Home>diy>Architecture & Design>Why Is 3D Modeling Important?

Architecture & Design

Why Is 3D Modeling Important?

Modified: January 4, 2024

Discover the significance of 3D modeling in architecture design and its impact on creating innovative and accurate visual representations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

3D modeling has revolutionized the way we design and create products, structures, and environments. This powerful technology has become an essential tool in various industries, ranging from architecture and manufacturing to healthcare and entertainment. Through the use of advanced software and techniques, 3D modeling allows us to create virtual representations of physical objects, spaces, and concepts.

But why is 3D modeling important? In this article, we will explore how 3D modeling enhances visual representations, improves design and prototyping, streamlines production processes, enhances communication and collaboration, reduces costs and saves time, and finds applications in various industries.

So, let’s dive into the world of 3D modeling and discover its significance in today’s technological landscape.

Key Takeaways:

- 3D modeling enhances visual representations by providing realistic renderings, enabling virtual walkthroughs, and supporting simulations and virtual reality experiences. Its ability to bring designs to life before they are actualized is a game-changer in many industries.

- 3D modeling vastly improves the design and prototyping process by offering flexibility, enabling analysis and optimization, enhancing collaboration, and facilitating the creation of physical prototypes. It empowers designers and engineers to create better, more efficient, and more functional products.

Read more: How Hard Is 3D Modeling

Enhancing Visual Representations

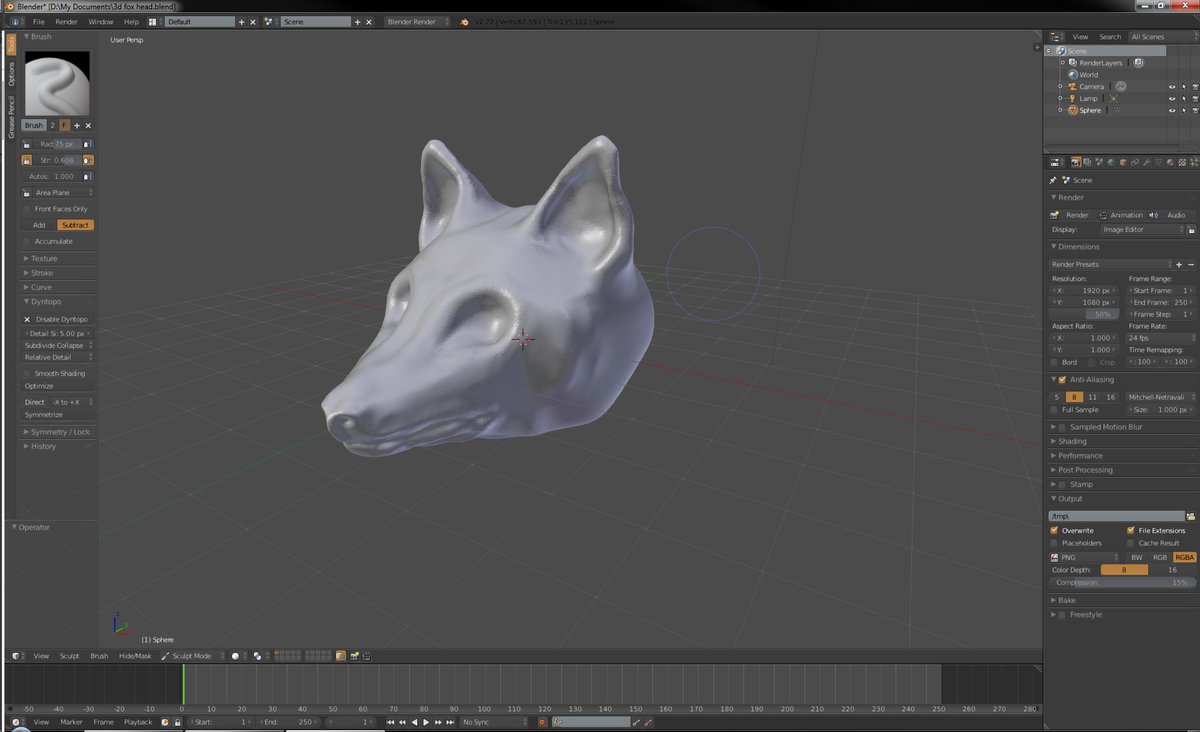

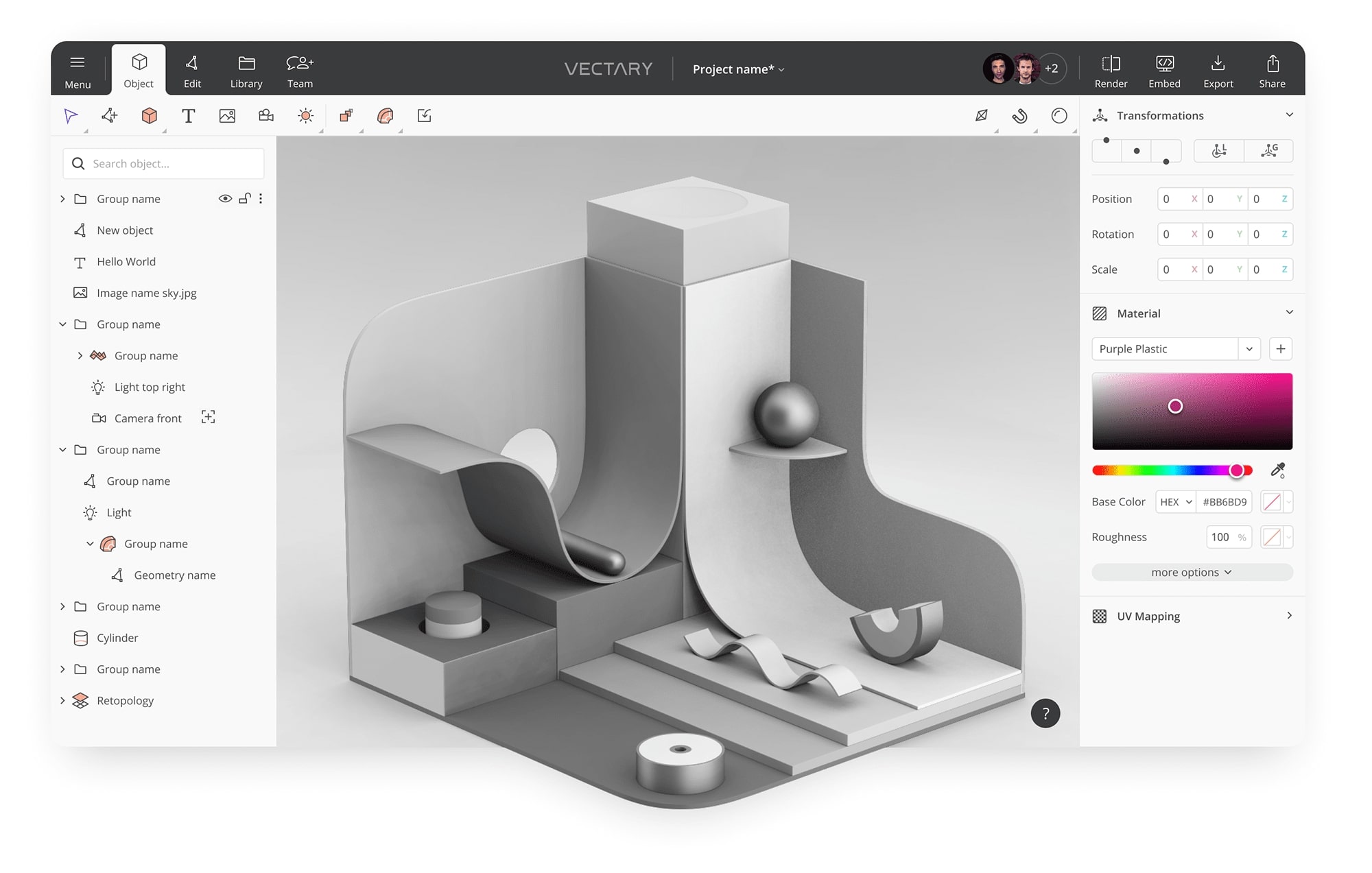

One of the major reasons why 3D modeling is important is its ability to enhance visual representations. Unlike traditional 2D designs, 3D models provide a more realistic and immersive representation of objects and spaces. By incorporating depth, texture, and lighting, 3D models allow designers and stakeholders to visualize the final product or environment before it is built.

With 3D modeling, architects can create virtual walkthroughs of buildings, allowing clients to experience the space and make informed decisions about the design. Interior designers can present realistic renderings of room layouts, enabling clients to visualize different furniture arrangements and color schemes. Additionally, product designers can create lifelike prototypes, giving them a better understanding of how the final product will look and function.

Moreover, 3D modeling enables the creation of photorealistic visualizations. By simulating materials, lighting conditions, and environmental factors, designers can generate visuals that closely resemble reality. This not only aids in marketing efforts but also helps in identifying design flaws and making necessary improvements. Whether it’s architectural visualization, product rendering, or character animation, 3D modeling opens up endless possibilities for visually stunning representations.

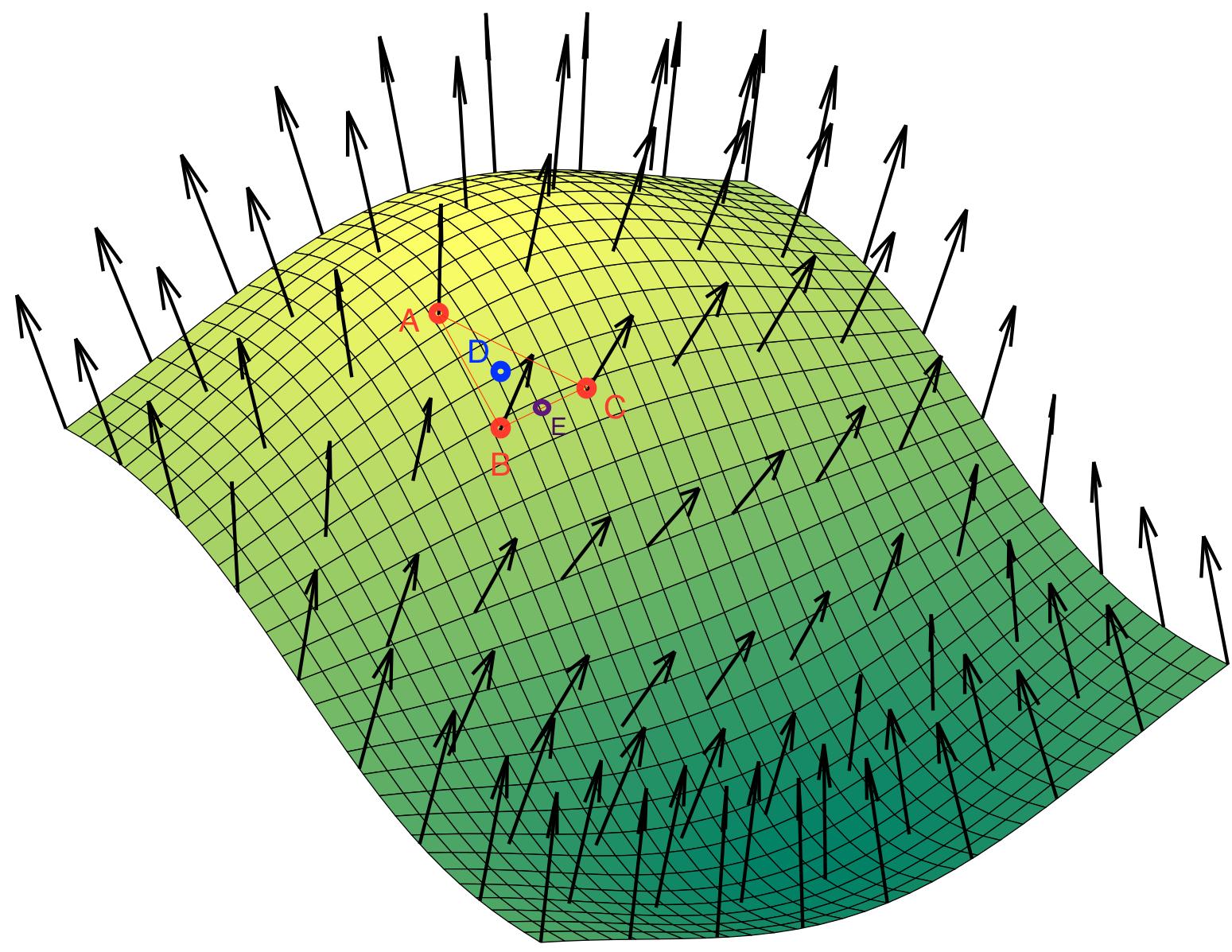

Beyond aesthetics, 3D models also play a crucial role in simulations and virtual reality experiences. By creating accurate virtual worlds, scientists, engineers, and researchers can explore scenarios and test hypotheses without the need for physical resources. This applies to fields such as aerospace, automotive, and medicine, where simulations are used to optimize performance, analyze potential risks, and develop new technologies.

In summary, 3D modeling enhances visual representations by providing realistic renderings, enabling virtual walkthroughs, facilitating product prototyping, and supporting simulations and virtual reality experiences. Its ability to bring designs to life before they are actualized is a game-changer in many industries.

Improved Design and Prototyping

3D modeling plays a crucial role in improving the design and prototyping process. By leveraging this technology, designers and engineers can iterate on their ideas more efficiently, resulting in better products and solutions.

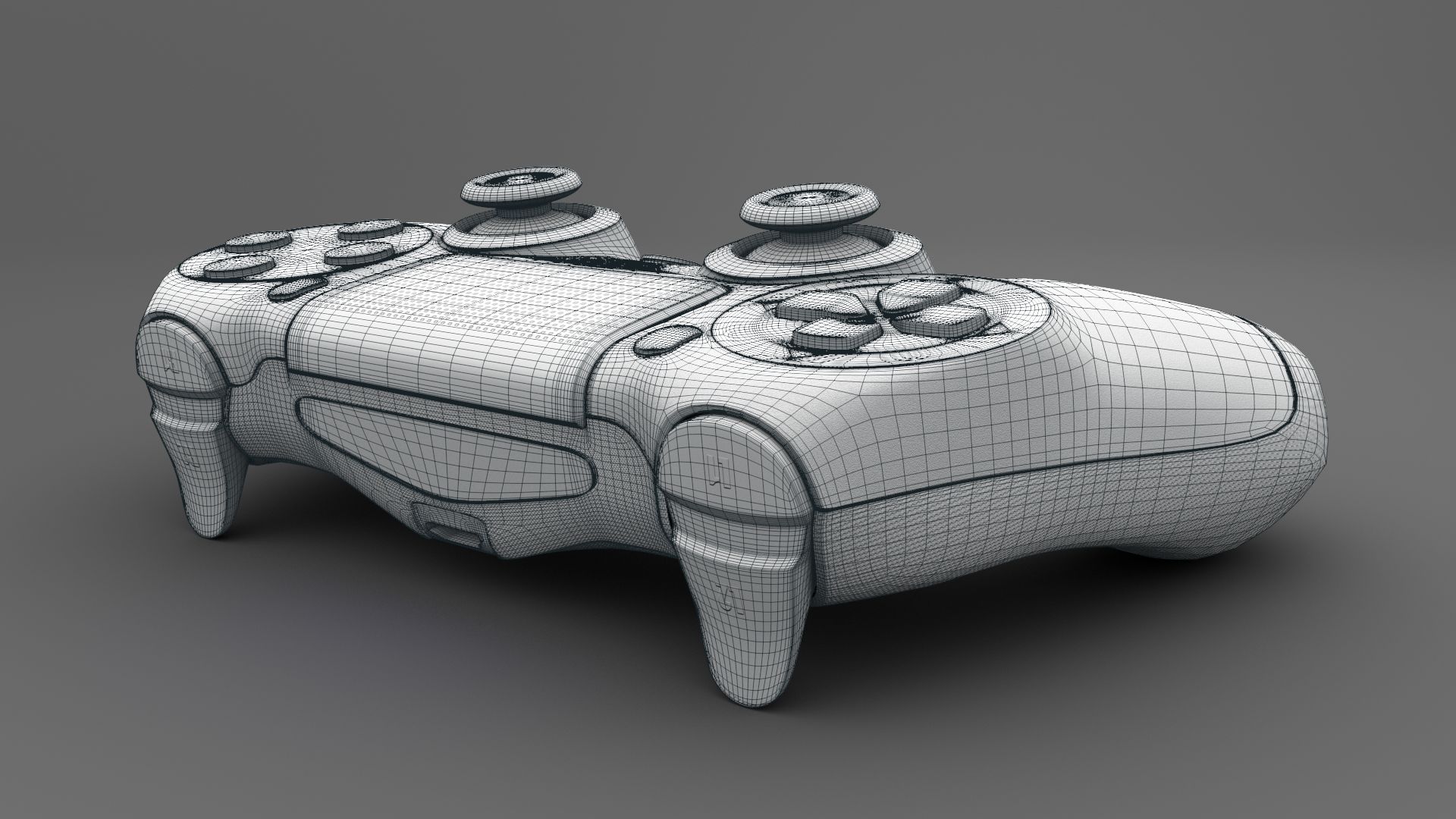

Traditionally, the design process involved creating physical prototypes, which could be time-consuming and costly. With 3D modeling, designers can rapidly create and modify virtual prototypes, allowing them to explore different design options without the need for physical materials. This flexibility enables designers to experiment with shapes, sizes, and functionalities, leading to innovative and optimized designs.

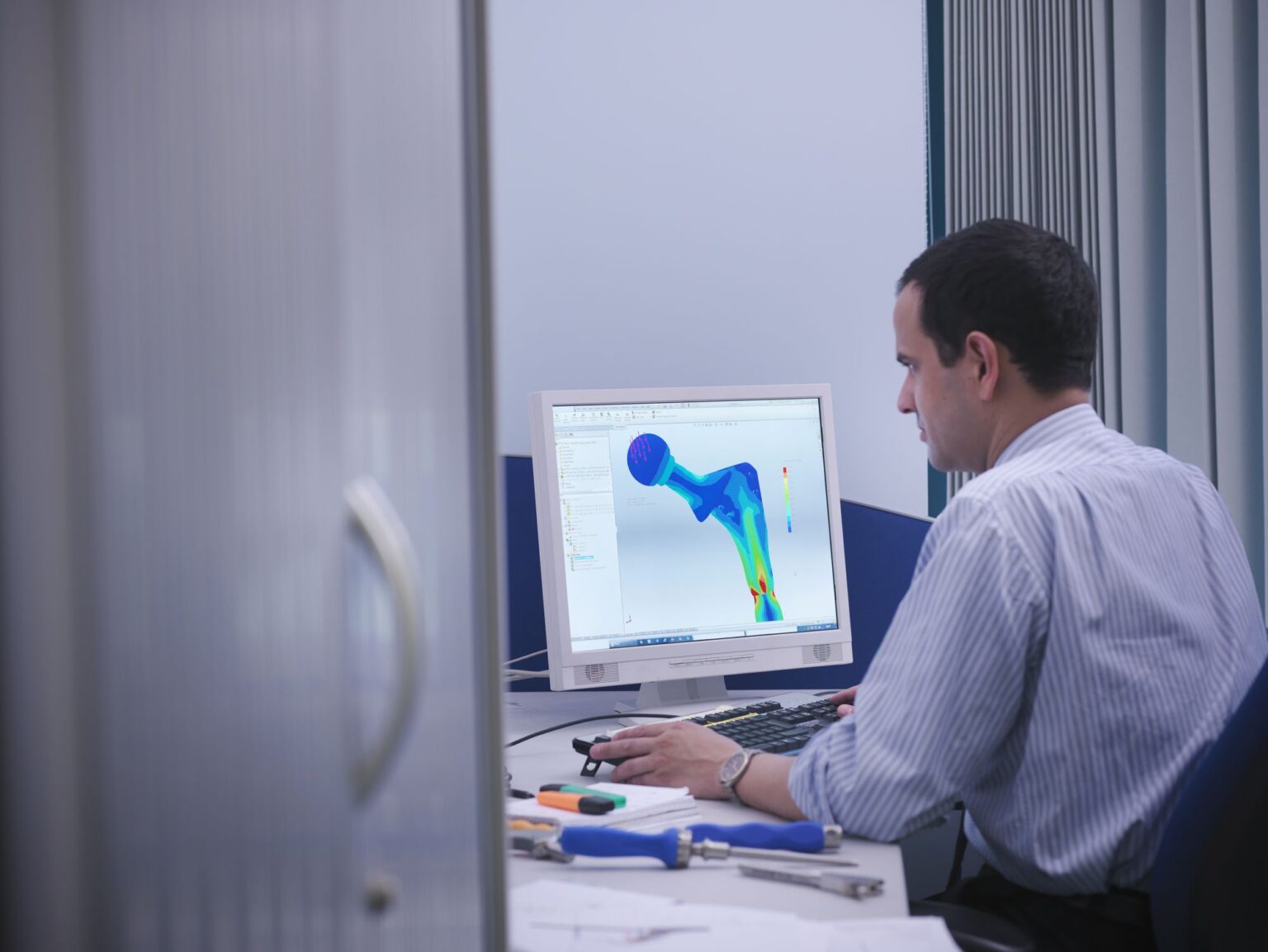

Furthermore, 3D modeling allows for the analysis and optimization of designs before moving forward with manufacturing. Through simulations and computer-aided engineering (CAE), designers can assess factors such as structural integrity, thermal performance, aerodynamics, and ergonomics. By uncovering design flaws and making necessary adjustments at an early stage, the risk of costly errors and rework is significantly reduced.

Collaboration is also greatly enhanced through 3D modeling. Designers can share digital models with team members and stakeholders, enabling them to provide feedback and make informed decisions. This streamlined communication process ensures that everyone involved is on the same page, reducing the potential for misunderstandings and costly revisions later on.

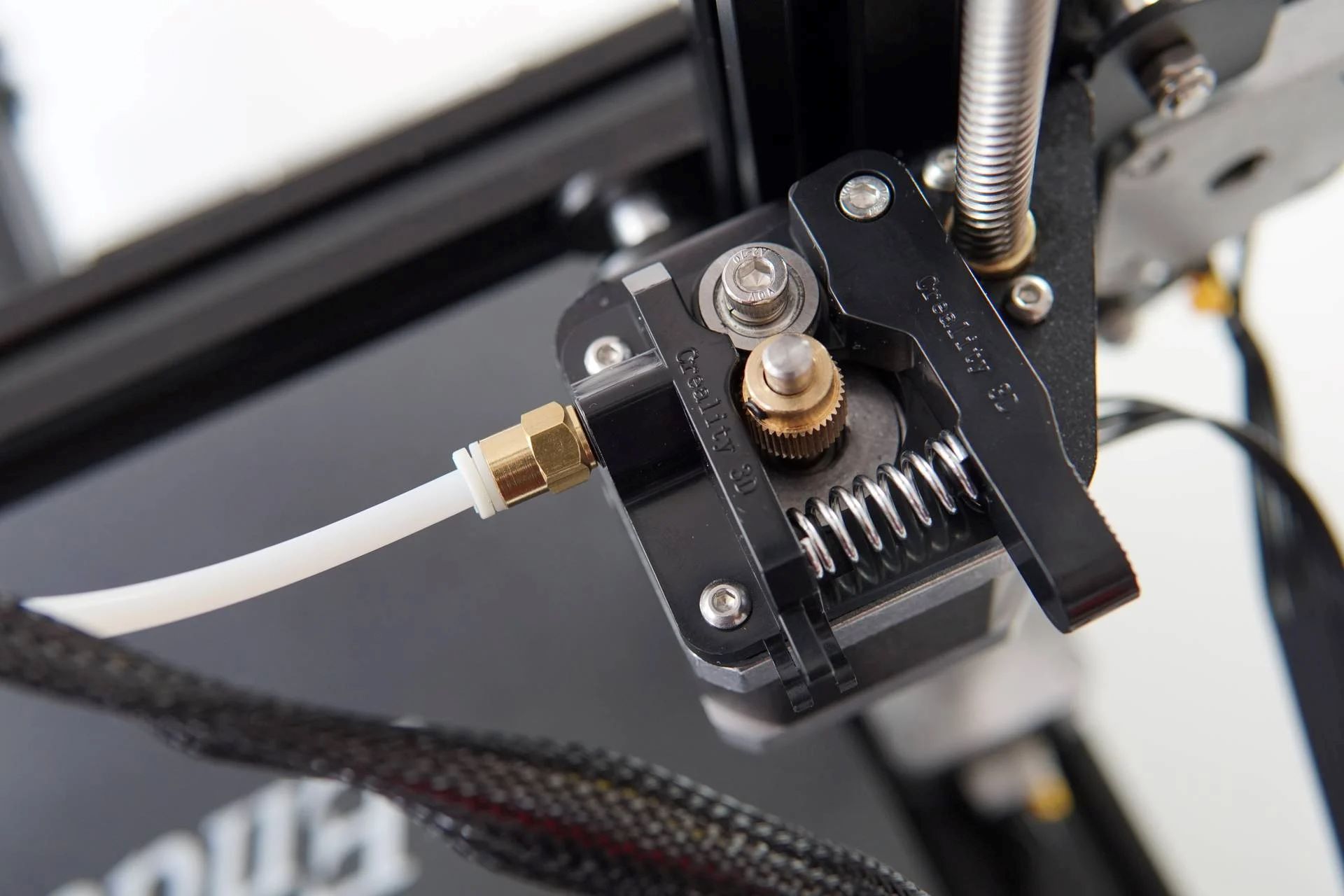

The use of 3D printing technology has revolutionized prototyping. With a 3D model as a blueprint, designers can quickly and cost-effectively create physical prototypes, giving them a tangible representation of their design. This allows for better evaluation of the product’s form, fit, and function, leading to further refinements before moving into full-scale production.

In summary, 3D modeling vastly improves the design and prototyping process by offering flexibility, enabling analysis and optimization, enhancing collaboration, and facilitating the creation of physical prototypes. It empowers designers and engineers to create better, more efficient, and more functional products.

Efficiency in Production Processes

3D modeling brings efficiency to production processes across various industries. By leveraging this technology, manufacturers can streamline their operations, reduce costs, and improve overall productivity.

One of the key advantages of 3D modeling in production is the ability to create accurate and detailed digital models of products. These models serve as a digital representation of the physical object and serve as a reference for manufacturing processes. With precise dimensions and specifications, manufacturers can ensure that the final product meets the desired quality standards.

Additionally, 3D models enable manufacturers to optimize their production workflows. By simulating the manufacturing processes virtually, companies can identify and eliminate potential bottlenecks, improve efficiency, and reduce time wastage. This includes analyzing assembly sequences, identifying optimal material utilization, and evaluating production line layouts for maximum throughput.

Furthermore, 3D modeling allows for the creation of manufacturing instructions and documentation. By integrating the digital models with Computer-Aided Manufacturing (CAM) software, manufacturers can generate step-by-step instructions for operators, reducing errors and improving consistency. This eliminates the need for manual interpretation of 2D drawings, leading to higher accuracy and repeatability in production.

The adoption of additive manufacturing, commonly known as 3D printing, has been one of the major advancements in production processes. With 3D printing, manufacturers can directly translate digital models into physical objects, bypassing traditional manufacturing methods. This enables rapid prototyping, on-demand production, and customization options that were previously impractical or costly.

Moreover, 3D modeling facilitates the implementation of automation and robotics in production. By programming robots to interact with digital models, manufacturers can automate repetitive tasks, improve precision, and increase production speed. This not only reduces labor costs but also minimizes the risk of human error.

In summary, 3D modeling drives efficiency in production processes by providing accurate digital representations, optimizing workflows, enabling advanced manufacturing techniques such as 3D printing, supporting automation and robotics, and enhancing documentation and instructions. It empowers manufacturers to achieve higher productivity, reduce costs, and meet the demands of a rapidly changing marketplace.

3D modeling is important because it allows for the creation of realistic visualizations, prototypes, and simulations, which can be used in various industries such as architecture, engineering, gaming, and manufacturing.

Enhanced Communication and Collaboration

Effective communication and collaboration are vital for the success of any project or business endeavor. 3D modeling plays a significant role in improving communication and fostering collaboration among team members, clients, and stakeholders.

One of the key benefits of 3D modeling is its ability to provide a visual and interactive representation of designs. Instead of relying solely on 2D drawings or verbal descriptions, team members can view and interact with 3D models, facilitating better understanding and comprehension. This visual communication aids in conveying complex concepts, design intentions, and project requirements more effectively.

Furthermore, 3D models serve as a common reference point for all parties involved. Architects, engineers, and designers can collaborate on a shared digital platform, making real-time updates and annotations to the 3D model. This eliminates the need for multiple iterations of design documents, reducing errors and ensuring that everyone is working with the most up-to-date information. This collaborative environment fosters teamwork, improves efficiency, and accelerates project timelines.

Presenting 3D models to clients and stakeholders helps bridge the gap between technical jargon and layman’s terminology. By visualizing the end product or environment, clients can gain a clearer understanding of the design and provide valuable feedback. They can explore different angles, analyze functionalities, and make informed decisions based on the visual representation of the project. This interactive and visual approach enhances client satisfaction and promotes stakeholder engagement.

Moreover, 3D modeling aids in interdisciplinary collaboration. In complex projects that involve multiple disciplines, such as architecture and engineering, seamless collaboration is paramount. By using 3D models as a common language, professionals from different fields can easily integrate their expertise, identify conflicts, and find collaborative solutions. This interdisciplinary collaboration ensures that all aspects of the project are considered, leading to comprehensive and well-rounded designs.

Additionally, with advancements in technology, 3D models can be easily shared and accessed remotely. This allows for effective communication and collaboration between distributed team members and stakeholders. Geographic barriers are no longer a limitation, as individuals can collaborate virtually, share ideas, and make informed decisions regardless of their physical location.

In summary, 3D modeling enhances communication and fosters collaboration by providing a visual and interactive representation, facilitating real-time updates and annotations, bridging the gap between technical and non-technical stakeholders, enabling interdisciplinary collaboration, and facilitating remote collaboration. It brings teams together, facilitates understanding, and promotes effective decision-making, ultimately leading to successful projects.

Cost Reduction and Time Savings

One of the significant advantages of 3D modeling is its potential to reduce costs and save time in various aspects of project development and production. By leveraging this technology, businesses can optimize their processes, eliminate waste, and improve overall efficiency.

Firstly, 3D modeling allows for faster and more accurate design iterations. Instead of relying on manual drafting or physical prototyping, designers can quickly make changes and adjustments to the digital model. This significantly reduces the time and resources spent on recreating designs from scratch. Additionally, digital models can be easily shared and collaborated on, ensuring that everyone involved is working with the most up-to-date information. This streamlined design process saves valuable time, enabling businesses to bring products to market faster.

Furthermore, 3D modeling enables the identification of design flaws and errors earlier in the development cycle. Through simulations and virtual testing, potential issues can be detected and addressed before moving forward with production. This reduces the risk of costly mistakes and rework, saving both time and money.

Another way 3D modeling contributes to cost reduction is through optimized material usage. By accurately modeling designs, manufacturers can calculate the exact quantities of materials required for production. This minimizes waste and reduces material costs, as there is little to no overage or scrap generated. Additionally, digital models can be used for nesting parts, optimizing the layout on raw materials to maximize yield and minimize waste further.

The adoption of additive manufacturing, or 3D printing, brings significant cost and time savings to production. By directly translating digital models into physical objects, businesses can eliminate the need for expensive tooling and molds. This reduces upfront costs and allows for on-demand production, eliminating the need for maintaining large inventories. Moreover, 3D printing offers faster turnaround times compared to traditional manufacturing methods, further speeding up the production process.

Additionally, 3D modeling enables remote collaboration and communication. This eliminates the need for frequent in-person meetings or travel costs, as stakeholders can review and discuss the digital models remotely. This not only saves money but also reduces the environmental impact associated with travel.

In summary, 3D modeling contributes to cost reduction and time savings by enabling faster and more accurate design iterations, identifying errors early in the development cycle, optimizing material usage, utilizing additive manufacturing, and facilitating remote collaboration. Businesses can operate more efficiently, reduce production costs, and bring products to market faster, gaining a competitive edge in the process.

Utilization in Various Industries

3D modeling has found widespread utilization across a range of industries, revolutionizing the way they operate and bringing significant benefits. Let’s explore some of the key sectors where 3D modeling plays a critical role.

Architecture and Construction: In the field of architecture, 3D modeling allows for the creation of realistic visualizations, enhancing the design process and enabling better communication with clients. It aids in spatial planning, structural analysis, and coordination of various building systems. Additionally, 3D printing enables architects to create intricate scale models and prototypes.

Manufacturing and Engineering: 3D modeling has transformed the manufacturing and engineering industries by optimizing design processes, improving product prototypes, and facilitating production. It enables the creation of accurate digital representations that can be used for simulations, testing, and quality control. Additive manufacturing allows for the rapid production of complex parts and customization options.

Healthcare: In the healthcare industry, 3D modeling has revolutionized medical imaging and surgical planning. By converting medical scans into 3D models, doctors can better visualize and analyze anatomical structures, aiding in diagnosis and treatment planning. Customized implants and prosthetics can also be designed and produced using 3D modeling and printing technologies.

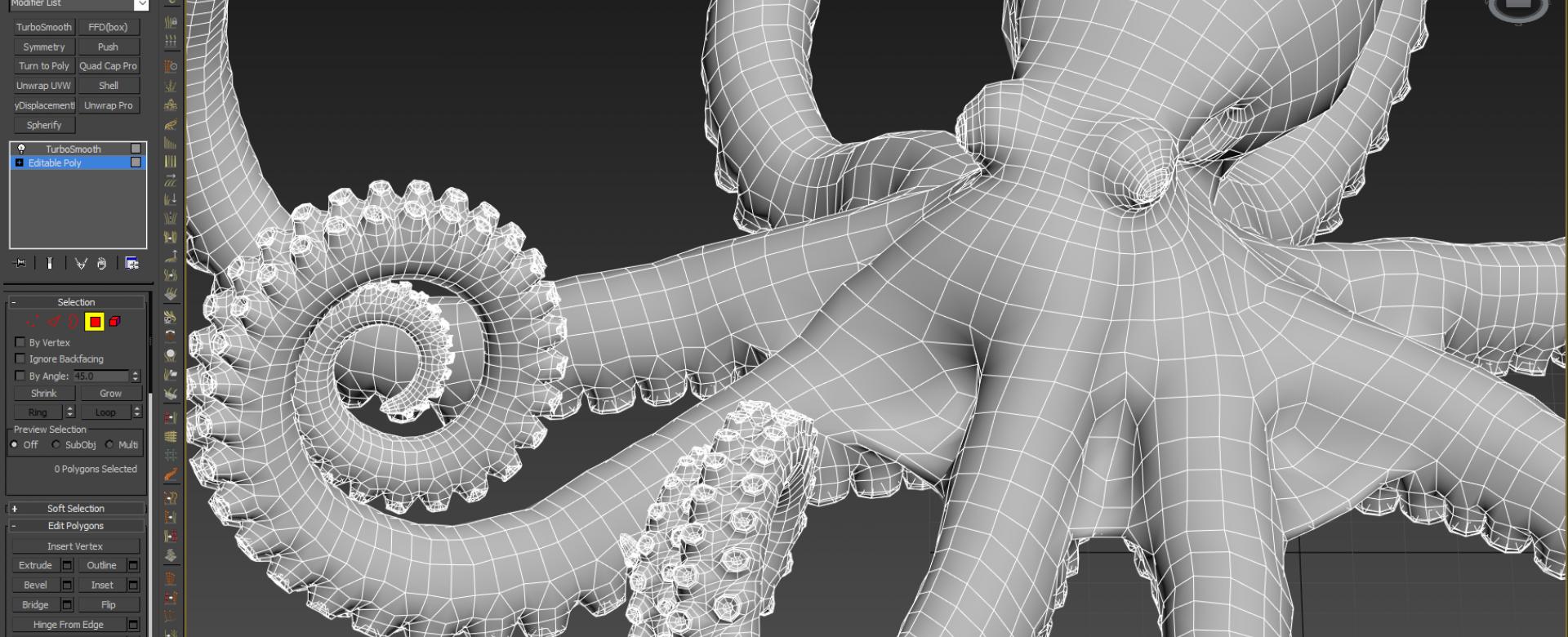

Entertainment and Media: 3D modeling plays a crucial role in the entertainment and media industries. In movies, visual effects, and animation, 3D models are used to create lifelike characters and realistic environments. Virtual reality experiences and video games heavily rely on 3D modeling to create immersive worlds and interactive gameplay.

Automotive and Aerospace: The automotive and aerospace industries utilize 3D modeling for product design, analysis, and manufacturing. It enables engineers to simulate fluid dynamics, test performance, and optimize fuel efficiency. Rapid prototyping and 3D printing contribute to faster product development and customization options.

E-commerce and Retail: In the e-commerce and retail sectors, 3D modeling allows for the creation of interactive and immersive product visualizations. Customers can view and customize products online, enhancing the purchasing experience. Virtual reality technologies integrated with 3D modeling offer virtual shopping experiences and showroom simulations.

Education and Research: 3D modeling plays a significant role in education and research, allowing students and researchers to explore and understand complex concepts in a visual and interactive manner. It enables the creation of detailed models for scientific visualization, archaeological reconstructions, and educational simulations.

In summary, 3D modeling has diverse applications across industries such as architecture and construction, manufacturing and engineering, healthcare, entertainment and media, automotive and aerospace, e-commerce and retail, and education and research. Its versatility and transformative capabilities make it an invaluable tool for innovation and progress in numerous sectors.

Conclusion

3D modeling has become an essential and transformative technology in today’s world. Its significance is evident in the way it enhances visual representations, improves design and prototyping, drives efficiency in production processes, enhances communication and collaboration, and reduces costs and saves time. Moreover, its utilization spans across various industries, revolutionizing the way businesses operate and unlocking new possibilities.

By providing realistic and immersive visualizations, 3D modeling enables designers and stakeholders to visualize the end product or environment before it is built. This enhances decision-making and client satisfaction, while also aiding in simulations and virtual reality experiences for research and testing purposes.

Furthermore, 3D modeling empowers designers and engineers to iterate on designs more efficiently, resulting in improved products and optimized manufacturing processes. The ability to identify and address design flaws early on minimizes costly mistakes and rework, saving both time and money.

Collaboration and communication are greatly enhanced through 3D modeling, fostering teamwork, reducing misunderstandings, and allowing stakeholders in different locations to collaborate seamlessly. This collaborative environment leads to better project outcomes and increased efficiency across industries.

Cost reduction and time savings are significant benefits of 3D modeling. From optimizing material usage to utilizing additive manufacturing and enabling remote collaboration, businesses can streamline their operations, reduce waste, and bring products to market faster.

Lastly, 3D modeling finds utilization in various industries, including architecture and construction, manufacturing and engineering, healthcare, entertainment and media, automotive and aerospace, e-commerce and retail, and education and research. Its versatility and wide-ranging applications demonstrate its ability to drive innovation and progress across sectors.

In conclusion, 3D modeling has revolutionized the way we design, create, and interact with the world around us. Its impact is seen in improved visual representations, streamlined design and production processes, enhanced collaboration and communication, and significant cost and time savings. As technology continues to advance, the potential of 3D modeling will only continue to grow, opening new doors for creativity, efficiency, and productivity.

Frequently Asked Questions about Why Is 3D Modeling Important?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Is 3D Modeling Important?”