Articles

What Is Rigid Board Insulation

Modified: January 9, 2024

Discover the benefits of using rigid board insulation for your next construction project. Read articles on its installation, efficiency, and cost-effectiveness.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Rigid board insulation is a type of insulation material that is widely used in construction projects to enhance energy efficiency and provide thermal protection. It is a versatile and durable option that offers excellent insulation properties, making it ideal for residential, commercial, and industrial applications.

Unlike other forms of insulation, such as fiberglass or cellulose, which are loose or fluffy, rigid board insulation is composed of solid panels or boards that are capable of providing a high level of insulation. These panels are typically made from materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate foam board (Polyiso).

In this article, we will explore the different types of rigid board insulation, discuss their advantages and applications, and provide insights into the installation considerations for this innovative insulation material.

Key Takeaways:

- Rigid board insulation offers exceptional thermal resistance, moisture resistance, and sound insulation benefits, making it a versatile and durable choice for enhancing energy efficiency in various construction projects.

- Proper installation considerations, such as sizing, airtightness, and moisture management, are crucial for maximizing the performance and longevity of rigid board insulation. Consulting with professionals ensures effective installation and compliance with building codes.

Read more: What Is Insulation Board

Definition of Rigid Board Insulation

Rigid board insulation, as the name suggests, refers to a type of insulation that is available in the form of solid panels or boards. It is a highly effective insulation material characterized by its ability to resist heat transfer and provide thermal insulation for various structures.

These rigid panels are typically made from different materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate foam (Polyiso). Each material has its own unique set of properties that determine its suitability for different applications.

Rigid board insulation is commonly used in a wide range of construction projects, including residential, commercial, and industrial buildings. It is primarily installed in walls, roofs, floors, and foundations to create a thermal barrier and prevent heat loss or gain, depending on the desired effect.

One of the key features of rigid board insulation is its high R-value, which measures its thermal resistance. The higher the R-value, the better the insulation performance. Rigid board insulation typically has a higher R-value compared to other types of insulation materials, making it an excellent choice for achieving energy efficiency and reducing heating and cooling costs.

Additionally, rigid board insulation provides key benefits such as sound insulation, moisture resistance, and fire retardancy. These properties make it a valuable choice for applications where moisture control, noise reduction, and fire safety are important considerations.

Overall, rigid board insulation offers a durable and versatile solution for enhancing energy efficiency and thermal comfort in buildings. Its solid construction, high R-value, and multiple material options make it a reliable choice for various applications.

Types of Rigid Board Insulation

There are several types of rigid board insulation available in the market, each with its own unique set of characteristics and advantages. The three most commonly used types of rigid board insulation are:

- Expanded Polystyrene (EPS) Rigid Board Insulation: EPS insulation is made from expanded polystyrene beads that are fused together under high heat and pressure. It is lightweight, cost-effective, and offers good thermal insulation properties. EPS insulation is moisture-resistant and does not easily degrade or deteriorate over time. It is commonly used in applications such as walls, roofs, and foundations.

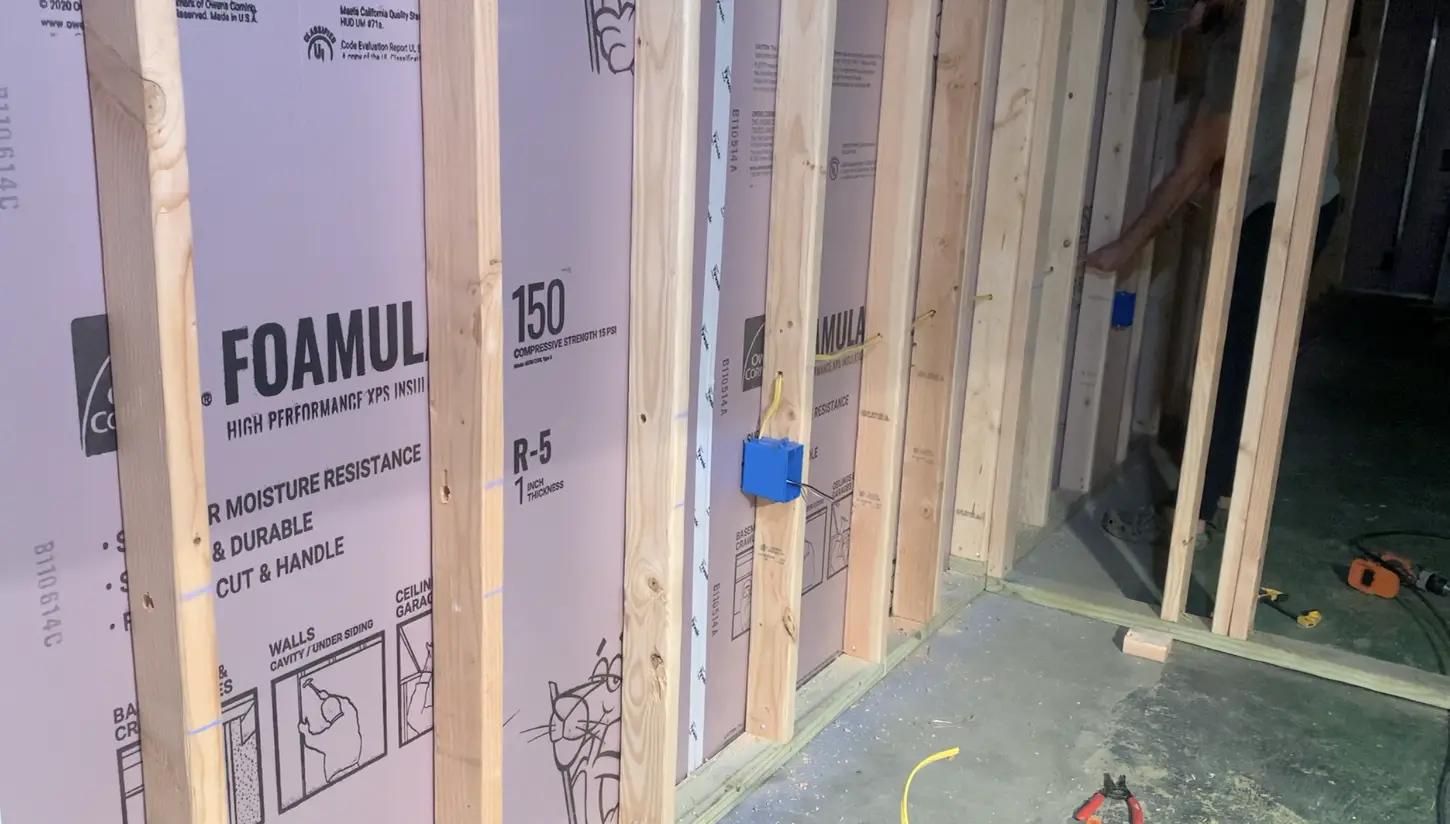

- Extruded Polystyrene (XPS) Rigid Board Insulation: XPS insulation is manufactured using a different process that results in a denser and more closed-cell structure compared to EPS insulation. This makes it more resistant to moisture infiltration and provides better thermal insulation. XPS insulation is highly durable, resistant to compression, and has a high R-value. It is commonly used in applications that require high moisture resistance, such as below-grade insulation, roofing systems, and basement walls.

- Polyisocyanurate (Polyiso) Foam Board Insulation: Polyiso insulation is a closed-cell foam insulation that offers excellent thermal insulation properties and high R-value per inch of thickness. It is known for its superior fire resistance and can withstand high temperatures. Polyiso insulation is used in a wide range of applications, including walls, roofs, and commercial insulation projects.

Each type of rigid board insulation has its own unique benefits, and the choice of insulation material should be based on factors such as the specific application, climate conditions, budget, and desired thermal performance.

It is important to consult with insulation professionals or manufacturers to determine the most suitable type of rigid board insulation for your project, ensuring that you achieve the desired insulation effectiveness while meeting the required building codes and standards.

Expanded Polystyrene (EPS) Rigid Board Insulation

Expanded Polystyrene (EPS) rigid board insulation is a popular choice among builders and homeowners due to its affordability, versatility, and excellent thermal insulation properties. It is made from expanded polystyrene beads that are fused together, creating a lightweight but rigid insulation material.

EPS rigid board insulation is known for its high R-value, which measures its thermal resistance. It provides effective insulation by reducing heat transfer, keeping the indoor environment comfortable and energy-efficient. EPS insulation can significantly reduce heating and cooling costs by minimizing heat loss or gain through walls, roofs, and floors.

One of the key advantages of EPS insulation is its moisture resistance. Thanks to its closed-cell structure, it is not easily infiltrated by water or vapor. This makes it a reliable choice for areas with high humidity or where moisture control is important, such as basements or crawl spaces.

In addition to its insulation and moisture resistance properties, EPS rigid board insulation also offers sound insulation benefits. Its dense cellular structure helps to absorb and dampen sound waves, reducing noise transfer between different areas of a building. This can contribute to a quieter and more comfortable indoor environment.

EPS insulation is lightweight, making it easy to handle and install. It can be cut to fit various shapes and sizes, allowing for flexibility during installation. Its versatility makes it suitable for a wide range of applications, including walls, roofs, foundations, and even under slab insulation.

Another advantage of EPS insulation is its durability. It does not easily degrade or deteriorate over time, ensuring long-term performance and efficiency. EPS is also resistant to pests, like termites, which can be a concern in certain regions.

EPS rigid board insulation is a cost-effective solution for achieving energy efficiency and thermal comfort in buildings. It combines affordability, excellent insulation properties, moisture resistance, and sound insulation capabilities, making it a reliable choice for various construction projects.

When choosing EPS insulation, it is important to consider the required R-value for the specific application, as well as local building codes and regulations. Consulting with insulation professionals can help ensure that the right thickness and installation methods are followed, maximizing the effectiveness of EPS rigid board insulation.

Extruded Polystyrene (XPS) Rigid Board Insulation

Extruded Polystyrene (XPS) rigid board insulation is a versatile and highly effective insulation material known for its exceptional thermal performance and moisture resistance. It is made by extruding polystyrene resin mixed with additives, resulting in a dense, closed-cell structure that offers superior insulation properties.

XPS rigid board insulation is widely used in construction projects that require high moisture resistance, such as below-grade applications, roofing systems, and foundations. Its closed-cell structure prevents the absorption of water, making it an ideal choice for areas prone to moisture infiltration.

One of the notable advantages of XPS insulation is its high R-value per inch of thickness. The high R-value ensures optimal thermal insulation, improving energy efficiency and reducing heating and cooling costs. XPS insulation effectively minimizes heat transfer, keeping the interior environment comfortable and reducing the reliance on heating and cooling systems.

The durability of XPS rigid board insulation is another key feature. Its dense structure makes it resistant to compression and capable of withstanding heavy loads. This makes it suitable for applications where the insulation material needs to provide structural support, such as below-grade insulation in foundations or as a protective layer in roofing systems.

In addition to its thermal and structural benefits, XPS insulation also provides excellent resistance to pests, including termites. Its closed-cell structure is not a suitable environment for pests to thrive, ensuring long-term performance and protection against infestations.

Installation of XPS insulation is relatively straightforward. The rigid boards are lightweight, making them easier to handle and maneuver during installation. The boards can be easily cut to fit complex shapes and sizes, allowing for greater flexibility in various construction projects.

When selecting XPS insulation, it is important to consider the specific requirements of the project, such as the desired R-value, local building codes, and environmental conditions. Consulting with insulation professionals will help determine the appropriate thickness and installation techniques to optimize the effectiveness of XPS rigid board insulation.

In summary, XPS rigid board insulation offers excellent thermal performance, moisture resistance, durability, and resistance to pests. Its versatility makes it suitable for a wide range of applications, providing long-term energy efficiency and thermal comfort in buildings.

Polyisocyanurate (Polyiso) Foam Board Insulation

Polyisocyanurate (Polyiso) foam board insulation is a popular choice for both residential and commercial construction projects due to its exceptional thermal insulation properties and versatility. It is a closed-cell foam insulation material that offers high R-value per inch of thickness, making it an effective solution for achieving energy efficiency and reducing heating and cooling costs.

Polyiso foam board insulation is composed of a foam core made from a blend of isocyanurate and polyol, which are combined and then cured. This resulting foam structure provides excellent thermal insulation by minimizing heat transfer through walls, roofs, and floors.

One of the significant advantages of Polyiso foam board insulation is its high R-value. It offers one of the highest R-values among insulation materials, making it highly effective in preventing heat loss in colder climates and reducing heat gain in hotter climates. This allows for optimal thermal comfort and energy efficiency all year round.

Another key benefit of Polyiso insulation is its superior fire resistance. The isocyanurate component of the foam contributes to its fire-retardant properties, making it suitable for applications where fire safety is a concern.

Polyiso foam board insulation is also known for its dimensional stability and durability. It remains rigid and retains its insulating properties even under changing temperature conditions, ensuring long-term performance and efficiency. Additionally, Polyiso foam is resistant to moisture, mold, and mildew, providing added protection against moisture-related issues in buildings.

The lightweight nature of Polyiso foam boards makes them easy to handle and install. They can be easily cut to the desired size and shape, allowing for precise fitting in various construction applications. Furthermore, Polyiso foam boards offer excellent dimensional stability, ensuring a consistent insulation barrier without the risk of settling or sagging over time.

Polyiso foam board insulation is commonly used in applications such as walls, roofs, and commercial insulation projects. It is particularly advantageous in situations where space is at a premium, as the high R-value of Polyiso foam allows for thinner insulation layers compared to other materials.

When considering Polyiso foam board insulation, it is essential to consult with insulation professionals to determine the appropriate thickness and installation methods based on the specific project requirements and local building codes.

In summary, Polyisocyanurate (Polyiso) foam board insulation offers exceptional thermal insulation, fire resistance, dimensional stability, and moisture resistance. Its high R-value and versatility make it an excellent choice for enhancing energy efficiency and thermal comfort in buildings.

When installing rigid board insulation, make sure to properly seal all joints and edges to prevent air leakage and maximize its effectiveness in insulating your space.

Advantages of Rigid Board Insulation

Rigid board insulation offers several advantages that make it a preferred choice for many construction projects. Let’s explore some of the key benefits:

- Excellent Thermal Insulation: Rigid board insulation provides superior thermal resistance, helping to minimize heat transfer through walls, roofs, floors, and foundations. This results in increased energy efficiency and reduced heating and cooling costs for the building.

- Durability: Rigid board insulation is known for its durability and long-lasting performance. It is resistant to moisture, mold, and pests, ensuring that it maintains its insulation properties over time and provides consistent thermal comfort.

- Structural Support: Rigid board insulation can provide additional structural support to buildings when used as sheathing or in combination with other construction materials. It can enhance the strength and integrity of walls and roofs, adding stability and resilience.

- Versatility: Rigid board insulation is versatile and can be used in various applications, including walls, roofs, floors, and foundations. It can easily be cut to fit specific sizes and shapes, making it suitable for both simple and complex construction projects.

- Moisture Resistance: Many types of rigid board insulation, such as XPS and Polyiso, exhibit excellent moisture resistance. This makes them suitable for areas prone to high humidity or where moisture control is essential, such as basements or in below-grade applications.

- Sound Insulation: Rigid board insulation can also provide sound insulation benefits. Its dense structure helps to absorb and dampen sound waves, reducing noise transfer and creating a quieter and more comfortable indoor environment.

- Fire Safety: Some types of rigid board insulation, such as Polyiso, offer superior fire resistance. This can enhance the safety of the building and provide added protection against fire hazards.

- Easy Installation: Rigid board insulation is relatively easy to handle and install. It can be cut, shaped, and installed efficiently, saving time and effort during the construction process. Additionally, the lightweight nature of rigid board insulation makes it easier to transport and maneuver on the job site.

Overall, the advantages of rigid board insulation make it a highly desirable choice for improving energy efficiency, providing thermal comfort, and enhancing the durability of buildings. Its versatility, durability, and excellent insulation properties make it suitable for a wide range of construction applications.

Energy-Saving Benefits of Rigid Board Insulation

Rigid board insulation offers significant energy-saving benefits that contribute to reduced energy consumption and lower heating and cooling costs. Let’s explore some key ways in which rigid board insulation helps save energy:

- Thermal Barrier: Rigid board insulation acts as a thermal barrier, reducing the transfer of heat through building envelopes. It helps to keep the cold air out during the winter months and prevents hot air from entering during the summer. This ensures that the indoor space remains at a comfortable temperature while minimizing the need for excessive heating or cooling, resulting in energy savings.

- Minimizing Heat Loss or Gain: By providing a high level of thermal insulation, rigid board insulation helps minimize heat loss or gain through walls, roofs, and floors. This reduces the reliance on heating systems in cold climates and air conditioning in hot climates, resulting in lower energy consumption and reduced utility bills.

- Reduced HVAC Loads: With improved thermal insulation provided by rigid board insulation, the demand on HVAC (heating, ventilation, and air conditioning) systems is reduced. These systems can operate more efficiently and at lower capacities, resulting in energy savings and potentially extending the lifespan of HVAC equipment.

- Preventing Air Leaks: Rigid board insulation helps seal gaps and air leaks in the building envelope, reducing the infiltration of outdoor air and the escape of conditioned indoor air. This minimizes heat transfer and the need for constant temperature adjustments, leading to energy savings and enhanced comfort.

- Moisture Management: Some types of rigid board insulation, such as XPS and Polyiso, have excellent moisture resistance properties. By effectively controlling moisture intrusion, these insulation materials help prevent the degradation of building components and reduce the risk of energy loss through damp materials.

- Lower Environmental Impact: By reducing energy consumption, rigid board insulation helps to lower greenhouse gas emissions and promote sustainability. It allows buildings to operate more efficiently, contributing to a greener and more environmentally friendly built environment.

- Long-Term Energy Efficiency: Rigid board insulation is durable and provides long-lasting energy efficiency benefits. Unlike other insulation types that may settle or degrade over time, rigid board insulation maintains its thermal performance for extended periods, resulting in consistent energy savings over the lifespan of the building.

With its exceptional insulating properties, rigid board insulation plays a crucial role in creating energy-efficient buildings. From reducing heat loss or gain, to minimizing HVAC loads, to preventing air leaks and managing moisture, rigid board insulation offers multiple energy-saving benefits that contribute to a more sustainable and cost-effective building environment.

Applications of Rigid Board Insulation

Rigid board insulation is a versatile insulation material that finds application in various areas of the construction industry. Let’s explore some common applications where rigid board insulation is used:

- Walls: Rigid board insulation is commonly used in both exterior and interior walls to provide thermal insulation and increase energy efficiency. It helps create a barrier against heat transfer and minimizes thermal bridging, ensuring a more comfortable indoor environment and reducing heating and cooling costs.

- Roofs: Rigid board insulation is frequently used in roofing systems to prevent heat gain in hot climates and heat loss in cold climates. These insulation boards are installed above the roof deck, reducing energy consumption and enhancing the overall performance of the roof by reducing thermal stress.

- Floors: Rigid board insulation is installed in floor assemblies to provide thermal insulation and improve energy efficiency. It helps prevent heat loss through the floor and provides enhanced comfort in areas such as basements, crawl spaces, and above unconditioned spaces like garages.

- Foundations: Rigid board insulation is used to insulate foundation walls, providing protection against heat loss and moisture infiltration. Insulating foundations with rigid board insulation helps maintain a consistent temperature inside the building and prevents moisture-related issues.

- Pipes and Ducts: Rigid board insulation is often applied to pipes and ductwork to minimize heat loss or gain. Insulating pipes and ducts with rigid board insulation prevents condensation, reduces energy loss during the transportation of fluids or air, and ensures efficient operation of heating, cooling, and ventilation systems.

- Exterior Sheathing: Rigid board insulation can be used as exterior sheathing to enhance both insulation and structural integrity. This application provides thermal insulation and additional support to walls, helping to reduce thermal bridging and improve energy efficiency.

- Commercial and Industrial Buildings: Rigid board insulation is widely used in commercial and industrial buildings, including warehouses, offices, and manufacturing facilities. It offers excellent insulation properties for large spaces, contributing to energy savings and creating a more comfortable working environment.

- Specialized Applications: Rigid board insulation is also used in specialized applications such as refrigeration systems, cold storage facilities, and transportation vehicles where temperature control is critical. The insulation helps maintain stable temperature conditions and prevents heat transfer, preserving the integrity of the stored goods or maintaining optimal operating conditions.

Rigid board insulation offers flexibility and adaptability, making it suitable for various construction applications. Choosing the right type of rigid board insulation and ensuring proper installation is essential to achieve optimum thermal performance, energy efficiency, and long-term durability in each specific application.

Installation Considerations for Rigid Board Insulation

When it comes to installing rigid board insulation, there are several important considerations that need to be taken into account to ensure optimal performance, energy efficiency, and durability. Let’s explore some key installation considerations:

- Proper Sizing and Placement: It is crucial to select the correct thickness and size of rigid board insulation for the specific application. Consult with insulation professionals or manufacturers to determine the appropriate insulation thickness to achieve the desired thermal performance and to meet local building codes and regulations.

- Airtight Installation: To maximize the benefits of rigid board insulation, it is important to ensure a tight and airtight installation. Properly seal joints, seams, and edges using appropriate insulation tapes or sealants to prevent air leakage and heat transfer through the insulation layer.

- Moisture Management: Proper moisture management is essential for the longevity and performance of rigid board insulation. Ensure that the insulation material is properly installed and protected from moisture infiltration. Take care to install a vapor retarder or barrier, as required, to control moisture diffusion and prevent condensation within the assembly.

- Compatibility with Building Materials: Consider the compatibility of the rigid board insulation with other building materials. Ensure that the insulation material is compatible with adhesives, fasteners, and masonry anchors used in the construction process. Opt for materials that will not degrade or react adversely when in contact with other building components or adhesives.

- Structural Support: Assess whether the rigid board insulation can provide sufficient structural support when used in load-bearing applications. Consult with engineers or professionals to ensure that the chosen insulation material meets the required structural requirements and can safely support the loads placed upon it.

- Fire Safety: Depending on the specific application and building codes, consider fire safety measures when installing rigid board insulation. Use fire-resistant materials or coatings as required to ensure compliance with fire safety regulations and to enhance the overall fire resistance of the building assembly.

- Proper Ventilation: Ensure that adequate ventilation is provided in areas where rigid board insulation is installed to prevent moisture buildup and promote airflow. Proper ventilation helps to maintain the efficiency of the insulation and prevents potential issues related to moisture retention or condensation.

- Professional Installation: Unless you have experience and expertise in insulation installation, it is recommended to hire professional installers for proper handling and installation of rigid board insulation. Professionals have the knowledge and tools to ensure a correct and efficient installation, reducing the risks of errors or gaps in insulation coverage.

By considering these installation factors, you can ensure the effective and long-term performance of rigid board insulation. Always follow manufacturer guidelines and consult with professionals to achieve optimal insulation effectiveness and compliance with building codes and regulations.

Conclusion

Rigid board insulation offers numerous advantages that make it a preferred choice for achieving energy efficiency, thermal comfort, and durability in construction projects. Whether it’s in residential, commercial, or industrial applications, rigid board insulation provides exceptional thermal insulation properties, moisture resistance, sound insulation benefits, and structural support.

With options like Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), and Polyisocyanurate (Polyiso) foam board insulation, builders and homeowners have a range of materials to choose from based on their specific needs and requirements. Each type of rigid board insulation offers unique characteristics and benefits, ensuring that there is an ideal solution for diverse applications.

The energy-saving benefits of rigid board insulation cannot be overstated. By providing a reliable thermal barrier, minimizing heat transfer, and reducing HVAC loads, rigid board insulation significantly reduces energy consumption and lowers heating and cooling costs. This not only enhances sustainability but also contributes to a more comfortable and environmentally friendly indoor environment.

Proper installation considerations, such as sizing, airtightness, moisture management, and compatibility with building materials, play a crucial role in maximizing the performance and longevity of rigid board insulation. Consulting with insulation professionals and following manufacturer guidelines ensure an effective installation process that meets building codes and regulations.

In conclusion, rigid board insulation is a versatile and effective solution for enhancing energy efficiency, thermal comfort, and durability in buildings. With its excellent insulation properties, moisture resistance, sound insulation benefits, and structural support, rigid board insulation offers long-term performance and energy savings. By choosing the right type, properly installing, and considering various factors, builders and homeowners can harness the full potential of rigid board insulation, creating sustainable and energy-efficient buildings for years to come.

Frequently Asked Questions about What Is Rigid Board Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Rigid Board Insulation”