Home>Technology>Smart Home Devices>What Can You Make With A 3D Printer

Smart Home Devices

What Can You Make With A 3D Printer

Modified: August 20, 2024

Discover endless possibilities with 3D printing for your smart home devices. Explore innovative ideas and create custom solutions with ease. Unlock the potential of 3D printing today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Introduction

Welcome to the fascinating world of 3D printing! In recent years, this innovative technology has revolutionized the way we create and manufacture objects, offering endless possibilities for both professionals and hobbyists. Whether you’re a tech enthusiast, a designer, an engineer, or simply curious about the latest advancements in manufacturing, 3D printing has something for everyone.

Imagine being able to transform digital designs into tangible, three-dimensional objects with just the touch of a button. This is the magic of 3D printing, also known as additive manufacturing. Unlike traditional subtractive manufacturing processes, which involve cutting away material from a solid block, 3D printing builds up objects layer by layer, using materials such as plastics, metals, ceramics, and even food ingredients. The ability to create complex shapes and intricate geometries with precision and efficiency sets 3D printing apart as a game-changing technology.

As we delve into the world of 3D printing, we’ll explore the technology behind it, the diverse applications it serves, the materials used in the process, and most excitingly, the incredible array of objects that can be produced with a 3D printer. Whether you’re interested in crafting custom prototypes, personalized accessories, or functional household items, 3D printing empowers you to bring your ideas to life in ways that were once unimaginable.

Overview of 3D Printing Technology

Key Takeaways:

- 3D printing offers endless possibilities, from creating prototypes and customized healthcare solutions to crafting artistic sculptures and functional household items. The technology empowers creativity and innovation across diverse industries.

- With 3D printing, you can bring your ideas to life by producing prototypes, personalized accessories, and even medical implants. The technology’s versatility and accessibility drive creativity and problem-solving in manufacturing and design.

Read more: What Can You Make With A 3D Printer To Sell

Overview of 3D Printing Technology

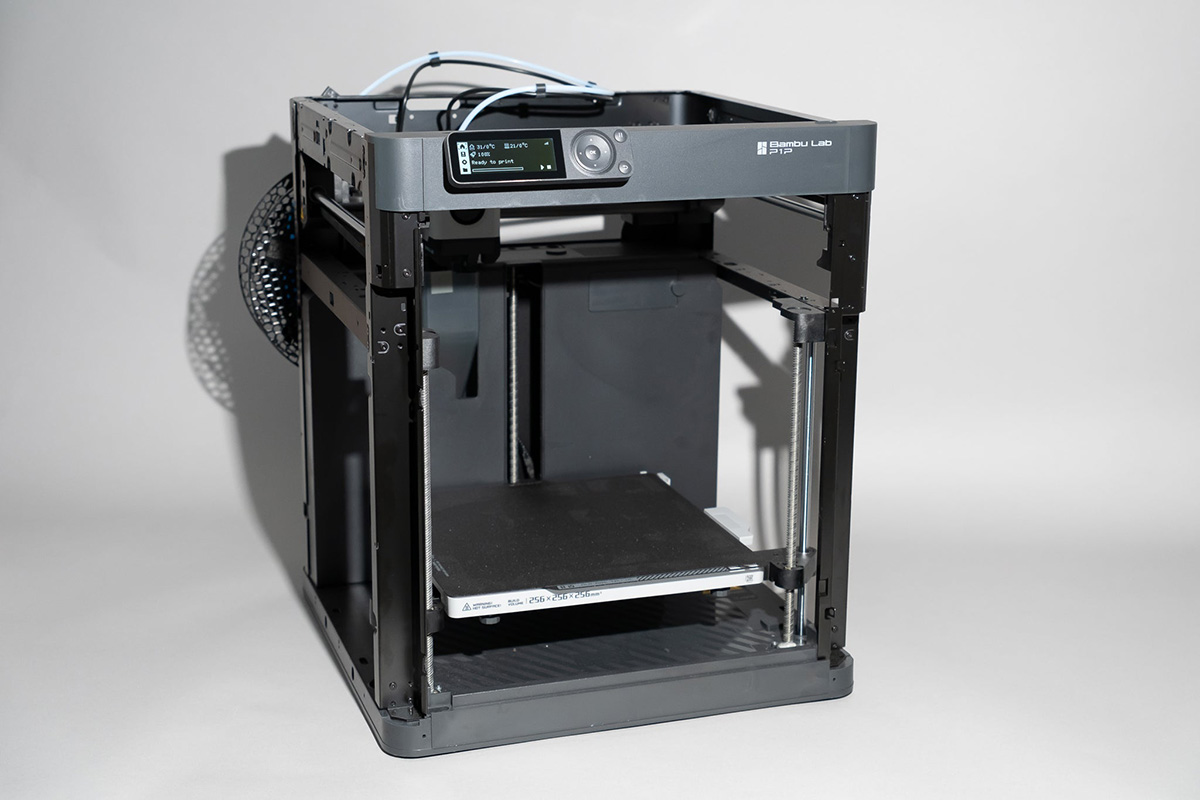

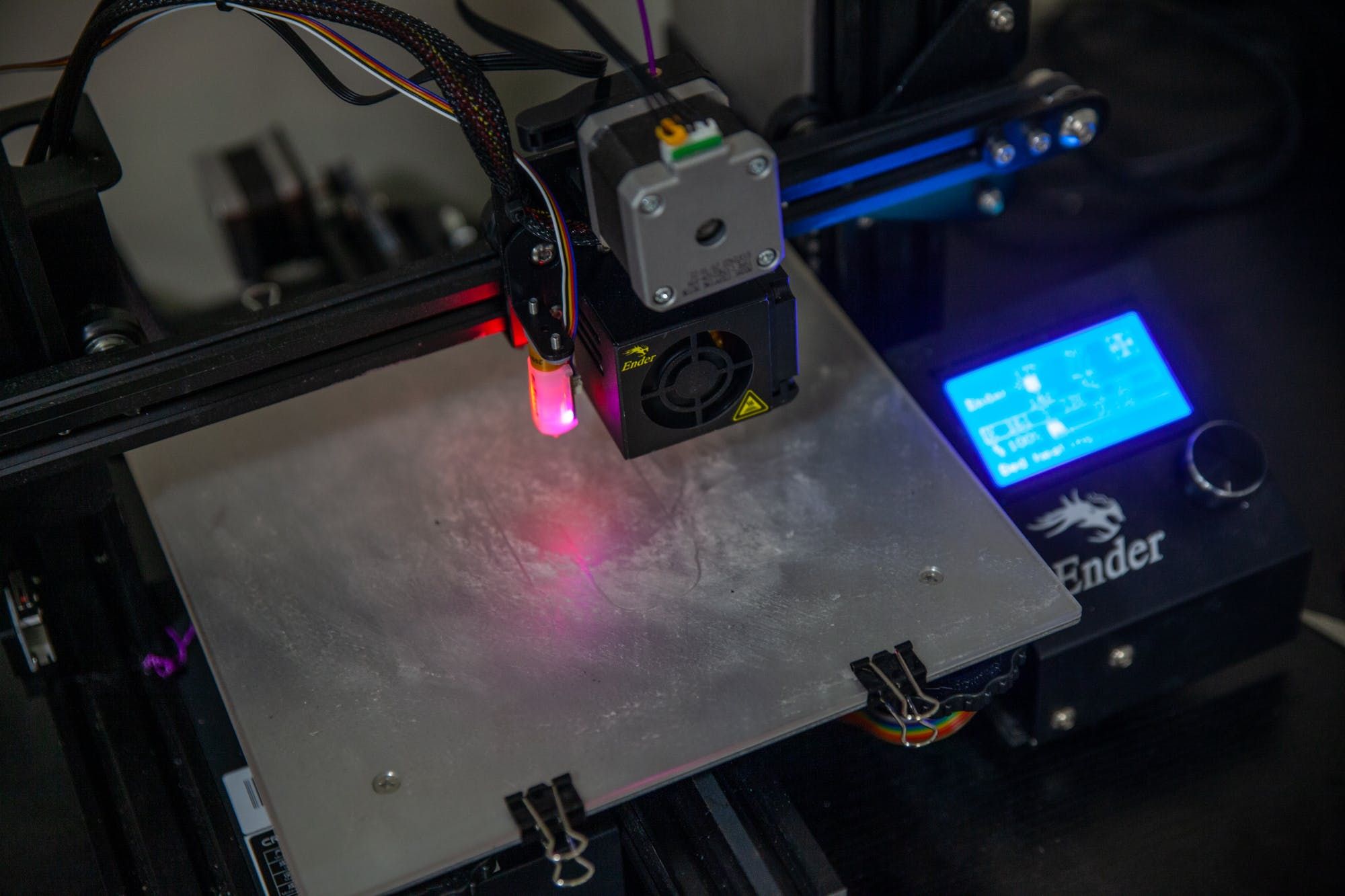

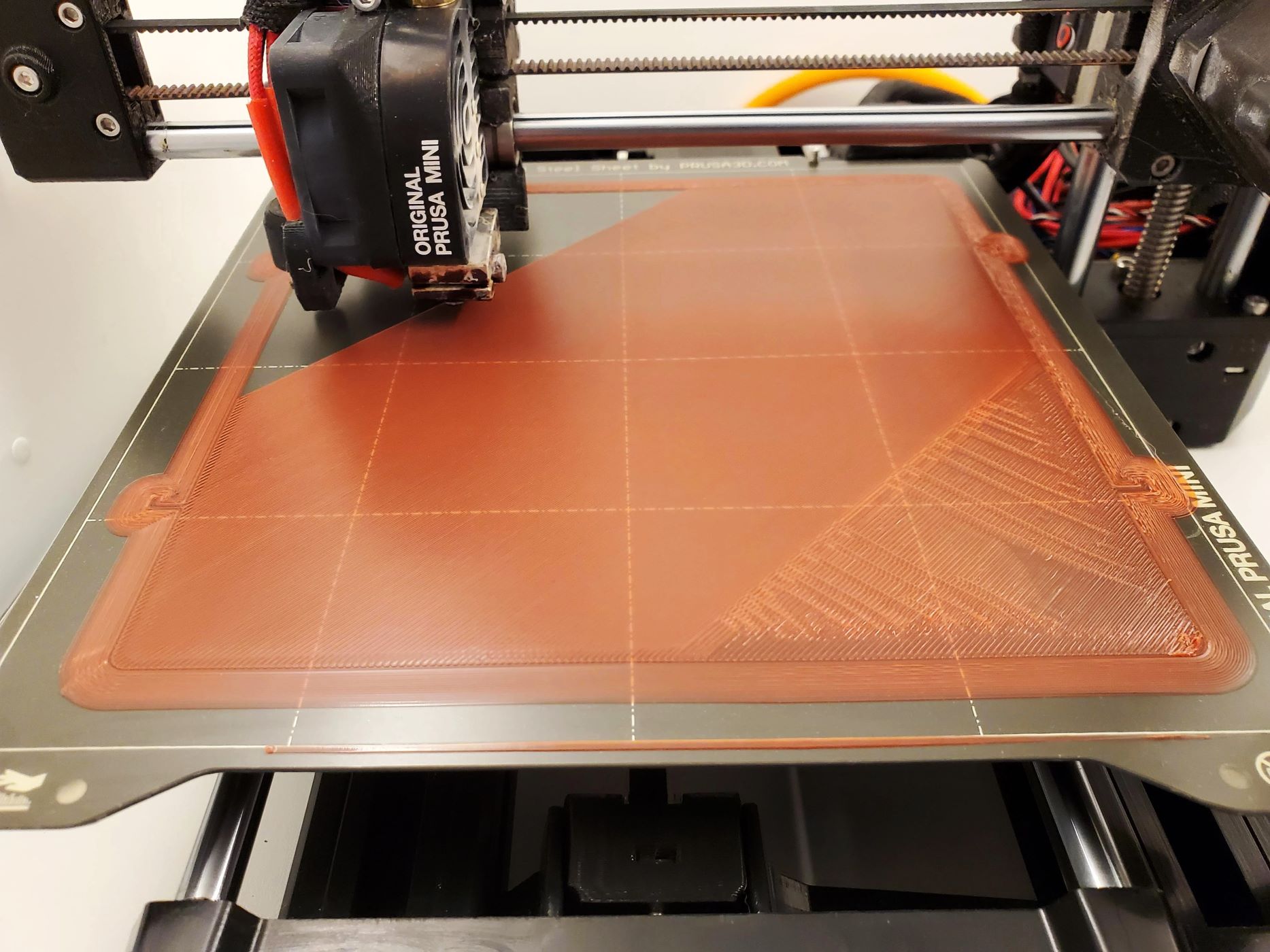

At its core, 3D printing is a process of creating three-dimensional objects from digital models by adding material layer by layer. This innovative technology encompasses a range of printing methods, each with its own unique capabilities and applications. The most common 3D printing processes include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP).

In Fused Deposition Modeling, a thermoplastic filament is heated and extruded through a nozzle, creating layers that solidify to form the desired object. Stereolithography, on the other hand, uses a UV laser to cure liquid resin, solidifying it layer by layer to produce precise and detailed parts. Selective Laser Sintering employs a high-powered laser to fuse powdered materials, such as nylon or metals, into a solid structure, while Digital Light Processing utilizes a digital light projector to cure photosensitive resin, offering high-resolution prints with exceptional surface quality.

One of the key advantages of 3D printing technology is its ability to produce complex and customized objects with relative ease. From rapid prototyping and small-scale production to creating intricate designs and functional components, 3D printing offers a level of flexibility and versatility that traditional manufacturing methods often struggle to match. Moreover, the accessibility of desktop 3D printers has empowered individuals and businesses to bring their concepts to fruition without the need for expensive industrial equipment.

With the continuous evolution of 3D printing technology, we are witnessing advancements in speed, precision, and material capabilities, opening up new avenues for innovation and creativity. As the technology becomes more refined and affordable, its impact on various industries, from healthcare and aerospace to fashion and education, continues to expand, driving the next wave of manufacturing and design possibilities.

Applications of 3D Printing

Applications of 3D Printing

The versatility of 3D printing technology has led to a wide array of applications across diverse industries, showcasing its potential to revolutionize traditional manufacturing processes and enable groundbreaking innovations. From rapid prototyping and custom production to creating intricate medical implants and artistic masterpieces, 3D printing has made a significant impact in the following areas:

- Rapid Prototyping: 3D printing accelerates the product development cycle by allowing designers and engineers to quickly produce prototypes for testing and validation. This iterative process enables faster design iterations and reduces time-to-market for new products.

- Customized Healthcare Solutions: The medical field has embraced 3D printing to fabricate patient-specific implants, prosthetics, surgical guides, and anatomical models. This personalized approach enhances patient care and surgical outcomes while driving advancements in medical technology.

- Aerospace and Automotive Components: 3D printing is used to manufacture lightweight and complex parts for aircraft, spacecraft, and automobiles, offering improved performance, reduced material waste, and streamlined production processes.

- Art and Fashion: Artists and designers leverage 3D printing to create intricate sculptures, avant-garde fashion pieces, and customizable accessories, pushing the boundaries of creativity and expression in the art and fashion industries.

- Education and Research: 3D printing has become a valuable tool in educational settings, empowering students and researchers to visualize abstract concepts, conduct experiments, and explore engineering and design principles in a hands-on manner.

- Customized Consumer Products: From personalized smartphone cases and jewelry to bespoke home decor and kitchen gadgets, 3D printing enables the customization of consumer goods, catering to individual preferences and tastes.

These applications represent just a fraction of the diverse uses of 3D printing technology, illustrating its potential to drive innovation, efficiency, and creativity across a spectrum of industries. As the technology continues to advance, the boundaries of what can be achieved with 3D printing are continuously expanding, paving the way for new possibilities and unforeseen applications.

3D Printing Materials

When using a 3D printer, make sure to use the correct type of filament for your project. Different filaments have different properties, such as strength, flexibility, and heat resistance, so choosing the right one is important for the success of your 3D printed object.

3D Printing Materials

The versatility of 3D printing extends beyond its diverse applications to encompass an extensive range of materials that can be utilized in the additive manufacturing process. These materials play a crucial role in determining the properties, aesthetics, and functionality of the printed objects. From thermoplastics and photopolymers to metals and composites, 3D printing materials offer a spectrum of options to suit various requirements and specifications.

Thermoplastics: One of the most commonly used materials in 3D printing, thermoplastics such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol) are renowned for their ease of use, durability, and versatility. These materials are widely employed in prototyping, manufacturing, and consumer product development.

Photopolymers: Resins that cure under ultraviolet light, known as photopolymers, are utilized in Stereolithography (SLA) and Digital Light Processing (DLP) 3D printing technologies. These materials offer exceptional detail, smooth surface finishes, and high resolution, making them ideal for creating intricate models, jewelry, and dental applications.

Metals and Alloys: 3D printing with metals, including stainless steel, titanium, aluminum, and nickel alloys, has gained prominence in aerospace, automotive, and medical industries due to the superior strength, heat resistance, and biocompatibility of metal components produced through additive manufacturing processes.

Composites: Blending materials such as carbon fiber, fiberglass, or Kevlar with thermoplastics or resins results in composite filaments that offer enhanced strength, stiffness, and lightweight properties. These materials find applications in high-performance parts for automotive, sports equipment, and industrial machinery.

Bioinks and Biomaterials: In the field of bioprinting, specialized bioinks and biomaterials are used to fabricate living tissues, organoids, and medical implants, paving the way for advancements in regenerative medicine, tissue engineering, and personalized healthcare solutions.

By harnessing the unique properties of these materials, 3D printing technology continues to push the boundaries of what can be achieved in manufacturing, design, and innovation. As material science evolves and new formulations are developed, the potential for creating functional, sustainable, and groundbreaking objects through additive manufacturing continues to expand.

What You Can Make With a 3D Printer

What You Can Make With a 3D Printer

The versatility of 3D printing technology enables the creation of a vast array of objects, ranging from practical tools and functional prototypes to artistic creations and intricate designs. Whether you’re a hobbyist, a professional designer, or an entrepreneur, the possibilities of what you can produce with a 3D printer are virtually limitless. Here are some compelling examples of items that can be crafted using this innovative technology:

- Prototypes and Product Models: 3D printing facilitates the rapid prototyping of new product designs, allowing engineers and designers to iterate and test concepts before moving into full-scale production. This capability accelerates the product development cycle and reduces costs associated with traditional prototyping methods.

- Customized Jewelry and Accessories: With 3D printing, jewelry designers can bring intricate and personalized pieces to life, incorporating complex geometries and fine details that would be challenging to achieve through traditional manufacturing techniques. Customized accessories, such as eyewear frames and watch bands, can also be tailored to individual preferences.

- Functional Tools and Household Items: From ergonomic kitchen gadgets and storage solutions to specialized tools and replacement parts, 3D printing empowers individuals to fabricate practical items tailored to their specific needs, fostering a culture of DIY innovation and sustainability.

- Architectural Models and Scale Replicas: Architects and model makers utilize 3D printing to create detailed architectural models, intricate landscapes, and scaled replicas of buildings and urban environments, aiding in visualization and presentation of design concepts.

- Artistic Sculptures and Decorative Objects: Artists and sculptors leverage 3D printing to explore new forms of expression, producing complex sculptures, decorative art pieces, and installations that push the boundaries of creativity and aesthetics.

- Medical Implants and Prosthetics: The medical industry harnesses 3D printing to fabricate patient-specific implants, prosthetic limbs, and anatomical models, offering customized solutions that enhance patient comfort and rehabilitation outcomes.

These examples merely scratch the surface of what can be achieved with a 3D printer. As the technology continues to evolve and the range of printable materials expands, the potential applications and the diversity of objects that can be produced through additive manufacturing are poised to grow exponentially, driving innovation and customization across various domains.

Conclusion

Read more: What Is An Extruder On A 3D Printer

Conclusion

As we conclude our exploration of 3D printing, it’s evident that this transformative technology has ushered in a new era of creativity, innovation, and manufacturing possibilities. From its diverse applications across industries to the ever-expanding range of materials and the captivating array of objects that can be produced, 3D printing continues to captivate the imagination of makers, designers, engineers, and enthusiasts worldwide.

With the ability to rapidly prototype new designs, create custom solutions for healthcare and consumer products, and push the boundaries of artistic expression, 3D printing has become a driving force in shaping the future of manufacturing and design. Its impact extends beyond traditional production methods, offering a sustainable and efficient approach to fabrication while empowering individuals and businesses to realize their ideas with unprecedented freedom and flexibility.

Looking ahead, the evolution of 3D printing technology holds immense promise, with ongoing advancements in speed, precision, and material capabilities. As the barriers to entry lower and accessibility increases, we can anticipate a surge in creativity, entrepreneurship, and problem-solving driven by the democratization of manufacturing through 3D printing.

Whether it’s the realization of complex engineering marvels, the personalization of consumer goods, or the advancement of medical and scientific frontiers, 3D printing stands at the forefront of a transformative wave, offering a glimpse into a future where the boundaries of what can be created are defined only by imagination.

As we continue to witness the evolution of this groundbreaking technology, let us embrace the endless opportunities it presents and celebrate the ingenuity and ingenuity it inspires in shaping a world where the extraordinary is not just imagined, but brought to life through the power of 3D printing.

Frequently Asked Questions about What Can You Make With A 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Can You Make With A 3D Printer”