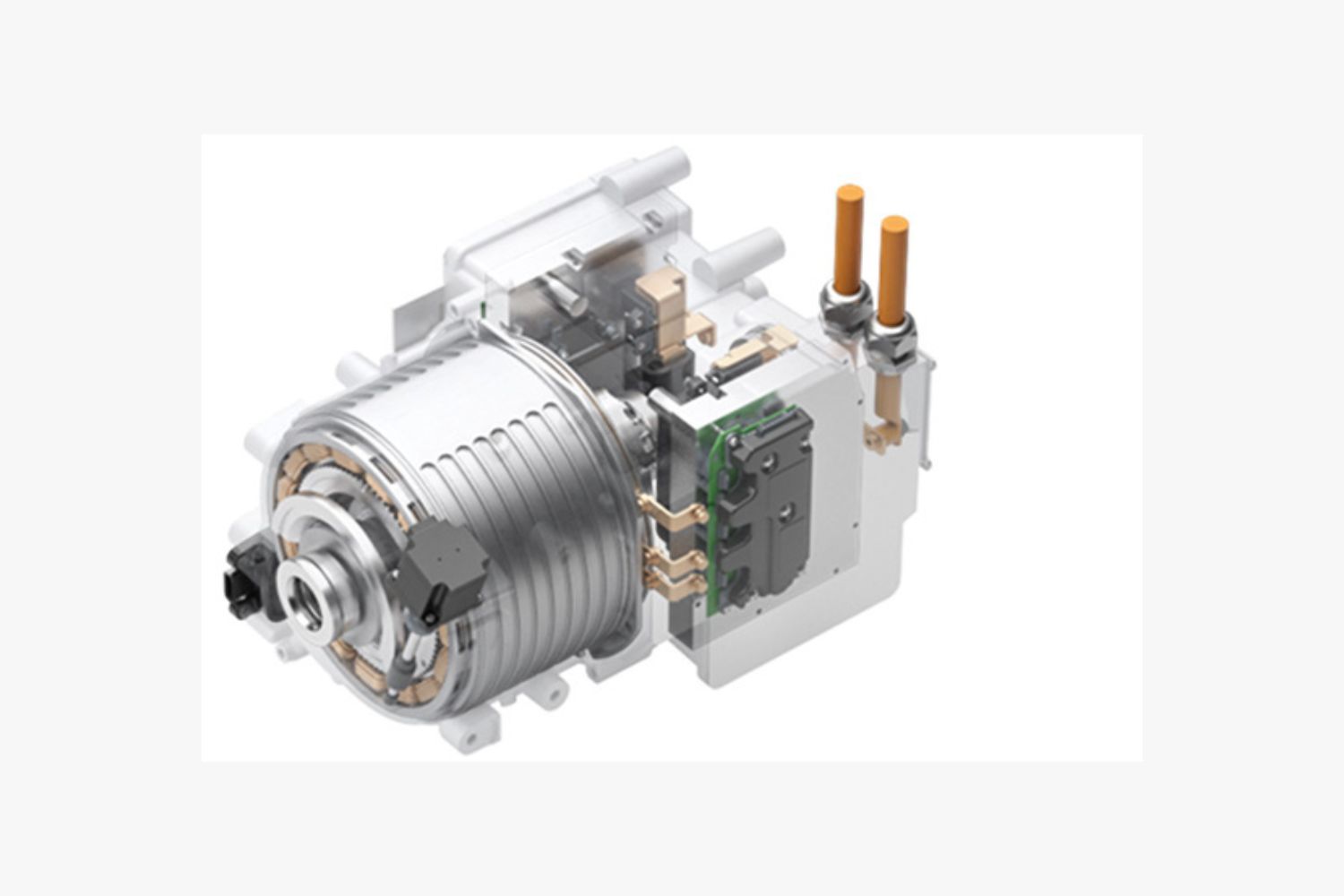

When it comes to recycling and salvaging valuable materials, electric motors are often overlooked. These powerhouses hidden within our everyday devices contain various components that can be recycled or repurposed for other projects. Not only is reusing these materials environmentally friendly, but it can also be financially rewarding.

In this article, we will guide you through the process of scrapping an electric motor. We will cover the necessary tools and materials, safety precautions, and the step-by-step process of disassembling and separating the different components. Additionally, we will discuss how to properly dispose of the non-recyclable parts.

Before we dive into the details, it’s important to note that safety should be your top priority throughout this process. Electric motors can contain hazardous materials and carry electrical currents, so taking proper precautions is essential.

Now, let’s gather our tools and get started on this exciting journey of scrapping electric motors!

Key Takeaways:

- Scrapping electric motors not only salvages valuable materials but also promotes sustainability by reducing the demand for new resources and minimizing environmental impact through recycling and repurposing.

- Prioritizing safety and proper disposal of non-recyclable parts are essential in the scrapping process, contributing to a cleaner and healthier environment while harnessing the power of recycling.

Read more: How To Scrap A Refrigerator

Tools and Materials Needed

Before you start scrapping an electric motor, it’s important to gather the necessary tools and materials. Here’s a list of what you’ll need:

- Wrench or socket set: You’ll need this to remove any bolts or screws holding the motor in place.

- Screwdriver: A set of screwdrivers with various sizes and types will be necessary for removing screws and prying open the motor.

- Wire cutters/strippers: These will be used to cut and strip the copper wires from the motor.

- Pliers: Pliers are handy for gripping and separating different components of the motor.

- Hammer: You might need a hammer to gently tap or break apart parts of the motor.

- Container or bucket: This will be used to collect the different components and materials as you disassemble the motor.

- Safety gloves and goggles: Protect your hands and eyes from any potential hazards, such as sharp edges or flying debris.

- Protective clothing: Wearing long sleeves and pants can help prevent any scratches or injury while handling the motor.

- Recycling bins: Prepare separate bins or containers for different materials, such as copper wires, aluminum, and steel.

These tools are the basic essentials you’ll need to effectively scrap an electric motor. Depending on the specific motor and your level of expertise, you might require additional tools such as a drill or angle grinder for more advanced disassembly.

Once you’ve gathered all the tools and materials, ensure that you have a well-ventilated workspace to carry out the scrapping process. It’s also a good idea to have a fire extinguisher nearby, in case of any accidental fires.

Now that you’re well-prepared, let’s move on to the next step: ensuring safety precautions.

Step 1: Safety Precautions

Before you begin scrapping an electric motor, it’s crucial to take the necessary safety precautions to protect yourself from potential hazards. Here are some important steps to follow:

- Ensure that you are working in a well-ventilated area to avoid inhaling any harmful fumes or dust particles.

- Wear safety gloves and goggles to protect your hands and eyes from sharp edges, flying debris, and any potential chemical spills.

- Put on protective clothing, such as long sleeves and pants, to prevent your skin from coming into contact with any hazardous materials.

- Make sure to have a fire extinguisher nearby in case of any accidental fires that may occur during the scrapping process.

- If you are working with a motor that is still connected to a power source, ensure that you have disconnected it properly and that it is not receiving any electricity.

- Take extra caution when handling any capacitors, as they can store electrical charge even after the motor is disconnected. Discharge them safely before proceeding.

- Be mindful of any toxic materials that may be present in the motor, such as mercury or lead. Take appropriate measures to handle and dispose of these materials safely.

By following these safety precautions, you can minimize the risk of accidents or injuries while scrapping electric motors. Remember, safety should always be your top priority throughout the entire process.

Now that you’re equipped with the proper safety measures, let’s move on to the next step: disassembling the electric motor.

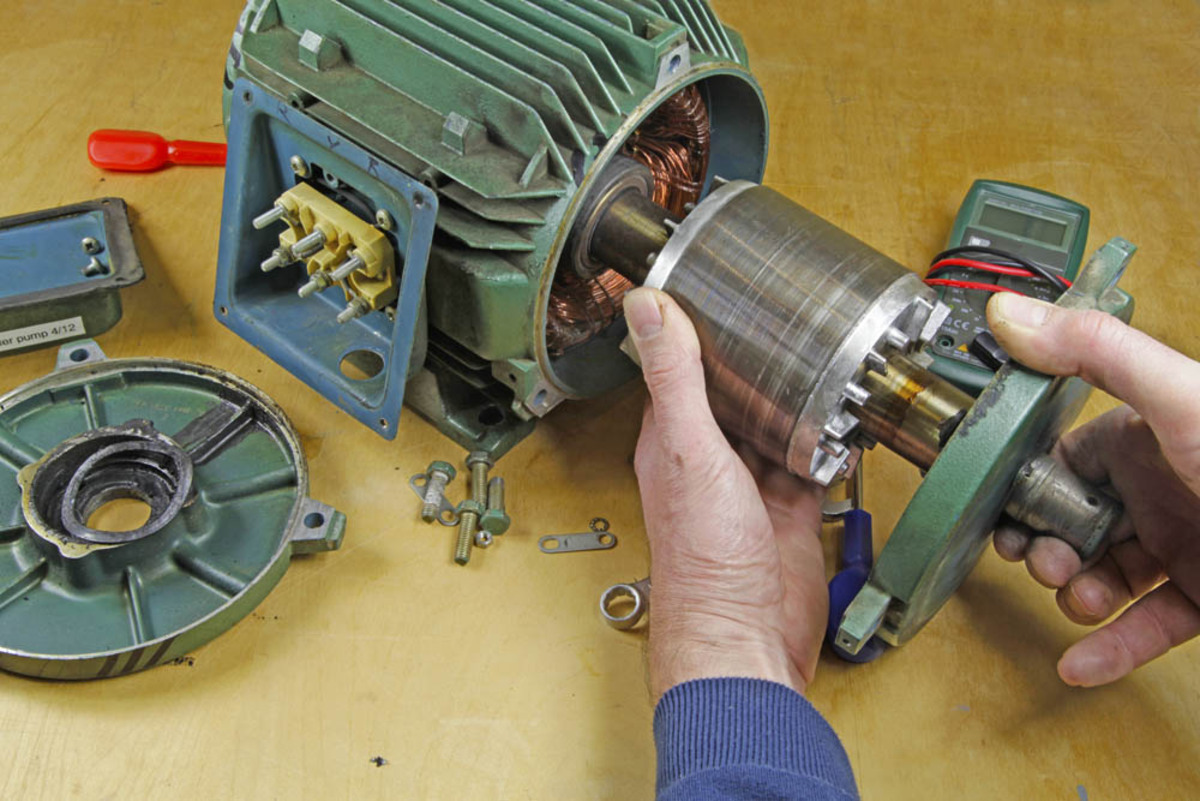

Step 2: Disassembling the Electric Motor

Now that you have taken the necessary safety precautions, it’s time to start the process of disassembling the electric motor. Follow these steps to effectively dismantle the motor:

- Locate the bolts or screws that are holding the motor in place. Use a wrench or socket set to loosen and remove them.

- Carefully lift the motor out of its housing and place it on a clean workspace.

- Inspect the motor and identify any additional screws or clips that may be securing the casing. Remove these as well.

- Using a screwdriver, gently pry open the motor casing. Be cautious of any springs or other components that may pop out.

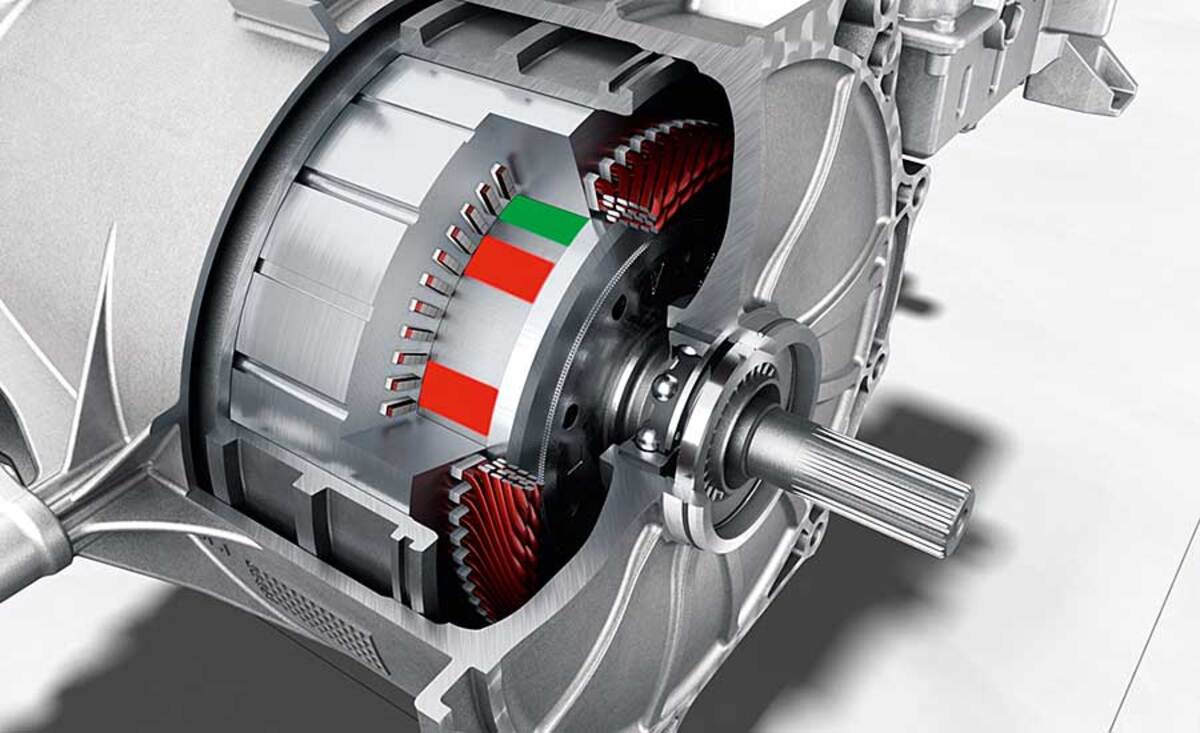

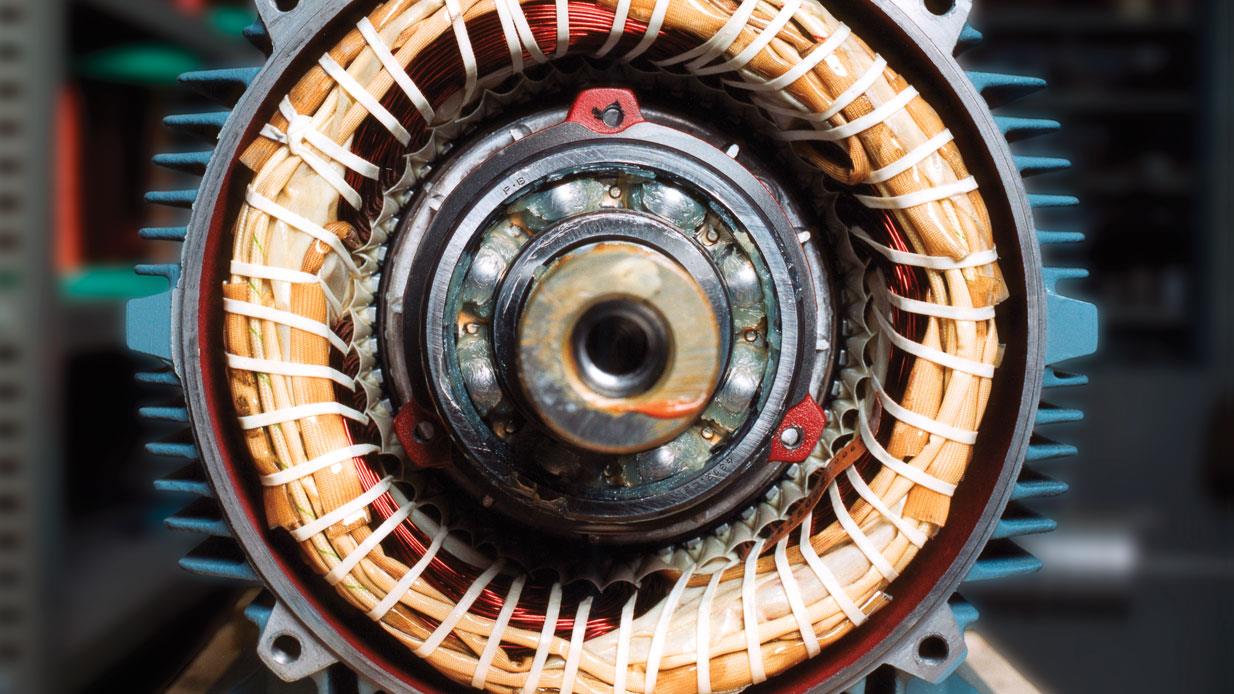

- Once the casing is removed, you will have access to the internal components of the motor.

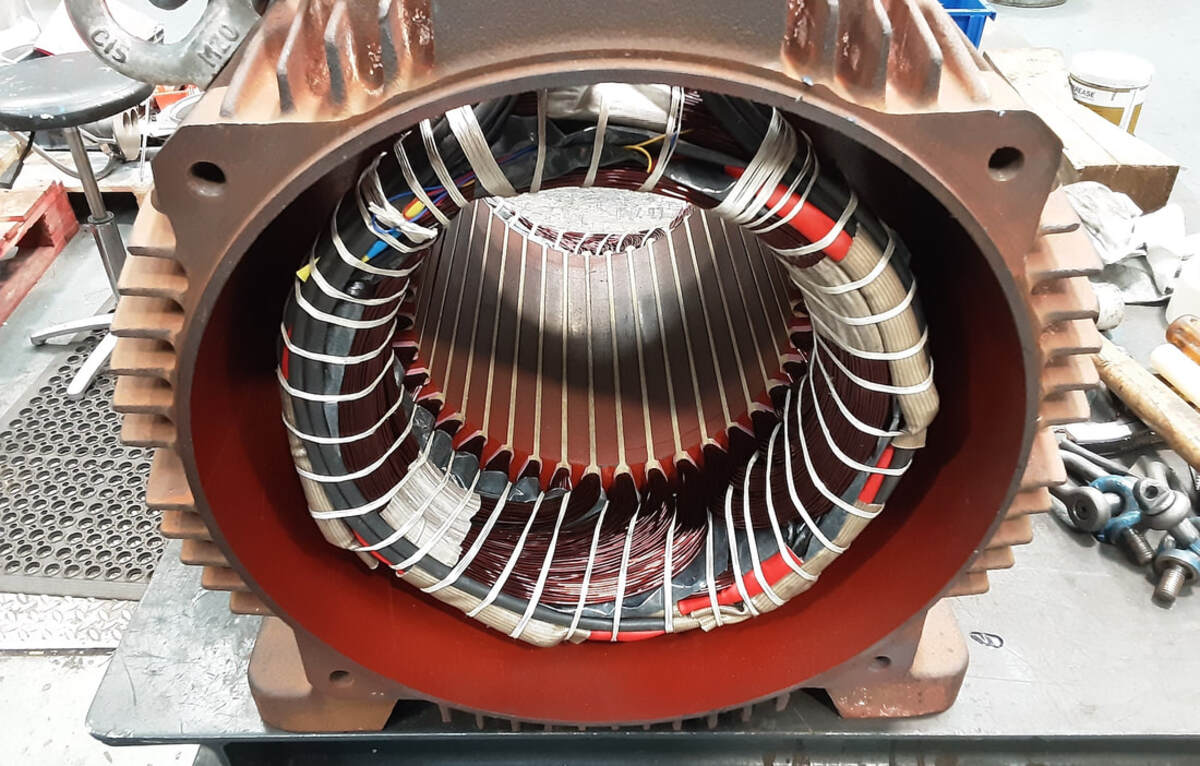

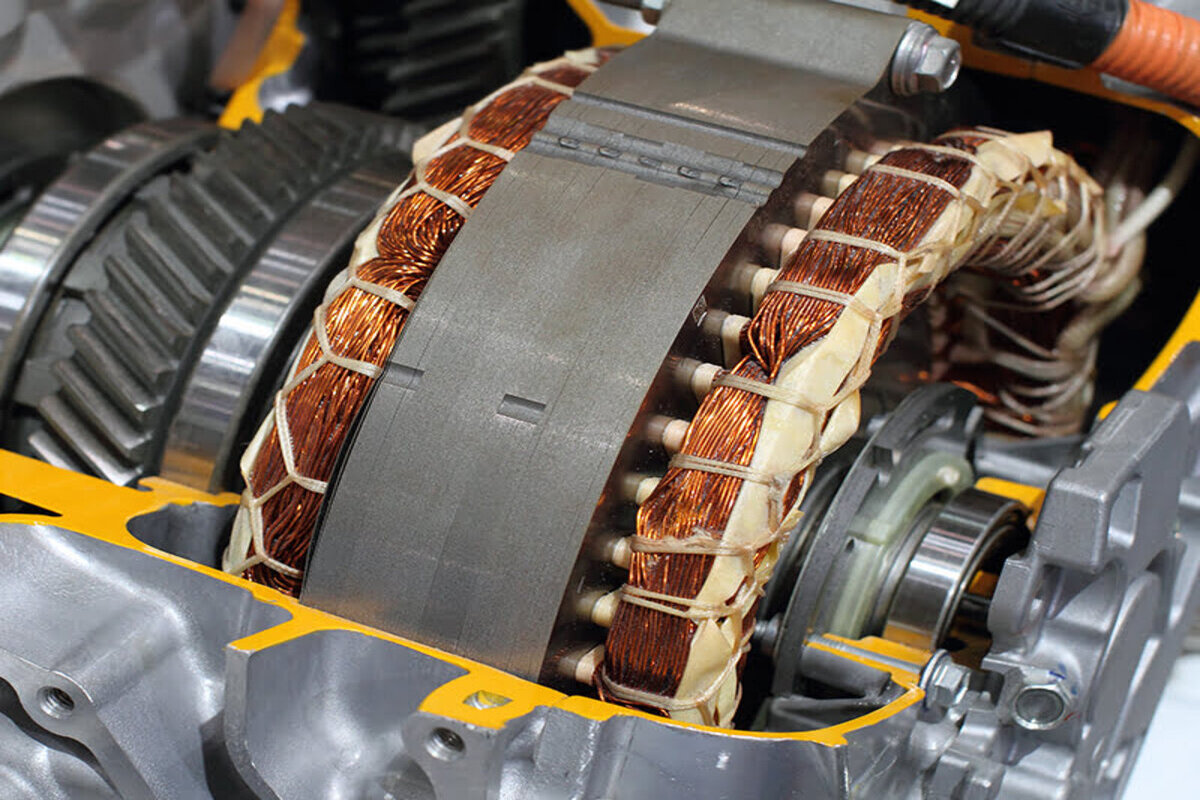

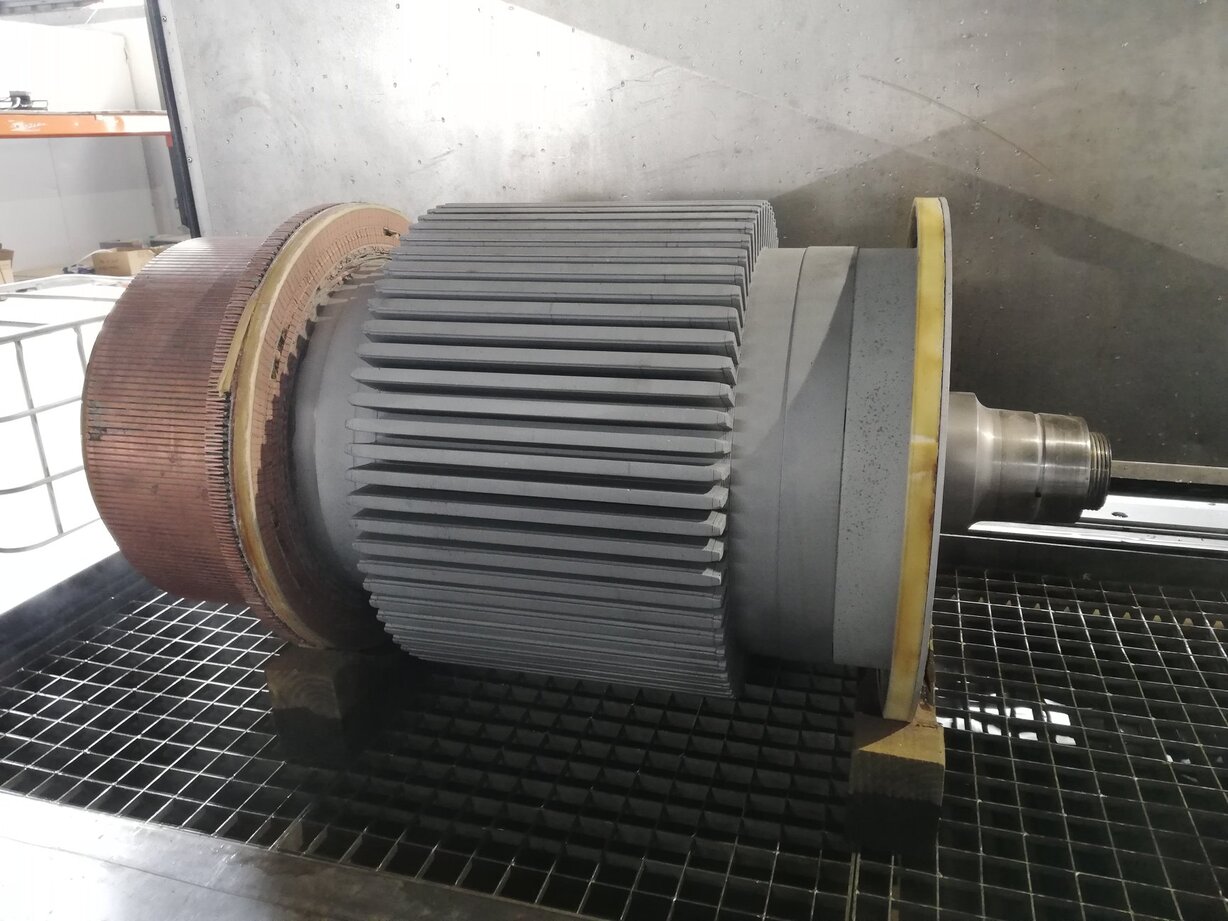

- Inspect the motor to identify the copper wires, steel, aluminum, and other valuable components that you want to salvage or recycle.

- If there are any bolts or screws holding the components together, use the appropriate tools to remove them.

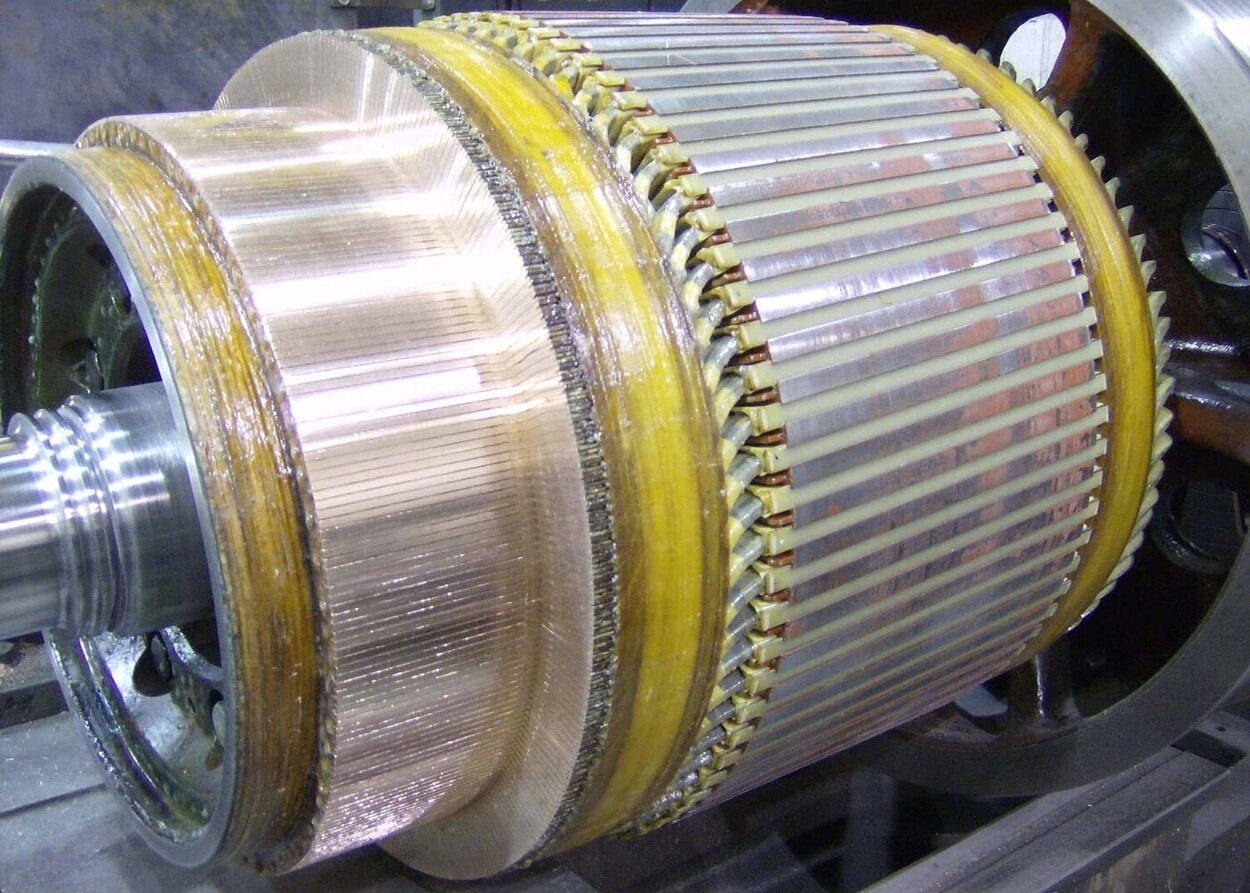

- Separate and remove the copper wires from the motor. Use wire cutters or strippers to carefully cut and strip the insulation.

- Set aside the copper wires for recycling. Copper is a valuable material that can fetch a good price at recycling centers.

- Continue disassembling the motor, separating the steel and aluminum components from other materials.

- Place each component in its respective recycling bin or container to keep them organized.

Remember to work patiently and avoid rushing through the disassembly process. Take note of how the motor is assembled, as this will be helpful when it comes to reusing or repurposing the components.

By carefully disassembling the electric motor, you are on your way to salvaging valuable materials and contributing to a more sustainable future. Let’s move on to the next step: removing the copper wires.

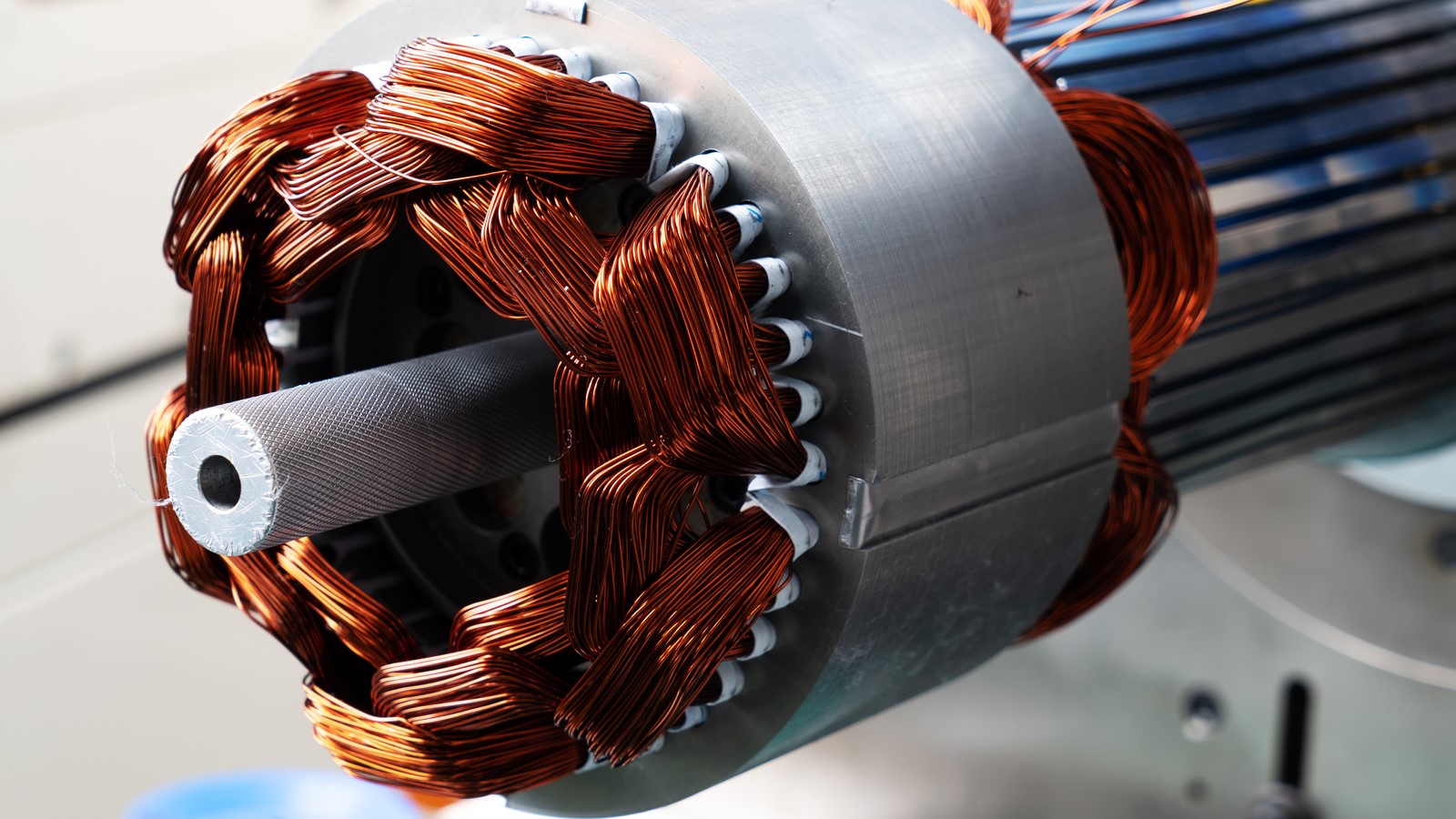

Step 3: Removing the Copper Wires

Now that you have successfully disassembled the electric motor, it’s time to focus on removing the valuable copper wires. Follow these steps to effectively extract the copper wires:

- Inspect the motor and identify the copper wires. They are typically thick and can be found wrapped around the various components inside the motor.

- Using wire cutters or strippers, carefully cut and strip the insulation covering the copper wires.

- Start at one end and cut the insulation, exposing the copper underneath. Continue cutting along the length of the wire until all the insulation is removed.

- Keep in mind that copper wires might be in different colors, which could indicate different levels of purity or types of copper. Separate them accordingly.

- Once the insulation is removed, gather the copper wires and place them in a separate container or bin designated for copper recycling.

- Repeat this process for all the copper wires you have extracted from the motor.

It’s important to note that copper is a valuable material and can be sold to recycling centers or scrap yards. The price of copper will vary depending on factors such as purity and current market conditions.

By removing the copper wires from the electric motor, you are not only salvaging a valuable resource but also reducing the demand for new copper mining and production, which has a significant environmental impact.

Now that you have successfully extracted and sorted the copper wires, it’s time to move on to the next step: separating the different components of the motor.

When scrapping an electric motor, be sure to remove any non-metal components such as plastic or rubber to get the best price for the scrap metal.

Read more: How To Grease Electric Motor

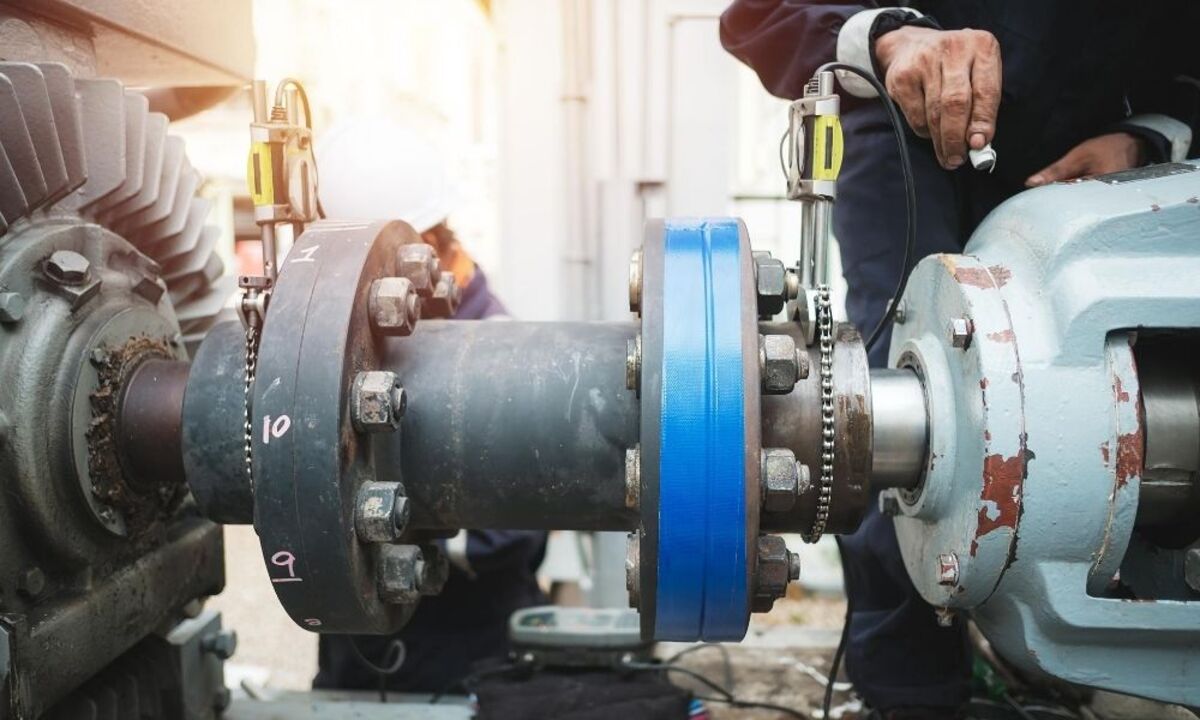

Step 4: Separating the Different Components

After removing the copper wires, it’s time to focus on separating the different components of the electric motor. This step will allow you to identify valuable materials and prepare them for recycling or repurposing. Here’s how to go about it:

- Review the disassembled motor and assess the various components, such as steel, aluminum, plastic, and other metals.

- Use pliers or other appropriate tools to separate the different materials. For example, you can use pliers to remove steel brackets or aluminum mounts.

- Set aside the separated components and place them in designated recycling bins or containers. Keep the different materials separate to ensure maximum recycling potential.

- Check for any other valuable metals, such as brass or bronze, within the motor. Separate them as well and place them in the appropriate containers for recycling.

- Some motors may have bearings that could be salvaged. Carefully remove these using pliers or appropriate tools and set them aside for further evaluation or reuse.

- Inspect the plastic components and determine if they are recyclable. Some plastics may have recycling symbols or codes, indicating the type of plastic they are made of. Separate and recycle them accordingly.

Separating the different components allows you to effectively recycle and repurpose various materials, reducing the need for new production and minimizing environmental impact.

By properly sorting and separating the components, you are contributing to a more sustainable approach to waste management and resource utilization.

Now that you have successfully separated the different components of the motor, it’s time to move on to the next step: sorting and recycling.

Step 5: Sorting and Recycling

After separating the different components of the electric motor, it’s important to properly sort and recycle each material. This ensures that the valuable resources are reused, reducing the strain on the environment and promoting a circular economy. Follow these steps to effectively sort and recycle the components:

- Review the different materials you have separated, such as copper wires, steel, aluminum, plastic, and other metals.

- Place each material in its respective recycling bin or container. Copper wires should be collected in a container specifically for copper recycling.

- Research local recycling centers or scrap yards that accept the different materials. Many centers offer competitive prices for copper, aluminum, and other recyclable metals.

- Prepare the components for recycling by cleaning them if necessary. Remove any excess dirt, grease, or other contaminants that may affect the recycling process.

- Transport the sorted materials to the recycling center or scrap yard. Follow their guidelines for drop-off or collection to ensure a smooth process.

- If you have a large volume of materials, consider contacting a recycling company that specializes in metal recycling. They may offer pickup services for bulk materials.

By sorting and recycling the components of the electric motor, you are reducing the demand for new resources, conserving energy, and minimizing greenhouse gas emissions associated with mining and production.

Remember to always follow local recycling guidelines and regulations for proper disposal and recycling of the materials.

Now that you have sorted and prepared the components for recycling, it’s time to move on to the next step: proper disposal of non-recyclable parts.

Step 6: Proper Disposal of Non-Recyclable Parts

After sorting and recycling the valuable components of the electric motor, there may still be some non-recyclable parts that need to be properly disposed of. These parts may include certain plastics, insulation materials, or other hazardous substances. It’s important to handle and dispose of them responsibly to minimize their impact on the environment. Follow these steps for the proper disposal of non-recyclable parts:

- Identify the non-recyclable parts that you were not able to separate for recycling.

- Consult with your local waste management or recycling facility to inquire about the proper disposal methods for these materials.

- Follow any specific instructions provided by the waste management facility, such as bagging or containing the non-recyclable parts separately.

- If there are hazardous materials, such as mercury or lead, within the non-recyclable parts, check local regulations for proper handling and disposal. There may be designated collection centers or hazardous waste facilities that can accept these materials.

- If there are any chemicals or fluids present in the motor, such as coolant or lubricants, ensure that they are properly drained and disposed of in accordance with local regulations.

- Take note of any electronic waste (e-waste) items within the motor, such as circuit boards or control panels. These often require special handling and should be taken to designated e-waste recycling facilities to ensure responsible disposal.

Proper disposal of non-recyclable parts is crucial to prevent environmental pollution and protect the well-being of your local community. By adhering to the guidelines provided by your waste management facility, you can contribute to a cleaner and healthier environment.

With step 6 complete, you have successfully tackled the process of scrapping an electric motor. By following these steps and taking the necessary safety precautions, you have not only salvaged valuable materials but also contributed to a more sustainable approach to waste management.

Remember, recycling and repurposing materials whenever possible is essential in our efforts to conserve resources, reduce waste, and mitigate the impact of human activities on the planet.

Congratulations on your scrapping journey and your commitment to sustainability!

For more information on recycling and responsible waste management, consult your local recycling facilities, waste management providers, or environmental organizations.

Conclusion

Scrapping an electric motor is not only a practical and cost-effective way to salvage valuable materials, but it also contributes to a more sustainable approach to waste management. By following the steps outlined in this article, you have learned how to safely disassemble the motor, extract valuable copper wires, separate the different components, and properly dispose of non-recyclable parts.

Throughout the process, it’s crucial to prioritize safety by wearing appropriate protective gear and working in a well-ventilated area. Remember to handle hazardous materials, such as capacitors or toxic substances, with caution and dispose of them properly.

By recycling and repurposing the valuable components, such as copper wires, steel, aluminum, and other metals, you are reducing the demand for new resources and minimizing the environmental impact of mining and production. Recycling also helps conserve energy and reduce greenhouse gas emissions associated with the manufacture of new materials.

Proper disposal of non-recyclable parts ensures that any potentially harmful substances are handled responsibly, protecting the environment and the well-being of your community.

Thank you for joining us on this journey of scrapping an electric motor. By harnessing the power of recycling and repurposing, we can make a positive impact on our planet and help create a more sustainable future.

Now, armed with the knowledge and understanding of the scrapping process, it’s time to take action. So, gather your tools, put on your safety gear, and start salvaging those electric motors!

Frequently Asked Questions about How To Scrap A Electric Motor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Scrap A Electric Motor”