Home>Technology>Smart Home Devices>How To Fix 3D Printer Stringing

Smart Home Devices

How To Fix 3D Printer Stringing

Modified: May 6, 2024

Learn how to fix 3D printer stringing issues with our comprehensive guide. Get expert tips and techniques for troubleshooting smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

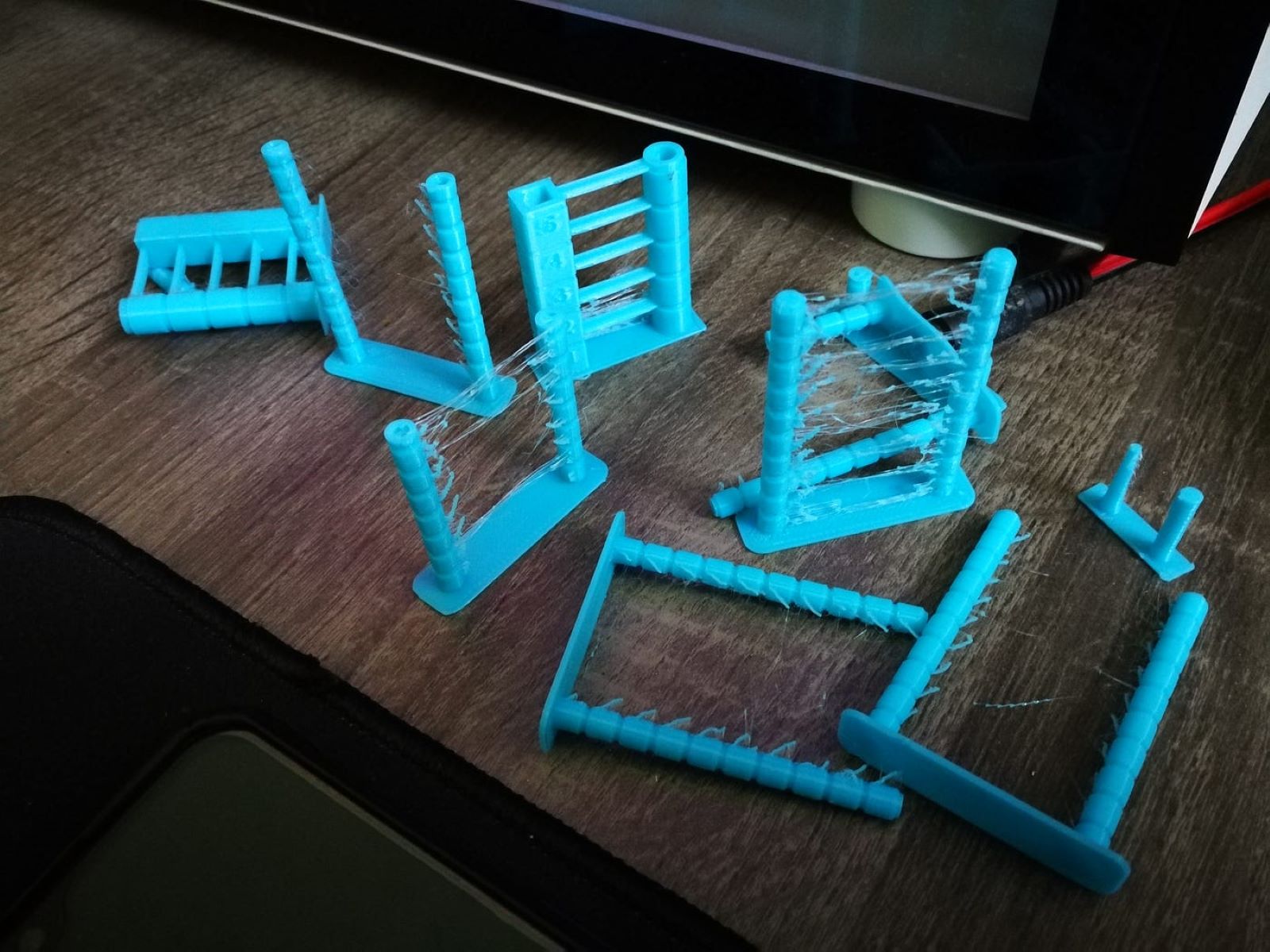

Welcome to the world of 3D printing, where the possibilities are endless and the technology continues to evolve at a rapid pace. As you delve into the fascinating realm of 3D printing, you may encounter a common issue known as stringing. This pesky problem occurs when thin strands of filament appear between the printed parts, marring the overall quality of your creations. However, fear not, as this article is here to guide you through understanding, preventing, and fixing 3D printer stringing.

Stringing can be a frustrating obstacle, but with the right knowledge and techniques, you can conquer this challenge and achieve pristine 3D prints. In the following sections, we will delve into the intricacies of stringing, exploring its causes, prevention methods, and effective solutions. By the end of this article, you will be equipped with the expertise to produce flawless 3D prints, free from the clutches of stringing. Let's embark on this enlightening journey to enhance your 3D printing prowess and elevate the quality of your creations.

**

Key Takeaways:

- Stringing in 3D printing happens when thin strands of filament appear between printed parts. Factors like filament type, printing temperature, and retraction settings can cause stringing.

- To prevent and fix stringing, adjust printing temperature, refine retraction settings, and optimize cooling. Experimentation and attention to detail are key in achieving flawless 3D prints.

Read more: How To Operate A 3D Printer

Understanding Stringing

**

Before delving into the prevention and resolution of 3D printer stringing, it is crucial to grasp a comprehensive understanding of this common issue. Stringing, also known as oozing or wisping, occurs when the extruder releases filament in unintended areas during the printing process. This results in thin, thread-like strands connecting different parts of the print or protruding from its surface.

Stringing is often attributed to the excessive oozing of molten filament from the nozzle when it moves between different areas of the print. This phenomenon is particularly noticeable when the nozzle travels over gaps or empty spaces, as the molten filament continues to flow and forms unwanted strands.

Several factors contribute to the occurrence of stringing, including the type of filament used, printing temperature, retraction settings, and the design of the 3D model. Understanding these variables is pivotal in effectively addressing and mitigating stringing issues. By comprehending the intricacies of stringing, you can proactively implement preventive measures and apply targeted solutions to eliminate this nuisance from your 3D prints.

As we unravel the causes and remedies for stringing in the subsequent sections, you will gain valuable insights into optimizing your 3D printing process and achieving impeccable results. Let’s embark on this enlightening journey to unravel the mysteries of stringing and empower you with the knowledge to conquer this common 3D printing challenge.

**

Causes of Stringing

**

Understanding the underlying causes of 3D printer stringing is essential for effectively addressing and preventing this issue. Several factors can contribute to the occurrence of stringing, and identifying these root causes is the first step toward achieving pristine 3D prints. Let’s explore the primary culprits behind stringing:

1. Filament Type: The composition of the filament plays a significant role in stringing. Certain materials, such as flexible or composite filaments, are more prone to oozing and stringing due to their unique properties. Additionally, the diameter and quality of the filament can impact its flow characteristics, influencing the likelihood of stringing.

2. Printing Temperature: The temperature at which the filament is extruded greatly influences its behavior. If the printing temperature is too high, the filament may become excessively fluid, leading to increased oozing and stringing. Conversely, printing at a temperature that is too low can cause insufficient melting and poor adhesion between layers.

3. Retraction Settings: Retraction is a crucial parameter that governs the withdrawal of filament from the nozzle when the extruder moves between different areas of the print. Inadequate retraction settings can result in filament oozing during travel moves, contributing to stringing issues.

4. Travel Speed: The speed at which the nozzle moves between different parts of the print, known as travel speed, can impact the occurrence of stringing. Higher travel speeds may exacerbate stringing due to increased filament oozing during rapid movements.

5. Cooling and Fan Settings: Proper cooling is vital for solidifying the extruded filament and minimizing stringing. Inadequate cooling or suboptimal fan settings can lead to excessive filament drooping and stringing, particularly in areas with overhangs or intricate geometries.

By recognizing these factors and their influence on stringing, you can strategically adjust your 3D printing parameters and implement targeted solutions to mitigate this issue. In the subsequent sections, we will delve into effective preventive measures and practical solutions to combat stringing, empowering you to achieve impeccable 3D prints with confidence and precision.

**

To fix 3D printer stringing, try adjusting the retraction settings in your slicer software. Increasing the retraction distance and speed can help reduce stringing between printed parts.

How to Prevent Stringing

**

Preventing 3D printer stringing requires a proactive approach that addresses the various factors contributing to this common issue. By implementing targeted preventive measures, you can optimize your 3D printing process and minimize the likelihood of stringing. Let’s explore effective strategies to prevent stringing and elevate the quality of your prints:

1. Optimize Printing Temperature: Fine-tuning the printing temperature based on the filament type and manufacturer’s recommendations is crucial for minimizing stringing. Conducting temperature calibration tests and adjusting the settings within the optimal range can significantly reduce filament oozing and stringing.

2. Refine Retraction Settings: Adjusting the retraction distance and speed can effectively mitigate stringing. Experiment with varying retraction parameters to find the optimal values that minimize filament oozing during travel moves, especially when traversing empty spaces within the print.

3. Fine-Tune Travel Speed: Optimizing the travel speed of the nozzle can help reduce stringing. By adjusting the travel speed settings, particularly when moving over gaps or areas with no printed features, you can minimize the likelihood of filament oozing and the formation of unwanted strands.

4. Enhance Cooling and Fan Control: Ensuring adequate cooling during the printing process is essential for preventing stringing, especially in areas with overhangs and intricate geometries. Adjusting fan settings and optimizing cooling parameters can promote the solidification of the extruded filament, reducing the occurrence of stringing.

5. Choose Filament Wisely: Selecting high-quality filament suited for your specific 3D printing application can contribute to stringing prevention. Consider the properties of the filament, such as viscosity and flow characteristics, and choose materials that are less prone to oozing and stringing.

By proactively addressing these preventive measures, you can significantly reduce the likelihood of stringing and enhance the overall quality of your 3D prints. The next section will delve into effective strategies for addressing stringing issues when they arise, providing you with practical solutions to rectify this common 3D printing challenge and achieve impeccable results.

**

How to Fix Stringing

**

When 3D printer stringing occurs, it is essential to employ effective strategies to rectify this issue and restore the quality of your prints. By implementing targeted solutions, you can effectively address stringing and achieve pristine results. Let’s explore practical methods for fixing stringing in your 3D prints:

1. Retraction Calibration: Fine-tuning the retraction settings can help alleviate stringing issues. Experiment with varying retraction distances and speeds to find the optimal values that minimize filament oozing during travel moves. Incremental adjustments and calibration tests can refine the retraction parameters for improved stringing control.

2. Temperature Adjustment: If stringing persists, adjusting the printing temperature may offer a viable solution. Lowering the temperature slightly can reduce the fluidity of the filament, minimizing oozing and the formation of unwanted strands. Conduct temperature calibration tests to identify the optimal printing temperature for mitigating stringing.

3. Post-Processing Techniques: After printing, employing post-processing techniques such as heat gun treatment or carefully targeted use of a soldering iron can help remove stringing artifacts. Caution must be exercised when utilizing heat-based methods to avoid damaging the print or compromising its structural integrity.

4. Manual Removal: In instances of minor stringing, manually removing the thin strands using precision tools or a craft knife can restore the visual appeal of the print. Exercise caution to avoid damaging the surrounding features and ensure meticulous attention to detail during the removal process.

5. Optimize Cooling: Enhancing cooling and fan control settings during the printing process can aid in mitigating stringing. Adjusting fan speeds and optimizing cooling parameters for specific areas of the print, especially those prone to stringing, can promote the solidification of the filament and reduce the occurrence of unwanted strands.

By implementing these targeted solutions, you can effectively address stringing issues and elevate the quality of your 3D prints. Experimentation, calibration, and meticulous attention to detail are key components of resolving stringing, empowering you to achieve impeccable results and unlock the full potential of your 3D printing endeavors.

**

Read more: How To Build A 3D Printer

Conclusion

**

Embarking on the journey of 3D printing unveils a world of boundless creativity and innovation, yet it also presents challenges such as the occurrence of stringing. However, armed with the knowledge and strategies shared in this article, you are well-equipped to conquer stringing and elevate the quality of your 3D prints.

By understanding the intricacies of stringing, recognizing its causes, and implementing proactive preventive measures, you can optimize your 3D printing process to minimize the likelihood of stringing. Fine-tuning parameters such as printing temperature, retraction settings, travel speed, and cooling control empowers you to achieve impeccable prints, free from the clutches of unwanted filament strands.

Moreover, when stringing does occur, the practical solutions outlined in this article offer effective strategies for rectifying the issue. From retraction calibration and temperature adjustment to post-processing techniques and meticulous manual removal, you have a diverse array of tools at your disposal to combat stringing and restore the visual appeal of your prints.

As you continue your 3D printing endeavors, remember that experimentation, calibration, and attention to detail are invaluable allies in your quest for flawless prints. Embrace the iterative nature of 3D printing, and view challenges such as stringing as opportunities for learning and refinement.

Armed with this comprehensive understanding of stringing and the strategies to prevent and address it, you are poised to unleash your creativity and bring your 3D designs to life with precision and excellence. Let the knowledge gained from this article serve as a guiding light on your 3D printing odyssey, empowering you to create awe-inspiring prints that captivate and inspire.

With a steadfast commitment to continuous improvement and a spirit of innovation, you are well-prepared to overcome any obstacle that arises in your 3D printing journey. As you harness the power of technology and creativity, may your prints reflect the brilliance and ingenuity that define the realm of 3D printing.

Now that you've got a handle on fixing stringing issues with your 3D printer, why stop there? Perfecting your printer setup is just as crucial. Dive into our next guide on how to calibrate a printer. This piece offers step-by-step instructions for ensuring your prints are precise and top-quality every time. Don't miss out on mastering this essential skill for any tech enthusiast or professional. Get ready to boost your printing precision!

Frequently Asked Questions about How To Fix 3D Printer Stringing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Fix 3D Printer Stringing”