Home>Articles>What Is The Ideal Wood Moisture Content For Woodworking

Articles

What Is The Ideal Wood Moisture Content For Woodworking

Modified: December 7, 2023

Learn about the ideal moisture content for woodworking in this informative article. Find out why moisture control is crucial for successful woodworking projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

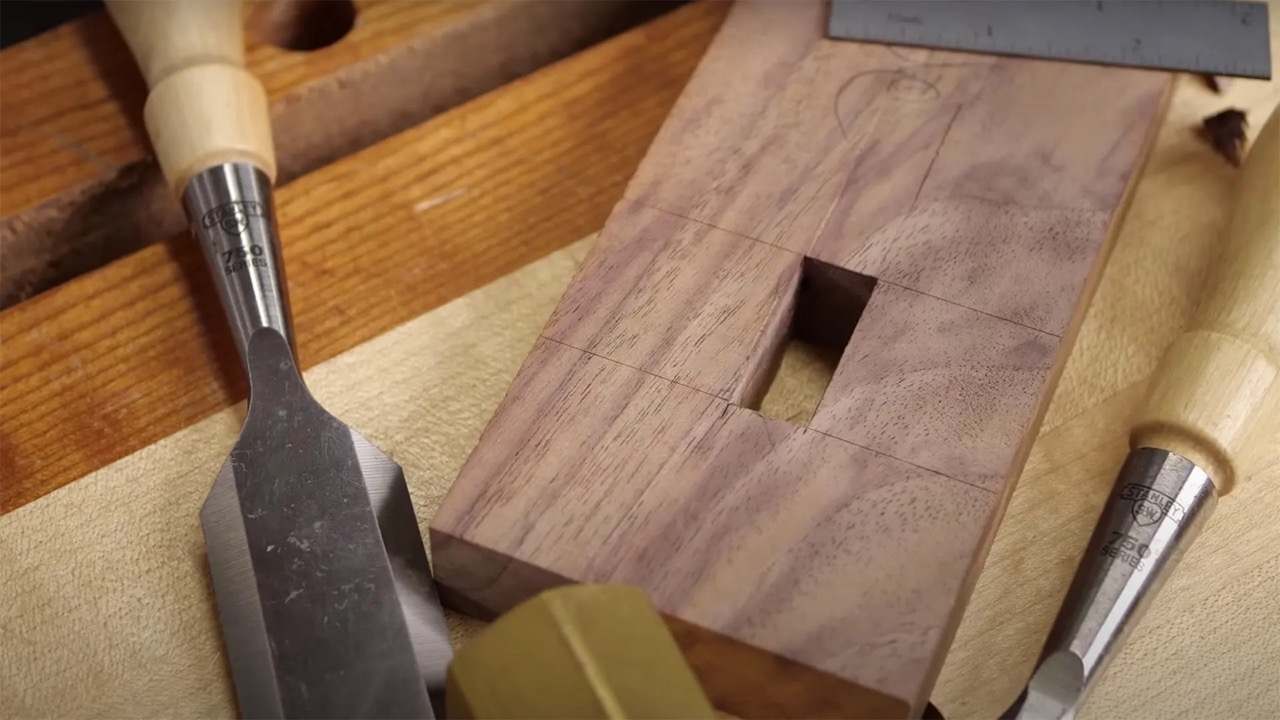

Welcome to the fascinating world of woodworking! Whether you are a seasoned craftsman or just starting out, understanding the importance of moisture content in wood is crucial for creating beautiful, durable, and long-lasting pieces. Wood is a natural material that breathes, expands, and contracts with changes in moisture levels. As such, knowing the ideal moisture content for different types of wood is essential for a successful woodworking project.

In woodworking, moisture content refers to the amount of moisture present in a piece of wood. It is typically expressed as a percentage, representing the weight of the water in the wood compared to the weight of the wood fibers themselves. The moisture content of wood has a direct impact on its dimensional stability, strength, and workability.

Wood with high moisture content is prone to warping, cracking, and shrinking, while wood with low moisture content may become brittle and difficult to work with. Therefore, achieving the appropriate moisture content in woodworking is crucial for ensuring the longevity and quality of the finished piece.

In this article, we will explore the importance of moisture content in woodworking, the ideal moisture content for different types of wood, methods for testing and measuring moisture content, the effects of high or low moisture content, tips for achieving and maintaining the appropriate moisture content, and common mistakes to avoid.

So, grab your tools and let’s dive deeper into the world of wood moisture content!

Key Takeaways:

- Properly managing wood moisture content is crucial for woodworking success. It affects stability, workability, and appearance, so choose the right wood, test moisture content, and avoid common mistakes.

- Understanding ideal moisture content for different wood types, testing methods, and effects of high/low moisture content is key. Achieve and maintain appropriate moisture content for durable, visually appealing woodworking projects.

Read more: How To Inlay Wood With Hand Tools

Importance of Moisture Content in Woodworking

Having the right moisture content in wood is vital for woodworking projects. It directly affects the stability and strength of the finished piece, as well as its overall appearance. Here are some reasons why moisture content is crucial in woodworking:

- Dimensional Stability: Wood is hygroscopic, meaning it absorbs and releases moisture depending on the surrounding environment. When wood is exposed to high humidity or moisture, it swells, causing expansion. Conversely, when wood dries out, it contracts. Understanding and controlling the moisture content ensures dimensional stability in the finished product, reducing the risk of warping, cracking, or splitting.

- Workability: Wood that is too wet or too dry can be challenging to work with. Wet wood is softer and more prone to tear-outs when cut or shaped. Dry wood, on the other hand, may become brittle and difficult to shape without splintering. By maintaining the optimal moisture content, woodworkers can achieve better results in cutting, shaping, and joinery processes.

- Strength and Durability: A balanced moisture content is essential for the structural integrity and longevity of woodworking projects. Excessive moisture weakens the wood fibers, compromising its strength. On the other hand, overly dry wood can become brittle and prone to breakage. By ensuring the right moisture content, woodworkers can create sturdy, reliable, and long-lasting pieces.

- Finishing and Appearance: Wood that is too wet may not accept finishes properly, leading to uneven absorption and poor adhesion. It can also result in issues like raised grain or blotchy stain application. Conversely, if the wood is too dry, it may absorb finishes too quickly, resulting in a blotchy or uneven appearance. Achieving the ideal moisture content ensures that the wood accepts finishes evenly, enhancing its natural beauty and aesthetics.

By understanding the importance of moisture content, woodworkers can successfully manage and manipulate wood to achieve desired outcomes in terms of stability, workability, strength, and appearance. It is essential to consider the moisture content of wood throughout the entire woodworking process, from the selection of materials to the design, construction, and finishing stages.

Now that we’ve explored why moisture content is vital in woodworking let’s move on to understanding the ideal moisture content for different types of wood.

Different Types of Wood and Their Ideal Moisture Content

Wood comes in various species, each with its own characteristics and ideal moisture content. Understanding the moisture content requirements for different types of wood is essential to ensure the best results in your woodworking projects. Here are some common woods and their recommended moisture content ranges:

- Hardwoods: Hardwoods such as oak, maple, walnut, and cherry typically have an ideal moisture content range of 6% to 8%. These woods are commonly used in furniture making, cabinetry, and decorative pieces. Properly dried hardwoods offer stability in terms of dimensional changes and are less likely to warp or crack.

- Softwoods: Softwoods like pine, spruce, and cedar have a slightly higher moisture content range of 9% to 12%. Softwoods are versatile and commonly used in construction, outdoor projects, and decorative accents. A slightly higher moisture content helps softwoods maintain their flexibility and resistance to splitting in outdoor environments.

- Exotic Woods: Exotic woods like teak, mahogany, and ebony require more specific moisture content considerations. The ideal moisture content for these woods can vary depending on the specific species and their intended use. It is essential to consult specific guidelines or suppliers to determine the appropriate moisture content for the particular exotic wood you are working with.

- Green Wood: Green wood refers to freshly cut or recently harvested wood that has not undergone any drying process. Green wood typically has a moisture content above 20% and requires significant drying time to reduce the moisture content to the ideal range for woodworking. Green wood is more prone to movement and should be carefully monitored and dried before use.

It is important to note that the ideal moisture content can also vary depending on the specific project requirements, environmental conditions, and regional climate. Factors such as humidity, temperature, and the intended use of the wood should be considered when determining the appropriate moisture content.

Woodworkers can use various tools and techniques to measure the moisture content of wood, such as moisture meters and oven drying methods. These methods allow for precise monitoring and adjustment of the moisture content to meet the desired range.

By understanding the moisture content requirements for different types of wood, woodworkers can ensure that their projects are built to last, with minimal issues related to stability, durability, and appearance.

Next, let’s explore the methods used for testing and measuring wood moisture content.

Testing and Measuring Wood Moisture Content

Accurately measuring the moisture content of wood is essential for ensuring the quality and durability of woodworking projects. There are several methods and tools available for testing and measuring wood moisture content, each with its own advantages and limitations. Here are some commonly used techniques:

- Moisture Meters: Moisture meters are handheld devices specifically designed to measure the moisture content of wood. They work by sending electrical currents through the wood and measuring the resistance. Moisture meters provide instant readings and are widely used due to their convenience and accuracy. There are two main types of moisture meters: pin-type and pinless. Pin-type meters use metal pins inserted into the wood, while pinless meters use sensors that scan the surface. Both types have their own benefits and are suitable for different woodworking scenarios.

- Oven-Drying Method: The oven-drying method involves weighing a wood sample, drying it in an oven at a specific temperature, and then reweighing it to determine the moisture content. This method provides accurate results and is commonly used as a reference standard. However, it can be time-consuming and may not be practical for on-site or large-scale projects.

- Electrical Resistance Method: The electrical resistance method utilizes specialized moisture meters that measure the electrical resistance between two electrodes placed on the wood’s surface. This method is quick and non-destructive but may require calibration and may be influenced by factors such as wood species, grain orientation, and temperature.

- Relative Humidity Testing: Relative humidity (RH) testing involves placing moisture sensors in close contact with the wood and monitoring the surrounding humidity. This method provides insights into the equilibrium moisture content of the wood, which is the moisture content it stabilizes at in a given environment. While relative humidity testing does not directly measure the moisture content, it helps understand how wood will behave in specific conditions.

When testing and measuring wood moisture content, it is important to take multiple readings from different parts of the wood to account for any variations. Additionally, it is essential to follow the instructions provided by the manufacturer for each specific testing method or tool to ensure accurate results.

The choice of testing method depends on factors such as project size, budget, portability requirements, and desired level of accuracy. Utilizing a combination of different methods can provide a more comprehensive assessment of the wood’s moisture content and help eliminate potential inaccuracies.

By regularly testing and monitoring the moisture content of wood throughout the woodworking process, craftsmen can make informed decisions and take appropriate measures to achieve and maintain the desired moisture content for optimal results in their projects.

Now that we’ve explored the methods for testing and measuring wood moisture content let’s examine the effects of high or low moisture content in woodworking.

Wood for woodworking should have a moisture content of 6-8% for indoor projects and 12-14% for outdoor projects. Use a moisture meter to ensure the wood is at the correct level before starting any project.

The Effects of High or Low Moisture Content in Woodworking

The moisture content of wood plays a significant role in the final outcome of woodworking projects. Both high and low moisture content can have adverse effects on the wood, compromising its stability, strength, and overall quality. Here are some of the effects of high or low moisture content in woodworking:

- High Moisture Content: When wood has a high moisture content, it is more prone to dimensional changes and movement. Excessive moisture can lead to warping, bowing, cupping, or twisting of the wood, making it challenging to work with and compromising the structural integrity of the finished piece. High moisture content also increases the risk of mold, fungi, and rot, which can deteriorate the wood over time.

- Low Moisture Content: On the other hand, wood with a low moisture content can become brittle and prone to cracking. It loses its flexibility and becomes challenging to shape or join without causing splits or fractures. Low moisture content can also result in an insufficient bond between adhesives and wood surfaces, leading to weak joints and potential failure. Additionally, dry wood may not accept finishes properly, resulting in uneven absorption and poor adhesion.

- Joint Failure: In woodworking, joints are crucial for the structural integrity of furniture, cabinets, and other wooden structures. High or low moisture content in wood can compromise the strength of joints. In high moisture environments, wood swells, placing excessive stress on the joints and leading to joint failure. In low moisture environments, joints may become loose or weakened due to the shrinkage of wood, leading to instability.

- Surface Defects: Both high and low moisture content can result in surface defects in wood. High moisture content can cause raised grain, leading to a rough and uneven surface. It can also result in blotchy stain application and poor adhesion of finishes. Low moisture content, on the other hand, can cause checking, splitting, and splintering on the wood surface, affecting its appearance and overall quality.

- Long-Term Durability: Wood with improper moisture content is more susceptible to long-term durability issues. High moisture can lead to decay, attracting pests and insects, and compromising the wood’s structure and integrity. Dry wood, on the other hand, may become prone to cracking and splitting over time, reducing its lifespan and durability.

To mitigate these effects, it is crucial to ensure that the moisture content of wood is within the appropriate range for the specific woodworking project and the target environment. Regularly testing and monitoring the moisture content, and taking necessary measures to bring it within the desired range, will greatly contribute to the success and longevity of the finished piece.

Next, let’s explore how woodworkers can achieve and maintain the appropriate moisture content in their woodworking projects.

Read more: What Should A Humidifier Be Set At

Achieving and Maintaining the Appropriate Moisture Content

Achieving and maintaining the appropriate moisture content in wood is crucial for successful woodworking. Here are some key steps and considerations to ensure that the wood used in your projects has the desired moisture content:

- Wood Selection: Start by selecting wood that is properly kiln-dried or air-dried to the appropriate moisture content. Kiln-dried wood is dried in a controlled environment, while air-dried wood is naturally dried over time. Both methods aim to reduce the moisture content to the desired range for optimal stability. Purchase wood from reputable suppliers who provide moisture content information for the specific wood species.

- Acclimation Period: Allow the wood to acclimate to the surrounding environment before starting your project. This will give the wood time to adjust to the humidity and temperature of the space. Acclimating the wood helps minimize moisture content changes once it is used in the project, reducing the risk of dimensional changes and defects.

- Monitoring and Testing: Regularly monitor and test the moisture content of the wood during different stages of the project. Use moisture meters or other testing methods to ensure that the moisture content remains within the desired range. Take multiple readings from different parts of the wood to account for any variations.

- Proper Storage: Store wood in a controlled environment with stable humidity and temperature conditions. Avoid exposing it to extreme changes in moisture levels, as this can cause the wood to absorb or release moisture, leading to dimensional changes. Use appropriate storage techniques, such as stacking wood with spacers to allow for air circulation and prevent moisture buildup.

- Sealing or Conditioning: When working with highly absorbent woods or in environments with extreme moisture variations, consider sealing the wood or conditioning it before use. Sealing the wood with appropriate finishes, such as sealers or primers, helps reduce moisture absorption or loss. Conditioning involves gradually adjusting the moisture content of the wood to match the target environment.

- Proper Joinery Techniques: Use proper joinery techniques that account for wood movement. Incorporate techniques such as loose-fitting joints, elongated screw holes, or floating panels to allow for natural expansion and contraction of the wood due to moisture changes. This helps prevent joint failure and structural issues.

- Regular Maintenance: Regularly inspect and maintain finished wood projects to ensure that the moisture content remains within the desired range. Perform necessary repairs or adjustments if any signs of dimensional changes or moisture damage are observed.

By following these steps and considerations, woodworkers can achieve and maintain the appropriate moisture content in their projects. This will help ensure dimensional stability, strength, and longevity of the finished piece, while reducing the risk of issues related to high or low moisture content.

However, it is important to note that wood is a natural material, and some minor changes in moisture content may still occur over time due to fluctuations in the surrounding environment. Regular monitoring and adjustments may be necessary to maintain the ideal moisture content in long-term projects or in areas with extreme environmental conditions.

Now, let’s discuss some common mistakes to avoid when dealing with wood moisture content.

Common Mistakes to Avoid in Wood Moisture Content

Properly managing the moisture content of wood is crucial for successful woodworking. Avoiding common mistakes can help ensure that the wood used in your projects remains stable, durable, and high in quality. Here are some common mistakes to avoid when dealing with wood moisture content:

- Skipping Moisture Content Testing: Neglecting to test and monitor the moisture content of the wood is a common mistake. Without knowing the moisture content, you risk working with wood that is either too wet or too dry, leading to potential issues such as warping, cracking, or joint failure. Regularly test the moisture content throughout the project to make informed decisions and adjustments.

- Using Green Wood: Working with green or freshly cut wood with a high moisture content can lead to significant problems. Green wood requires proper drying before use to reduce the moisture content to the appropriate range. Avoid using green wood as it can result in excessive dimensional changes and other issues associated with high moisture content.

- Not Allowing for Wood Acclimation: Failing to allow the wood to acclimate to the environment before starting a project can cause problems. Wood needs time to adjust to the humidity and temperature of its surroundings. Skipping the acclimation period can lead to moisture content changes during or after construction, resulting in dimensional instability.

- Working with Inconsistent Moisture Content: Using wood with varying moisture content throughout a project can result in uneven dimensional changes and joint failure. Ensure that all wood pieces have a similar moisture content, especially in projects where different wood pieces are joined together. This helps maintain consistency and reduces the risk of stress on the joints.

- Ignoring Environmental Factors: Failure to consider environmental factors such as humidity and temperature can impact the moisture content of wood. Wood is always trying to reach equilibrium with its environment, so changes in humidity can cause the moisture content of wood to fluctuate. Take into account the environmental conditions of the woodworking space and adjust accordingly to maintain the desired moisture content.

- Overlooking Proper Storage: Improper storage of wood can lead to moisture content issues. Storing wood in damp or poorly ventilated areas can result in excessive moisture absorption. On the other hand, storing wood in excessively dry environments can cause the wood to dry out and become brittle. Properly store wood in a controlled environment with stable humidity and temperature conditions.

- Not Factoring in Wood Movement: Wood expands and contracts with changes in moisture content. Failure to account for this movement in the design and construction of a project can lead to joint failure or structural issues. Incorporate joinery techniques that allow for natural wood movement, such as leaving proper gaps or using floating components.

- Ignoring Finishing Considerations: Finishes can impact the moisture content of wood. Applying finishes or sealers without considering the moisture content can trap moisture in the wood or hinder proper moisture exchange. Follow the manufacturer’s guidelines for applying finishes and ensure that the wood is within the appropriate moisture content range before sealing or finishing.

Avoiding these common mistakes and being proactive in managing wood moisture content will greatly improve the success and quality of your woodworking projects. By understanding and addressing these potential pitfalls, you can ensure that the wood used in your projects remains stable, durable, and aesthetically pleasing.

Now that we’ve explored the common mistakes to avoid, let’s wrap up our discussion.

Conclusion

Understanding and managing the moisture content of wood is essential for successful woodworking projects. The moisture content of wood directly impacts its dimensional stability, workability, strength, and overall appearance. By maintaining the appropriate moisture content, woodworkers can ensure that their creations are durable, visually appealing, and built to last.

In this article, we explored the importance of moisture content in woodworking and its effects on the wood. We learned that high moisture content can lead to warping, cracking, and decay, while low moisture content can result in brittleness and difficulty in working with the wood. We also discussed the ideal moisture content ranges for different types of wood and methods for testing and measuring moisture content.

To achieve and maintain the appropriate moisture content in wood, it is crucial to carefully select properly dried wood, allow for acclimation, monitor and test the moisture content throughout the project, and implement proper storage and joinery techniques. Avoiding common mistakes such as skipping moisture content testing, using green wood, and ignoring environmental factors will help ensure the success of your woodworking projects.

By paying attention to the moisture content of wood, woodworkers can create pieces that are structurally sound, aesthetically pleasing, and resilient against environmental factors. Properly managed moisture content minimizes the risk of issues such as warping, splitting, and joint failure, ultimately resulting in high-quality, long-lasting woodworking projects.

So, as you embark on your woodworking journey, remember the significance of moisture content in wood and the impact it has on the success of your projects. By understanding, testing, and managing the moisture content of wood, you have the power to create beautiful, functional, and enduring pieces of craftsmanship.

Frequently Asked Questions about What Is The Ideal Wood Moisture Content For Woodworking

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Ideal Wood Moisture Content For Woodworking”