Home>diy>Architecture & Design>What Does CAD Stand For In 3D Printing

Architecture & Design

What Does CAD Stand For In 3D Printing

Modified: August 23, 2024

Discover what CAD stands for in the world of 3D printing and understand its significance in architecture design. Unveil the power of CAD technology today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to the world of 3D printing and design, CAD is a term that often pops up. But what does CAD actually stand for, and why is it so crucial in the realm of 3D printing? In this article, we will explore the meaning of CAD in the context of 3D printing, its applications, benefits, and challenges.

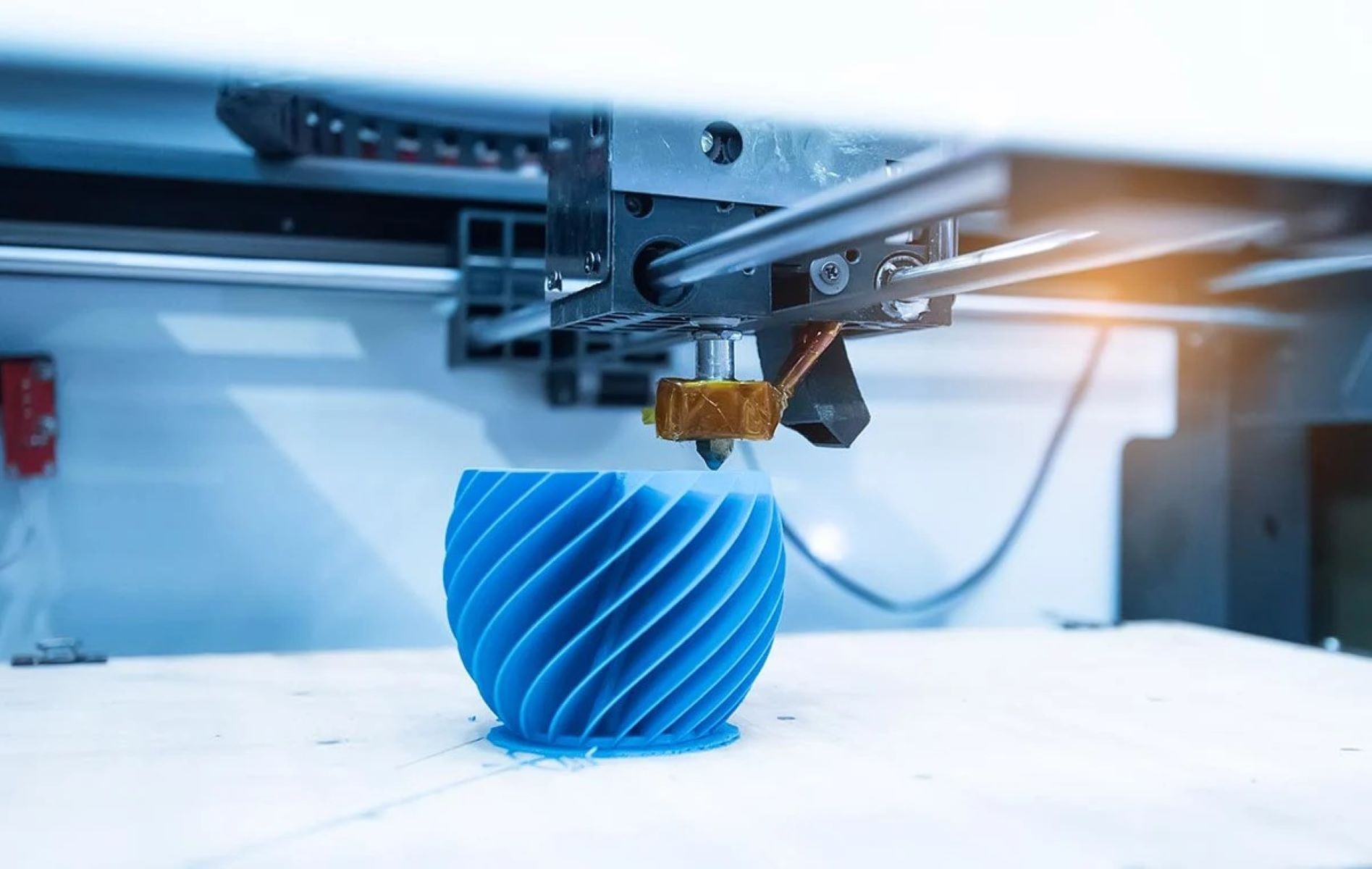

CAD stands for Computer-Aided Design. It refers to the use of computer software to create, modify, and optimize designs for various purposes. In the case of 3D printing, CAD plays a vital role in transforming creative ideas into tangible 3D models.

Before the advent of CAD, designers would create blueprints and physical prototypes manually, which was a time-consuming and labor-intensive process. With the introduction of CAD software, designers gained access to advanced tools and functionalities that revolutionized the way objects are designed and produced.

CAD software allows designers to create digital models of objects, providing them with complete control over every aspect of the design. From simple geometric shapes to complex mechanical parts, CAD software enables the creation of intricate designs with precision and accuracy. This level of control and precision is essential for successful 3D printing.

Today, CAD software is widely used by professionals in various industries, including engineering, architecture, product design, and manufacturing. The seamless integration of CAD and 3D printing has opened up new possibilities for creative expression and has transformed the way prototypes and functional parts are developed.

In the next sections, we will delve deeper into the definition of CAD, its applications in 3D printing, the benefits it brings to the design process, and the challenges faced when using CAD in conjunction with 3D printing technology.

Key Takeaways:

- CAD, or Computer-Aided Design, is a powerful software technology that revolutionizes the design process by enabling precision, customization, and rapid prototyping in the realm of 3D printing.

- While CAD brings efficiency and innovation to 3D printing, designers must navigate challenges such as software complexity, material considerations, and post-processing requirements to ensure successful outcomes.

Read more: How To Create A CAD File For 3D Printing

Definition of CAD

CAD, short for Computer-Aided Design, is a software-based technology that allows designers and engineers to create, modify, analyze, and optimize digital models of products and objects. CAD software provides a comprehensive set of tools and functionalities that enable users to design with precision and accuracy.

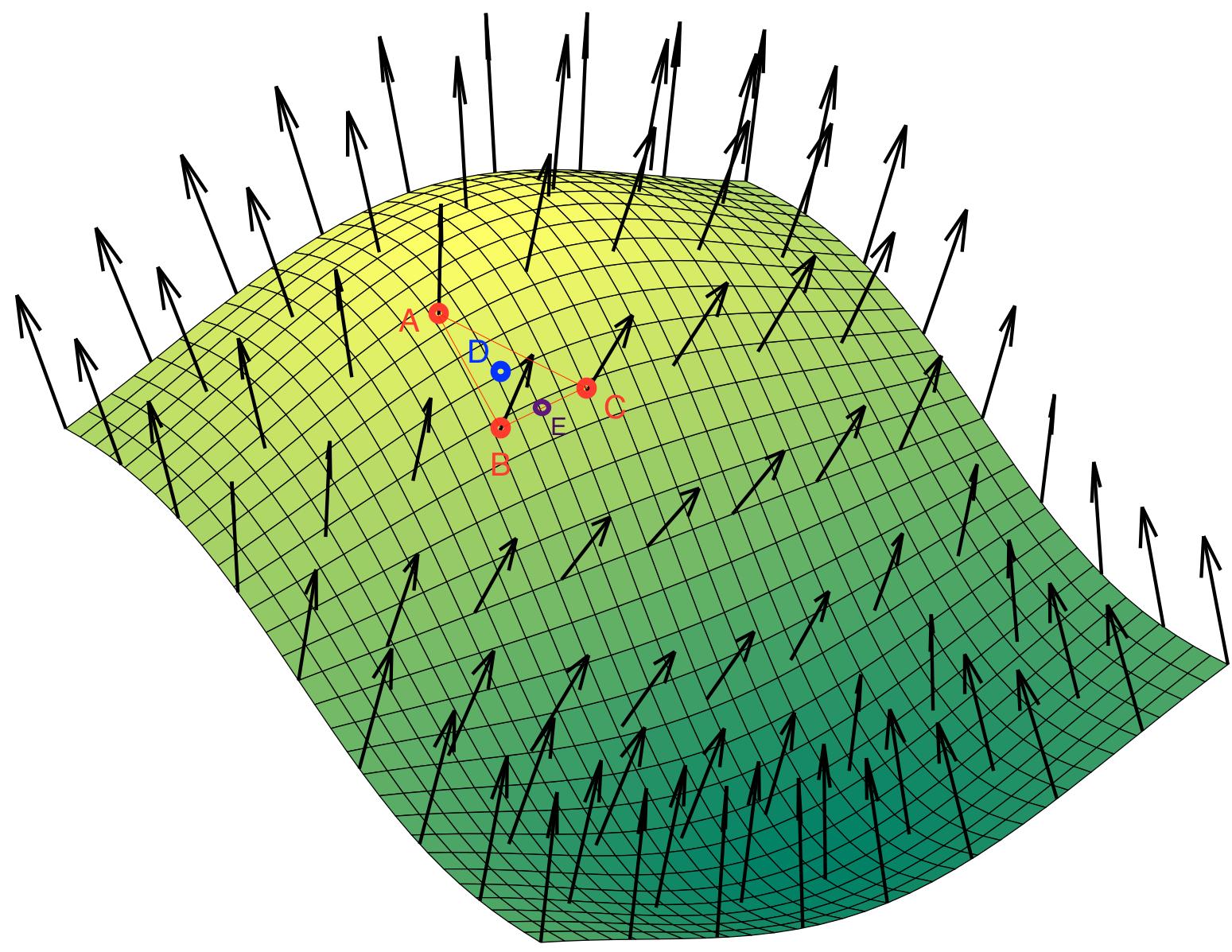

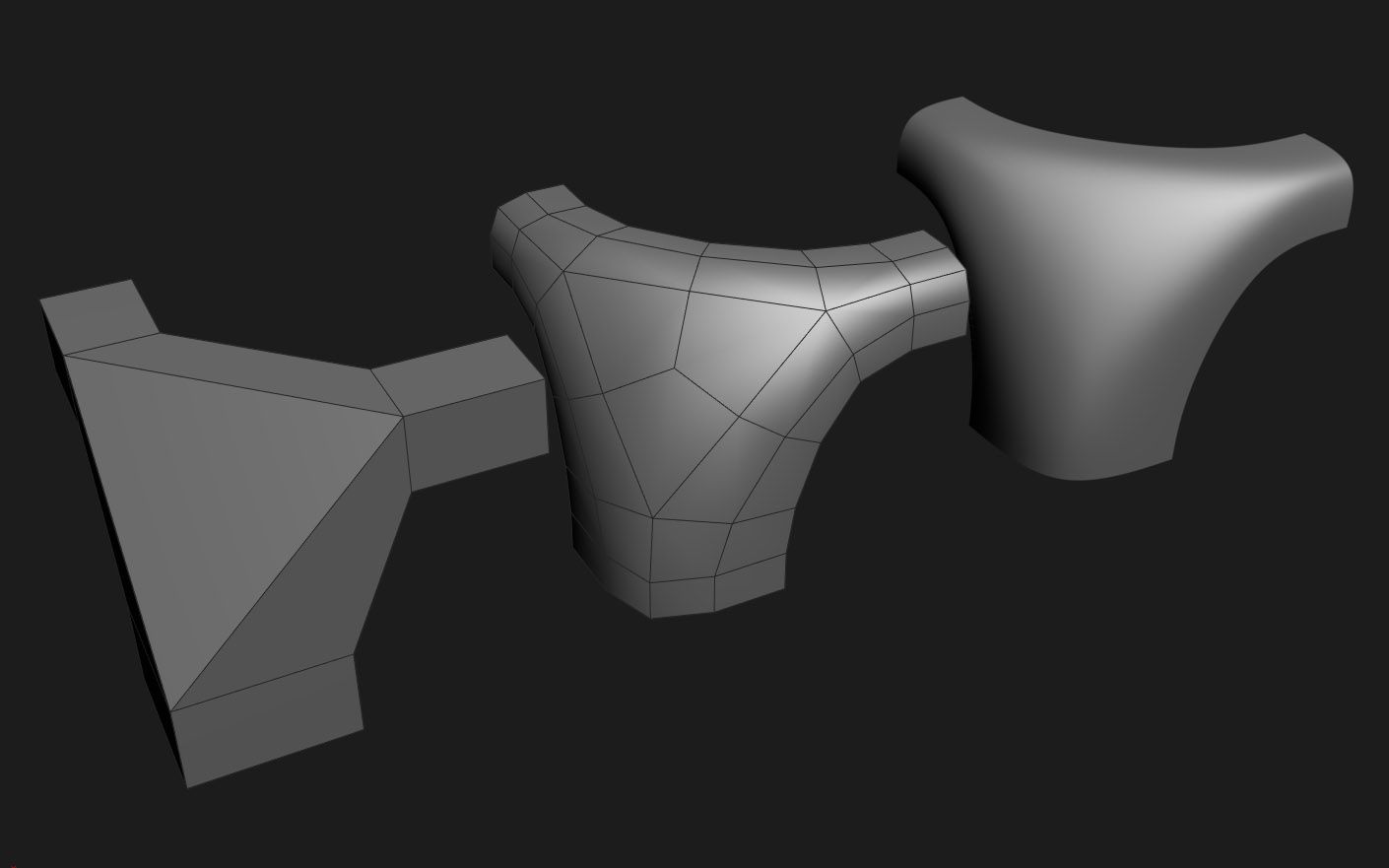

With CAD, designers can create 2D or 3D representations of objects using geometric shapes, lines, curves, and surfaces. These models serve as virtual prototypes that can be viewed and manipulated on a computer screen. The software offers features like zooming, rotating, and scaling to examine the design from different angles and perspectives.

CAD software also allows designers to apply various materials, textures, and colors to their models, providing a realistic visual representation of the final product. Additionally, CAD enables the inclusion of detailed annotations, dimensions, and other technical information, ensuring accurate and clear communication between designers, engineers, and manufacturers.

One of the key advantages of CAD is its parametric modeling capability. This means that the dimensions and properties of the design can be easily modified by changing the input parameters. Whenever a change is made, the model automatically adjusts accordingly, minimizing the need for manual rework. This flexibility allows designers to quickly iterate and refine their designs, resulting in improved efficiency and time-saving.

CAD software is often equipped with a wide range of specialized tools for specific design disciplines. For example, architectural CAD software offers features tailored for building design, while mechanical CAD software provides tools for creating intricate mechanical parts and assemblies. This versatility makes CAD applicable to diverse industries and design fields.

Moreover, CAD software supports file formats that are compatible with 3D printers, enabling direct translation of digital models into physical objects. This seamless integration between CAD and 3D printing has played a significant role in advancing the capabilities and accessibility of additive manufacturing.

In summary, CAD is a powerful tool that empowers designers and engineers to bring their ideas to life by creating precise and realistic digital models. Its versatility, parametric modeling capabilities, and integration with 3D printing make it an essential component of the modern design and manufacturing process.

Applications of CAD in 3D Printing

CAD has a wide range of applications in the field of 3D printing, revolutionizing the way objects are designed, prototyped, and manufactured. Here are some key areas where CAD plays a crucial role:

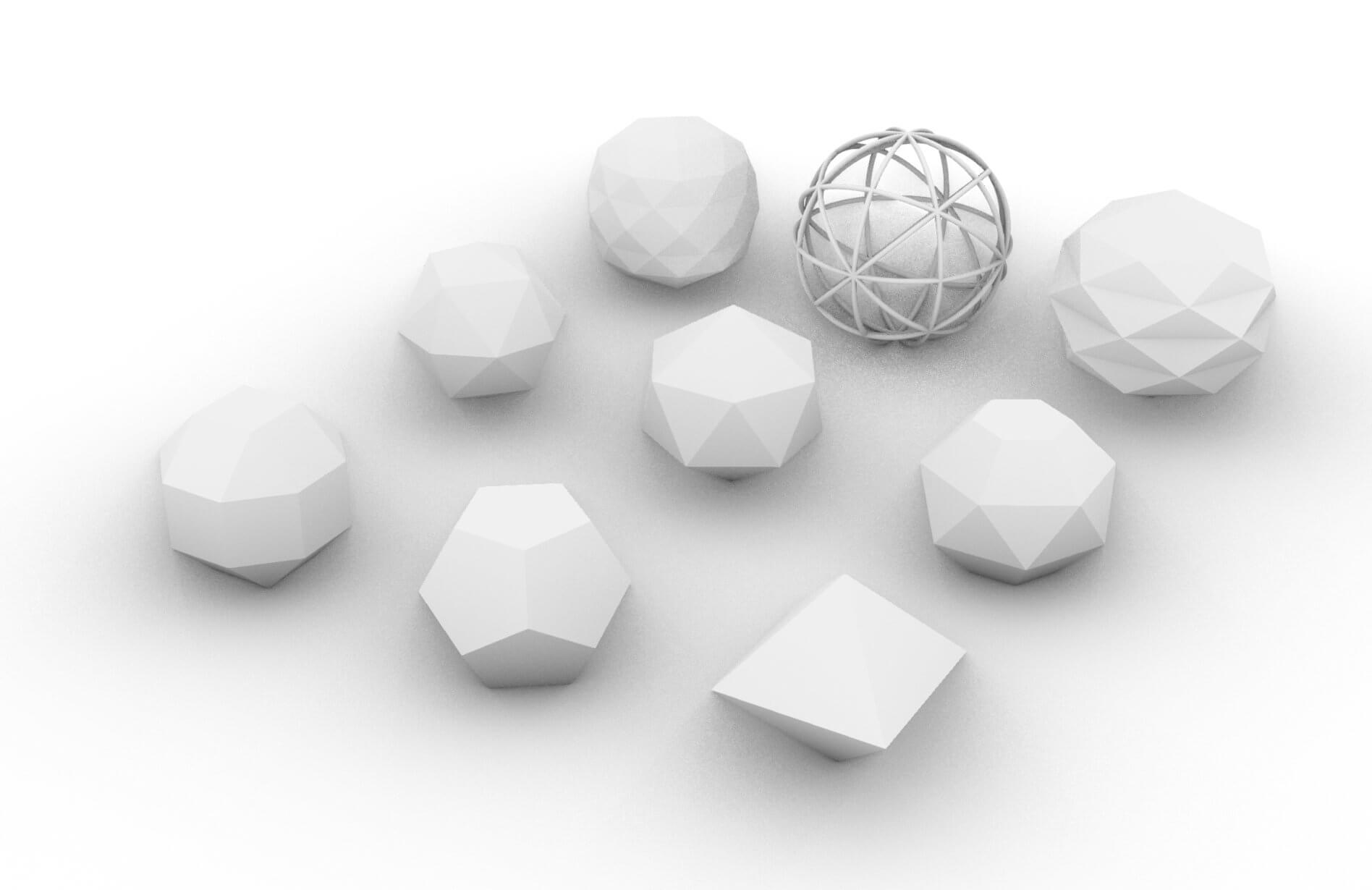

- Product Design: CAD enables product designers to create intricate and complex designs for a wide range of industries. Whether it’s consumer products, automotive parts, medical devices, or architectural elements, CAD software allows designers to visualize and refine their ideas before bringing them to life with 3D printing.

- Prototyping: One of the most significant advantages of CAD in 3D printing is its ability to rapidly prototype designs. With CAD, designers can create detailed virtual models, make adjustments based on user feedback, and quickly produce physical prototypes through 3D printing. This iterative process saves time and resources, allowing for faster product development cycles.

- Customization and Personalization: CAD software enables intricate customization and personalization of designs. Whether it’s creating bespoke jewelry, personalized phone cases, or tailored prosthetics, CAD allows designers to adapt their designs to meet the unique needs and preferences of individuals.

- Architectural Modeling: CAD software offers specialized features for architectural design and visualization. Architects can create detailed 3D models of buildings, incorporating fine details and exploring different design options. This allows stakeholders to have a better understanding of the final product and make informed decisions before construction begins.

- Engineering and Mechanical Design: CAD is widely used in engineering and mechanical design to create complex parts and assemblies. Engineers can simulate stresses, forces, and movement within the design to ensure its functionality and durability. This helps in identifying potential design flaws and optimizing designs for efficient manufacturing and assembly.

- Education and Learning: CAD is increasingly being incorporated into educational curricula to teach design and engineering principles. Students can learn design thinking, problem-solving, and digital modeling skills through CAD software, preparing them for careers in various industries that utilize 3D printing technologies.

These are just a few examples of the many applications of CAD in 3D printing. The combination of CAD software and 3D printing technology opens up endless possibilities for innovation, creativity, and efficiency in the design and manufacturing processes.

CAD stands for Computer-Aided Design. It is the use of computer software to create 2D or 3D models, which are essential for 3D printing as they serve as the blueprint for the object being printed.

Benefits of CAD in 3D Printing

The integration of CAD with 3D printing technology brings numerous benefits to the design and manufacturing process. Here are some key advantages of using CAD in 3D printing:

- Efficiency and Time Savings: CAD enables designers to quickly create and modify digital models, saving time compared to traditional manual drafting methods. The parametric modeling capabilities of CAD allow for easy design iterations, reducing the time required to refine and finalize a design. This efficiency translates into shorter product development cycles and faster time-to-market.

- Precision and Accuracy: CAD software ensures high levels of precision and accuracy in design. Designers can specify exact dimensions, tolerances, and other specifications, which translates into precise and consistent 3D printed objects. This precision is essential for functional parts and prototypes that require specific geometries and complex assemblies.

- Design Visualization: CAD provides a realistic visual representation of the final product before it is 3D printed. Designers can visualize the object from different angles, apply textures and colors, and simulate real-world environments. This helps in making informed design decisions and effectively communicating ideas with clients, stakeholders, and manufacturers.

- Complex Geometry and Customization: CAD software allows designers to create objects with intricate and complex geometries that may be impossible or challenging to produce with traditional manufacturing methods. From organic shapes to intricate lattice structures, CAD enables the realization of highly customized and visually stunning designs that were once only a dream.

- Prototyping and Iterative Design: CAD, combined with 3D printing, enables rapid prototyping and iterative design cycles. Designers can quickly convert their digital models into physical prototypes, allowing for hands-on testing, verification, and user feedback. This iterative process helps identify design flaws, optimize functionality, and reduce costly errors before committing to full production.

- Design Optimization and Simulation: CAD software offers powerful simulation tools that allow designers to test the performance and functionality of their designs before printing. They can simulate factors like stress, heat, fluid flow, and assembly interactions to optimize designs for better performance and minimize production issues. This reduces the risk of design failures and ensures optimal functionality.

These benefits highlight the significant role that CAD plays in enhancing the capabilities and efficiency of 3D printing. CAD empowers designers to unleash their creativity, produce highly customized objects, and optimize designs for better performance and functionality.

Challenges of CAD in 3D Printing

While CAD brings numerous benefits to the world of 3D printing, it also presents some challenges that designers and engineers need to address. Here are some key challenges associated with CAD in 3D printing:

- Complexity of CAD Software: CAD software can be complex and feature-rich, requiring a significant learning curve for users who are new to the technology. Designers need to invest time and effort into mastering the software and its various tools to fully harness its capabilities.

- Design Limitations: Despite the flexibility of CAD software, there are practical limitations in designing for 3D printing. Certain intricate geometries, overhangs, or unsupported structures may require additional support structures or modifications to ensure successful printing. Designers must be aware of these limitations and design with them in mind.

- Material Considerations: Not all CAD designs can be directly translated into 3D printed objects. Different materials have specific properties and limitations, and designers need to consider the material requirements, such as strength, flexibility, and heat resistance, when designing for 3D printing. Material selection can significantly impact the success and performance of the final 3D printed object.

- Printability and Resolution: Designers need to ensure that their CAD models are printable with the selected 3D printing technology. Factors like resolution, layer thickness, and print bed size need to be considered to optimize the design for successful printing. Ignoring these factors may result in failed prints or loss of intricate details.

- File Compatibility: CAD software supports various file formats, and ensuring compatibility between the CAD file and the 3D printer is crucial. Designers must export the CAD file in a format that the specific 3D printer can read and process, avoiding compatibility issues and potential errors during the printing process.

- Cost Considerations: Designing complex models with intricate details may lead to longer print times and higher material costs. Designers need to strike a balance between design complexity and affordability, considering factors like print time, material usage, and post-processing requirements for successful printing within budget constraints.

- Post-Processing Requirements: 3D printed objects often require post-processing to achieve the desired finish and functionality. Designers need to consider additional steps like sanding, painting, assembly, or support removal to ensure the final object meets the intended specifications. These post-processing tasks can add time and effort to the overall production process.

Addressing these challenges requires a deep understanding of both CAD software and the specific requirements of 3D printing. Designers must continuously update their skills, stay informed about the latest advancements in both domains, and consider these challenges when designing for optimal results.

Conclusion

The combination of CAD and 3D printing has revolutionized the world of design and manufacturing. CAD software, with its powerful tools and functionalities, enables designers to create, modify, and optimize digital models with precision and accuracy. When integrated with 3D printing technology, CAD brings numerous benefits to the design process, including efficiency, customization, rapid prototyping, and the ability to produce complex geometries.

However, using CAD in conjunction with 3D printing also presents its fair share of challenges. Designers must overcome the complexities of CAD software, consider design limitations and material requirements, optimize designs for printability, and address compatibility and cost considerations. Post-processing tasks may also be necessary to achieve the desired finish and functionality of 3D printed objects.

Despite these challenges, the advantages of CAD in 3D printing outweigh the drawbacks. CAD empowers designers to visualize and refine their ideas, rapidly prototype designs, and optimize functionality before committing to full production. It enables customization, complex geometries, and the ability to simulate and test designs for optimal performance. The integration of CAD with 3D printing technology opens up new possibilities for innovation, creativity, and efficiency in various industries.

To overcome these challenges, designers should continuously update their skills and stay informed about the latest advancements in both CAD software and 3D printing technology. Collaboration and communication between designers, engineers, and manufacturers are key to ensuring successful outcomes in the design and manufacturing process.

In conclusion, CAD is an indispensable tool in the realm of 3D printing. Its ability to transform digital models into physical objects has revolutionized the way products are designed, prototyped, and manufactured. With CAD and 3D printing, the possibilities are endless, and designers are poised to shape a future where creativity and innovation know no bounds.

Frequently Asked Questions about What Does CAD Stand For In 3D Printing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does CAD Stand For In 3D Printing”