Home>Ideas and Tips>Setting Up A 3D Printing Station In Your Home Workshop

Ideas and Tips

Setting Up A 3D Printing Station In Your Home Workshop

Modified: October 28, 2024

Learn how to set up a 3D printing station in your home workshop with tips on location, equipment, and maintenance for optimal performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

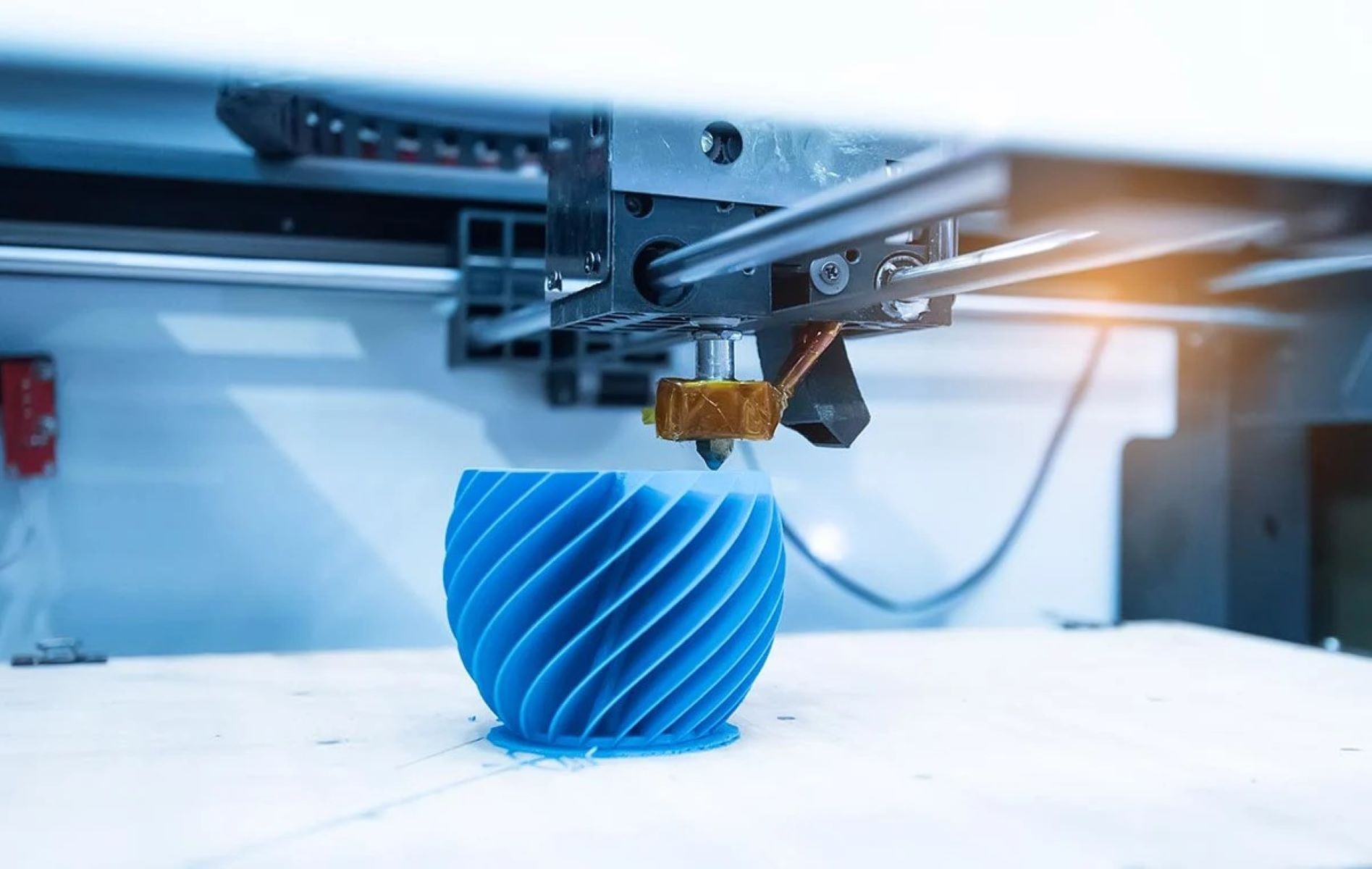

In recent years, 3D printing has become an increasingly popular tool for both hobbyists and professionals. Whether you're looking to create custom parts for your home projects, prototype new designs, or even build entire houses, 3D printing offers a versatile and innovative way to bring your ideas to life. However, setting up a 3D printing station in your home workshop can be a daunting task, especially if you're new to the technology. In this article, we'll guide you through the process of setting up a 3D printing station, from choosing the right location to maintaining your equipment and optimizing your workflow.

Choosing the Right Location

The first step in setting up your 3D printing station is to choose the right location. This decision will significantly impact the efficiency and safety of your operation. Here are some key considerations:

Space Requirements

-

Size and Layout: Ensure that you have enough space to accommodate your 3D printers, as well as any additional equipment or materials you might need. A dedicated desk or table can be ideal for smaller setups, but larger operations may require shelving systems or even a dedicated room.

-

Accessibility: The location should be easily accessible and convenient for frequent use. Avoid placing your 3D printing station in a hard-to-reach area, as this can lead to frustration and decreased productivity.

-

Noise and Heat: 3D printing can generate significant noise and heat, especially when multiple printers are in operation. Consider the noise levels and heat output when selecting a location to avoid disturbing others or causing discomfort.

-

Electrical Outlets: Ensure that the chosen location has sufficient electrical outlets to power your 3D printers and any additional equipment. Daisy chaining extension cords is not recommended as it can be hazardous and inefficient.

Examples of Effective Layouts

-

Dedicated Desk Setup: For a single printer, setting up a dedicated desk right next to you can be very convenient. This setup allows for easy monitoring and quick access to the printer.

-

Shelving System: For multiple printers, a shelving system can help keep the workspace organized and efficient. This is particularly useful in larger setups where space is limited.

-

Custom Built Stations: Some users opt for custom-built stations using materials like Swedish particle board and 3D printed spacers. These setups can be very purpose-built but may not be as convenient as having a printer right next to you.

Preparing Your Workspace

Once you've chosen the right location, it's time to prepare your workspace. Here are some essential steps:

Organizing Materials

-

Storage Solutions: Invest in storage solutions like bins, baskets, and shelves to keep your workspace organized. This will help you quickly locate the materials you need without wasting time searching through cluttered areas.

-

Labeling: Labeling your storage solutions can make it easier to find specific materials when needed. Use clear labels that indicate what is inside each container.

-

Work Surface: Ensure that your work surface is clean and clear of any obstructions. A clutter-free workspace will help you stay focused and avoid accidents.

Maintaining Your 3D Printer

-

Regular Cleaning: Regularly clean your 3D printer to prevent dust buildup and ensure optimal performance. Use compressed air to remove dust from the printer's nozzles and fans.

-

Software Updates: Keep your 3D printing software up to date with the latest firmware and software updates. These updates often include bug fixes and performance improvements.

-

Material Management: Properly manage your filament by storing it in a cool, dry place away from direct sunlight. This will help prevent degradation of the filament over time.

Troubleshooting Common Issues

-

Noise Issues: If your printer is producing excessive noise, check if any parts are significantly wearing down like belts or if they are out of alignment. Proper alignment can significantly reduce noise levels.

-

Dust Issues: If you notice black dust around your printer, it could be due to worn-out belts or misaligned parts. Regularly inspect these parts and replace them if necessary.

Selecting the Right Equipment

Choosing the right equipment for your 3D printing station is crucial for optimal performance and efficiency. Here are some key considerations:

Read more: What Grit Sandpaper For 3D Prints

Types of 3D Printers

-

FFF (Fused Filament Fabrication) Printers: These are the most common type of 3D printers and are suitable for a wide range of applications. They use melted plastic to create objects layer by layer.

-

SLA (Stereolithography) Printers: These printers use a laser to solidify liquid resin layer by layer, creating highly detailed prints but requiring more maintenance.

-

SLS (Selective Laser Sintering) Printers: These printers use a laser to fuse together particles of a powdered material, creating strong and durable prints but often requiring specialized materials.

Evaluating Equipment Needs

-

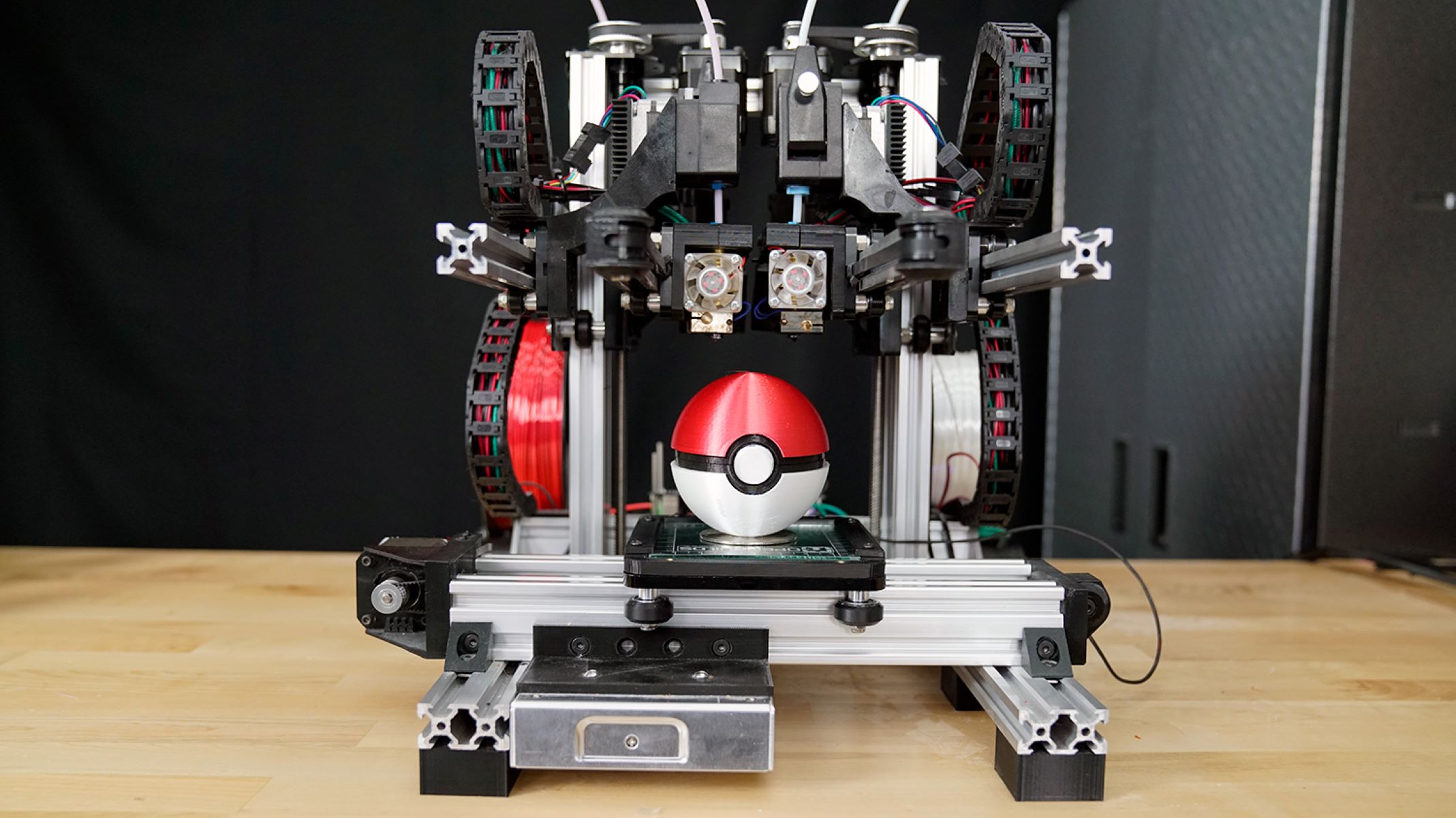

Intended Applications: Determine what you will be using your 3D printer for. If you need to produce small models, a few inexpensive printers like Flashforges might suffice. For larger prints, you'll need a more robust printer.

-

Material Requirements: Most 3D printing involves using ABS or PLA filament, which are available in various colors and generally cost around $20 to $30 per kilogram.

-

Additional Tools: While not essential, tools like print cleaning stations with tools for cleaning off support material can be very useful in maintaining your printer's performance.

Setting Up Your 3D Printing Station

Once you've selected your equipment, it's time to set up your 3D printing station. Here are some steps to follow:

Step 1: Plan Your Layout

-

Measure Your Space: Take measurements of your workspace to determine the best layout for your equipment and materials.

-

Create a CAD Model: Use CAD software to create a model of your workspace layout. This will help you visualize how everything will fit together before printing any physical models.

-

Print Models: Use your 3D printer to print out scale models of furniture and other items in your workspace. This allows for rapid and iterative design changes without having to physically move heavy items around.

Read more: How To Remove Print From A 3D Printer

Step 2: Assemble Your Station

-

Arrange Furniture: Use your printed models to arrange furniture and other items in your workspace. This step is crucial for ensuring that everything fits together efficiently and effectively.

-

Add Storage Solutions: Install storage solutions like bins, baskets, and shelves according to your layout plan.

-

Label Everything: Label each storage solution clearly so that you can quickly locate what you need without wasting time searching through cluttered areas.

Step 3: Maintain Your Station

-

Regular Cleaning: Regularly clean your workspace and equipment to prevent dust buildup and maintain optimal performance.

-

Update Software: Keep your software up to date with the latest firmware and software updates.

-

Monitor Performance: Regularly monitor the performance of your equipment and address any issues promptly to avoid downtime.

Using 3D Printing for Home Improvement Projects

3D printing is not just limited to hobbyists; it can also be a valuable tool for home improvement projects. Here are some ways you can use 3D printing in your home:

Custom Parts

-

Door Handles: Create custom door handles that fit perfectly with your home's design aesthetic.

-

Light Switch Plates: Design and print custom light switch plates that match your home's interior design.

-

Shelving Units: Build custom shelving units that fit perfectly into tight spaces or match specific design requirements.

Read more: How Small Can A 3D Printer Print

Decorative Items

-

Custom Decorations: Print custom decorations like wall art, vases, or figurines that add a personal touch to your home decor.

-

Furniture Prototypes: Use 3D printing to create prototypes of furniture pieces before investing in expensive materials for the final product.

-

Home Organization Tools: Design and print tools like hooks, baskets, or organizers that help keep your home organized and clutter-free.

Using 3D Printing for Social Impact

While 3D printing is often associated with personal projects, it also has the potential to make a significant social impact. Here are some ways you can use 3D printing for social good:

Affordable Housing

-

3D Printed Houses: Companies like ICON are using 3D printing technology to construct affordable houses quickly and efficiently. This technology has the potential to address homelessness by providing safe and affordable housing options.

-

Community Projects: Use 3D printing to create items for community projects such as playground equipment, benches, or other public amenities.

-

Disaster Relief: Print essential items like shelter components, medical equipment, or tools for disaster relief efforts.

Conclusion

Setting up a 3D printing station in your home workshop requires careful planning and preparation. By choosing the right location, organizing your workspace effectively, selecting appropriate equipment, and maintaining your station regularly, you can optimize your workflow and achieve better results. Whether you're using 3D printing for personal projects or social impact initiatives, this technology offers endless possibilities for innovation and creativity. With these steps in mind, you'll be well on your way to creating an efficient and productive 3D printing station that meets all your needs.

Read more: How To Create A CAD File For 3D Printing

Additional Resources

For more detailed information on setting up a desktop fabrication station for FFF 3D printing, you can refer to resources like MatterHackers' guide on how to set up a desktop fabrication station. Additionally, if you're interested in learning more about using 3D printing for home improvement projects or social impact initiatives, exploring resources such as Instructables' guide on efficiently planning your home or workspace with 3D printing can be very helpful.

By following these steps and leveraging available resources, you'll be able to create a comprehensive and efficient 3D printing station that enhances both your personal projects and contributes positively to your community.

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Setting Up A 3D Printing Station In Your Home Workshop”