Articles

What Causes An AC Compressor To Stop Working

Modified: January 6, 2024

Discover the common factors that can cause an AC compressor to stop working and learn how to troubleshoot and fix the issue. Read more articles on AC compressor problems and solutions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

The AC compressor is a vital component of the air conditioning system that plays a crucial role in cooling your home and maintaining a comfortable indoor environment. It is responsible for compressing and circulating the refrigerant, enabling the transfer of heat from the inside of your home to the outside. However, like any mechanical device, the AC compressor is susceptible to various problems that can cause it to stop working.

Understanding the common causes of AC compressor failure is essential for any homeowner. By identifying and addressing these issues promptly, you can potentially avoid expensive repairs or the need for a complete replacement of the compressor. In this article, we will explore the most frequent culprits behind AC compressor failure and provide some preventive measures to help you maintain the optimal functioning of your air conditioning system.

Key Takeaways:

- Regular maintenance, changing air filters, cleaning condenser coils, and keeping the area around the unit clear are crucial preventive measures to avoid AC compressor failure. These simple steps can extend the lifespan of your air conditioning system and ensure reliable cooling performance.

- Addressing common causes of AC compressor failure, such as insufficient lubrication, electrical issues, and overheating, through regular maintenance and prompt repairs can minimize the risk of costly breakdowns. Investing in preventive measures helps maintain optimal functioning and efficiency of your air conditioning system.

Common Causes of AC Compressor Failure

AC compressor failure can occur due to various reasons. It is important to identify these causes to prevent future breakdowns and costly repairs. Here are some of the common culprits behind AC compressor failure:

- Insufficient Lubrication: Lack of proper lubrication can lead to friction and wear on the compressor’s moving parts. This can cause the compressor to overheat and eventually fail. Regular maintenance, including lubrication checks, can help prevent this issue.

- Electrical Issues: Problems with the electrical components of the AC system, such as faulty wiring or a malfunctioning thermostat, can put excess strain on the compressor. This can cause it to shut down or fail altogether.

- Overheating: High temperatures can overwork the AC compressor, leading to overheating and potential failure. This can be caused by a variety of factors, including dirty condenser coils, lack of airflow, or refrigerant leakage.

- Refrigerant Leak: Insufficient refrigerant levels due to leaks can cause the compressor to work harder, resulting in increased strain and potential failure. Regular inspections and leak detection can help identify and address this issue.

- Dirty Condenser Coils: Dirt, debris, and other contaminants can accumulate on the condenser coils, hindering heat transfer and causing the compressor to work harder. Regular cleaning and maintenance of the coils can minimize this risk.

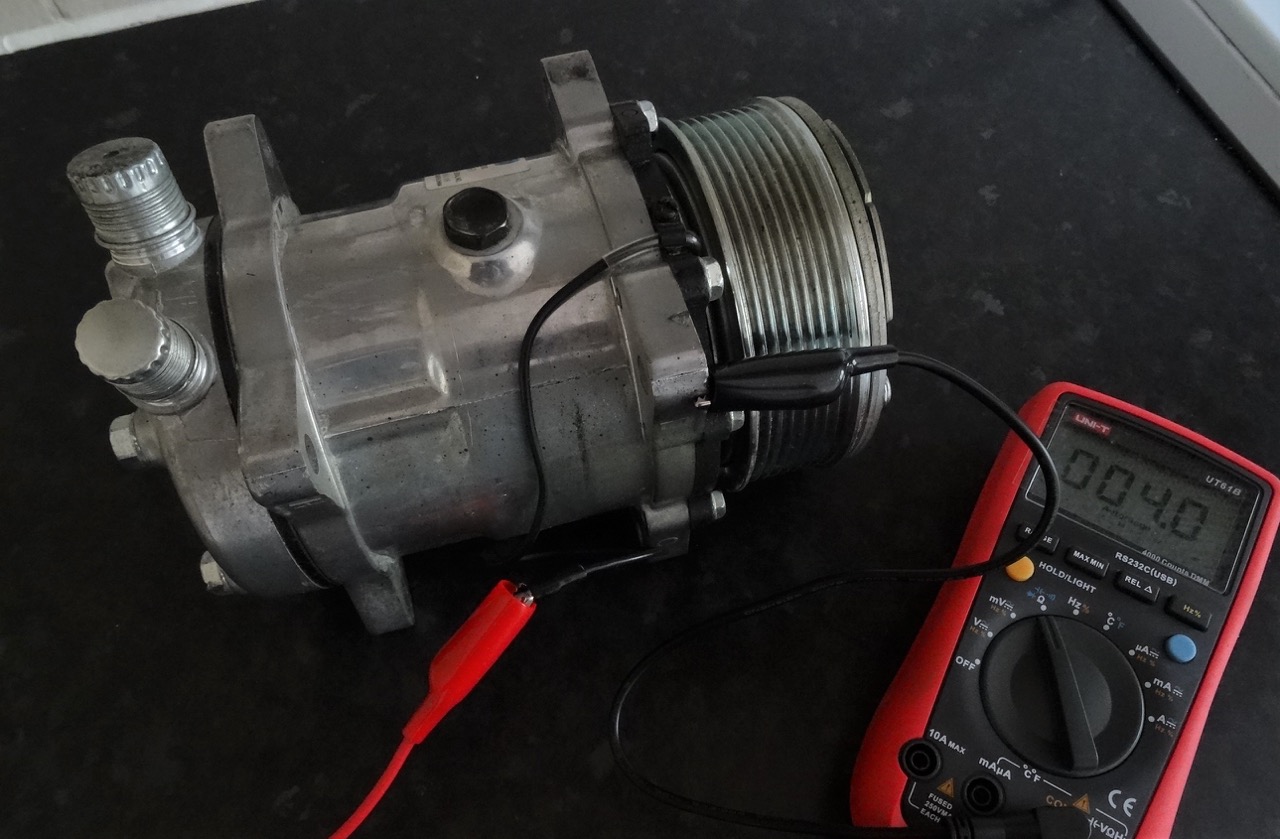

- Faulty Capacitor: The capacitor provides an electrical charge to start the compressor. If the capacitor malfunctions, it can prevent the compressor from starting or cause it to stop working. Periodic inspection and replacement of faulty capacitors are crucial.

- Blocked Suction Lines: Blockages in the suction lines can impede the flow of refrigerant, causing the compressor to struggle and potentially fail. Keeping the lines clear and free from obstructions is important for optimal compressor performance.

Understanding these common causes of AC compressor failure can help you take proactive measures to prevent them and ensure the longevity and efficiency of your air conditioning system.

Insufficient Lubrication

Insufficient lubrication is a common cause of AC compressor failure. The compressor requires adequate lubrication to maintain smooth operation and reduce friction between its moving parts. Over time, the lubricating oil can break down or leak, resulting in insufficient lubrication.

When the compressor lacks proper lubrication, the metal components can rub against each other, causing excessive heat and wear. This added strain can lead to the compressor overheating and eventually failing.

To prevent compressor failure due to insufficient lubrication, regular maintenance is crucial. During routine AC service visits, a professional technician will check the lubrication levels and inspect for any leaks. If the oil levels are low, they will add the appropriate lubricant to ensure proper lubrication.

In addition to regular maintenance, it’s important to address any refrigerant leaks promptly. Refrigerant leaks not only affect the cooling efficiency but can also lead to a decrease in the oil levels in the compressor. These leaks should be repaired and the refrigerant levels should be replenished to maintain optimal lubrication.

It’s worth mentioning that attempting to add lubricant yourself without proper knowledge can do more harm than good. Different types of compressors require different lubricants, and adding the wrong oil can cause severe damage to the system. It is always best to rely on a qualified HVAC technician to handle lubrication matters.

By ensuring that your AC compressor has sufficient lubrication, you can reduce the risk of failure and prolong its lifespan. Regular maintenance and addressing refrigerant leaks promptly are key to preventing compressor failures caused by insufficient lubrication.

Electrical Issues

Electrical issues can contribute to AC compressor failure and are another common cause of system breakdowns. The electrical components of an air conditioning system, including the wiring, relays, and thermostat, play a crucial role in the proper functioning of the compressor.

Faulty wiring or improper electrical connections can result in inadequate electrical supply to the compressor. This can cause the compressor to strain or fail to start altogether. Additionally, a malfunctioning thermostat can disrupt the compressor’s operation by sending incorrect signals or not activating the cooling cycle when needed.

Regular inspection of the electrical components during routine maintenance can help identify any potential issues. A qualified HVAC technician can check for loose connections, frayed wires, or signs of electrical damage that may affect the compressor’s performance. Resolving electrical issues promptly is essential to prevent further damage and potential compressor failure.

It’s important to note that attempting to diagnose or repair electrical problems on your own can be dangerous if you’re not familiar with electrical systems. It’s always recommended to hire a professional technician who has the knowledge and expertise to handle electrical repairs safely.

To minimize the risk of electrical issues and potential compressor failure, it’s wise to invest in regular AC maintenance. This includes inspecting and tightening electrical connections, testing the thermostat for accuracy, and ensuring that all electrical components are functioning correctly.

By addressing electrical issues promptly and ensuring proper electrical connections, you can help prevent AC compressor failure and keep your air conditioning system operating efficiently.

Overheating

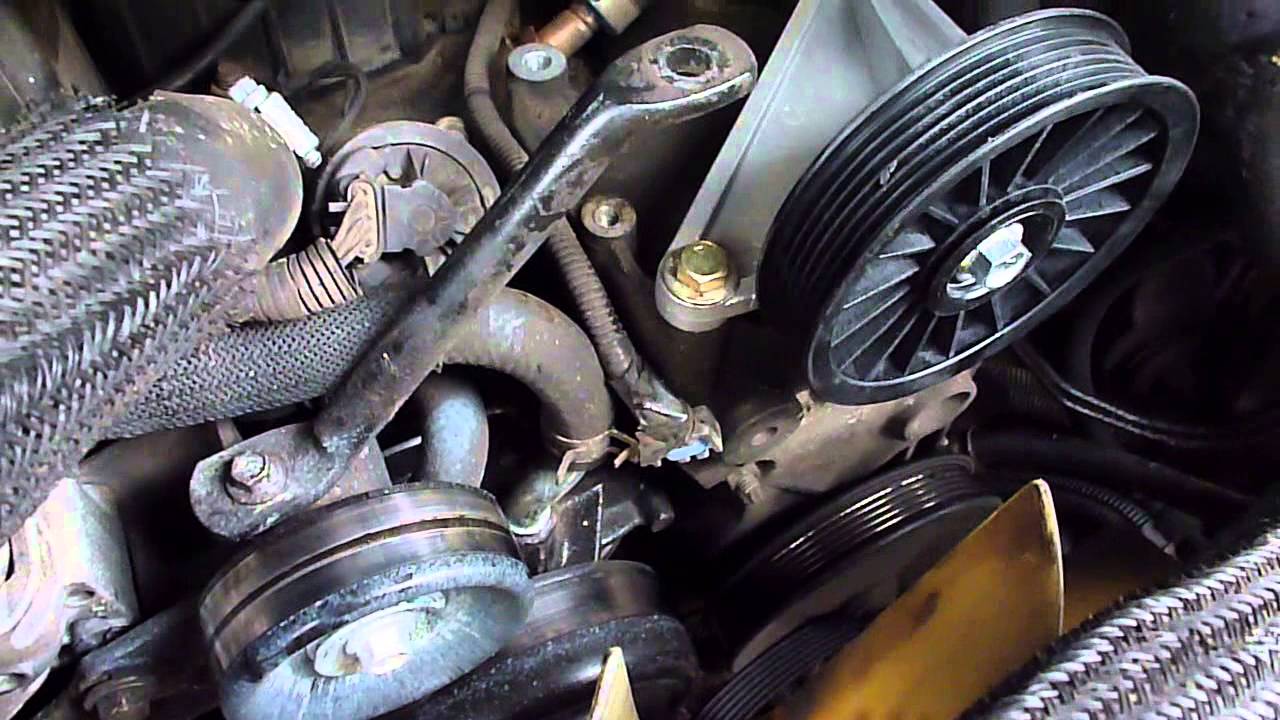

Overheating is a significant cause of AC compressor failure and can result from various factors. When the compressor becomes too hot, it can lead to excessive wear and tear on its internal components, ultimately causing it to fail. Understanding the causes of overheating and taking preventive measures can help avoid compressor breakdowns.

One common cause of compressor overheating is dirty or blocked condenser coils. The condenser coils are responsible for releasing heat from the refrigerant, allowing the system to cool properly. Over time, these coils can become clogged with dirt, dust, and debris. When the coils are obstructed, heat transfer becomes inefficient, leading to increased compressor temperature.

To prevent overheating due to dirty coils, it is essential to regularly clean and maintain them. Using a soft brush or a vacuum cleaner, gently remove any debris or buildup on the coils. It’s also recommended to schedule professional HVAC maintenance to ensure a thorough cleaning of the condenser coils.

Another cause of compressor overheating is inadequate airflow. When the airflow around the outdoor unit is restricted, the compressor has to work harder to cool the refrigerant. This increased workload can cause the compressor to overheat. To prevent this, ensure that the area around the outdoor unit is clear of any obstructions, such as tall grass, bushes, or debris.

Refrigerant leaks can also contribute to compressor overheating. When the refrigerant levels are low, the compressor has to work harder to maintain the desired temperature, leading to overheating. Regular inspections and prompt repairs of any refrigerant leaks can help prevent this issue.

Lastly, it’s important to ensure that the system is appropriately sized for your home. An oversized AC system can cool the space too quickly, causing the compressor to cycle on and off frequently, which increases the risk of overheating. A professional HVAC technician can properly assess the cooling needs of your home and recommend the right-sized unit.

By addressing the causes of overheating and taking preventive measures such as regular cleaning, maintaining adequate airflow, addressing refrigerant leaks, and ensuring proper system sizing, you can minimize the risk of compressor overheating and prolong the lifespan of your air conditioning system.

Read more: How Does A AC Compressor Work

Refrigerant Leak

A refrigerant leak is a common cause of AC compressor failure. The refrigerant is a vital component of the cooling process, absorbing heat from the indoor air and transferring it outside. When there is a leak in the refrigerant lines, the system loses its ability to properly cool, resulting in increased strain on the compressor.

A refrigerant leak can occur due to various factors, such as corrosion, physical damage to the lines, or poor installation. Over time, the refrigerant levels decrease, and the compressor has to work harder to achieve the desired cooling. This increased workload can lead to overheating and compressor failure.

Identifying a refrigerant leak can be challenging as the refrigerant is a colorless and odorless gas. However, there are some signs that may indicate a leak, such as decreased cooling performance, hissing sounds near the unit, or ice buildup on the evaporator coils. If you suspect a refrigerant leak, it is crucial to contact a professional HVAC technician to accurately diagnose and repair the issue.

Repairing refrigerant leaks is essential to prevent compressor failure and ensure the efficiency of your air conditioning system. The technician will locate the leak, repair or replace the damaged components, and then recharge the system with the proper amount of refrigerant.

Preventing refrigerant leaks involves proper installation and regular maintenance of the AC system. Ensure that the system is installed by a qualified professional to minimize the risk of damage to the refrigerant lines. Additionally, scheduling routine maintenance visits with a licensed HVAC technician allows for periodic inspection and early detection of any potential leaks.

By promptly addressing refrigerant leaks and maintaining the proper refrigerant levels, you can prevent compressor failure and ensure the smooth operation of your air conditioning system.

Dirty Condenser Coils

Dirty condenser coils are a common cause of AC compressor failure. The condenser coils are located in the outdoor unit of the air conditioning system and play a crucial role in releasing heat from the refrigerant. When these coils become dirty or clogged, it can hinder the heat transfer process and put excessive strain on the compressor.

Over time, outdoor debris such as dirt, dust, leaves, and grass clippings can accumulate on the condenser coils. This buildup acts as an insulator, preventing efficient heat dissipation. As a result, the compressor has to work harder to achieve the desired cooling, leading to increased energy consumption, reduced system performance, and potential compressor failure.

To prevent compressor failure due to dirty condenser coils, regular cleaning and maintenance are essential. Here are a few steps you can take to keep the condenser coils clean:

- Turn off the power: Before starting any maintenance, ensure that the power to the AC unit is turned off to avoid any risk of electric shock.

- Remove debris: Use a soft brush or a vacuum cleaner to gently remove any debris, leaves, or grass clippings from the surface of the condenser coils. Be careful not to bend or damage the delicate fins on the coils.

- Clean with water or coil cleaner: Depending on the level of dirt and grime, you may need to use water or a coil cleaner to thoroughly clean the coils. Follow the manufacturer’s instructions or consult a professional technician for guidance.

- Rinse thoroughly: After cleaning, rinse the condenser coils with water to remove any remaining dirt and cleaning solution. Ensure that the water flows in the opposite direction of the airflow through the coils.

- Trim vegetation: Maintain a clear space around the outdoor unit by trimming any bushes, plants, or foliage that may obstruct the airflow to the condenser coils.

Regular maintenance of the condenser coils helps ensure proper heat transfer, reduces strain on the compressor, and minimizes the risk of compressor failure. However, if you’re unsure about performing this task yourself or if the coils are heavily soiled, it’s best to contact a professional HVAC technician for a thorough cleaning.

By keeping the condenser coils clean and free from debris, you can maintain the optimal performance of your air conditioning system and help prevent compressor failure.

Faulty Capacitor

A faulty capacitor is another common cause of AC compressor failure. The capacitor is an electrical component that provides an electrical charge to start the compressor motor. It stores and releases electrical energy to assist in the smooth startup of the compressor.

Over time, capacitors can suffer from wear and tear, or they may fail prematurely due to electrical issues or manufacturing defects. When a capacitor becomes faulty, it can affect the compressor’s ability to start and run properly. This can result in the compressor not turning on at all or frequently shutting off during operation.

If you notice that your air conditioning system is having trouble starting, is experiencing frequent on-off cycles, or is not cooling effectively, a faulty capacitor may be to blame. It’s best to have a qualified HVAC technician inspect and test the capacitor to determine if it needs to be replaced.

Replacing a faulty capacitor is a relatively simple task for a professional technician. They will match the specifications of the faulty capacitor and install a new one, ensuring that it is properly connected and functioning correctly. It’s important to address this issue promptly, as a defective capacitor can put additional strain on the compressor, potentially leading to compressor failure if left unattended.

To prevent capacitor-related compressor failure, regular maintenance is essential. During routine AC service visits, the HVAC technician will inspect and test the capacitor for any signs of weakness or malfunction. By identifying and replacing a faulty capacitor before it fails completely, you can avoid unexpected compressor breakdowns and ensure the smooth operation of your air conditioning system.

Remember, working with electrical components can be dangerous, so it’s always recommended to leave capacitor replacement and other electrical repairs to a qualified professional to ensure safety and proper installation.

Regular maintenance, such as cleaning the coils and changing the air filter, can help prevent the AC compressor from stopping due to dirt and debris buildup.

Blocked Suction Lines

Blocked suction lines are a common cause of AC compressor failure. The suction line is responsible for carrying the cool refrigerant vapor from the evaporator coil back to the compressor, where it is compressed to restart the cooling cycle. When the suction lines become obstructed or blocked, the flow of refrigerant is restricted, leading to problems with the compressor.

There are several reasons why suction lines may become blocked. One common cause is debris accumulation, such as dirt, dust, or pet hair, that can find its way into the lines. Over time, this debris can restrict the flow of refrigerant, preventing the compressor from functioning properly.

To prevent compressor failure due to blocked suction lines, it’s important to perform regular maintenance and keep the system clean. Here are a few steps you can take:

- Inspect the suction lines: During routine maintenance, check the suction lines for any visible signs of debris or blockages. If you notice any obstructions, it’s best to contact a professional HVAC technician to clean or clear the lines safely.

- Clean or clear the lines: Depending on the severity of the blockage, the technician may use specialized tools or techniques to clean or clear the suction lines. This may involve using compressed air or a vacuum to remove the debris.

- Maintain a clean environment: Keep the area around the outdoor unit clear of debris, leaves, and other obstructions that can potentially enter the suction lines. Regularly trim any vegetation that may impede the proper airflow around the unit.

Blocked suction lines not only restrict the flow of refrigerant but can also cause the compressor to work harder, leading to increased energy consumption and potential compressor failure. By regularly inspecting and maintaining the suction lines, you can prevent these issues and ensure the efficient operation of your air conditioning system.

It’s important to note that attempting to clean or clear the suction lines yourself can be dangerous if you’re not familiar with HVAC systems. It’s always best to rely on a qualified professional to handle this task.

By addressing blocked suction lines through regular maintenance and taking preventive measures to maintain a clean environment, you can help prevent compressor failure and ensure the longevity of your air conditioning system.

Read more: What Is An AC Compressor

Preventive Measures to Avoid AC Compressor Failure

To avoid AC compressor failure and ensure the smooth operation of your air conditioning system, implementing preventive measures is crucial. Here are some preventive steps you can take to maintain the optimal functioning of your AC compressor:

- Regular Maintenance: Schedule regular maintenance visits with a licensed HVAC technician to inspect, clean, and tune-up your air conditioning system. They can identify any potential issues and perform necessary repairs or adjustments to keep the compressor in good working condition.

- Changing Air Filters: Regularly change or clean the air filters in your HVAC system to prevent dust, dirt, and debris from clogging the system. Clogged air filters restrict airflow and put additional strain on the compressor.

- Cleaning Condenser Coils: Keep the condenser coils clean and free from debris to ensure optimal heat transfer and prevent the compressor from overheating. Regularly inspect and clean the coils, or hire a professional technician to perform this task.

- Keeping the Area Around the Unit Clear: Maintain a clear space around the outdoor unit by removing any obstructions, such as vegetation, leaves, or debris. Clearing the area ensures proper airflow to the unit and prevents blockages in the suction lines.

By following these preventive measures, you can minimize the risk of AC compressor failure and extend the lifespan of your air conditioning system. Regular maintenance and good upkeep help identify potential issues early on and address them before they escalate into major problems.

Additionally, it’s important to address any malfunctions or signs of trouble promptly. If you notice unusual noises, reduced cooling performance, or frequent system cycling, it’s best to contact a professional HVAC technician for a thorough inspection and necessary repairs.

Remember, attempting to diagnose or repair complex HVAC issues yourself can be risky and may cause further damage. It’s always recommended to seek the expertise of a qualified technician who can safely and effectively address any compressor-related concerns.

By practicing preventive measures and staying proactive in the maintenance of your air conditioning system, you can enjoy reliable cooling, lower energy consumption, and avoid costly compressor replacements.

Regular Maintenance

Regular maintenance is one of the most important preventive measures to avoid AC compressor failure. By scheduling routine maintenance visits with a licensed HVAC technician, you can ensure that your air conditioning system is in optimal condition and catch potential issues before they escalate into major problems.

During a maintenance visit, the technician will thoroughly inspect your AC system, including the compressor. They will check for any signs of wear and tear, leaks, electrical problems, or other issues that could affect the performance of the compressor. If any problems are detected, they can address them promptly, preventing further damage to the compressor and the entire system.

In addition to inspection, regular maintenance also involves cleaning and tuning-up the AC system. The technician will clean the condenser coils, remove any debris or obstructions, and ensure proper airflow to the compressor. They will also lubricate moving parts, tighten electrical connections, and test the thermostat’s accuracy to ensure the proper operation of the compressor.

By periodically maintaining your AC system, you can keep the compressor running smoothly, reduce the risk of failure, and extend its lifespan. Regular maintenance also helps maximize energy efficiency, resulting in lower utility bills and a more comfortable indoor environment.

To establish a regular maintenance schedule, consult with a trusted HVAC professional. They can recommend the ideal frequency of visits based on your specific system and usage. Generally, it is recommended to schedule maintenance visits at least once a year, preferably before the start of the cooling season.

In between professional maintenance visits, you can also perform some basic maintenance tasks yourself. These include regularly cleaning or changing the air filters, ensuring proper airflow around the outdoor unit, and keeping the indoor vents unobstructed.

Remember, regular maintenance is an investment in the longevity and efficiency of your air conditioning system. It not only helps prevent AC compressor failure but also maintains optimum performance, reduces energy consumption, and improves indoor air quality.

Changing Air Filters

Changing air filters regularly is a simple yet essential preventive measure to avoid AC compressor failure. Air filters play a crucial role in maintaining the efficiency and performance of your air conditioning system by keeping the air clean and free from dust, dirt, and debris.

As air is drawn into the HVAC system, the air filters trap particles, preventing them from entering the system and clogging the components, including the AC compressor. Over time, these filters can become dirty and clogged, restricting airflow and causing the compressor to work harder to achieve the desired cooling. This added strain can lead to compressor failure if not addressed timely.

It’s recommended to check the air filters on a monthly basis and change them as needed. The frequency of filter changes depends on various factors, including the type of filter, the air quality in your area, and the usage of your HVAC system. In general, standard disposable filters should be replaced every 1-3 months, while higher-quality filters can last up to 6 months or even longer.

When replacing air filters, make sure to choose the correct size and type that is compatible with your AC system. Follow the manufacturer’s instructions or consult a professional technician if you’re unsure about the appropriate filter choice.

In addition to keeping the air clean and preventing compressor failure, changing air filters regularly offers several benefits. It helps maintain good indoor air quality by trapping allergens and pollutants, improves energy efficiency by allowing proper airflow, and extends the lifespan of your AC system.

Remember, proper maintenance of air filters goes beyond just changing them regularly. It’s also important to keep the filter housing clean and free from debris. Regularly vacuum or wipe down the filter housing to remove any accumulated dirt or dust that can hinder the effectiveness of the filter.

By incorporating the habit of replacing air filters on time and ensuring a clean filter housing, you can reduce the likelihood of AC compressor failure, maintain optimal airflow, and enjoy clean and comfortable air in your home.

Cleaning Condenser Coils

Cleaning the condenser coils is an important preventive measure to avoid AC compressor failure. Condenser coils, located in the outdoor unit of your air conditioning system, play a vital role in releasing heat from the refrigerant. Over time, these coils can become dirty or clogged with dirt, dust, leaves, and other debris, hindering heat transfer and putting strain on the compressor.

When the condenser coils are dirty, the compressor has to work harder to cool the refrigerant and maintain the desired indoor temperature. This increased workload can lead to overheating, reduced cooling performance, and potential compressor failure.

To clean the condenser coils, follow these steps:

- Turn off the power: Before beginning any maintenance, ensure that the power to the AC unit is turned off to avoid any risk of electric shock.

- Remove debris: Use a soft brush or a vacuum cleaner with a brush attachment to gently remove any visible debris, leaves, grass clippings, or dirt from the surface of the condenser coils. Take care not to bend or damage the delicate fins of the coils.

- Clean with water or coil cleaner: Depending on the level of dirt and grime buildup, you may need to use water or a coil cleaner specifically designed for cleaning condenser coils. Follow the manufacturer’s instructions carefully if using a coil cleaner. If using water, make sure to direct the flow opposite to the normal airflow direction to avoid pushing the dirt further into the coils.

- Rinse thoroughly: After cleaning, thoroughly rinse the condenser coils with water to remove any remaining dirt and cleaning solution. Ensure that the water flows away from the AC unit.

- Allow to dry: Once rinsed, allow the condenser coils to air dry completely before restoring power to the AC unit.

Cleaning the condenser coils on a regular basis, at least once or twice a year, will help maintain optimal heat transfer, improve the efficiency of your air conditioning system, and reduce the risk of compressor failure.

If cleaning the condenser coils seems challenging or if they are heavily soiled, it’s best to contact a professional HVAC technician. They have the necessary tools and expertise to effectively clean the coils without causing damage to the delicate fins.

Remember, keeping the condenser coils clean is vital for the proper functioning of the compressor. Regular maintenance and cleaning not only help prevent compressor failure but also improve the overall performance and longevity of your air conditioning system.

Read more: How To Change AC Compressor

Keeping the Area Around the Unit Clear

Keeping the area around your air conditioning unit clear is an essential preventive measure to avoid AC compressor failure. The outdoor unit, also known as the condenser, needs proper airflow to operate efficiently. If the area around the unit is obstructed or cluttered, it can impede airflow, strain the compressor, and lead to reduced cooling performance or even compressor failure.

Here are some key steps to keep the area around the unit clear:

- Trim vegetation: Regularly trim any plants, bushes, or trees near the outdoor unit to maintain at least two feet of clearance on all sides. This prevents vegetation from obstructing the airflow and ensures efficient operation of the AC system.

- Clear debris: Remove any debris, such as leaves, grass clippings, or twigs, that may have accumulated around the unit. Debris can block airflow and potentially enter the unit, causing damage to the compressor and other components.

- Avoid storage: Do not store any items, such as gardening tools or furniture, near the outdoor unit. Not only can this restrict airflow, but it can also pose a safety hazard if items come into contact with the unit during operation.

- Protect from animals: Install a protective cover or guard around the unit to prevent animals from nesting inside or causing damage. Animals can create blockages, chew through wires, or damage vital components, including the compressor.

- Provide shade: If possible, consider providing shade for the outdoor unit to help reduce heat exposure. However, ensure that the shade does not obstruct airflow or create an enclosed space around the unit.

By maintaining a clear area around the AC unit, you promote proper airflow, reduce stress on the compressor, and improve the overall efficiency and performance of the system. It also helps prevent debris from entering the system and causing damage to the compressor or other critical components.

Regularly inspect the area around the unit and address any obstructions promptly. If you notice any signs of damage or issues caused by vegetation, animals, or debris, contact a professional HVAC technician for evaluation and necessary repairs.

Remember, a clear area around the unit is crucial for the optimal functioning of the compressor and the air conditioning system as a whole. Don’t underestimate the significance of maintaining a clutter-free and well-ventilated space around the outdoor unit.

Conclusion

AC compressor failure can be a costly and inconvenient problem to deal with. However, by implementing preventive measures and addressing potential issues promptly, you can significantly reduce the risk of compressor failure and ensure the smooth operation of your air conditioning system.

In this article, we explored the common causes of AC compressor failure, including insufficient lubrication, electrical issues, overheating, refrigerant leaks, dirty condenser coils, faulty capacitors, and blocked suction lines. Each of these factors can put strain on the compressor and lead to its failure if not addressed in a timely manner.

To avoid AC compressor failure, regular maintenance is essential. Scheduling routine maintenance visits with a licensed HVAC technician allows for inspections, cleaning, and necessary repairs. Additionally, changing air filters, cleaning condenser coils, and keeping the area around the unit clear are simple yet effective preventive measures to maintain the optimal functioning of the compressor.

By following these preventive measures, you can ensure that your AC compressor remains in good condition, prolong its lifespan, and enjoy reliable cooling performance. It’s essential to address any signs of trouble promptly and seek the assistance of a qualified HVAC technician for accurate diagnosis and resolution of issues.

Remember, neglecting regular maintenance and overlooking potential problems can lead to costly repairs or the need for a complete compressor replacement. By investing in preventive measures and keeping your air conditioning system in top shape, you can enjoy a comfortable and cool indoor environment while avoiding the inconvenience and expenses associated with compressor failure.

Frequently Asked Questions about What Causes An AC Compressor To Stop Working

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Causes An AC Compressor To Stop Working”