Home>Technology>Smart Home Devices>How To Make 3D Printer Faster

Smart Home Devices

How To Make 3D Printer Faster

Modified: August 20, 2024

Discover effective strategies to optimize your 3D printer speed and efficiency with smart home devices. Streamline your printing process and achieve faster results today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the exciting world of 3D printing, where creativity knows no bounds and innovation is at your fingertips. As technology continues to evolve, 3D printing has become increasingly accessible, empowering enthusiasts and professionals alike to bring their ideas to life in three dimensions. However, one common challenge that 3D printing enthusiasts encounter is the issue of print speed. In this article, we will explore various strategies for optimizing 3D printer speed, allowing you to unleash your creativity with greater efficiency and productivity.

Whether you are a hobbyist, an entrepreneur, or a professional in the fields of engineering, design, or architecture, the ability to enhance 3D printing speed can significantly impact your workflow and project timelines. By understanding the factors that influence print speed, implementing hardware upgrades, and leveraging software optimizations, you can elevate your 3D printing experience to new heights.

Join us on this journey as we delve into the intricacies of 3D printing speed and uncover valuable insights and techniques for accelerating your printing processes. Let's embark on this exploration of 3D printing speed optimization, where we will unravel the secrets to making your 3D printer faster and more efficient.

Key Takeaways:

- Adjusting settings like layer height and infill density can speed up 3D printing without sacrificing quality. It’s like finding the perfect balance between speed and detail for your projects.

- Upgrading hardware components and using advanced slicing software can make your 3D printer faster. It’s like giving your printer a turbo boost for quicker and more efficient printing.

Read more: How To Make Money With A 3D Printer

Understanding the Basics of 3D Printing Speed

When it comes to 3D printing, speed plays a crucial role in determining the efficiency and turnaround time of your projects. The speed of 3D printing is influenced by various factors, each of which can impact the overall printing process. Understanding these fundamental aspects is essential for optimizing and maximizing the speed of your 3D printer.

Layer height, also known as the resolution or thickness of each printed layer, directly affects the speed of the printing process. A smaller layer height results in finer details and smoother surfaces but requires more time to complete the print. Conversely, a larger layer height accelerates the printing speed but may compromise the level of detail and surface finish. Finding the optimal balance between layer height and speed is crucial for achieving the desired print quality within a reasonable timeframe.

Another key factor influencing 3D printing speed is the infill density, which determines the internal structure of the printed object. Higher infill densities contribute to stronger and more durable prints but can significantly extend the printing time. Conversely, reducing the infill density can expedite the printing process at the expense of structural integrity. Balancing infill density with speed is essential for achieving the desired strength and print duration for each project.

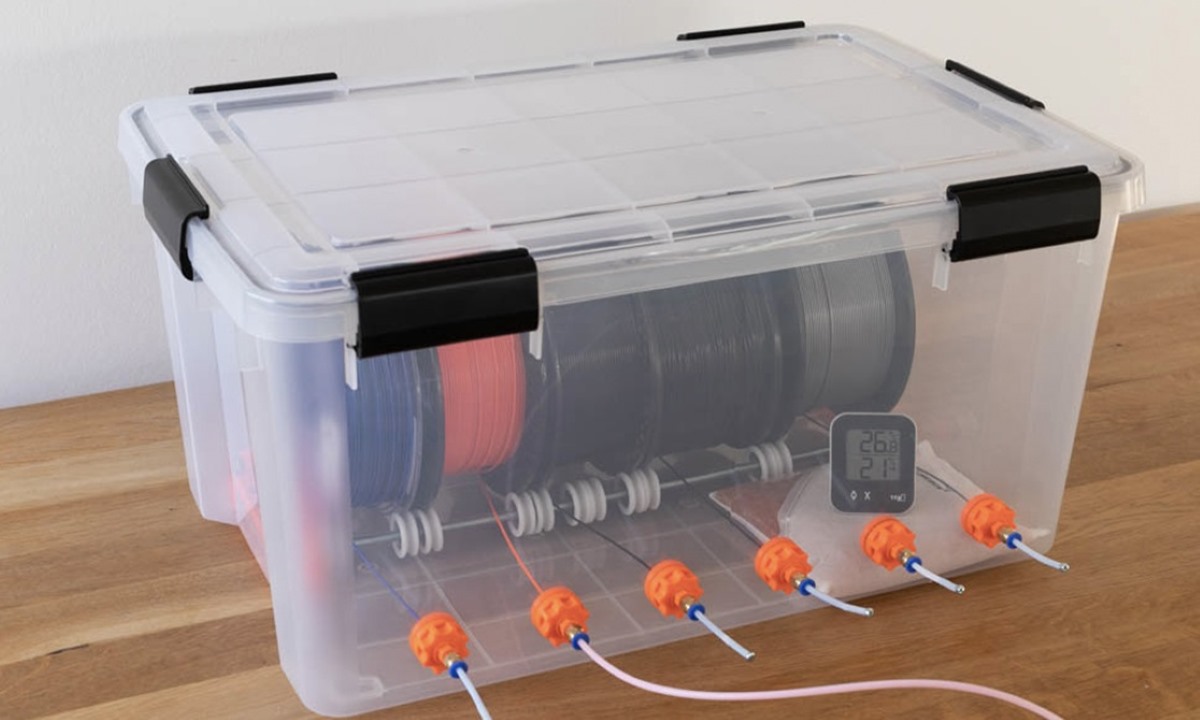

Furthermore, the type and temperature of the printing filament can impact the speed and quality of the prints. Different filaments, such as PLA, ABS, PETG, and TPU, have varying optimal printing temperatures and flow characteristics. Understanding the ideal printing parameters for each filament type enables you to optimize speed without compromising print quality.

Additionally, the design complexity of the 3D model influences the printing speed. Intricate and highly detailed designs require more time to print, while simpler designs can be completed at a faster pace. Optimizing the design of your 3D models by reducing unnecessary complexity and minimizing overhangs and unsupported features can expedite the printing process without sacrificing the intended aesthetics and functionality.

By comprehending the interplay of these factors, you can strategically adjust the settings of your 3D printer to achieve an optimal balance between speed, quality, and structural integrity. In the subsequent sections, we will delve into actionable tips and techniques for optimizing 3D printer speed, empowering you to unleash the full potential of your 3D printing endeavors.

Tips for Optimizing 3D Printer Speed

Optimizing the speed of your 3D printer involves a combination of strategic adjustments and best practices that can significantly enhance the efficiency of your printing processes. By implementing the following tips, you can streamline your workflow and achieve faster print times without compromising the quality of your 3D prints.

- Adjust Layer Height: Fine-tuning the layer height settings allows you to strike a balance between print quality and speed. Experiment with different layer heights to determine the optimal setting for your specific projects. For prototypes and functional parts that do not require ultra-fine details, increasing the layer height can expedite the printing process.

- Optimize Infill Density: Assess the structural requirements of your prints and adjust the infill density accordingly. For decorative or non-load-bearing objects, reducing the infill density can significantly reduce print time without compromising the visual appeal. Conversely, for functional parts that demand strength, a higher infill density is essential.

- Minimize Support Structures: Design your 3D models with careful consideration for overhangs and unsupported features. Minimizing the need for extensive support structures can expedite the printing process and reduce material usage, resulting in faster and more efficient prints.

- Utilize Draft Mode: Many slicing software packages offer a draft mode or fast print setting, which prioritizes speed over intricate details. When speed is paramount and fine details are not critical, utilizing the draft mode can significantly reduce print times while maintaining acceptable quality.

- Optimal Filament Temperature: Ensure that the printing temperature of your filament is calibrated to the recommended range for the specific material. Printing at the lower end of the temperature range can expedite the extrusion process without compromising print quality, especially for non-critical parts.

- Print Multiple Objects Simultaneously: When feasible, arrange multiple smaller objects on the print bed to be printed simultaneously. This approach maximizes the printer’s efficiency by utilizing the available print area for concurrent printing, reducing overall print time per object.

- Use High-Speed Print Profiles: Some slicing software provides predefined high-speed print profiles optimized for rapid printing. These profiles are tailored to maximize speed while maintaining acceptable print quality, making them ideal for non-critical or large-scale prints.

- Invest in a High-Flow Nozzle: Upgrading to a high-flow nozzle can significantly increase the extrusion rate, allowing for faster deposition of filament during the printing process. This upgrade is particularly beneficial for larger prints and can expedite the overall print time.

By incorporating these tips into your 3D printing workflow, you can harness the full potential of your 3D printer’s speed capabilities, enabling you to complete projects more efficiently and effectively. In the next sections, we will explore hardware upgrades and software optimizations that further enhance the speed and performance of 3D printing.

To make a 3D printer faster, try increasing the print speed in the printer settings, using larger nozzle sizes, and optimizing the design for faster printing. Keep in mind that increasing speed may affect print quality.

Upgrading Hardware for Faster 3D Printing

Enhancing the speed of your 3D printer often involves upgrading key hardware components to optimize performance and throughput. By investing in hardware upgrades, you can elevate the capabilities of your 3D printer and achieve faster print times without compromising print quality. The following hardware enhancements are proven to accelerate the printing process and unlock new levels of efficiency.

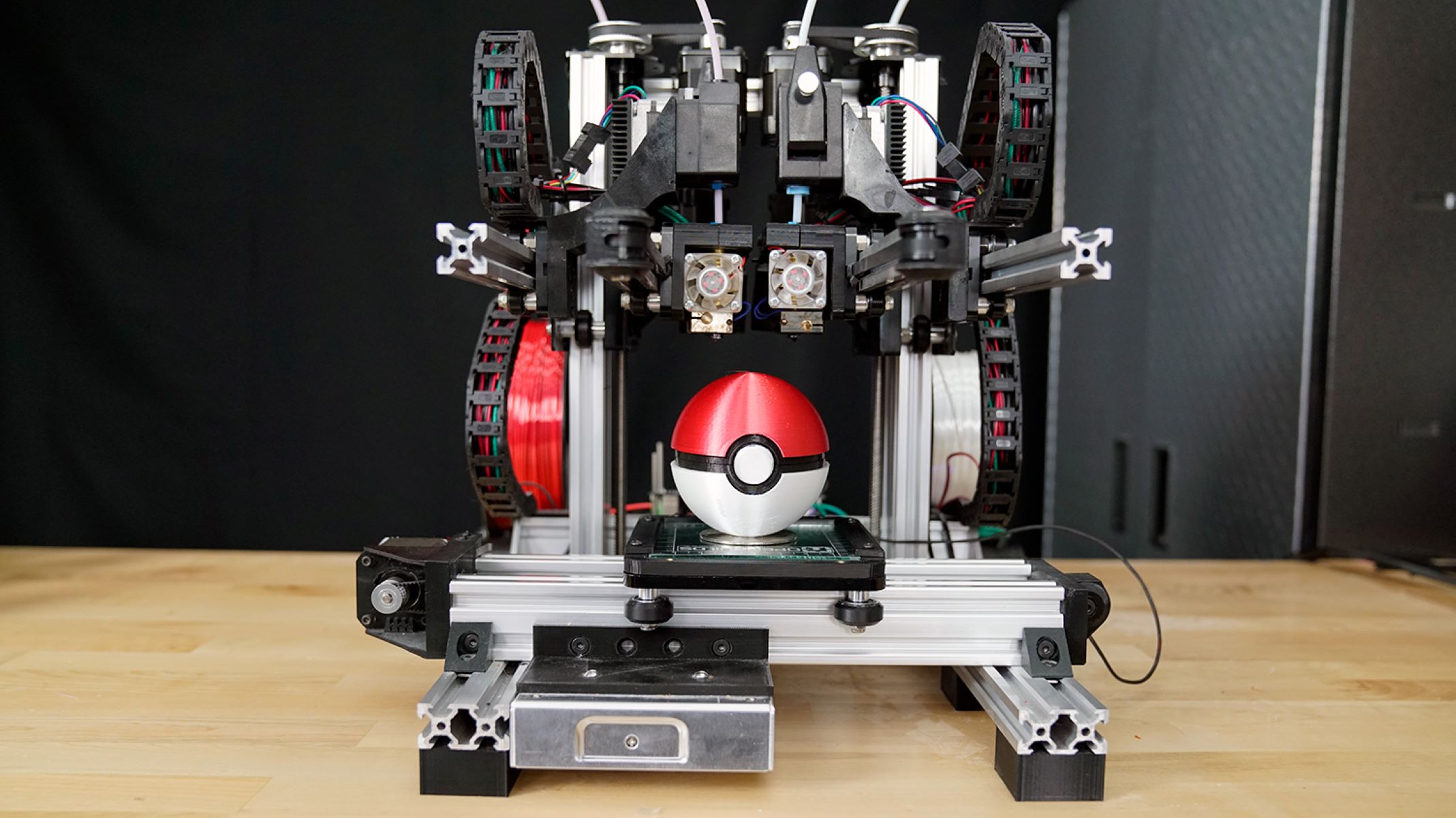

- High-Speed Extruder: Upgrading to a high-speed extruder assembly can significantly boost the filament deposition rate, allowing for faster and more consistent extrusion during the printing process. This upgrade is especially beneficial for large-scale prints and complex geometries, reducing print times while maintaining precision.

- Upgraded Hotend Assembly: Installing a high-performance hotend assembly with improved thermal conductivity and filament flow characteristics can enhance the overall extrusion efficiency. A high-quality hotend ensures uniform filament melting and deposition, contributing to faster and more reliable prints.

- Linear Rail Systems: Retrofitting your 3D printer with linear rail systems enhances the stability, smoothness, and precision of the print head’s movements. The reduced friction and improved rigidity provided by linear rails enable faster print speeds and higher acceleration, resulting in shorter print times without sacrificing accuracy.

- Upgraded Control Board: Installing a modern, high-performance control board with advanced microstepping capabilities and optimized processing power can enhance the overall motion control and print management of your 3D printer. A superior control board enables smoother and more efficient movements, contributing to faster print speeds and improved print quality.

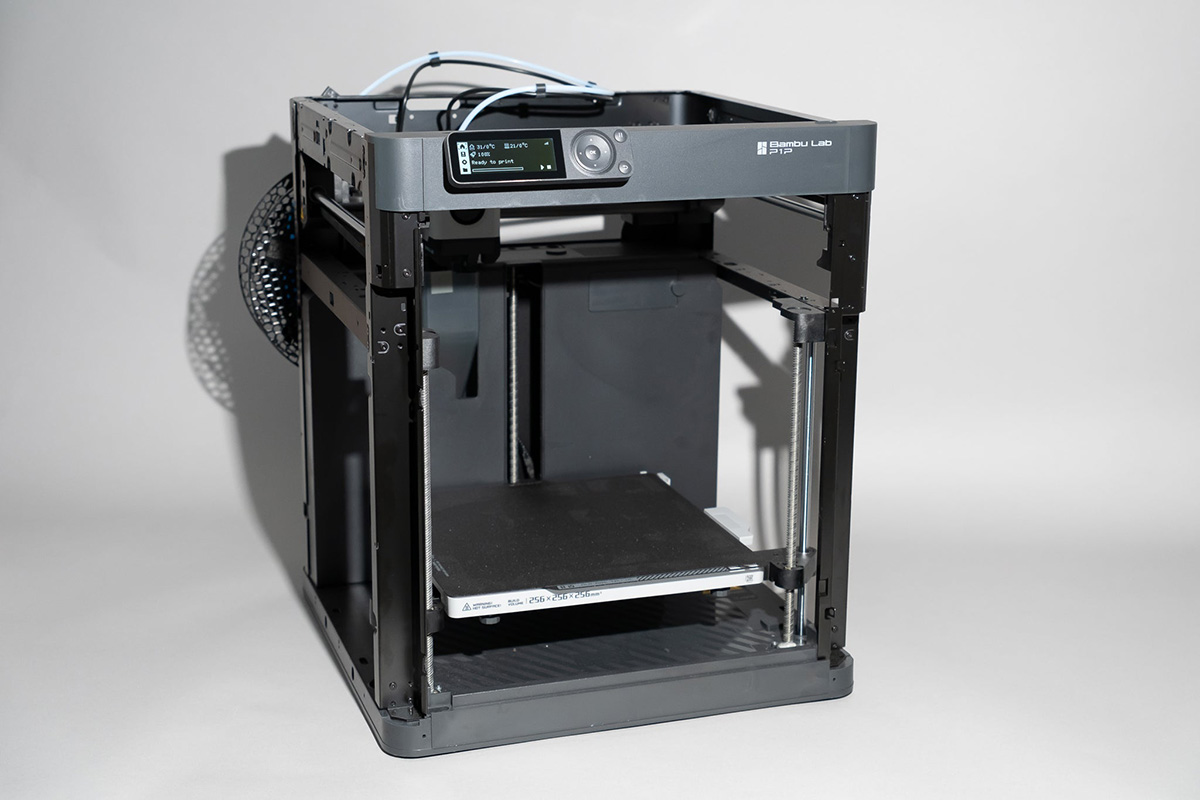

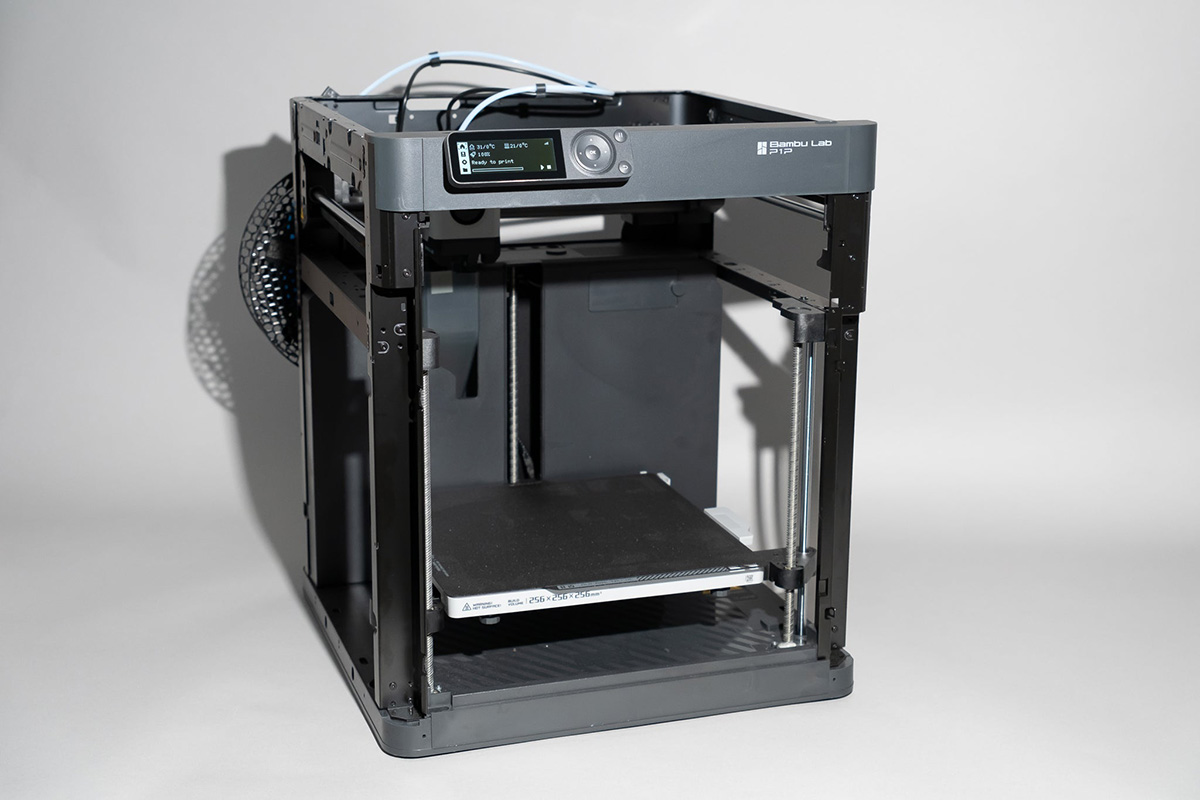

- Enclosed Print Chamber: Retrofitting your 3D printer with an enclosed print chamber can create a controlled environment with stable temperatures, minimizing warping and improving adhesion for various filament materials. The enhanced print quality and reliability enable faster print speeds, especially for larger prints and complex geometries.

- Upgraded Cooling System: Enhancing the cooling system with high-performance fans and optimized ducting can improve the overall print quality and enable faster print speeds, particularly for prints with intricate details and overhangs. Efficient part cooling reduces the likelihood of print defects and enables faster layer-to-layer solidification.

- High-Capacity Heated Bed: Upgrading to a high-capacity heated bed with rapid heating capabilities and uniform temperature distribution can expedite the print preparation process and minimize idle time. The enhanced thermal performance enables faster print start times and improved adhesion for various filament materials.

By strategically upgrading key hardware components, you can transform your 3D printer into a high-speed, high-performance printing platform capable of delivering exceptional results in less time. These hardware enhancements not only accelerate the printing process but also expand the capabilities and versatility of your 3D printer, empowering you to pursue ambitious projects with confidence and efficiency.

Software Tweaks for Speeding Up 3D Printing

Optimizing the software settings and parameters of your 3D printer is instrumental in achieving faster print times and maximizing the efficiency of the printing process. By leveraging advanced slicing software features and implementing strategic tweaks, you can fine-tune the printing parameters to accelerate print speeds without compromising the quality of your 3D prints. The following software optimizations are proven to enhance the speed and performance of 3D printing:

- Advanced Slicing Settings: Explore the advanced slicing settings in your preferred slicing software to customize parameters such as print speed, acceleration, and jerk control. Fine-tuning these settings enables you to maximize the printing speed while maintaining precise control over the print head’s movements and extrusion rates.

- Optimized Retraction Settings: Adjusting the retraction settings, including retraction distance and speed, can minimize filament oozing and stringing, allowing for smoother and faster print transitions. Optimized retraction settings contribute to cleaner prints and reduced print times, especially for models with intricate details and fine features.

- Dynamic Print Speed Control: Implement dynamic print speed control features offered by advanced slicing software. These features enable varying print speeds based on specific segments of the print, allowing for accelerated movements in less critical areas and finer details in intricate sections, resulting in overall faster print times.

- Adaptive Layer Height: Some slicing software packages offer adaptive layer height features, allowing the printer to automatically adjust the layer height based on the complexity and detail requirements of each section of the model. This dynamic optimization minimizes print times without compromising the visual quality of the prints.

- Intelligent Support Generation: Utilize advanced support generation algorithms to optimize the placement and structure of support material. Efficient support generation reduces unnecessary material usage and print time, resulting in faster and more streamlined prints with minimal post-processing requirements.

- Print Simulation and Optimization: Leverage print simulation and optimization tools to analyze and refine the printing parameters before initiating the actual print. By simulating the print process and identifying potential bottlenecks or inefficiencies, you can optimize the settings for faster and more reliable prints.

- Multi-Part Nesting and Arrangement: Utilize the nesting and arrangement features of slicing software to efficiently position multiple smaller objects on the print bed, maximizing the printer’s capacity and enabling simultaneous printing. This approach reduces idle time and accelerates the overall print duration.

- Custom Print Profiles: Create custom print profiles tailored to specific filament types, model complexities, and speed requirements. By optimizing the print settings for each scenario, you can achieve faster print times while preserving the intended quality and structural integrity of the prints.

By harnessing the capabilities of advanced slicing software and implementing these strategic tweaks, you can unleash the full speed potential of your 3D printer while maintaining precise control over the printing process. These software optimizations empower you to achieve faster print times and elevate the efficiency of your 3D printing endeavors, enabling you to bring your ideas to life with unparalleled speed and precision.

Read more: How To Make 3D Printer Designs

Conclusion

Congratulations on embarking on this enlightening journey through the realm of 3D printing speed optimization. As we conclude our exploration, it is evident that the quest for faster 3D printing is a multifaceted endeavor that encompasses hardware upgrades, software optimizations, and strategic adjustments to printing parameters. By understanding the fundamental factors influencing print speed and implementing the actionable tips and techniques discussed in this article, you are poised to elevate your 3D printing experience to new heights of efficiency and productivity.

Throughout our journey, we have unraveled the intricate interplay of factors such as layer height, infill density, filament characteristics, and design complexity, each of which influences the speed and quality of 3D prints. By carefully balancing these elements and leveraging advanced slicing software features, you can achieve faster print times without compromising the integrity and precision of your prints.

Furthermore, the prospect of upgrading key hardware components, such as the extruder, hotend assembly, and control board, presents an opportunity to transform your 3D printer into a high-speed, high-performance printing platform capable of delivering exceptional results in less time. These hardware enhancements not only accelerate the printing process but also expand the capabilities and versatility of your 3D printer, enabling you to pursue ambitious projects with confidence and efficiency.

As you continue your 3D printing journey, remember that the pursuit of speed should not overshadow the pursuit of quality and innovation. Striking a harmonious balance between speed and precision is essential in realizing the full potential of your 3D printer. Embrace the iterative nature of 3D printing, where each print serves as a learning experience and an opportunity for refinement.

With the knowledge and insights gained from this exploration, you are well-equipped to embark on your future 3D printing endeavors with confidence and ingenuity. Whether you are a hobbyist, a professional, or an entrepreneur, the ability to optimize 3D printing speed empowers you to bring your ideas to life with unparalleled efficiency and creativity.

As you apply the strategies and techniques shared in this article, may your 3D printing endeavors be marked by swift progress, remarkable innovation, and the fulfillment of your boldest creative visions. Embrace the art and science of 3D printing speed optimization, and let your passion for innovation propel you toward new horizons of achievement and excellence.

Frequently Asked Questions about How To Make 3D Printer Faster

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make 3D Printer Faster”