Home>Technology>Smart Home Devices>How To Dry 3D Printer Filament

Smart Home Devices

How To Dry 3D Printer Filament

Modified: August 20, 2024

Learn how to properly dry 3D printer filament to improve the quality of your prints. Get expert tips and techniques for smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of 3D printing! As you delve into this innovative realm, you'll encounter various factors that can impact the quality of your prints. One crucial element to consider is the moisture content of your 3D printer filament.

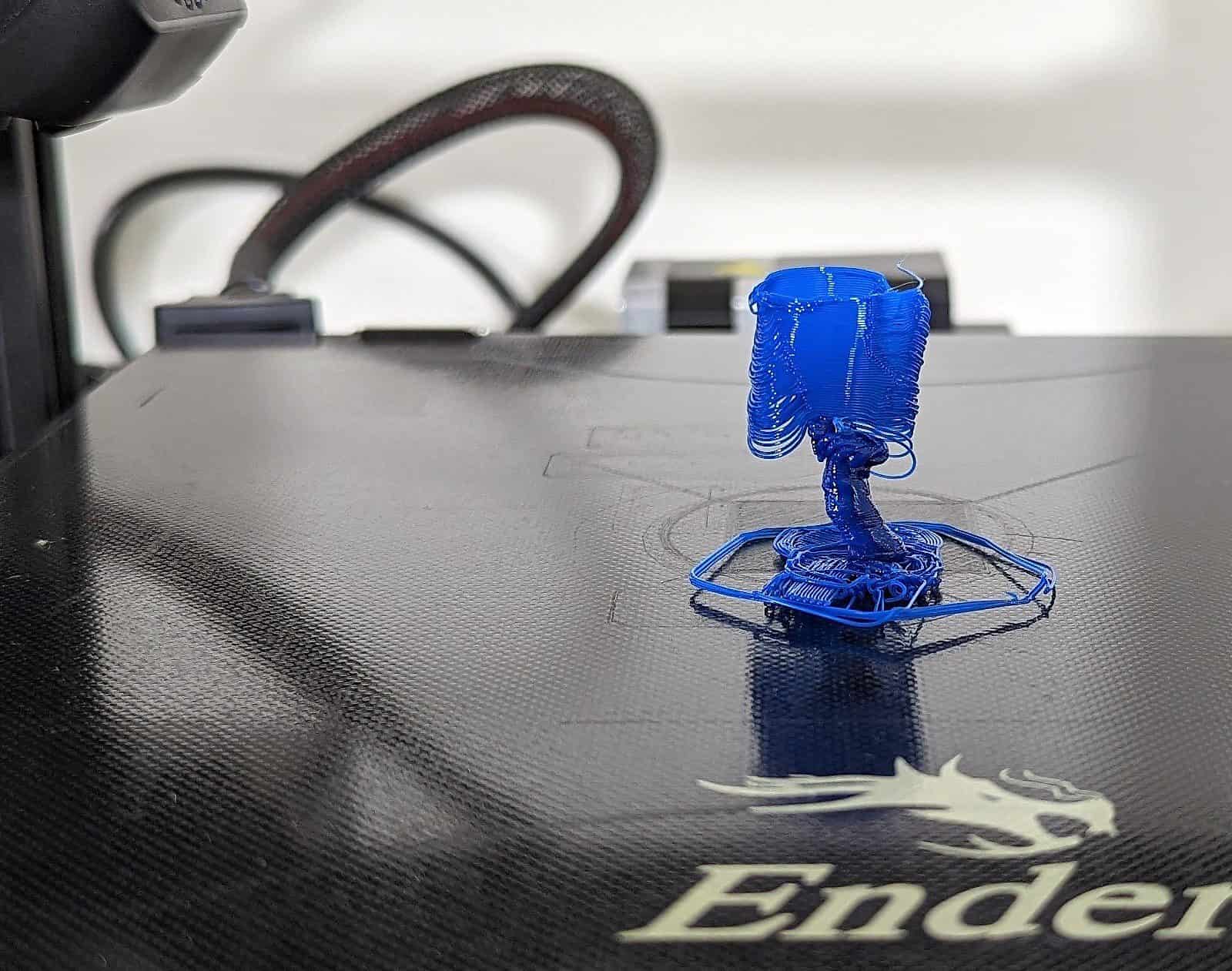

Moisture absorption can significantly affect the printability and structural integrity of filament, leading to issues such as poor layer adhesion, filament popping, and rough surface finishes. To mitigate these challenges, it's essential to understand the impact of moisture on filament and explore effective methods for drying it.

In this comprehensive guide, we'll delve into the nuances of 3D printer filament, uncover the detrimental effects of moisture absorption, and explore practical techniques for drying filament to ensure optimal printing results. Whether you're a seasoned 3D printing enthusiast or a novice eager to unleash your creativity, this article will equip you with valuable insights to enhance your printing experience.

Let's embark on this enlightening journey to unravel the art and science of drying 3D printer filament, empowering you to achieve impeccable print quality and unleash the full potential of your 3D printing endeavors.

Key Takeaways:

- Keep your 3D printer filament dry to avoid print defects. Use a food dehydrator, silica gel packets, or a filament dryer to restore moisture-affected filament for flawless 3D printing.

- Understanding filament vulnerability to moisture is crucial. By mastering drying methods, you can unleash your creativity with confidence and achieve impeccable 3D printing results.

Read more: How To Store 3D Printer Filament

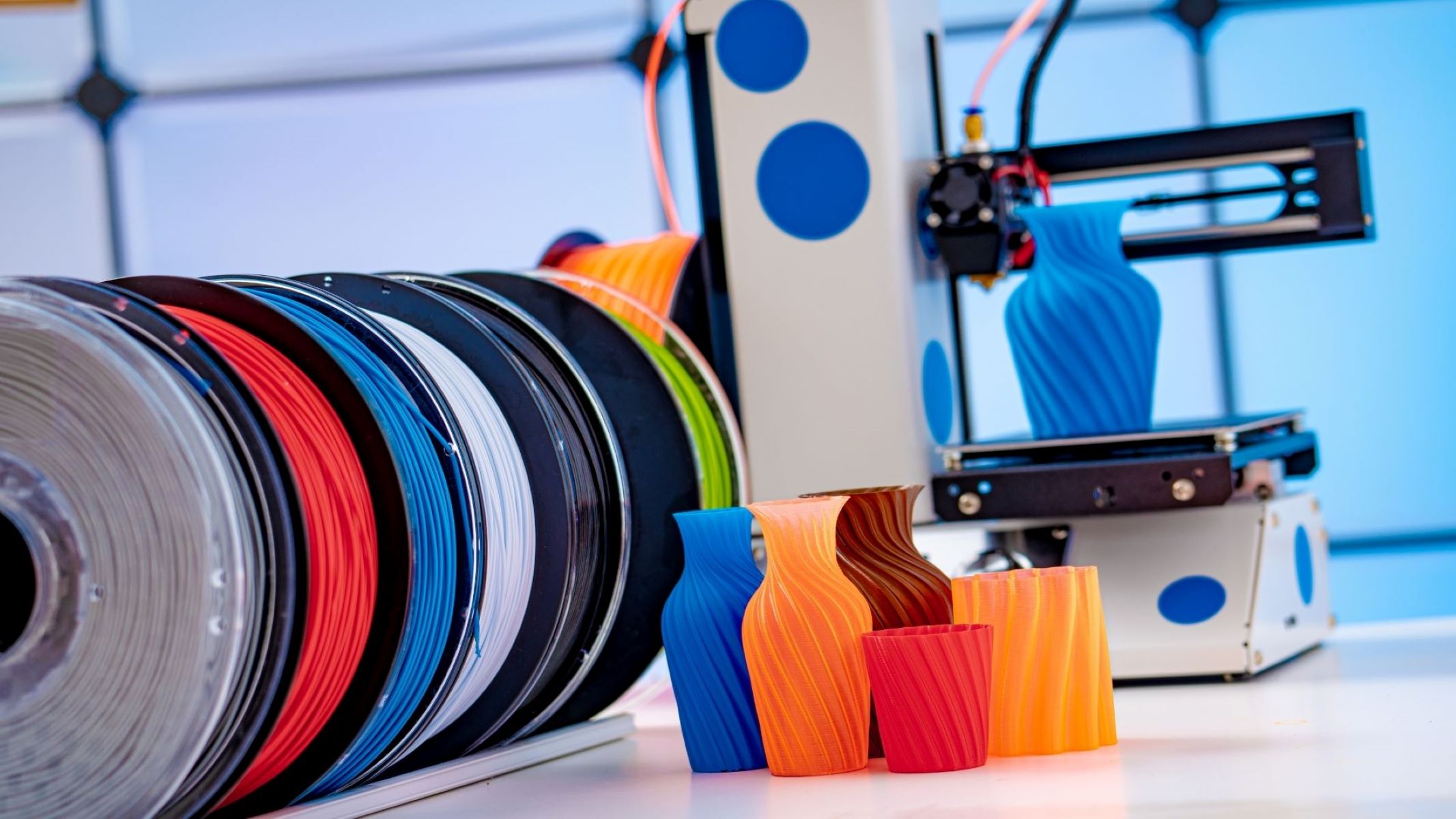

Understanding 3D Printer Filament

3D printer filament serves as the lifeblood of your 3D printing ventures, dictating the quality, durability, and intricacy of your printed creations. Comprehending the composition and characteristics of filament is pivotal in optimizing your printing process.

Commonly crafted from thermoplastic materials such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and TPU (Thermoplastic Polyurethane), 3D printer filament boasts diverse properties that cater to distinct printing requirements. This versatile range of materials enables creators to fabricate an array of objects, from rigid prototypes to flexible, resilient components.

Despite the diversity of filament types, they share a susceptibility to moisture absorption, which can compromise their printability and structural integrity. When exposed to humid environments, filament readily absorbs moisture from the air, leading to filament degradation and print defects. This phenomenon is particularly pronounced in hygroscopic materials like nylon, which exhibit a high affinity for moisture absorption.

Moisture-laden filament can manifest various printing challenges, including erratic extrusion, filament popping, and surface irregularities. These issues can mar the precision and aesthetics of your prints, underscoring the criticality of maintaining dry filament for optimal printing outcomes.

By comprehending the intrinsic vulnerability of 3D printer filament to moisture, you can proactively implement measures to safeguard its integrity and preserve print quality. This awareness sets the stage for exploring effective methods to dry filament, empowering you to surmount moisture-related impediments and elevate the caliber of your 3D printed creations.

Now that we've delved into the fundamental characteristics of 3D printer filament and its susceptibility to moisture, let's embark on a journey to uncover practical techniques for drying filament, ensuring that your printing endeavors yield impeccable results.

Methods for Drying 3D Printer Filament

Effectively drying 3D printer filament is imperative for maintaining print quality and mitigating the adverse effects of moisture absorption. Fortunately, several practical methods can be employed to restore filament to its optimal moisture content, ensuring smooth and flawless printing outcomes.

When selecting a drying method, it’s essential to consider factors such as convenience, efficacy, and the specific requirements of the filament material. Let’s explore three prominent techniques for drying 3D printer filament:

- Using a Food Dehydrator: A food dehydrator can serve as a versatile tool for drying 3D printer filament. By setting the dehydrator to a low temperature (typically around 45-50°C) and placing the filament spool inside for several hours, moisture can be effectively removed. This method is particularly suitable for PLA and ABS filaments, offering a convenient and accessible solution for filament drying.

- Using Silica Gel Packets: Silica gel packets, renowned for their moisture-absorbing properties, can be utilized to dry 3D printer filament. By enclosing the filament spool in an airtight container with silica gel packets, the desiccant properties of the silica gel facilitate the extraction of moisture from the filament. This method is simple and cost-effective, making it an appealing option for filament drying.

- Using a Filament Dryer: Dedicated filament dryers are specifically designed to restore moisture-laden filament to its optimal state. These devices feature precise temperature and humidity control, ensuring thorough and uniform drying of the filament. Filament dryers are compatible with various filament materials and offer a comprehensive solution for maintaining filament integrity.

By leveraging these effective drying methods, you can rejuvenate moisture-affected filament and fortify it against the detrimental implications of moisture absorption. The versatility and accessibility of these techniques empower 3D printing enthusiasts to uphold the quality and consistency of their prints, fostering a seamless and rewarding printing experience.

As we delve deeper into the nuances of each drying method, you’ll gain valuable insights into the practical implementation and benefits of these approaches, equipping you with the knowledge to optimize your filament drying endeavors and elevate the standard of your 3D printed creations.

Using a Food Dehydrator

Employing a food dehydrator as a filament drying solution offers a convenient and accessible method to restore moisture-laden filament to its optimal state. This versatile kitchen appliance, commonly utilized for dehydrating fruits, vegetables, and meats, can be repurposed to effectively dry 3D printer filament.

The process of using a food dehydrator to dry filament involves several key steps to ensure thorough and uniform moisture removal:

- Temperature Setting: To initiate the drying process, set the food dehydrator to a low temperature, typically ranging from 45 to 50 degrees Celsius. This gentle heat facilitates the evaporation of moisture from the filament without subjecting it to excessive thermal stress, preserving the filament’s structural integrity.

- Spool Placement: Carefully position the filament spool inside the food dehydrator, ensuring that it is arranged in a manner that allows for adequate air circulation and even heat distribution. This arrangement promotes consistent drying and prevents localized moisture retention within the filament.

- Drying Duration: The duration of the drying process varies based on factors such as the filament material and the extent of moisture absorption. Typically, several hours of exposure to the controlled heat within the food dehydrator are sufficient to effectively eliminate moisture from the filament.

It’s important to exercise caution and monitor the drying progress periodically to prevent overheating and ensure optimal results. By adhering to these guidelines, you can harness the capabilities of a food dehydrator to rejuvenate moisture-affected filament and restore it to an ideal condition for seamless 3D printing.

The accessibility and versatility of using a food dehydrator for filament drying make it an appealing option for 3D printing enthusiasts seeking a practical and cost-effective solution. By repurposing this common kitchen appliance, you can proactively address moisture-related challenges and uphold the quality and consistency of your 3D printed creations.

As we delve deeper into the intricacies of drying filament with alternative methods, you’ll gain further insights into the practical implementation and benefits of these approaches, equipping you with the knowledge to optimize your filament drying endeavors and elevate the standard of your 3D printed creations.

To dry 3D printer filament, place it in a food dehydrator at 45-50°C for 4-6 hours. This will remove any moisture and improve print quality.

Using Silica Gel Packets

Utilizing silica gel packets presents a simple yet effective method for drying moisture-laden 3D printer filament. Renowned for their exceptional moisture-absorbing properties, silica gel packets offer a convenient and cost-effective solution to restore filament to an optimal state for seamless 3D printing.

The process of using silica gel packets to dry filament involves the following key steps:

- Enclosure in Airtight Container: Place the moisture-affected filament spool inside an airtight container, ensuring a snug and secure enclosure. This airtight environment prevents the ingress of external moisture and facilitates the moisture extraction process, optimizing the efficacy of the silica gel packets.

- Inclusion of Silica Gel Packets: Introduce several silica gel packets into the airtight container alongside the filament spool. The desiccant properties of the silica gel enable it to actively absorb moisture from the surrounding environment, effectively extracting moisture from the filament.

- Duration of Drying: The duration of the drying process is contingent upon the extent of moisture absorption and the ambient humidity levels. Allowing the filament to remain enclosed with the silica gel packets for a sufficient duration ensures comprehensive moisture removal, restoring the filament to an ideal state for printing.

By harnessing the moisture-absorbing capabilities of silica gel packets, you can efficiently address moisture-related challenges and preserve the integrity of your filament, paving the way for consistent and high-quality 3D printing outcomes.

The accessibility and affordability of this method make it an attractive option for 3D printing enthusiasts seeking a straightforward and reliable approach to filament drying. By leveraging silica gel packets, you can proactively safeguard your filament against the detrimental effects of moisture absorption, fostering a seamless and rewarding 3D printing experience.

As we delve further into the nuances of drying filament with alternative methods, you’ll gain additional insights into the practical implementation and benefits of these approaches, empowering you to optimize your filament drying endeavors and elevate the standard of your 3D printed creations.

Read more: How To Reuse 3D Printer Filament

Using a Filament Dryer

Employing a dedicated filament dryer offers a comprehensive and precise solution for restoring moisture-laden 3D printer filament to its optimal state. These specialized devices are engineered to deliver controlled heating and humidity regulation, ensuring thorough and uniform drying of filament materials, thereby enhancing print quality and consistency.

The process of using a filament dryer to dry filament involves several key components and operational steps to facilitate effective moisture removal:

- Filament Compatibility: Filament dryers are designed to accommodate various filament materials, including PLA, ABS, PETG, TPU, and more. This versatility enables users to address the moisture-related challenges associated with a diverse range of filament types, enhancing the applicability and efficacy of the drying process.

- Precise Temperature Control: Filament dryers feature precise temperature control mechanisms, allowing users to set and maintain the ideal drying temperature for the specific filament material. This meticulous temperature regulation prevents thermal degradation of the filament while expediting the evaporation of moisture, ensuring optimal drying outcomes.

- Uniform Heat Distribution: The design of filament dryers facilitates uniform heat distribution throughout the filament spool, preventing localized overheating or moisture retention. This uniformity promotes consistent drying and mitigates the risk of structural compromise or print defects due to uneven moisture extraction.

- Humidity Regulation: Filament dryers incorporate humidity regulation features to create an environment conducive to moisture removal. By controlling the humidity levels within the drying chamber, these devices optimize the drying process, preserving filament integrity and print quality.

By leveraging the advanced capabilities of a filament dryer, you can proactively address moisture-related challenges and fortify your filament against the detrimental effects of moisture absorption. The precision and comprehensiveness of this drying method empower 3D printing enthusiasts to consistently achieve superior print quality and elevate the standard of their printed creations.

The dedicated functionality and efficacy of filament dryers make them an invaluable asset for 3D printing enthusiasts seeking a sophisticated and reliable solution for filament drying. By harnessing the capabilities of these specialized devices, you can optimize the integrity and printability of your filament, fostering a seamless and rewarding 3D printing experience.

As we delve further into the intricacies of drying filament with alternative methods, you’ll gain additional insights into the practical implementation and benefits of these approaches, equipping you with the knowledge to optimize your filament drying endeavors and elevate the standard of your 3D printed creations.

Conclusion

Congratulations! You’ve embarked on a captivating journey through the realm of 3D printer filament and the art of drying it to perfection. By delving into the nuances of filament composition, moisture susceptibility, and practical drying methods, you’ve gained valuable insights to enhance your 3D printing endeavors and elevate the quality of your printed creations.

Understanding the intrinsic vulnerability of 3D printer filament to moisture absorption is pivotal in fortifying your printing process against the challenges posed by excessive humidity. Whether you’re working with PLA, ABS, PETG, TPU, or other filament materials, the detrimental effects of moisture can manifest in various print defects, underscoring the criticality of maintaining dry filament for optimal printing outcomes.

By exploring versatile drying methods such as using a food dehydrator, silica gel packets, and dedicated filament dryers, you’ve equipped yourself with an array of effective solutions to rejuvenate moisture-affected filament and ensure consistent print quality. Whether you prefer the accessibility of repurposing a food dehydrator, the simplicity of employing silica gel packets, or the comprehensive functionality of a filament dryer, these methods empower you to proactively address moisture-related challenges and uphold the integrity of your filament.

As you continue your 3D printing journey, armed with the knowledge and practical insights gleaned from this guide, you’re poised to unleash your creativity with confidence, knowing that you possess the expertise to optimize your filament drying endeavors and achieve impeccable printing results.

So, go forth and immerse yourself in the boundless possibilities of 3D printing, fueled by the assurance that you possess the acumen to conquer moisture-related obstacles and craft exceptional creations. Your 3D printing odyssey awaits, brimming with innovation, precision, and the transformative power of perfectly dried filament.

Embrace the art and science of filament drying, and let your 3D printed marvels inspire awe and admiration, propelled by the meticulous care and expertise you invest in preserving the integrity of your filament. Your journey to unparalleled 3D printing excellence begins here, where the mastery of filament drying converges with your boundless creativity and ingenuity.

Frequently Asked Questions about How To Dry 3D Printer Filament

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Dry 3D Printer Filament”