Home>diy>Building & Construction>How Does 3D Printing Help In A Construction Project

Building & Construction

How Does 3D Printing Help In A Construction Project

Modified: January 24, 2024

Discover how 3D printing revolutionizes building-construction, offering faster, more efficient methods for creating custom structures and reducing construction costs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Over the past few decades, technology has dramatically transformed many industries, and the construction sector is no exception. One of the most promising innovations in recent years is 3D printing. This cutting-edge technology has the potential to revolutionize the construction industry by increasing efficiency, reducing costs, and enabling architects and engineers to push the boundaries of design. In this article, we will explore how 3D printing is being implemented in the construction sector and the various benefits it offers.

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects by depositing layers of material based on a digital model. While the concept may seem futuristic, it has already started to make its mark in various industries, including aerospace, healthcare, automotive, and now, construction.

Traditional construction methods often require months, if not years, of manual labor, extensive logistical planning, and the use of numerous materials. 3D printing, on the other hand, has the potential to significantly reduce construction time and labor costs. By using specialized 3D printers that can extrude concrete or other construction materials in precise shapes, entire structures can be built in a matter of days or weeks.

But speed is not the only advantage of 3D printing in construction. This technology also enables architects and designers to create complex and intricate structures that were once thought impossible. The flexibility of 3D printing allows for unique shapes, organic curves, and custom designs, giving architects and engineers newfound freedom to explore innovative and sustainable construction solutions. This not only enhances the aesthetic value but also improves the overall functionality and durability of the structures.

Another major advantage of 3D printing in construction is the potential to reduce material waste. Traditional construction methods often involve over-ordering materials to account for any miscalculations or unforeseen circumstances. With 3D printing, materials can be used more efficiently as they are only deposited precisely where they are needed. This not only reduces waste but also decreases the environmental impact of construction projects.

In the next sections of this article, we will delve deeper into the various applications of 3D printing in construction and discuss real-world examples of how this technology is being implemented. We will also explore the challenges and limitations of 3D printing in construction and speculate on its future potential. So, let’s continue our journey into the world of 3D printing in construction and explore the exciting possibilities it holds.

Key Takeaways:

- 3D printing in construction offers speed, efficiency, and design freedom, revolutionizing the industry by reducing construction time, costs, and material waste while enabling architects to create intricate and sustainable structures.

- Despite challenges, the future of 3D printing in construction looks promising, with increased adoption, advancements in materials, on-site printing, and integration with other technologies, paving the way for innovation, sustainability, and improved efficiency in the built environment.

Read more: What Is 3D Printing Construction

Overview of 3D Printing Technology

Before we delve into the applications and benefits of 3D printing in construction, let’s take a closer look at how this technology works.

3D printing, also known as additive manufacturing, is a process that involves creating three-dimensional objects by depositing layers of material on top of each other. This is in contrast to traditional manufacturing methods, which involve subtracting material through cutting, drilling, or molding.

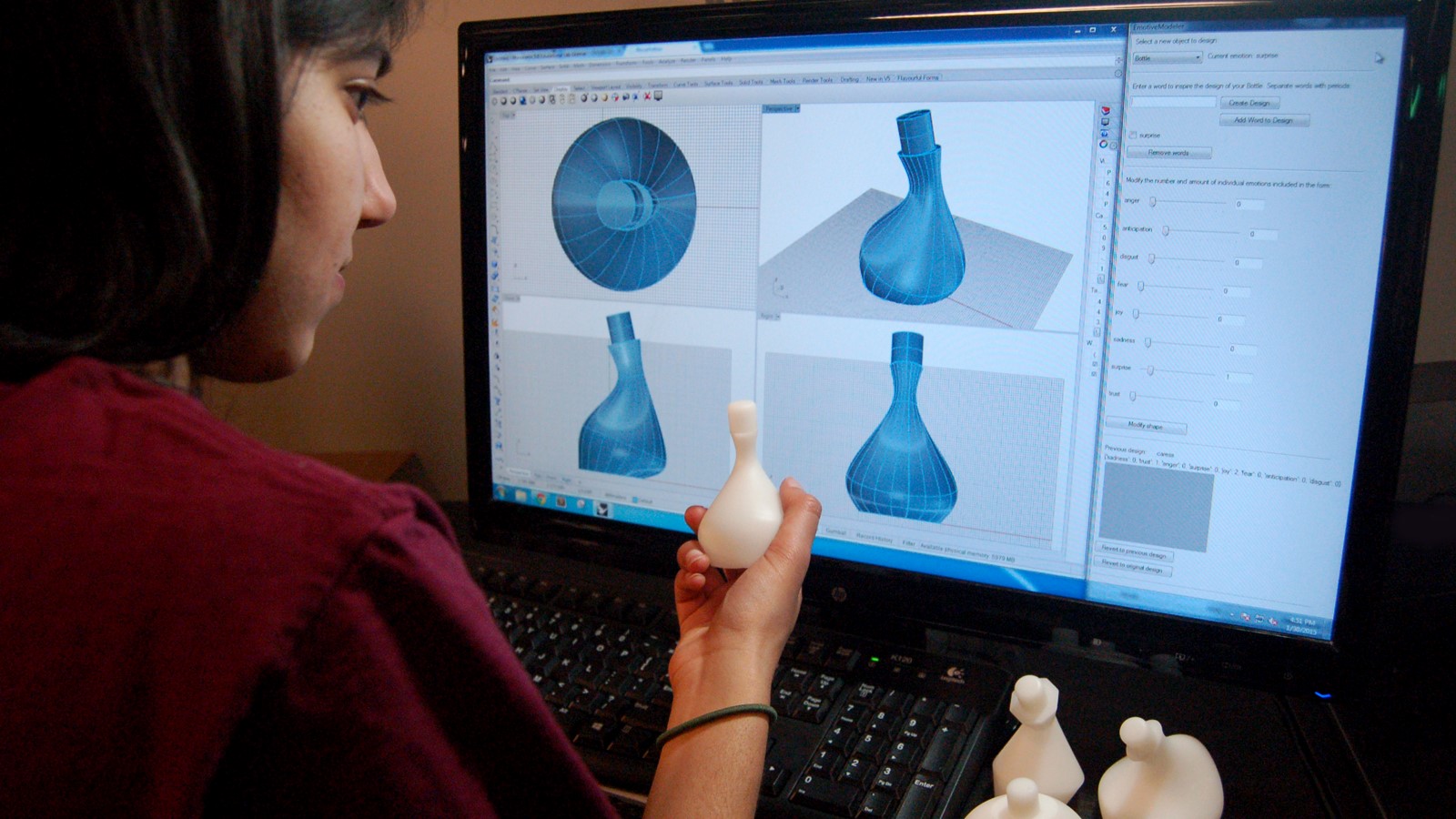

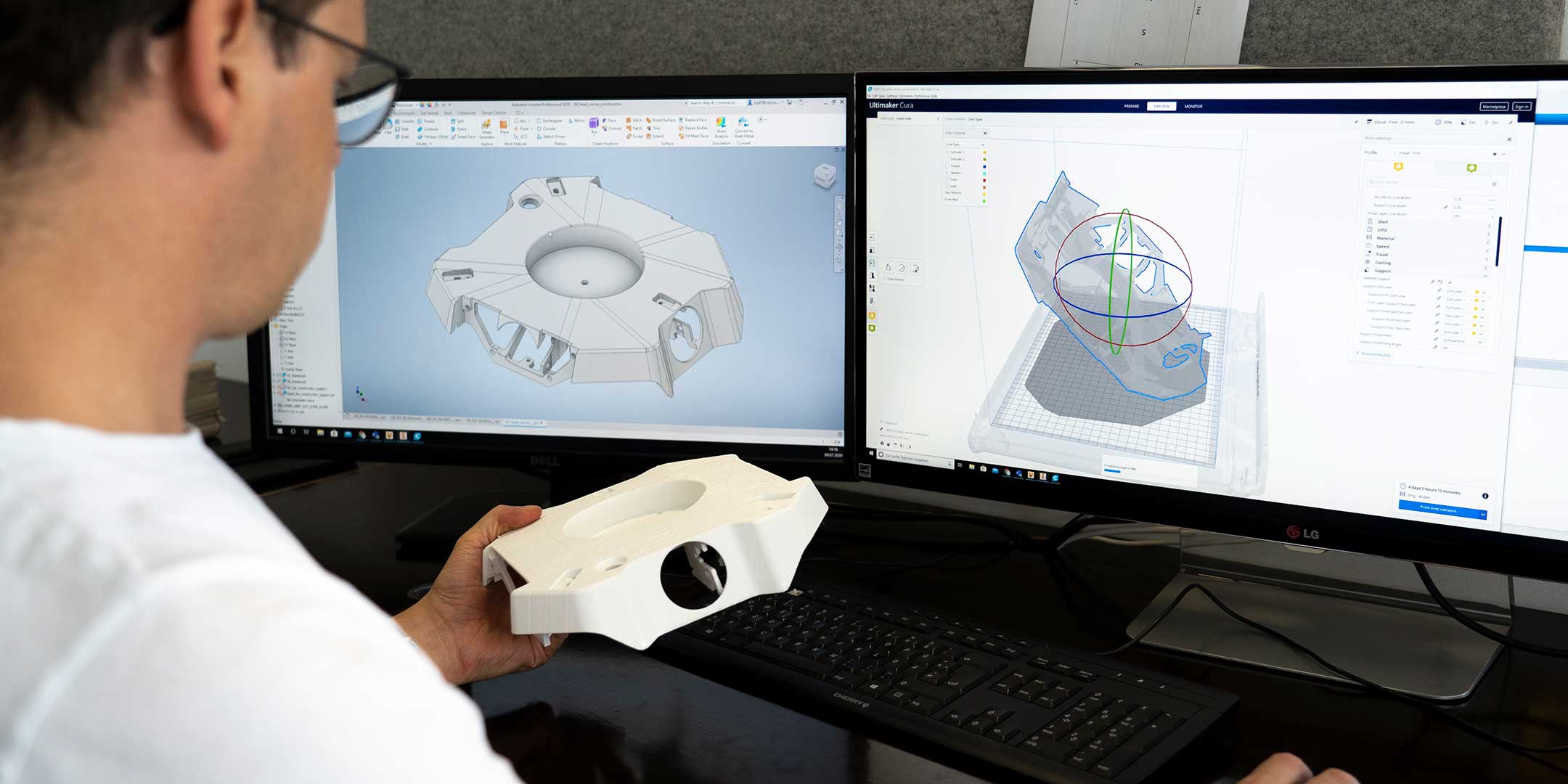

The foundation of 3D printing lies in a digital model or design. This design is created using computer-aided design (CAD) software, which allows architects and engineers to create intricate and precise objects. The digital design is then translated into a format that can be read by the 3D printer.

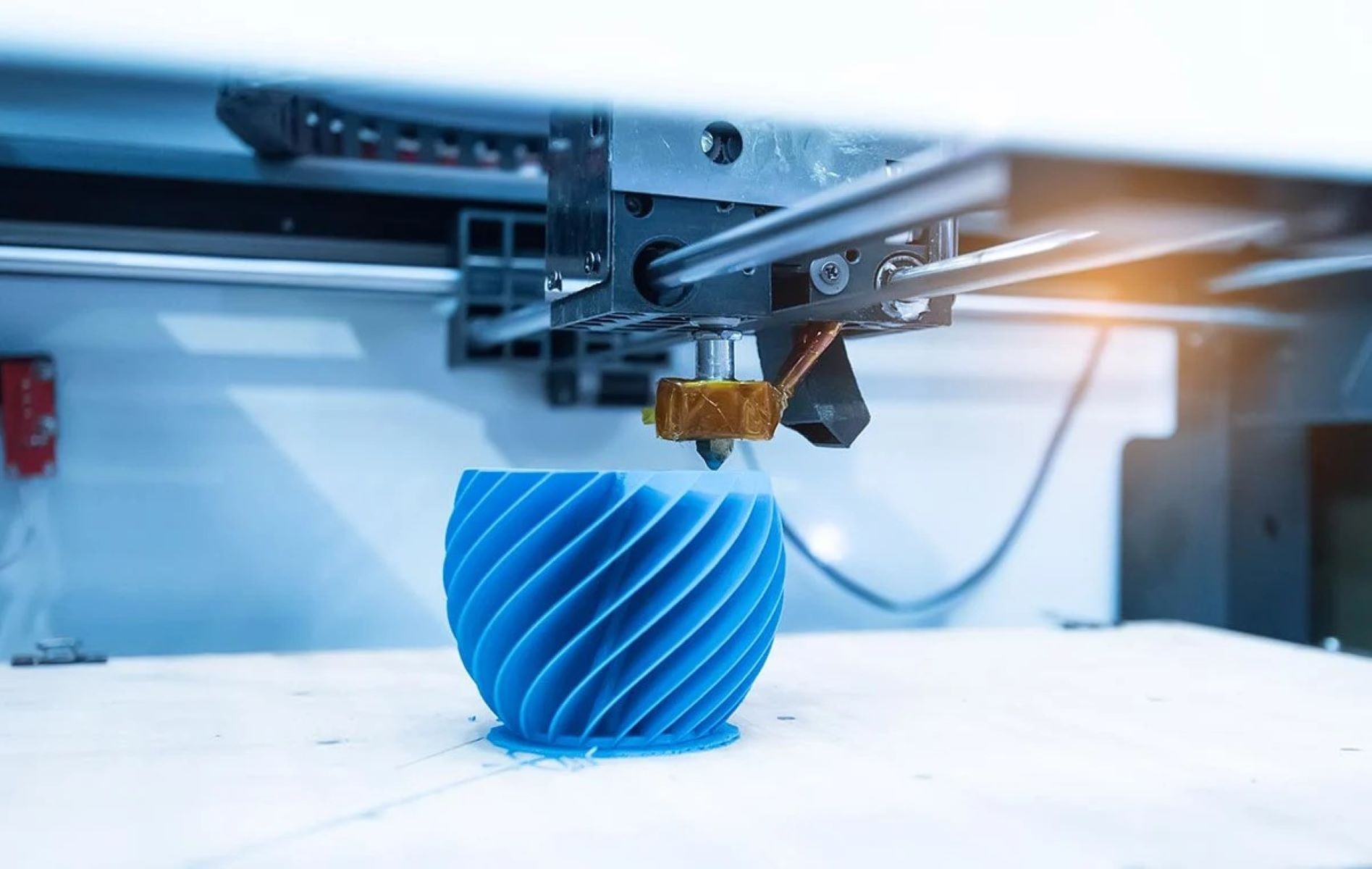

Once the design is ready, the 3D printer begins the printing process. There are several different types of 3D printers, but the most common method used in construction is known as extrusion-based printing. In this method, a specially formulated material, such as concrete, is loaded into the printer’s extruder.

The extruder heats the material until it reaches a semi-liquid state, allowing it to be easily squeezed out through a nozzle. As the material is extruded, it solidifies almost instantly, creating the desired shape. The printer moves along predefined paths, layer by layer, until the complete object is formed.

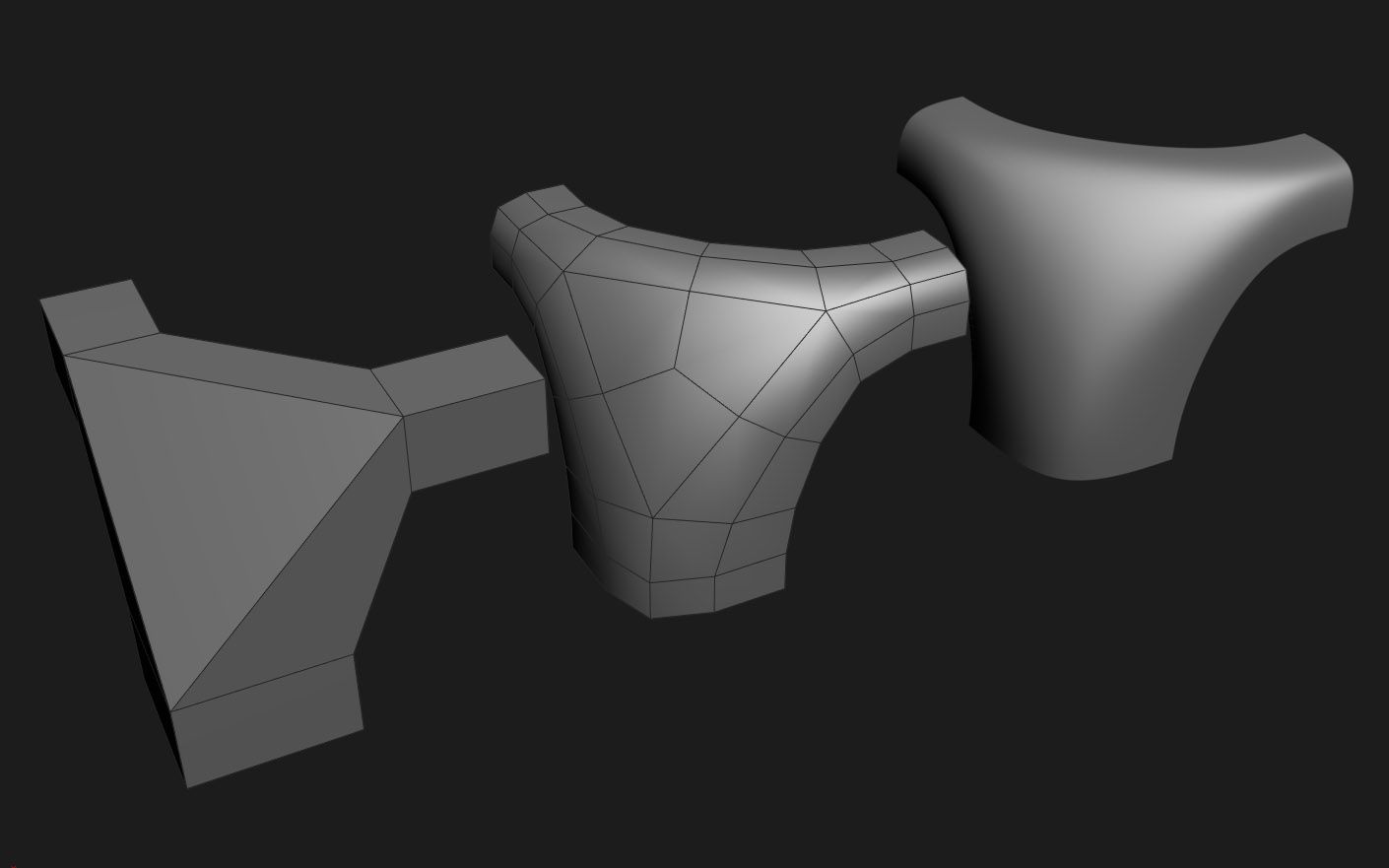

One of the key advantages of 3D printing is its ability to create complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods. This opens up a whole new world of possibilities for architects and designers, enabling them to create structures with unique shapes and intricate details.

In addition, 3D printing allows for a high level of customization. Unlike mass production, where each object is identical, 3D printing enables the creation of custom-made objects tailored to specific requirements. This level of customization is particularly valuable in the construction industry, where each project often has unique specifications and constraints.

Furthermore, 3D printing technology offers significant time and cost savings. Traditional construction methods can be labor-intensive and time-consuming, often involving multiple contractors and extensive coordination. With 3D printing, entire structures can be printed in a fraction of the time, reducing construction timelines and labor costs.

It is important to note that 3D printing technology is still evolving and being refined for construction applications. Researchers and industry experts are continuously exploring new materials, improving print quality, and developing more advanced printing techniques. As the technology progresses, we can expect even greater advancements in the field of 3D printing in construction.

In the following sections, we will explore the many advantages and applications of 3D printing in construction, providing insights into how this innovative technology is transforming the industry.

Advantages of 3D Printing in Construction

3D printing has the potential to revolutionize the construction industry by offering numerous advantages over traditional construction methods. Let’s explore some of the key benefits of using 3D printing technology in construction:

- Speed and Efficiency: One of the significant advantages of 3D printing in construction is its ability to significantly reduce construction time. Traditional construction methods often involve lengthy processes, coordination between various contractors, and manual labor that can span months or even years. With 3D printing, entire structures can be printed in a matter of days or weeks, offering substantial time savings. This increased efficiency not only streamlines construction projects but also enables quicker completion deadlines and faster project turnaround times.

- Cost Savings: 3D printing technology has the potential to significantly reduce construction costs. By eliminating the need for a large workforce and reducing material waste, construction projects can be completed at a fraction of the cost compared to traditional methods. Additionally, as 3D printing becomes more widely adopted, economies of scale will come into play, further driving down the cost of materials and equipment.

- Design Freedom and Flexibility: 3D printing allows for unparalleled design freedom and flexibility in construction. Architects and designers can create complex and intricate structures, including curved walls, unique geometries, and customized features, that were once challenging or impossible to achieve with traditional construction methods. This design flexibility opens up new possibilities for creative expression and architectural innovation, resulting in visually stunning and functionally efficient structures.

- Sustainability: Sustainable construction practices are becoming increasingly important in today’s world. 3D printing technology promotes sustainability in several ways. First, it reduces material waste by only using the necessary amount of material for the construction project. Additionally, the ability to create highly efficient and lightweight structures allows for optimal resource utilization. Furthermore, 3D printing enables the use of eco-friendly and recyclable materials, contributing to a greener and more sustainable construction industry.

- Improved Safety and Quality: 3D printing technology offers improved safety and quality in construction. By automating the construction process, it reduces the need for workers to perform dangerous tasks at great heights or in hazardous environments. This, in turn, minimizes the risk of accidents and injuries on construction sites. Additionally, the precision and accuracy of 3D printing ensure consistent quality, eliminating human error and producing reliable and durable structures.

These advantages clearly demonstrate the potential impact of 3D printing on the construction industry. However, it is essential to understand that the widespread adoption of 3D printing in construction is still in its early stages. As the technology continues to advance and more research is conducted, we can expect to see even greater benefits and applications of 3D printing in construction.

Applications of 3D Printing in Construction

The applications of 3D printing in construction are numerous and diverse, ranging from small-scale components to entire buildings. Let’s explore some of the key areas where 3D printing technology is being implemented:

- Prototyping and Conceptual Design: 3D printing technology allows architects and designers to create physical models and prototypes of their designs quickly and accurately. This enables them to visualize and test their concepts before proceeding with full-scale construction. The ability to physically hold and examine a model helps to identify design flaws, make necessary modifications, and improve the overall design process.

- Structural Components: 3D printing is increasingly being used to fabricate structural components of buildings, such as walls, columns, and beams. By using large-scale 3D printers, these components can be printed directly on-site, eliminating the need for costly and time-consuming transportation. The design freedom offered by 3D printing allows for the creation of optimized structures, resulting in lighter, stronger, and more efficient building elements.

- Facades and Ornamental Features: The intricate and complex designs that can be achieved through 3D printing make it an ideal technology for creating elaborate facades and ornamental features. 3D printed facades can incorporate detailed patterns, textures, and intricate geometries, adding a unique visual appeal to buildings. Additionally, the customization options offered by 3D printing allow for the creation of one-of-a-kind ornamental elements that can enhance the overall aesthetics of a structure.

- Modular Construction: 3D printing enables the creation of modular components that can be easily assembled on-site to construct entire buildings. These prefabricated modules can be produced off-site and then transported to the construction site, resulting in faster and more efficient construction. Modular construction using 3D printing reduces labor costs, minimizes construction waste, and allows for greater precision in the manufacturing and assembly process.

- Infrastructure and Disaster Relief: 3D printing technology has the potential to reshape how infrastructure is built in remote or disaster-affected areas. By using portable 3D printers, it becomes possible to rapidly construct temporary or permanent structures, such as emergency shelters, bridges, and even entire communities. The ability to quickly deploy 3D printing technology in these situations can provide a cost-effective and efficient solution for rebuilding and restoring infrastructure.

These are just a few examples of the many applications of 3D printing in the construction industry. As the technology continues to advance and gain wider acceptance, we can expect to see even more innovative applications and creative uses of 3D printing in the construction of buildings and infrastructure.

When using 3D printing in construction, consider the benefits of reduced material waste, faster construction times, and the ability to create complex and customized designs.

Case Studies and Examples

Several real-world examples demonstrate the practical application of 3D printing technology in the construction industry. Let’s take a look at a few notable case studies:

- Apis Cor Project, Russia: In 2017, the Russian company Apis Cor made headlines by successfully 3D printing a house in just 24 hours. Using a robotic arm, the company extruded layers of a special concrete mix to construct the walls of the house. The project showcased the potential of 3D printing to rapidly build affordable and durable homes, especially in remote or disaster-stricken areas.

- Office of the Future, Dubai: Dubai is known for its architectural marvels, and 3D printing has found its way into the city’s skyline. The Office of the Future, completed in 2016, became the first fully functional 3D-printed office building. The entire structure, including walls, floors, and furniture, was 3D printed using a specialized cement-based mixture. This project showcased how 3D printing technology can be used to construct innovative and sustainable office spaces.

- MX3D Bridge, Netherlands: The MX3D Bridge in Amsterdam is a groundbreaking project that showcases the potential of 3D printing for large-scale infrastructure. In collaboration with architects and engineers, MX3D used industrial robotic 3D printers to create a stainless steel pedestrian bridge. The bridge, which spans the Oudezijds Achterburgwal canal, demonstrates the feasibility of using 3D printing to create complex and structurally sound infrastructure.

- WinSun Demonstration, China: In 2014, the Chinese construction company WinSun gained international attention by 3D printing ten houses in a single day. Using a mix of construction waste and a specially formulated concrete material, WinSun showcased the potential of 3D printing technology to address affordable housing challenges and reduce construction waste.

- Italian Pavilion, 2015 Milan Expo: The Italian Pavilion at the 2015 Milan Expo was an architectural masterpiece created using 3D printing. The futuristic structure, shaped like a sea urchin, was made up of 1,600 printed pieces assembled on-site. The project not only demonstrated the design possibilities of 3D printing but also highlighted its potential for constructing eye-catching and sustainable buildings.

These case studies illustrate the diverse applications of 3D printing in construction, ranging from residential buildings and office spaces to infrastructure and architectural wonders. They serve as a testament to the transformative power of 3D printing technology in the construction industry, paving the way for innovation, sustainability, and improved efficiency.

Challenges and Limitations of 3D Printing in Construction

While 3D printing technology holds tremendous promise for the construction industry, it is important to acknowledge that there are still significant challenges and limitations that need to be overcome. Below are some of the key challenges associated with 3D printing in construction:

- Scale and Size: 3D printing large-scale structures presents a major challenge. Most 3D printers available today have limitations on the size of the objects they can print. Constructing multi-story buildings or large infrastructure projects using 3D printing technology is still a complex and costly process that requires specialized equipment and techniques.

- Material Selection and Compatibility: Another limitation of 3D printing in construction is the limited range of materials that can be used. While concrete is the most commonly used material for construction 3D printing, other building materials such as steel, wood, or glass are not yet widely compatible with 3D printing processes. Developing new materials that are suitable for 3D printing and meet building code requirements is a significant challenge.

- Regulatory and Code Compliance: The adoption of 3D printing in construction necessitates the development of new regulations and building codes specific to this innovative technology. Regulatory bodies and authorities need to establish guidelines and standards to ensure the safety, structural integrity, and durability of 3D-printed structures. This process may take time, as it involves navigating complex legal and regulatory frameworks.

- Skills and Expertise: The successful implementation of 3D printing in construction requires a skilled workforce familiar with the technology and its intricacies. Architects, engineers, and construction professionals need to acquire the necessary knowledge and training to design and construct 3D-printed structures effectively. Currently, there is a shortage of professionals with expertise in 3D printing technology, which poses a challenge to its widespread adoption.

- Cost of Equipment and Infrastructure: Investing in large-scale 3D printers and infrastructure required for construction 3D printing can be costly. The initial investment in the equipment, materials, and technical support needed for construction 3D printing can be a barrier for smaller construction firms or economies with limited resources. However, as the technology matures and becomes more widely adopted, the cost is expected to decrease.

While these challenges and limitations exist, it is worth noting that the construction industry has always been marked by innovation and adaptation. As 3D printing technology continues to advance and more research and development is conducted, many of these challenges are likely to be addressed. Over time, we can expect improvements in scalability, materials compatibility, regulatory frameworks, and the availability of skilled professionals in the field of 3D printing in construction.

Despite the challenges, the potential benefits of 3D printing in construction far outweigh the limitations. As the technology continues to evolve, it has the capacity to revolutionize the construction industry and reshape the way we design, build, and inhabit our built environment.

Future of 3D Printing in Construction

The future of 3D printing in construction is brimming with possibilities and holds the potential to reshape the industry in significant ways. As the technology continues to advance and more research is conducted, we can expect to see several developments in the coming years:

- Increased Adoption and Integration: As awareness and understanding of 3D printing in construction grow, we can anticipate a higher rate of adoption across the industry. More construction companies, architects, and engineers will recognize the value and benefits of 3D printing and incorporate it into their projects. This increased integration of 3D printing technology will drive further innovation and specialization in the field.

- Advancements in Materials: The development of new materials that are compatible with 3D printing will open up even more design possibilities in construction. Researchers are already exploring the use of sustainable and recyclable materials, as well as light-weight and high-strength composites that have excellent thermal and acoustic properties. These advancements will contribute to more efficient and sustainable construction practices.

- Widespread Use of Robotics and Automation: Robotics and automation will play a crucial role in the future of 3D printing in construction. The integration of robotic arms and automated systems will streamline the printing process, improve accuracy, and increase production speeds. This will not only enhance efficiency but also reduce labor costs and minimize human error.

- On-Site 3D Printing: Currently, most 3D printing in construction takes place in a controlled environment, such as a factory. However, in the future, on-site 3D printing is expected to become more prevalent. This will eliminate the need for transportation and assembly of printed components, further reducing construction timelines and costs.

- Bespoke and Customized Construction: 3D printing facilitates high levels of customization, allowing architects and designers to create unique, one-of-a-kind structures. In the future, we can expect to see a surge in bespoke and customized construction projects. These projects will cater to specific client needs and site conditions, resulting in truly personalized and tailored architectural solutions.

- Integration of IoT and Building Information Modeling (BIM): The integration of 3D printing with other emerging technologies, such as the Internet of Things (IoT) and Building Information Modeling (BIM), will revolutionize the construction process. Real-time monitoring of printed structures, automated data collection, and integration with BIM software will enhance quality control, improve project management, and enable predictive maintenance.

The future of 3D printing in construction is exciting and holds immense potential for innovation, sustainability, and improved construction practices. As the technology matures, we can expect to see more intricate and complex structures, increased cost savings, reduced project timelines, and a greater emphasis on customization and sustainability in the built environment.

However, it is important to note that the full realization of the future of 3D printing in construction will require collaboration between industry stakeholders, continuous research and development, and the establishment of regulatory frameworks to ensure safety and compliance. With ongoing advancements and investments in the field, 3D printing technology has the power to revolutionize the construction industry, driving us towards a more efficient, sustainable, and imaginative built environment.

Conclusion

3D printing technology has the potential to transform the construction industry by offering numerous advantages over traditional methods. Its ability to reduce construction timelines, lower costs, enable intricate design possibilities, and promote sustainability makes it a promising innovation for the future of construction.

By utilizing 3D printing in construction, architects and engineers can push the boundaries of design, create complex structures, and customize buildings to meet specific requirements. The flexibility of this technology allows for the construction of unique and innovative designs that were once unimaginable.

Additionally, 3D printing in construction can enhance efficiency and sustainability. It reduces material waste by using only the necessary amount of material, offers better resource utilization, and supports the use of eco-friendly materials. This aligns with the increasing demand for green and sustainable construction practices.

While there are challenges and limitations associated with 3D printing in construction, ongoing research and development, as well as collaboration between industry stakeholders, will address these issues over time. The future of 3D printing in construction looks promising, with increased adoption, advancements in materials, on-site printing, integration with other technologies, and wider customization options.

As the construction industry embraces 3D printing, it will redefine the way we build and inhabit structures. With faster construction times, cost savings, improved design capabilities, and increased sustainability, 3D printing has the potential to revolutionize the construction industry for the better.

As we move forward, it is essential for architects, engineers, construction professionals, and regulatory bodies to embrace and explore the possibilities of 3D printing in construction. This innovative technology will shape the future of construction, offering new opportunities for creativity, efficiency, and sustainability in building practices.

Frequently Asked Questions about How Does 3D Printing Help In A Construction Project

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does 3D Printing Help In A Construction Project”