Home>Technology>Smart Home Devices>How Loud Is A 3D Printer

Smart Home Devices

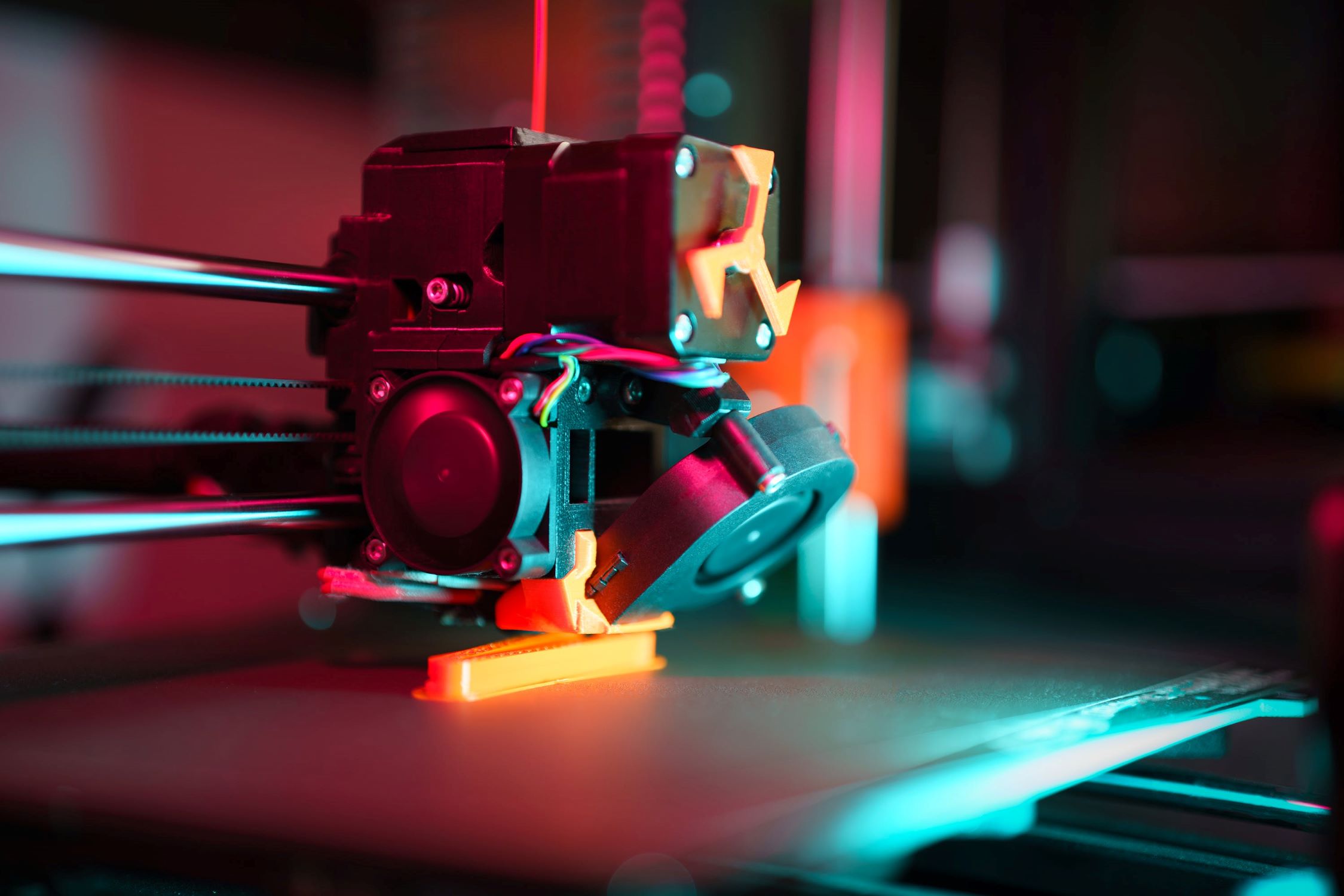

How Loud Is A 3D Printer

Modified: August 17, 2024

Discover the noise level of 3D printers and how it impacts your smart home devices. Learn how to minimize disruptions with quieter printing options.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of 3D printing! As you embark on your journey to unleash your creativity and bring your designs to life, you might be curious about the noise levels associated with 3D printers. The question "How loud is a 3D printer?" is a common one among enthusiasts and beginners alike. In this article, we will delve into the realm of decibels, explore the noise levels of 3D printers, examine the factors that influence their sound output, and provide valuable tips for reducing 3D printer noise.

The evolution of 3D printing technology has revolutionized the way we conceptualize and manufacture objects. From intricate prototypes to functional components, 3D printers have found their place in various industries and the homes of DIY enthusiasts. However, like any mechanical device, 3D printers generate a certain level of noise during operation. Understanding the factors contributing to this noise and discovering methods to mitigate it can significantly enhance the overall 3D printing experience.

In the upcoming sections, we will unravel the concept of decibels, the standard unit for measuring sound intensity, and its relevance to 3D printer noise. We will also explore the typical noise levels associated with different types of 3D printers, shedding light on the variations that exist within this domain. Furthermore, we will investigate the factors that influence the noise output of 3D printers, offering insights into the mechanics behind the sounds they produce.

Moreover, this article aims to equip you with practical tips for reducing the noise generated by your 3D printer, allowing you to create in a more serene environment. By implementing these strategies, you can minimize disruptions and enjoy a more tranquil workspace while your 3D printer brings your designs to fruition.

So, let's embark on this sonic exploration of 3D printer noise, unraveling its intricacies and discovering the means to achieve a harmonious coexistence with this innovative technology. Whether you are a seasoned 3D printing aficionado or a newcomer to the realm of additive manufacturing, this article will provide valuable insights into the world of 3D printer noise and empower you to optimize your printing environment.

Key Takeaways:

- 3D printers produce varying noise levels, with FDM printers ranging from 45-65 dB, SLA printers from 35-55 dB, and SLS printers similar to FDM. Understanding these levels helps in choosing the right printer for a quieter environment.

- Practical tips such as strategic placement, enclosure installation, and firmware optimization can help reduce 3D printer noise, creating a more peaceful and enjoyable printing experience.

Read more: Where To Put A 3D Printer

Understanding Decibels

Before delving into the noise levels of 3D printers, it’s essential to grasp the concept of decibels and their significance in quantifying sound intensity. Decibels, denoted by the symbol "dB," serve as the standard unit for measuring the volume or intensity of sound. This logarithmic unit provides a convenient and standardized approach to express the magnitude of sound in a comprehensible manner.

Sound, being a form of energy, propagates through the air in the form of pressure waves. The human ear perceives these pressure variations and interprets them as sound. Decibels offer a means to quantify the magnitude of these pressure fluctuations, allowing us to gauge the loudness or quietness of a given sound.

When it comes to decibels, it’s important to note that the scale is logarithmic rather than linear. This means that a small change in decibel level corresponds to a substantial change in actual sound intensity. For instance, an increase of 10 dB represents a tenfold increase in sound intensity, while a decrease of 10 dB signifies a tenfold reduction in intensity.

Understanding the decibel scale is crucial for assessing the noise levels of 3D printers and comprehending the impact of various sound intensities on our auditory experience. By familiarizing ourselves with this scale, we can gain a deeper appreciation of the significance of decibel measurements in evaluating and comparing the noise outputs of different 3D printers.

As we navigate the realm of 3D printer noise in the subsequent sections, this foundational understanding of decibels will serve as a valuable tool for interpreting and contextualizing the noise levels associated with these innovative devices. Armed with this knowledge, we can embark on a more informed exploration of 3D printer noise and its implications for our printing environments.

Now that we’ve established a fundamental understanding of decibels and their role in quantifying sound intensity, let’s venture further into the realm of 3D printer noise, where we will unravel the specific noise levels associated with these cutting-edge devices and explore the factors influencing their acoustic output.

Noise Levels of 3D Printers

3D printers, renowned for their ability to materialize digital designs into physical objects, exhibit varying noise levels depending on their design, construction, and operational characteristics. The noise produced during the printing process can emanate from several sources, including the movement of mechanical components, the operation of cooling fans, and the extrusion of filament. Understanding the typical noise levels associated with different types of 3D printers is essential for evaluating their acoustic impact and making informed decisions regarding their placement and usage.

The noise levels of 3D printers are often measured in decibels (dB), providing a standardized metric for comparing the acoustic outputs of various models. While the specific noise levels can vary significantly among different 3D printer models, certain generalizations can be made based on the printer’s technology and construction.

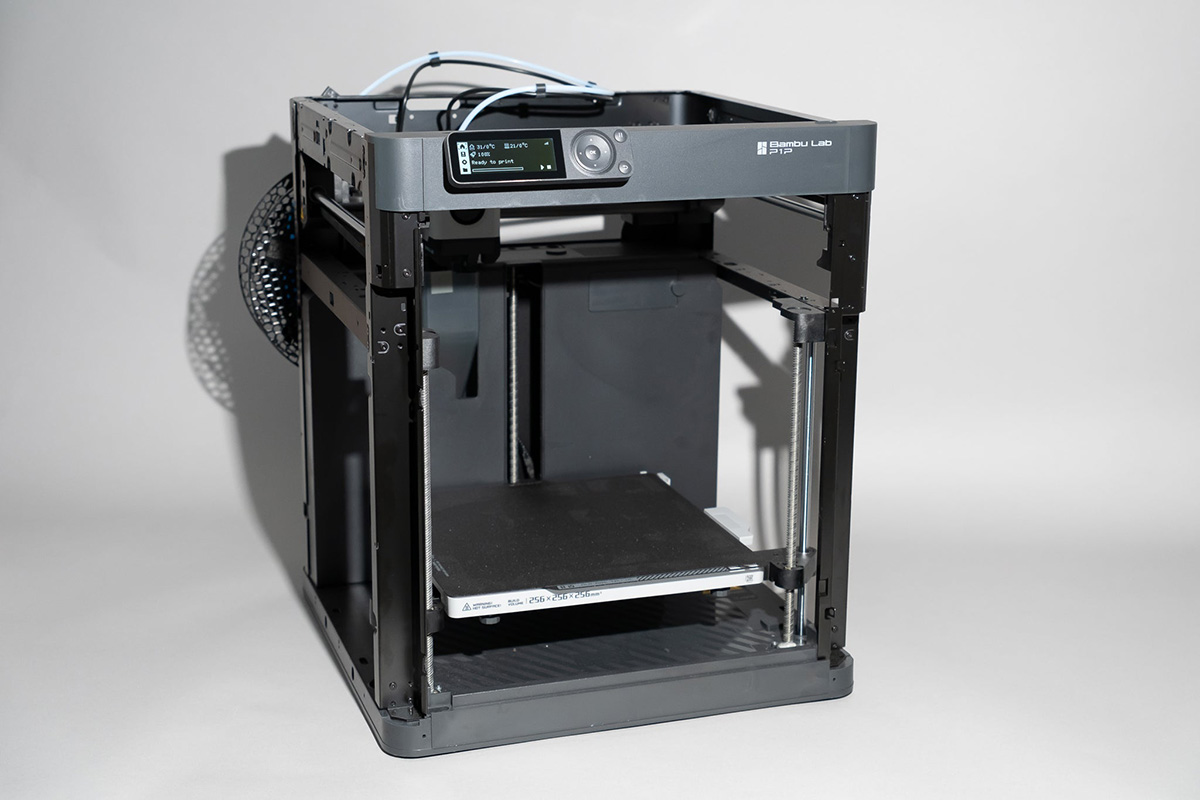

- Fused Deposition Modeling (FDM) Printers: FDM printers, which operate by extruding thermoplastic filament to build objects layer by layer, are known for their relatively moderate noise levels. The movement of the print head and the operation of the filament feeding mechanism contribute to the overall sound output of FDM printers. On average, FDM printers produce noise levels ranging from 45 dB to 65 dB during operation, with higher levels occurring during rapid movements and filament retraction.

- Stereolithography (SLA) Printers: SLA printers utilize a different approach, employing a UV laser to solidify liquid resin and create intricate 3D objects. Compared to FDM printers, SLA printers are generally quieter due to the absence of motorized filament handling and the smoother movement of the print components. The noise levels of SLA printers typically range from 35 dB to 55 dB, offering a quieter printing experience compared to their FDM counterparts.

- Selective Laser Sintering (SLS) Printers: SLS printers, which utilize a laser to sinter powdered material and form objects, exhibit noise levels similar to those of FDM printers. The operation of the laser and the movement of the print bed contribute to the overall sound output, resulting in noise levels ranging from 45 dB to 65 dB during the printing process.

These noise level ranges are approximate and can vary based on factors such as the specific printer model, the printing speed, and the materials being used. Additionally, the environment in which the printer is placed can influence the perceived noise levels, with enclosed spaces potentially amplifying the sound.

By understanding the typical noise levels associated with different types of 3D printers, users can make informed decisions regarding the placement of their printers and take proactive measures to mitigate the impact of printer noise on their working environment. In the following sections, we will explore the factors that contribute to the noise output of 3D printers and provide practical tips for reducing and managing 3D printer noise.

Wearing ear protection while operating a 3D printer is a good idea, as they can produce noise levels of around 50-70 decibels, similar to a conversation or background music.

Factors Affecting Noise Output

The noise output of 3D printers is influenced by a multitude of factors, encompassing the printer’s design, operational characteristics, and environmental conditions. Understanding these factors is crucial for assessing and managing the acoustic impact of 3D printers in various settings. By examining the key elements that contribute to 3D printer noise, users can gain valuable insights into the mechanisms underlying the sound production and implement strategies to minimize its impact.

- Printer Type and Construction: The design and construction of the 3D printer play a significant role in determining its noise output. Printers utilizing different technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS), exhibit varying noise levels due to the distinct operational mechanisms and moving parts involved. Additionally, the rigidity and vibration-dampening capabilities of the printer’s frame and components can influence the overall noise production.

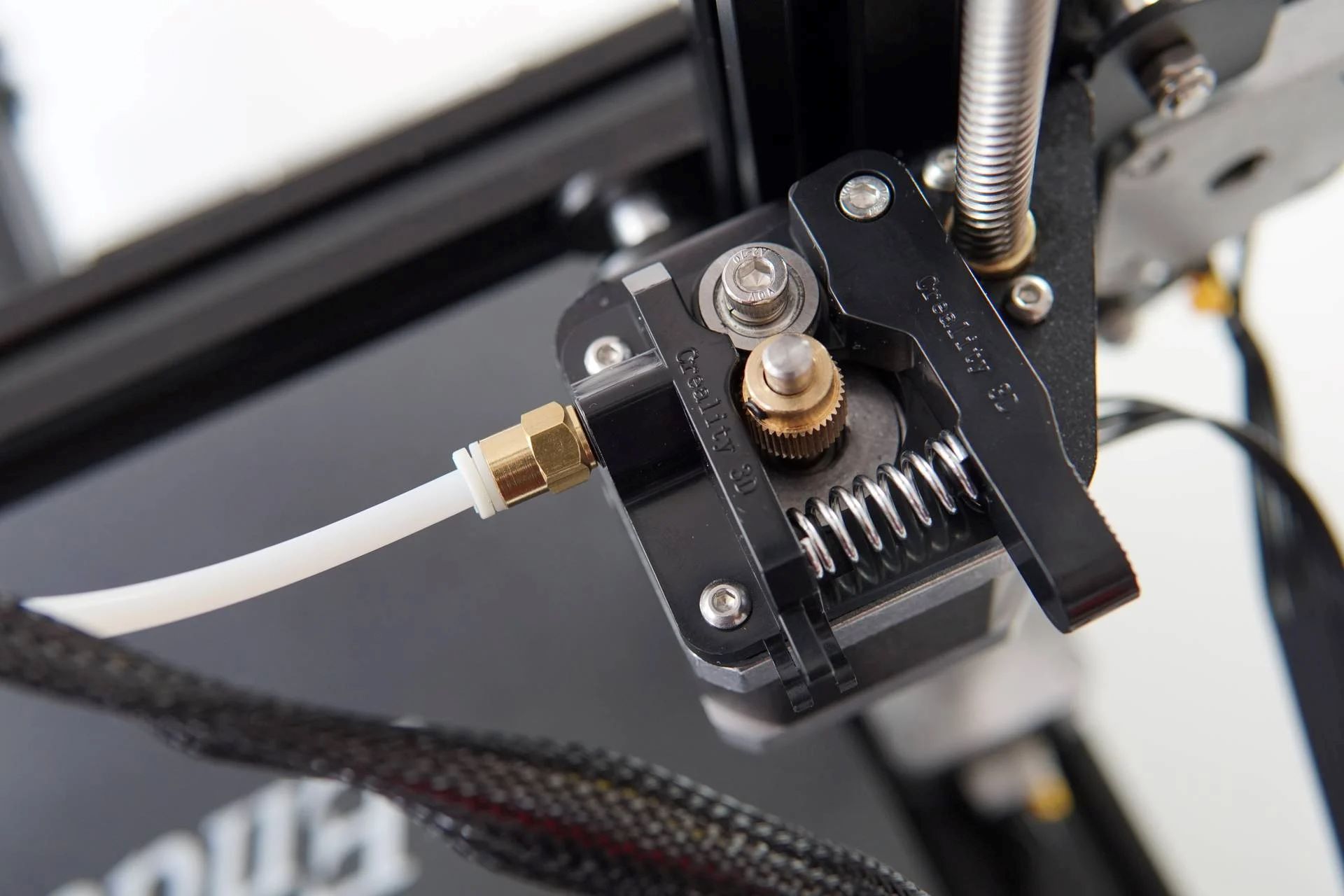

- Movement and Mechanisms: The movement of mechanical components, including the print head, print bed, and filament handling systems, contributes to the noise generated during 3D printing. Rapid movements, sudden accelerations, and abrupt changes in direction can amplify the sound output. Additionally, the operation of cooling fans, stepper motors, and other auxiliary components adds to the overall acoustic emissions.

- Printing Speed and Settings: The speed at which the printer operates, along with the specific printing settings chosen by the user, can impact the noise levels. Higher printing speeds often result in increased mechanical vibrations and movement-related noise, while certain settings, such as rapid travel movements and retraction operations, can introduce additional sound disturbances.

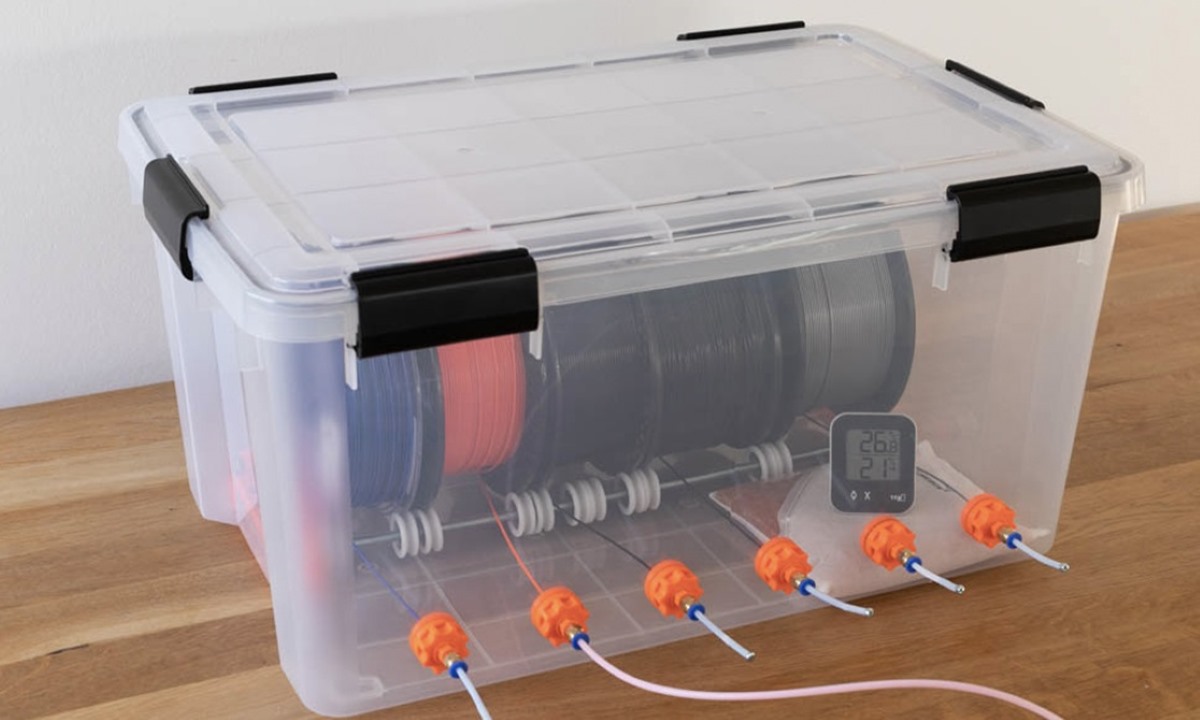

- Enclosure and Dampening: The presence of an enclosure around the 3D printer can affect the perceived noise levels. Enclosures have the potential to contain and muffle the sound, reducing its impact on the surrounding environment. Additionally, the use of vibration-dampening materials and isolation mounts can help minimize the transmission of mechanical vibrations and reduce the overall noise output.

- Environmental Conditions: The ambient environment in which the 3D printer is situated can influence its noise output. Factors such as room acoustics, background noise, and the proximity of the printer to reflective surfaces can impact the perceived sound levels. Additionally, the layout of the workspace and the presence of sound-absorbing materials can alter the acoustic characteristics of the printing environment.

By taking these factors into consideration, users can gain a comprehensive understanding of the elements contributing to 3D printer noise and devise effective strategies to mitigate its impact. In the subsequent section, we will explore practical tips and techniques for reducing 3D printer noise, empowering users to create a more serene and conducive printing environment.

Tips for Reducing 3D Printer Noise

Minimizing the noise generated by a 3D printer can significantly enhance the overall printing experience, creating a more tranquil and harmonious working environment. By implementing practical strategies and leveraging sound-reducing techniques, users can mitigate the impact of 3D printer noise and foster a quieter printing space. The following tips offer actionable guidance for reducing 3D printer noise and optimizing the acoustic environment:

- Strategic Placement: Position the 3D printer in a location that minimizes its acoustic impact on the surrounding area. Placing the printer on a stable and vibration-resistant surface can help reduce the transmission of mechanical vibrations and minimize noise propagation.

- Enclosure Installation: Constructing or acquiring an enclosure for the 3D printer can contain and dampen the noise generated during printing. Enclosures made of sound-absorbing materials, such as foam or specialized acoustic panels, can effectively mitigate the transmission of sound waves and reduce the perceived noise levels.

- Vibration Dampening: Utilize vibration-dampening pads or mounts to isolate the printer from the surrounding environment and minimize the transfer of mechanical vibrations. These specialized materials can help attenuate the impact of operational vibrations and reduce the overall noise output.

- Firmware and Settings Optimization: Explore the printer’s firmware and settings to identify options for reducing noise without compromising print quality. Adjusting parameters related to acceleration, jerk control, and motor currents can help mitigate the impact of rapid movements and mechanical noise during printing.

- Maintenance and Lubrication: Regular maintenance and lubrication of the printer’s moving components, such as rods, bearings, and lead screws, can contribute to smoother and quieter operation. Ensuring that the mechanical parts are well-maintained can help reduce friction-related noise and improve overall printing performance.

- Sound Absorption Materials: Integrate sound-absorbing materials into the printing environment to minimize reverberation and dampen sound reflections. Acoustic panels, foam padding, and sound-absorbing curtains can help attenuate the impact of printer noise and create a more acoustically balanced workspace.

- Printing Schedule: Consider scheduling print jobs during periods when the ambient noise levels are lower, such as during off-peak hours or when the workspace is less occupied. This can help mitigate the perceptual impact of printer noise and promote a more peaceful printing environment.

By incorporating these tips into their 3D printing setup, users can effectively reduce the impact of printer noise and create a more serene and conducive workspace. These practical strategies empower individuals to optimize their printing environments and enjoy a quieter and more enjoyable 3D printing experience.

As we conclude our exploration of 3D printer noise and the means to mitigate its impact, it’s evident that proactive measures and thoughtful adjustments can significantly enhance the acoustic environment in which 3D printing takes place. By leveraging these tips and techniques, users can embrace the innovative capabilities of 3D printing while cultivating a more peaceful and harmonious printing space.

Read more: What Is An Extruder On A 3D Printer

Conclusion

Our journey into the realm of 3D printer noise has provided valuable insights into the acoustic characteristics of these innovative devices and the means to manage their impact on the printing environment. By unraveling the concept of decibels, exploring the noise levels of various 3D printer technologies, and delving into the factors influencing their noise output, we have gained a comprehensive understanding of the acoustic landscape of 3D printing.

From the moderate noise levels associated with Fused Deposition Modeling (FDM) printers to the quieter operation of Stereolithography (SLA) printers, we have observed the diverse acoustic profiles of different 3D printing technologies. Understanding these noise levels and the factors contributing to them empowers users to make informed decisions regarding the placement, usage, and optimization of their 3D printers.

Moreover, our exploration of the factors affecting 3D printer noise has shed light on the multifaceted nature of sound production within the 3D printing environment. By considering elements such as printer type, movement characteristics, printing settings, and environmental conditions, users can devise effective strategies for reducing and managing 3D printer noise, fostering a more tranquil and conducive printing space.

The practical tips for reducing 3D printer noise presented in this article offer actionable guidance for mitigating the impact of printer noise and creating a quieter printing environment. From strategic placement and enclosure installation to firmware optimization and sound absorption materials, these strategies empower users to proactively address the acoustic challenges associated with 3D printing.

As we conclude our exploration, it’s evident that the management of 3D printer noise is not only feasible but also essential for cultivating a harmonious and enjoyable printing experience. By leveraging the knowledge and strategies outlined in this article, individuals can embrace the transformative potential of 3D printing while fostering a more serene and acoustically balanced workspace.

As the world of additive manufacturing continues to evolve, the integration of sound-reducing techniques and the optimization of printing environments will play a pivotal role in enhancing the overall 3D printing experience. By prioritizing the management of 3D printer noise, users can unlock the full creative potential of 3D printing while enjoying a quieter and more harmonious printing journey.

With a deeper understanding of decibels, noise levels, and sound management strategies, individuals are equipped to embark on their 3D printing endeavors with a heightened awareness of the acoustic landscape and the means to create a more tranquil and conducive printing environment.

Frequently Asked Questions about How Loud Is A 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Loud Is A 3D Printer”