Home>Technology>Smart Home Devices>How To Lubricate A 3D Printer

Smart Home Devices

How To Lubricate A 3D Printer

Modified: August 20, 2024

Learn how to properly lubricate your 3D printer for optimal performance and maintenance. Keep your smart home devices running smoothly with these essential tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

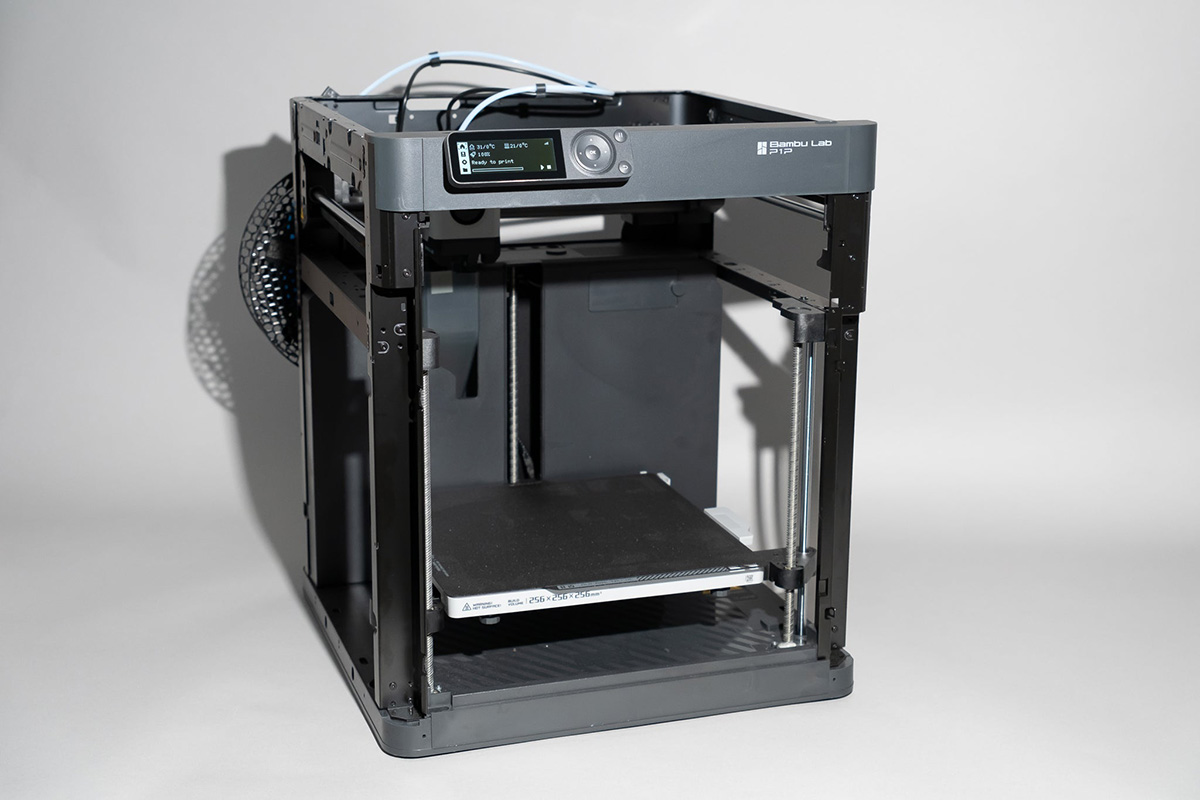

Welcome to the exciting world of 3D printing! As technology continues to advance, 3D printers have become increasingly popular for both personal and professional use. These innovative devices have the remarkable ability to transform digital designs into physical objects, making them indispensable tools for hobbyists, engineers, and designers alike.

While 3D printing opens up a world of creative possibilities, it's crucial to ensure that your 3D printer remains in optimal working condition. One essential aspect of maintaining a 3D printer is proper lubrication. In this comprehensive guide, we will explore the significance of lubricating a 3D printer, the types of lubricants suitable for these devices, and a step-by-step tutorial on how to lubricate a 3D printer effectively.

Whether you're a seasoned 3D printing enthusiast or a newcomer to the world of additive manufacturing, understanding the importance of lubrication and knowing how to perform this maintenance task will contribute to the longevity and reliability of your 3D printer. So, let's dive in and discover the ins and outs of lubricating a 3D printer to ensure smooth and precise printing results.

Key Takeaways:

- Proper lubrication of a 3D printer is crucial for smooth operation, enhanced print quality, and reduced wear and tear, ensuring long-lasting performance and high-quality results.

- Choosing the right lubricant and following proper lubrication techniques are essential for maintaining a 3D printer’s functionality, preventing common mistakes, and maximizing its potential for additive manufacturing.

Read more: Where To Put A 3D Printer

Importance of Lubricating a 3D Printer

Proper lubrication is a critical aspect of maintaining a 3D printer and ensuring its optimal performance. The moving parts within a 3D printer, such as the rods, bearings, and lead screws, require smooth and consistent motion to facilitate accurate printing and prevent premature wear and tear. Here are several key reasons why lubricating a 3D printer is of utmost importance:

- Reduced Friction: Lubrication minimizes friction between moving components, allowing them to operate smoothly and efficiently. By reducing friction, the risk of parts seizing or wearing out prematurely is significantly decreased, ultimately prolonging the lifespan of the printer.

- Enhanced Print Quality: Well-lubricated components contribute to improved print quality by ensuring precise and consistent movement during the printing process. This results in smoother and more accurate prints with finer details, which is essential for intricate designs and functional prototypes.

- Noise Reduction: Properly lubricated moving parts produce less noise during operation, creating a quieter and more pleasant working environment. This is particularly beneficial for individuals using 3D printers in shared spaces or home settings.

- Prevention of Wear and Tear: Continuous friction and mechanical stress can lead to wear and tear on the printer’s components over time. Lubrication acts as a protective barrier, reducing the impact of mechanical forces and preventing premature degradation of critical parts.

- Improved Overall Reliability: Regular lubrication maintenance enhances the overall reliability of a 3D printer, reducing the likelihood of unexpected malfunctions and downtime. This is especially crucial for businesses and professionals relying on 3D printing for their projects and production needs.

By understanding the importance of lubricating a 3D printer and recognizing the positive impact it has on performance, print quality, and longevity, users can proactively maintain their printers and enjoy consistent, high-quality results.

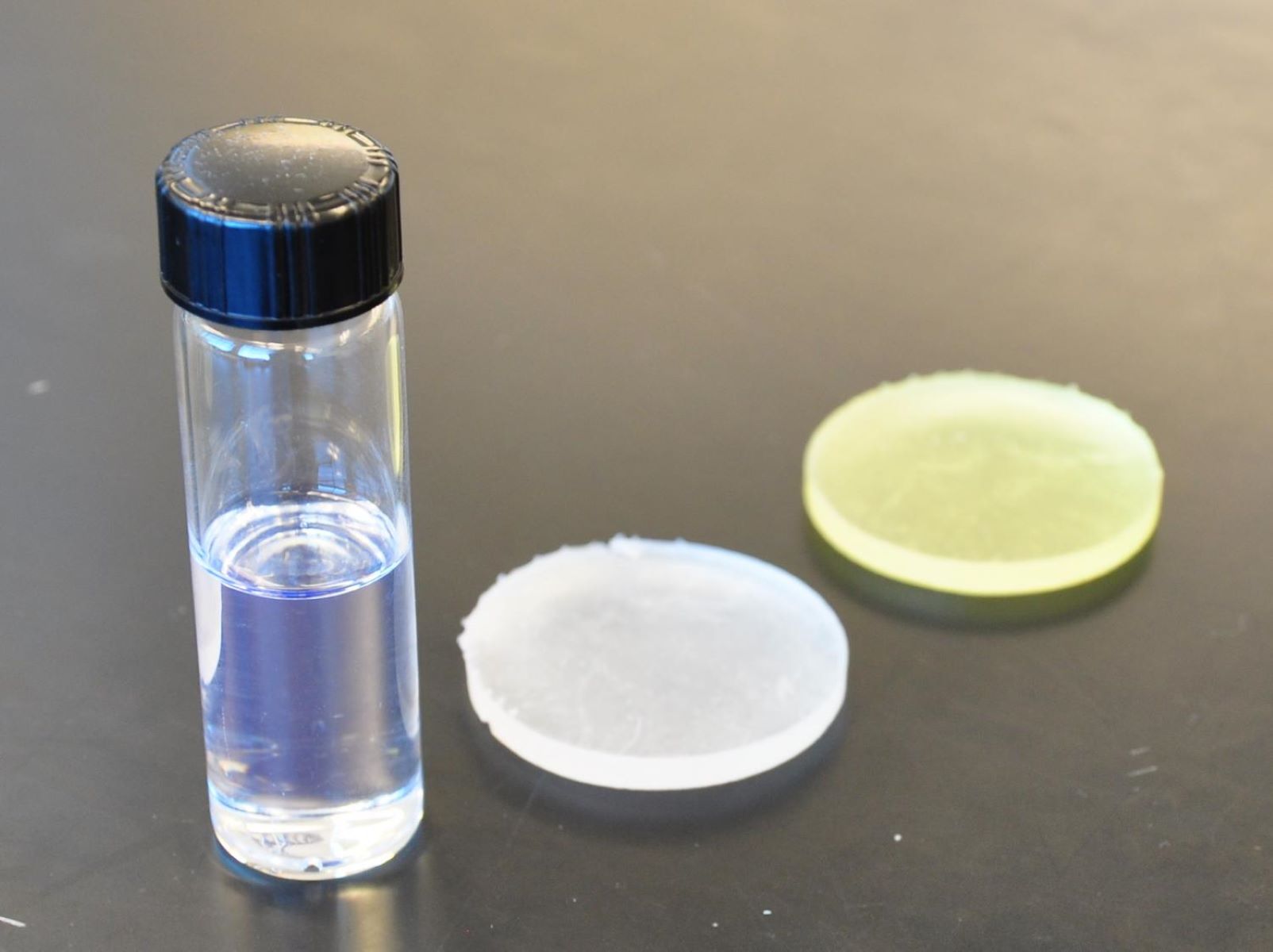

Types of Lubricants for 3D Printers

When it comes to lubricating a 3D printer, selecting the right type of lubricant is crucial to ensure optimal performance and longevity of the printer’s moving parts. Here are the primary types of lubricants commonly used for 3D printers:

- PTFE-Based Lubricants: Polytetrafluoroethylene (PTFE) lubricants, also known as Teflon lubricants, are widely used in 3D printing due to their low friction properties and resistance to high temperatures. PTFE-based lubricants are suitable for lubricating metal-on-metal and metal-on-plastic components, such as linear bearings, lead screws, and rods.

- Silicone-Based Lubricants: Silicone lubricants are known for their excellent water resistance and wide temperature tolerance. They are suitable for lubricating 3D printer components that may be exposed to moisture or require a lubricant that remains effective across varying temperatures.

- White Lithium Grease: White lithium grease is a versatile lubricant that provides long-lasting lubrication and protection against rust and corrosion. It is commonly used to lubricate the lead screws and threaded rods in 3D printers, ensuring smooth and consistent motion.

- Synthetic Oils: Synthetic oils, such as machine oils or sewing machine oils, are effective for lubricating the moving parts of a 3D printer. These lightweight oils offer low viscosity and excellent penetration, making them suitable for intricate components and hard-to-reach areas.

- Graphite-Based Lubricants: Graphite lubricants are ideal for reducing friction and providing dry lubrication to 3D printer components. They are particularly useful for applications where traditional wet lubricants may attract dust or debris, potentially affecting the printer’s performance.

It’s important to note that when selecting a lubricant for a 3D printer, it’s essential to consider factors such as the material compatibility, temperature range, application method, and the specific components that require lubrication. Additionally, users should adhere to the manufacturer’s recommendations regarding lubrication to ensure optimal printer performance and longevity.

By understanding the characteristics and applications of different types of lubricants, 3D printer enthusiasts and professionals can make informed decisions when maintaining and lubricating their printers, ultimately contributing to reliable and high-quality 3D printing results.

When lubricating a 3D printer, use a high-quality lubricant specifically designed for 3D printers. Apply a small amount to the moving parts such as the rods and lead screws to ensure smooth and consistent movement.

Step-by-Step Guide to Lubricating a 3D Printer

Lubricating a 3D printer is a straightforward yet essential maintenance task that can significantly impact the printer’s performance and longevity. Follow this step-by-step guide to ensure proper lubrication of your 3D printer’s moving components:

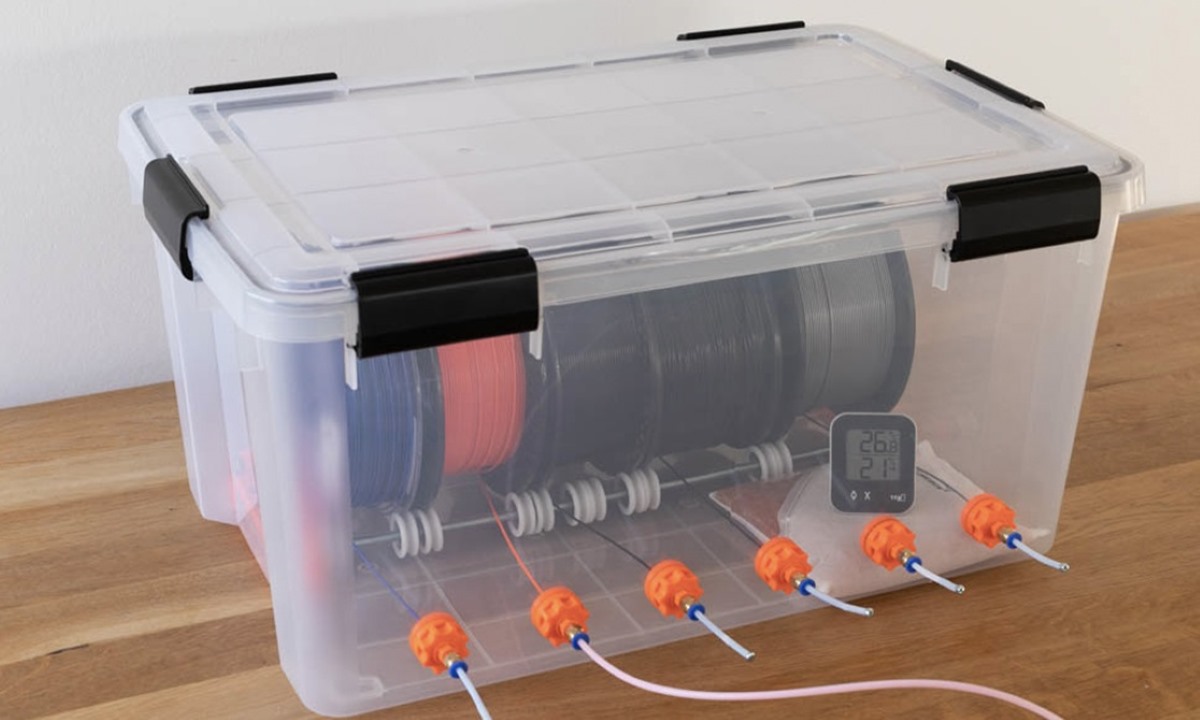

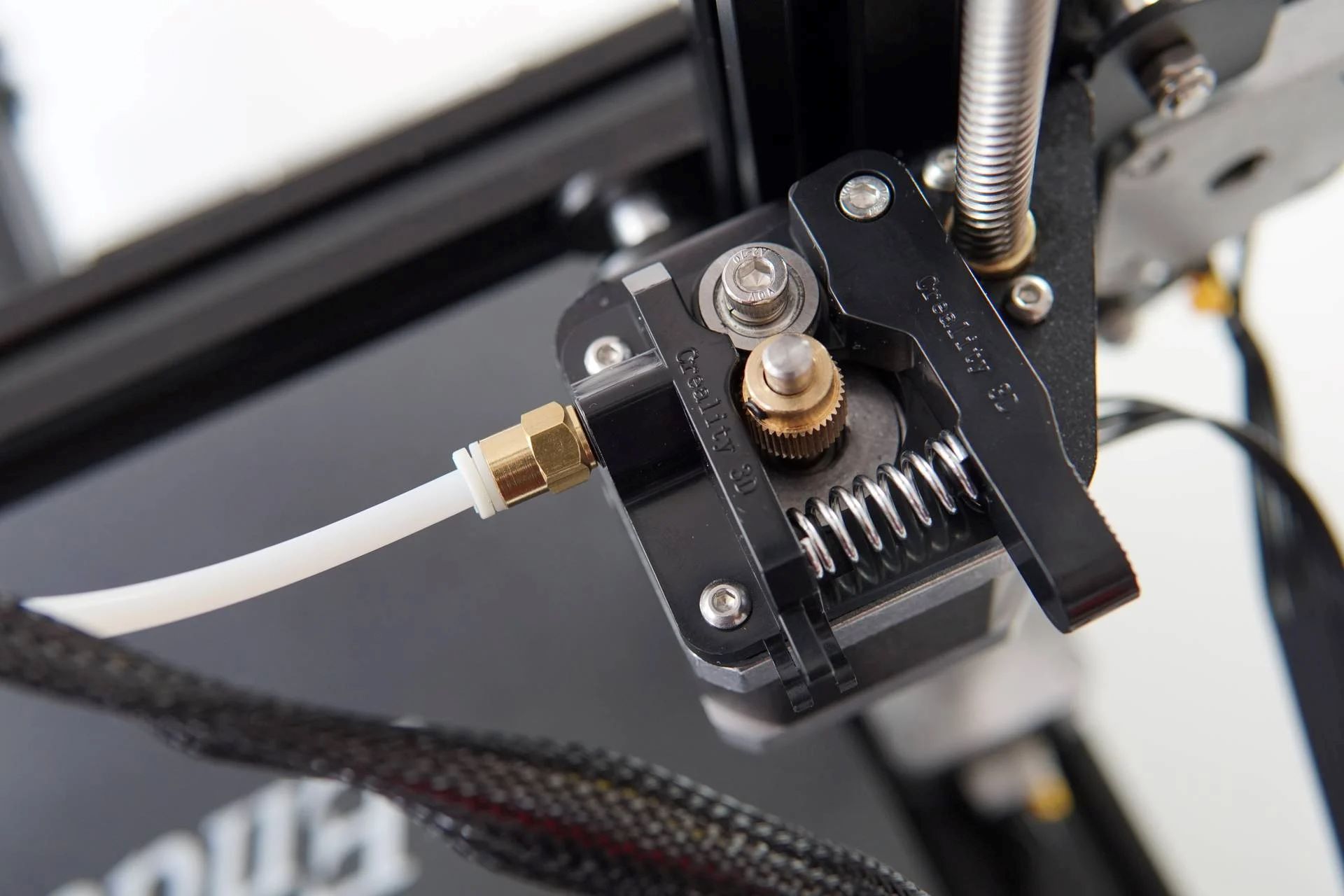

- Identify the Components: Begin by identifying the key components of the 3D printer that require lubrication. These typically include the rods, linear bearings, lead screws, and any other moving parts specified by the printer’s manufacturer.

- Clean the Components: Before applying lubricant, ensure that the components are clean and free from dust, debris, or old lubricant residue. Use a lint-free cloth or cotton swab to gently clean the surfaces of the components.

- Choose the Right Lubricant: Select the appropriate type of lubricant based on the printer’s specifications and the materials used in its construction. Refer to the manufacturer’s guidelines or recommendations for the most suitable lubricant for your specific 3D printer model.

- Apply the Lubricant: Using a small amount of the chosen lubricant, apply it to the designated areas of the components requiring lubrication. Ensure that the lubricant is evenly distributed and that excess lubricant is wiped away to prevent buildup.

- Exercise the Components: After applying the lubricant, move the relevant components back and forth to distribute the lubricant evenly and allow it to penetrate the moving parts. This helps to ensure that the lubricant reaches all necessary areas for smooth operation.

- Perform Regular Maintenance: Incorporate lubrication into your regular maintenance schedule to keep the 3D printer’s moving parts in optimal condition. Regular lubrication will contribute to consistent performance and prevent premature wear and tear.

By following these steps and incorporating regular lubrication into your 3D printer maintenance routine, you can help maintain the printer’s functionality, extend its lifespan, and ensure high-quality printing results. Proper lubrication is a simple yet effective way to preserve the performance and reliability of your 3D printer.

Common Mistakes to Avoid When Lubricating a 3D Printer

While lubricating a 3D printer is a relatively simple maintenance task, it’s important to be mindful of potential mistakes that could compromise the effectiveness of the lubrication process and the overall performance of the printer. Avoiding these common mistakes will help ensure that your 3D printer remains in optimal working condition:

- Over-Lubrication: Applying excessive lubricant to the printer’s components can lead to the accumulation of debris and attract dust, ultimately hindering smooth movement and causing potential damage. It’s essential to apply a moderate amount of lubricant as recommended by the printer’s manufacturer.

- Using the Wrong Lubricant: Selecting an inappropriate lubricant for the printer’s specific components or materials can result in ineffective lubrication or potential damage. Always refer to the manufacturer’s recommendations or guidelines when choosing a lubricant for your 3D printer.

- Neglecting Cleaning: Failing to clean the components before applying lubricant can trap debris and old residue, diminishing the effectiveness of the lubrication and potentially causing damage to the printer’s moving parts. Ensure that the components are clean and free from any contaminants before lubricating them.

- Applying Lubricant to Non-Moving Parts: It’s important to identify the specific moving parts of the printer that require lubrication and avoid applying lubricant to non-moving or electronic components. Applying lubricant to non-moving parts can lead to unnecessary buildup and potential damage to sensitive components.

- Ignoring Manufacturer Guidelines: Disregarding the manufacturer’s recommendations or guidelines for lubrication can lead to suboptimal performance and potential damage to the printer. Always adhere to the specific instructions provided by the printer’s manufacturer when performing lubrication maintenance.

- Infrequent Lubrication: Neglecting to incorporate lubrication into the printer’s regular maintenance routine can result in increased friction, premature wear, and reduced print quality. Regular and consistent lubrication is essential for preserving the printer’s functionality and longevity.

By being mindful of these common mistakes and following best practices for lubricating a 3D printer, users can effectively maintain their printers and enjoy reliable performance and high-quality printing results. Proper lubrication, when performed correctly, is a key aspect of ensuring the longevity and optimal functionality of a 3D printer.

Read more: What Is An Extruder On A 3D Printer

Conclusion

As we conclude this guide on lubricating a 3D printer, it is evident that proper lubrication is a fundamental aspect of maintaining the optimal performance and longevity of these innovative devices. By understanding the importance of lubrication, selecting the appropriate lubricants, and following best practices, 3D printer enthusiasts and professionals can ensure smooth and precise printing results while preserving the printer’s moving components.

Regular lubrication not only reduces friction and wear on critical parts but also contributes to enhanced print quality, reduced noise levels, and improved overall reliability. By incorporating lubrication into the printer’s routine maintenance, users can proactively safeguard their investment and enjoy consistent and high-quality 3D printing outcomes.

It is essential to be mindful of common mistakes to avoid when lubricating a 3D printer, such as over-lubrication, using the wrong lubricant, neglecting cleaning, and disregarding manufacturer guidelines. By steering clear of these pitfalls, users can ensure that the lubrication process effectively supports the printer’s performance and longevity.

Whether you are a hobbyist, designer, engineer, or business professional utilizing 3D printing technology, understanding the significance of proper lubrication and implementing the recommended maintenance practices will contribute to the seamless operation and durability of your 3D printer.

As the world of 3D printing continues to evolve, it is crucial to prioritize the maintenance and care of these remarkable devices. By embracing the principles of effective lubrication and adhering to best practices, users can maximize the potential of their 3D printers and continue to explore the boundless opportunities offered by additive manufacturing.

So, take the time to lubricate your 3D printer, follow the recommended guidelines, and enjoy the consistent and high-quality printing results that come with a well-maintained and properly lubricated 3D printer.

Frequently Asked Questions about How To Lubricate A 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Lubricate A 3D Printer”