Home>Technology>Smart Home Devices>How To Make A 3D Printer File

Smart Home Devices

How To Make A 3D Printer File

Published: January 21, 2024

Learn how to create 3D printer files for smart home devices. Follow our step-by-step guide to design and optimize your 3D printing projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

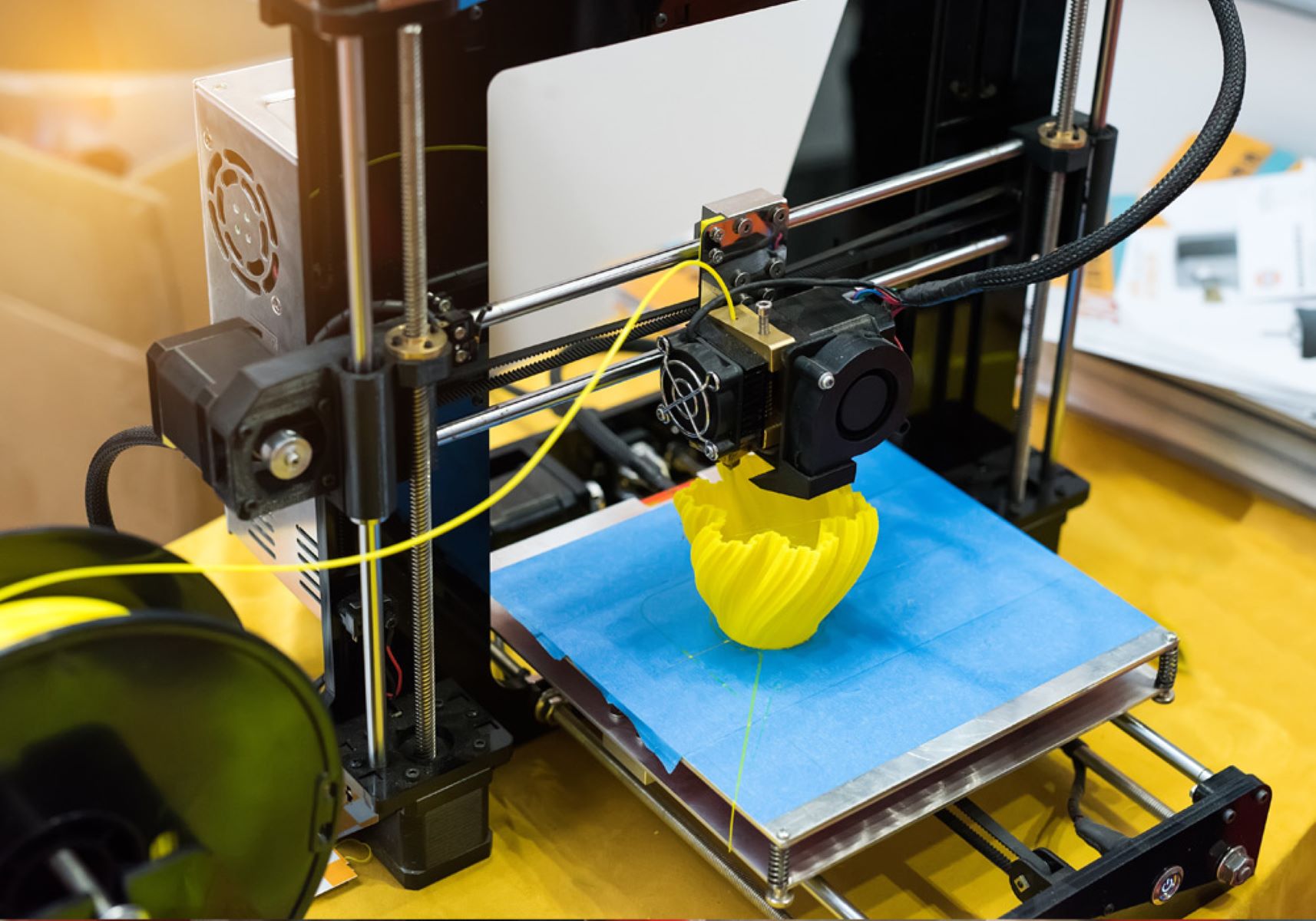

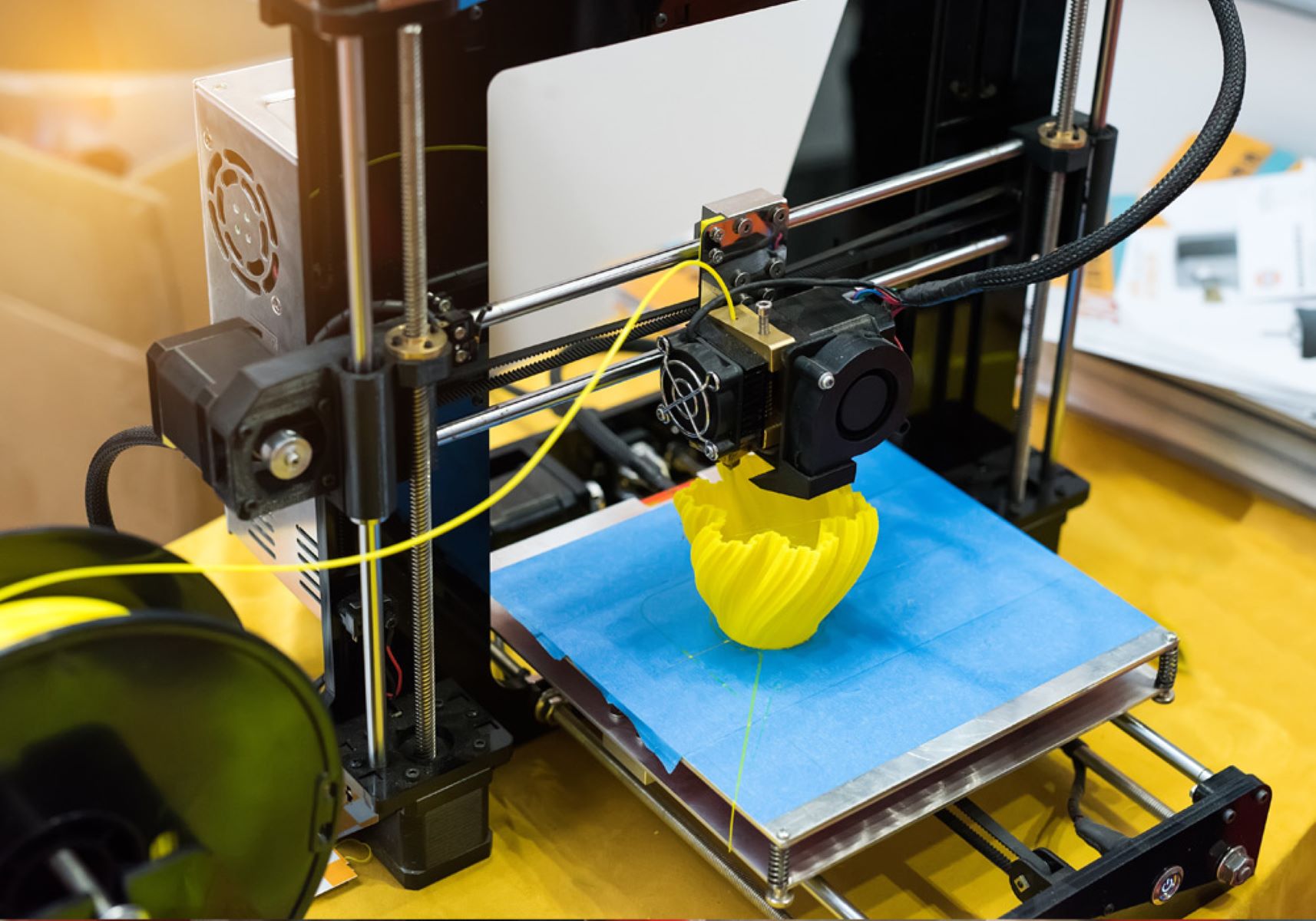

Welcome to the fascinating world of 3D printing! The ability to bring digital designs to life through additive manufacturing has revolutionized various industries, from engineering and architecture to healthcare and fashion. In this comprehensive guide, we will explore the process of creating a 3D printer file, from understanding the fundamentals of 3D printing to choosing the right software and designing the model. Whether you are a hobbyist, a student, or a professional seeking to delve into the realm of 3D printing, this article will equip you with the knowledge and tools to embark on this exciting journey.

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by depositing successive layers of material based on a digital model. The versatility of 3D printing extends to various materials, including plastics, metals, ceramics, and even food. This innovative technology has significantly impacted prototyping, customization, and small-scale manufacturing, offering endless possibilities for innovation and creativity.

As we delve into the intricacies of 3D printing, we will navigate through the process of choosing the right software for 3D modeling, understanding the design considerations, and exporting the 3D printer file. By the end of this guide, you will have a comprehensive understanding of the steps involved in creating a 3D printer file and be well-equipped to embark on your 3D printing endeavors.

So, let's embark on this enlightening journey into the world of 3D printing, where creativity knows no bounds and innovation thrives. Let's explore the intricacies of 3D printing software, design considerations, and the process of exporting a 3D printer file, empowering you to bring your digital creations to life in the physical realm.

Key Takeaways:

- 3D printing revolutionizes design and manufacturing by creating objects layer by layer from digital models, offering endless possibilities for innovation and creativity across various industries.

- Choosing the right 3D modeling software and meticulously designing and exporting the 3D printer file are crucial steps in bringing digital creations to life through the wonders of additive manufacturing.

Read more: How Do You Make 3D Printer Files

Understanding 3D Printing

Before delving into the intricacies of creating a 3D printer file, it is essential to grasp the fundamental concepts of 3D printing. At its core, 3D printing is a form of additive manufacturing that enables the creation of three-dimensional objects from digital models. Unlike traditional subtractive manufacturing processes that involve cutting away material from a solid block, 3D printing builds objects layer by layer, offering unparalleled design freedom and customization.

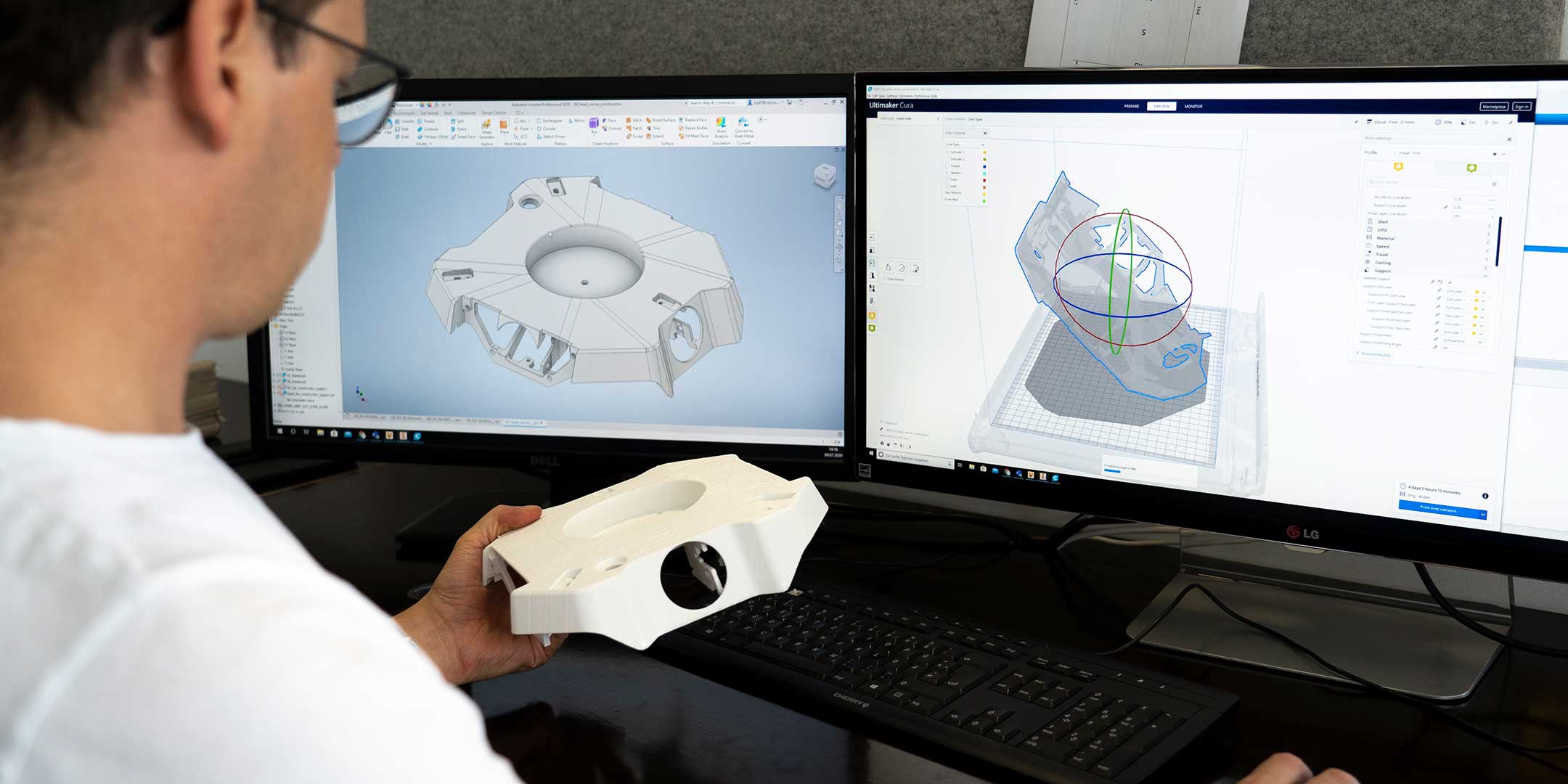

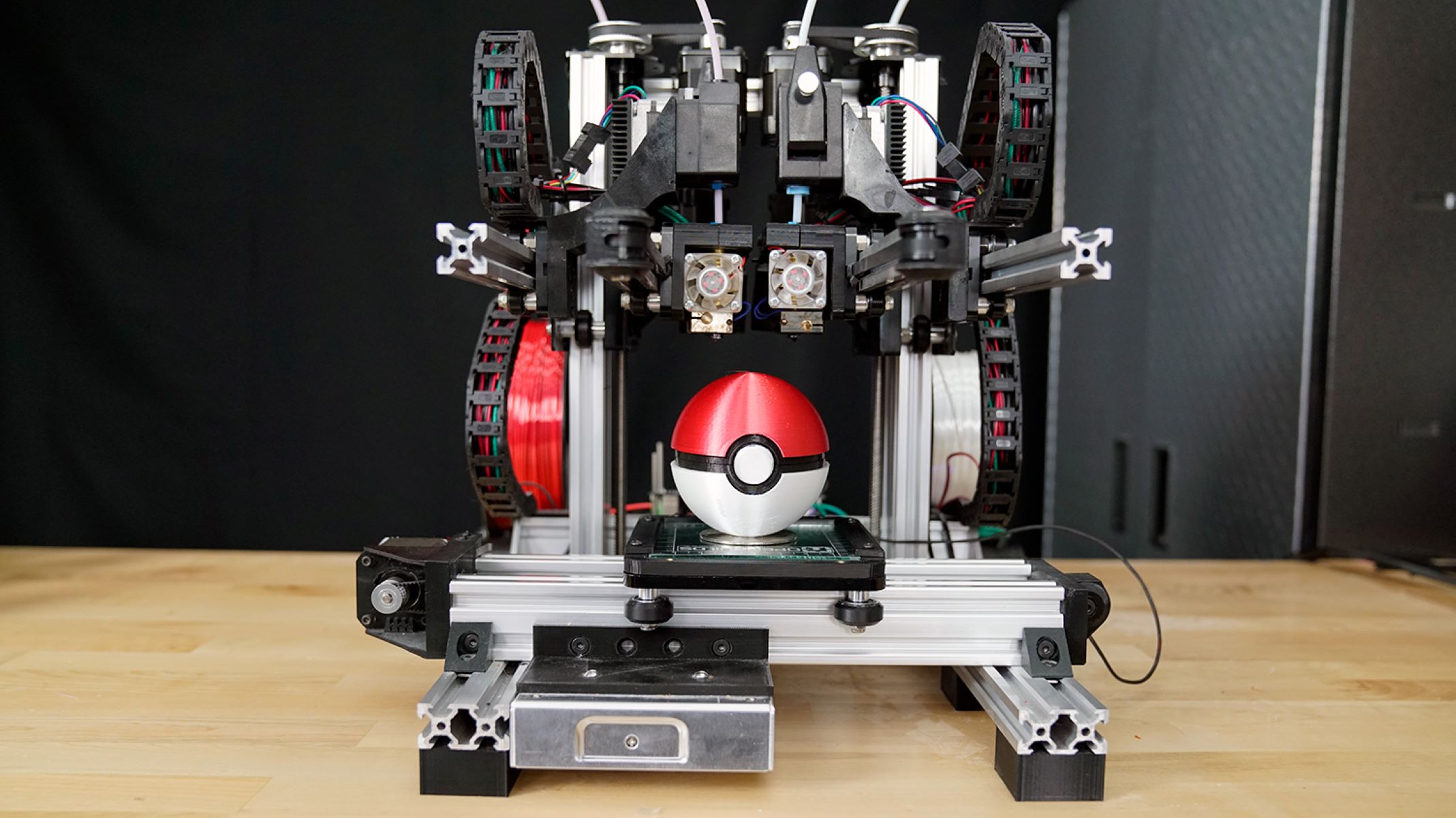

The process of 3D printing typically begins with a digital 3D model created using computer-aided design (CAD) software or obtained from a 3D scanner. This digital model is sliced into thin horizontal cross-sections using slicing software, which generates a set of instructions for the 3D printer to follow. These instructions dictate the precise deposition of material layer by layer, resulting in the gradual formation of the physical object.

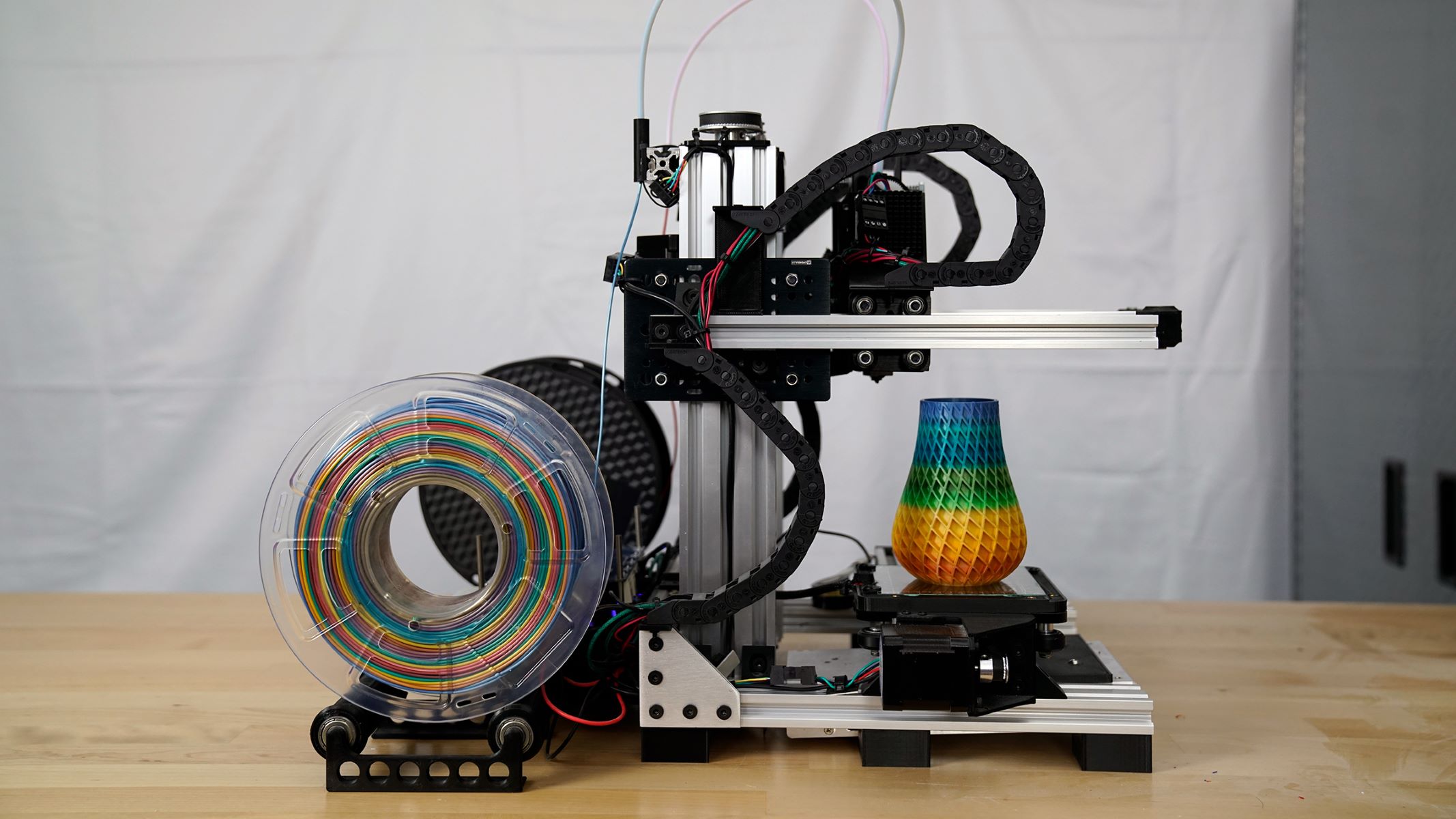

3D printing encompasses a wide array of technologies and materials, each offering unique advantages and applications. Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP) are among the popular 3D printing technologies, each employing distinct mechanisms for material deposition and solidification.

Furthermore, the materials used in 3D printing span a diverse spectrum, ranging from thermoplastics and photopolymers to metals and composite materials. The choice of material depends on the desired properties of the final object, such as strength, flexibility, heat resistance, and aesthetic appeal.

3D printing has revolutionized various industries, enabling rapid prototyping, customized manufacturing, and complex geometries that were previously unattainable through traditional manufacturing methods. From aerospace components and medical implants to intricate art pieces and consumer products, the impact of 3D printing continues to permeate diverse sectors, driving innovation and pushing the boundaries of what is possible.

As we proceed with this guide, we will delve into the crucial steps involved in creating a 3D printer file, encompassing the selection of 3D printing software, the design process, and the exportation of the final 3D model. By understanding the foundational principles of 3D printing, you will be well-prepared to embark on the journey of transforming digital designs into tangible objects through the marvels of additive manufacturing.

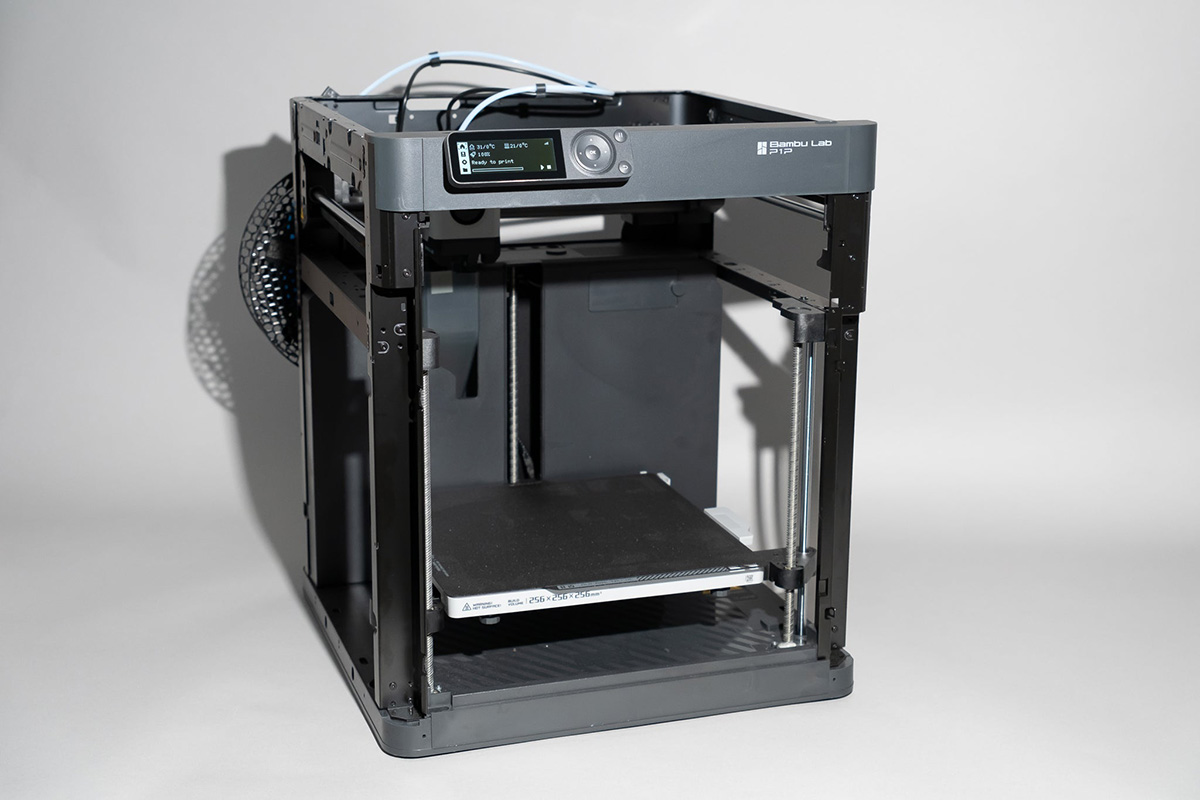

Choosing the Right 3D Printing Software

When venturing into the realm of 3D printing, selecting the appropriate software for 3D modeling is a pivotal decision that significantly influences the design process and the eventual creation of a 3D printer file. The market offers a diverse array of 3D modeling software, each tailored to cater to specific user requirements, skill levels, and design complexities.

For beginners and enthusiasts seeking user-friendly yet powerful 3D modeling tools, options such as TinkerCAD and SketchUp present intuitive interfaces and simplified workflows, enabling the creation of basic to moderately complex 3D models without steep learning curves. These platforms are ideal for individuals venturing into 3D printing as a hobby or for educational purposes, providing a stepping stone into the world of digital design and additive manufacturing.

For intermediate to advanced users, software like Autodesk Fusion 360 and SolidWorks offers robust features for parametric modeling, assembly design, and simulation, catering to professionals and students in engineering, product design, and mechanical prototyping. These platforms empower users to create intricate and functional 3D models, incorporating precise measurements, geometric constraints, and mechanical simulations to validate the design’s performance.

Furthermore, if your focus extends to artistic and organic modeling, software such as Blender and ZBrush provides powerful sculpting and texturing tools, unleashing boundless creativity for creating visually stunning and intricate 3D designs. These platforms are favored by artists, animators, and game developers, offering versatile tools for sculpting characters, creatures, and detailed environments.

It is essential to consider the compatibility of the chosen 3D modeling software with the file formats supported by your 3D printer. Most 3D printers accept STL (stereolithography) files, a standard format for 3D printing, ensuring seamless compatibility between the digital model and the physical printing process.

As you embark on the journey of selecting the right 3D printing software, consider your proficiency level, design requirements, and long-term aspirations. Whether you seek simplicity, engineering precision, or artistic freedom, the diverse landscape of 3D modeling software offers a tailored solution to suit your unique needs, empowering you to bring your digital creations to life through the marvels of 3D printing.

When creating a 3D printer file, make sure to use a 3D modeling software like Tinkercad or Fusion 360. Design your object with precise measurements and consider the printing material to ensure a successful print.

Designing the 3D Model

Embarking on the design phase of creating a 3D printer file is an exhilarating journey that demands creativity, precision, and an understanding of the intended application of the final 3D model. Whether you are crafting a functional prototype, an artistic sculpture, or a mechanical component, the design process forms the crux of transforming your digital concept into a tangible object through the wonders of 3D printing.

When initiating the design process, it is essential to conceptualize the intended functionality, form, and aesthetic appeal of the 3D model. Consider the dimensions, tolerances, and structural integrity required for the object to fulfill its purpose. For mechanical components, engineering principles such as load-bearing capabilities, material properties, and assembly considerations play a pivotal role in the design phase, ensuring that the final 3D printed part meets the desired functional specifications.

For artistic and organic modeling endeavors, the design process embraces a realm of boundless creativity, encompassing sculpting, texturing, and intricate detailing. Artists and designers leverage 3D modeling software to carve intricate forms, imbue textures, and infuse life into their digital creations, transcending the constraints of traditional sculpting methods and unlocking new dimensions of artistic expression.

As you delve deeper into the design process, consider the geometry of the 3D model, ensuring that it is conducive to 3D printing. Factors such as overhangs, support structures, and print orientation influence the manufacturability of the design, necessitating thoughtful consideration to optimize the model for successful 3D printing. Many 3D modeling software offer tools for analyzing and preparing models for 3D printing, enabling users to identify potential issues and implement necessary modifications to enhance printability.

Moreover, if your design entails multiple components or assemblies, consider the interplay of these elements and their seamless integration post-printing. Incorporate features such as alignment guides, snap-fit connections, and assembly clearances to facilitate the assembly of printed parts, ensuring a cohesive and functional final product.

Throughout the design phase, iterate and refine your 3D model, leveraging the capabilities of the chosen 3D modeling software to validate the design’s integrity, visualize the final outcome, and make informed adjustments. Embrace the fusion of technical precision and artistic innovation as you sculpt, engineer, and refine your digital creation, laying the foundation for the eventual realization of the 3D printer file.

As you immerse yourself in the design process, envision the transformation of your digital concept into a physical reality, harnessing the power of 3D printing to materialize your imagination and bring your designs to life.

Exporting the 3D Printer File

As the culmination of the design process unfolds, the pivotal stage of exporting the 3D printer file emerges, marking the transition from the digital realm to the physical manifestation of your meticulously crafted design. The process of exporting the 3D printer file encompasses critical considerations that ensure the seamless translation of your digital model into a format compatible with 3D printing technology.

Before exporting the 3D printer file, it is essential to validate the integrity of the design and address any potential issues that may impede the printing process. Many 3D modeling software offer built-in tools for inspecting and repairing models, identifying issues such as non-manifold geometry, intersecting components, or thin walls that could compromise the printability of the design. By meticulously preparing the 3D model, you mitigate the risk of encountering printing failures and enhance the overall manufacturability of the design.

Subsequently, the process of exporting the 3D printer file involves selecting the appropriate file format that aligns with the requirements of your 3D printer. The STL (stereolithography) file format stands as the standard for 3D printing, encapsulating the geometric data of the 3D model in a format that 3D printers can interpret and translate into physical layers of material. When exporting the STL file, consider factors such as the desired level of detail, the scale of the model, and the presence of multiple components or assemblies within the design.

Furthermore, if your design incorporates intricate textures, colors, or multi-material compositions, consider the compatibility of the chosen file format with the capabilities of your 3D printer. Some advanced 3D printing technologies support file formats that encompass color information and material specifications, enabling the realization of vibrant and multi-material 3D prints that faithfully capture the nuances of your digital design.

Prior to exporting the 3D printer file, it is advisable to conduct a final review of the design, ensuring that all critical elements, details, and considerations have been meticulously addressed. Validate the dimensions, tolerances, and structural integrity of the model, affirming that it aligns with your envisioned outcome and functional requirements.

With the 3D printer file meticulously prepared and exported in the appropriate format, you stand at the threshold of transforming your digital creation into a physical reality. The exported file encapsulates the culmination of your design journey, poised to be translated into successive layers of material through the marvels of 3D printing, bringing your imagination to life in tangible form.

As you embark on the process of exporting the 3D printer file, envision the forthcoming realization of your digital creation, embracing the transformative power of 3D printing to materialize your designs and innovate within the realm of additive manufacturing.

Read more: What File Does 3D Printer Use

Conclusion

Congratulations on embarking on this enlightening journey into the realm of 3D printing and the creation of 3D printer files. Throughout this comprehensive guide, we have navigated through the intricacies of understanding 3D printing, choosing the right 3D printing software, designing the 3D model, and exporting the 3D printer file, equipping you with the knowledge and tools to materialize your digital designs through the marvels of additive manufacturing.

3D printing stands as a transformative force that transcends traditional manufacturing constraints, offering boundless opportunities for innovation, customization, and creativity. From functional prototypes and mechanical components to artistic sculptures and intricate designs, the realm of 3D printing empowers individuals to bring their digital concepts to life in tangible form, shaping the future of manufacturing and design.

As you venture forth into the world of 3D printing, remember that the journey encompasses continual learning, exploration, and refinement. Embrace the fusion of technical precision and artistic innovation as you sculpt, engineer, and refine your digital creations, harnessing the transformative power of 3D printing to realize your imagination and innovate within the realm of additive manufacturing.

Whether you are a hobbyist, a student, or a professional seeking to delve into the realm of 3D printing, the knowledge and insights garnered from this guide serve as a foundation for your endeavors. Embrace the potential of 3D printing to revolutionize industries, drive innovation, and unleash your creativity, as you embark on the captivating journey of transforming digital designs into tangible objects through the wonders of additive manufacturing.

As you navigate the intricacies of creating 3D printer files, remember that the realm of 3D printing is replete with possibilities, awaiting your exploration and creativity. Let your designs transcend the digital realm and materialize into physical form, as you harness the transformative power of 3D printing to innovate, create, and shape the future of manufacturing and design.

So, with your newfound knowledge and insights, venture forth into the realm of 3D printing, where creativity knows no bounds and innovation thrives, and let your digital creations flourish in the physical world through the marvels of additive manufacturing.

Frequently Asked Questions about How To Make A 3D Printer File

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make A 3D Printer File”