Articles

How To Store Chains

Modified: January 5, 2024

Learn the best ways to store chains and keep them organized with these helpful articles. Avoid tangled messes and easily access your chains when you need them.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Chains are commonly used in various industries and applications, such as construction, agriculture, and manufacturing. They are incredibly versatile and durable, making them an essential tool for heavy-duty tasks and transportation. However, storing chains properly is crucial to maintain their longevity and functionality.

In this article, we will discuss the best practices for storing chains, ensuring they remain in optimal condition and are ready for use when needed. From choosing the right storage area to protecting the chains from corrosion and tangling, we will cover everything you need to know to store your chains effectively.

Whether you have chains for lifting, securing loads, or operating machinery, proper storage is essential for maintaining their strength and integrity. Neglecting the storage aspect can result in premature wear, rust formation, and even safety hazards.

By following the tips outlined in this article, you can ensure that your chains are stored in a way that minimizes damage, extends their lifespan, and allows for easy retrieval and use.

Now, let’s dive into the details of how to store your chains effectively!

Key Takeaways:

- Properly storing and maintaining chains is crucial for their longevity, functionality, and safety. Follow best practices for choosing the right storage area, cleaning and preparing the chains, and selecting appropriate containers to ensure optimal chain storage.

- Storing chains in a climate-controlled environment, protecting them from moisture and corrosion, and implementing regular maintenance and inspection practices are essential for preserving chain integrity and performance. By following these guidelines, you can ensure your chains are always ready for use.

Read more: How To Store Gold Chains

Choosing the Right Storage Area

When it comes to storing chains, selecting the right storage area is vital to ensuring their preservation and functionality. Here are some factors to consider when choosing the ideal storage space for your chains:

- Indoor vs. Outdoor: Whenever possible, it is best to store chains indoors to protect them from the elements. Exposure to rain, extreme temperatures, and sunlight can cause corrosion and degradation. If indoor storage is not feasible, consider using a weatherproof container or covering to shield the chains.

- Adequate Space: Make sure the storage area is spacious enough to accommodate the length and size of the chains. Avoid compressing or tightly coiling the chains, as this can lead to tangling and damage.

- Accessibility: Ensure that the storage area is easily accessible, allowing for convenient retrieval of the chains when needed. This is particularly important in situations where quick access to chains is essential, such as emergency situations or time-sensitive tasks.

- Security: Consider the security of the storage area. Chains can be valuable assets, so it’s important to safeguard them against theft or unauthorized access. If necessary, use a lockable storage container or install security measures such as cameras or alarms.

- Avoidance of Hazards: Choose a storage area that is free from potential hazards that could cause damage to the chains. This includes areas with sharp objects, chemicals, excessive moisture, or high levels of dust or dirt.

- Stability: Ensure that the chosen storage area is stable and sturdy. Avoid locations that are prone to vibrations or movements, as they can cause unnecessary stress on the chains and potentially lead to damage.

By considering these factors, you can select an appropriate storage area that provides the necessary protection and accessibility for your chains. Now that we have covered choosing the right storage space, let’s move on to the next step: cleaning and preparing the chains for storage.

Cleaning and Preparing the Chains

Before storing your chains, it is crucial to clean and prepare them properly. This step ensures the removal of dirt, debris, and contaminants that can cause corrosion and deterioration over time. Here are some guidelines for cleaning and preparing your chains:

- Inspect the Chains: Before cleaning, carefully inspect the chains for any signs of damage, wear, or weak spots. If you notice any issues, consider getting them repaired or replaced before storage.

- Remove Dirt and Debris: Use a stiff brush or compressed air to remove dirt, dust, and other loose particles from the chains. Pay special attention to areas where dirt tends to accumulate, such as links, crevices, and hooks.

- Use a Cleaning Solution: Depending on the level of dirt and grime, you may need to use a mild cleaning solution. Avoid harsh chemicals that can damage the metal. Instead, opt for a gentle cleaner, such as a mixture of mild dish soap and warm water.

- Scrub the Chains: Dip a soft brush or cloth into the cleaning solution and scrub the chains thoroughly. Focus on removing any stubborn stains or residues. Be gentle to avoid excessive force that could scratch or damage the chains.

- Rinse and Dry: After cleaning, rinse the chains with clean water to remove any remaining soap or cleaning solution. Pat them dry with a clean towel, or allow them to air dry completely before proceeding to the next step.

- Apply Lubrication: To prevent rust and ensure smooth operation, apply a light coating of lubricating oil to the chains. This will help to keep them well-maintained during storage. Be sure to use an appropriate lubricant for the type of chains you have (e.g., oil-based for standard chains, or silicone-based for stainless steel chains).

- Remove Excess Lubricant: After applying the lubricant, wipe off any excess with a clean cloth to prevent it from attracting dirt or becoming sticky over time.

By following these cleaning and preparation steps, you can ensure that your chains are free from dirt, corrosion, and other contaminants that can impede their performance. Now that the chains are cleaned and ready, let’s move on to the next section: selecting appropriate containers for storage.

Selecting Appropriate Containers

Selecting the right containers for storing your chains is crucial for keeping them well-organized, protected, and easily accessible. Here are some considerations when choosing containers for chain storage:

- Size and Capacity: Ensure that the containers are spacious enough to accommodate the size and length of your chains without excessive coiling or compressing. Adequate space will prevent tangling and damage.

- Durability: Look for containers made of durable materials that can withstand the weight and potential rough handling of chains. Plastic or metal containers are popular choices for their strength and resilience.

- Coverage: Opt for containers with lids or covers to provide additional protection from dust, moisture, and other external elements. This will help to prevent corrosion and keep the chains in optimal condition.

- Accessibility: Choose containers that allow for easy access and retrieval of the chains. Consider options with a hinged lid or removable top for convenient and hassle-free storage and retrieval.

- Stackability: If you have multiple containers of chains, consider containers that are stackable. This will optimize storage space and keep the chains organized and easily identifiable.

- Clear or Labeled: Labeling the containers or using transparent containers can help in quickly identifying the type and size of the chains stored inside. This can save time and effort when searching for specific chains.

- Add Padding: To further protect the chains and prevent them from shifting within the container, consider adding padding such as foam inserts or bubble wrap. This will cushion the chains and reduce the risk of damage during storage or transportation.

- Consider Hanging Hooks: If you have longer chains or want to keep them organized and easily accessible, consider using hanging hooks or racks within the containers. This will prevent tangling and facilitate easy selection of the desired chain.

By selecting appropriate containers that meet these criteria, you can ensure that your chains remain well-organized, protected, and easily accessible when needed. Now that we have discussed selecting containers, let’s move on to arranging the chains for storage.

Arranging Chains for Storage

Properly arranging your chains for storage is essential to prevent tangling, minimize damage, and ensure easy retrieval when needed. Here are some tips for arranging chains in your chosen storage containers:

- Straighten and Untangle: Before placing the chains in the container, straighten them out and untangle any knots or twists. This will help prevent tangling and make it easier to retrieve specific chains later on.

- Coil or Fold Neatly: Depending on the length and flexibility of the chains, coil or fold them neatly to maximize space and prevent excessive bending or kinking. Avoid tight or compressed coils that can lead to stress on the chains.

- Separate Different Types or Sizes: If you have chains of different types or sizes, separate and group them accordingly. This will make it easier to locate the desired chain without going through the entire container.

- Use Dividers or Compartments: If your storage container allows, consider using dividers or compartments to further organize and separate the chains. This will prevent them from shifting around and tangling with each other.

- Secure Loose Ends: Use zip ties, Velcro straps, or twist ties to secure any loose ends of the chains. This will prevent them from unraveling or getting tangled with other chains during storage.

- Arrange by Frequency of Use: If you have chains that are used more frequently, place them towards the top or front of the storage container for easy access. This will save time and effort when retrieving commonly used chains.

- Consider Weight Distribution: If you have multiple containers or a storage system with multiple compartments, distribute the weight of the chains evenly to maintain balance and stability. This will prevent the containers from tipping over or causing unnecessary strain on the chains.

- Leave Room for Expansion: Chains may expand or contract slightly with temperature changes. Ensure that you leave some room within the container to accommodate any potential expansion without causing stress or damage to the chains.

By arranging your chains in a thoughtful and organized manner within the storage containers, you can minimize the risk of tangling, damage, and confusion when retrieving the desired chain. Now that we have covered arranging the chains, let’s move on to the next section: storing chains in a climate-controlled environment.

Read more: How To Store Tire Chains

Storing Chains in a Climate-Controlled Environment

Storing chains in a climate-controlled environment is highly beneficial for their preservation and longevity. Extreme temperature fluctuations, high humidity, and excessive moisture can all contribute to corrosion, rust formation, and degradation of the chains’ metal surfaces. Here’s how you can ensure your chains are stored in a climate-controlled environment:

- Temperature Control: Maintain a consistent temperature within the storage area. Fluctuations in temperature can cause expansion and contraction of the metal, leading to stress and potential damage to the chains. Aim for a moderate, stable temperature range.

- Humidity Control: Keep the humidity level low to prevent moisture buildup. Excessive humidity can contribute to corrosion and rust on metal surfaces. Consider using dehumidifiers or moisture-absorbing agents, such as silica gel packets, to maintain a dry environment.

- Avoid Extreme Conditions: Avoid storing chains in areas prone to extreme conditions, such as direct sunlight, high heat, or freezing temperatures. These extreme conditions can accelerate the degradation process and weaken the chains.

- Air Circulation: Ensure proper air circulation in the storage area. Stagnant or trapped air can contribute to the buildup of moisture and humidity. Use fans or natural ventilation to promote airflow and reduce the risk of condensation.

- Sealable Containers: Use sealable containers to further protect the chains from external environmental factors. Airtight or moisture-resistant containers can help maintain a controlled environment and prevent moisture from seeping into the storage area.

- Regular Monitoring: Regularly monitor the temperature and humidity levels in the storage area. Use a thermometer and hygrometer to ensure the conditions remain within the desired range. Adjust as needed to maintain optimal storage conditions.

- Periodic Inspections: Conduct periodic inspections of the storage area to check for any signs of moisture, rust, or other environmental issues. Address any issues promptly to prevent further damage to the chains.

- Consider Professional Storage: If you have valuable or sensitive chains, consider utilizing professional storage services that offer climate-controlled facilities. These facilities are specifically designed to provide optimal storage conditions and added security for your chains.

By storing your chains in a climate-controlled environment, you can significantly prolong their lifespan and maintain their performance. Now that we have covered climate-controlled storage, let’s move on to protecting chains from moisture and corrosion.

To store chains, use a pegboard or hooks to hang them individually. This prevents tangling and makes it easy to see and access each chain. Keep them in a dry, cool place to prevent rusting.

Protecting Chains from Moisture and Corrosion

Moisture and corrosion are two common enemies of chains. Exposure to moisture can lead to rust formation and deterioration, compromising the strength and functionality of the chains. To ensure the long-term preservation of your chains, it is essential to take proactive measures to protect them from moisture and corrosion. Here are some tips:

- Apply a Protective Coating: Use a corrosion-resistant coating on the surface of the chains to provide an additional layer of protection. Several options are available, including paint, wax, or specialized chain lubricants with anti-corrosion properties.

- Dry the Chains: Before storing the chains, ensure they are completely dry. Moisture trapped in the chains can accelerate corrosion. After cleaning or exposure to water, thoroughly dry the chains using a towel or allow them to air dry before storage.

- Use Desiccants: Place desiccant packets or moisture-absorbing products, such as silica gel packs, in the storage containers or near the chains to absorb any excess moisture. This helps to create a drier environment and reduce the risk of rust formation.

- Consider Rust Inhibitors: Rust inhibitors are chemical compounds designed to prevent or slow down the rusting process. Look for rust inhibitor sprays or products and apply them to the chains according to the manufacturer’s instructions.

- Regular Maintenance: Implement regular maintenance routines to ensure the chains are in optimal condition. Inspect them periodically for any signs of moisture, rust, or corrosion. If you notice any issues, clean and address them promptly to prevent further damage.

- Keep Chains Elevated: When storing chains, consider elevating them from the ground or any damp surfaces. Moisture can rise from the ground, leading to corrosion. Use pallets, shelves, or storage racks to keep the chains off the floor.

- Control Moisture in the Storage Area: Employ methods to control moisture levels in the storage area. Use dehumidifiers, moisture barriers, or even desiccant containers to maintain a dry environment. Avoid storing the chains in areas prone to moisture, such as basements or damp rooms.

- Monitor and Address Issues: Regularly monitor the chains for any signs of corrosion or moisture buildup. If you notice any rust spots or signs of degradation, address the issue immediately by cleaning, applying protective coatings, or seeking professional assistance if necessary.

By taking precautionary measures and implementing proper maintenance techniques, you can effectively protect your chains from moisture and corrosion, preserving their integrity and performance. Now that we have covered protecting chains from moisture and corrosion, let’s move on to preventing tangling and knotting.

Preventing Tangling and Knotting

Tangling and knotting of chains can be not only frustrating but also damaging to their structure. Untangling knotted chains can be time-consuming and may lead to kinks or weakened links. To prevent tangling and knotting, follow these tips:

- Straighten and Align: Before storing or handling the chains, straighten them out and align the links. This will help prevent them from getting entangled or forming knots.

- Use Dividers or Spools: Consider using dividers, spools, or separate containers for each chain to keep them untangled and organized. This is particularly useful if you have a large number of chains or different types of chains to store.

- Secure Ends: Always secure the ends of the chains to prevent them from intertwining with other chains. Use clips, twist ties, or hooks at the ends of the chains to keep them separate and avoid tangles.

- Avoid Overstuffing Containers: Do not overcrowd the storage containers or compartments with too many chains. Leave sufficient space to allow for free movement and minimize the risk of tangling. If necessary, use larger containers or divide the chains into smaller groups.

- Wrap and Bundle: For longer chains, consider wrapping them around a sturdy object or bundling them together using straps or rubber bands. This will keep them neatly organized and prevent tangling.

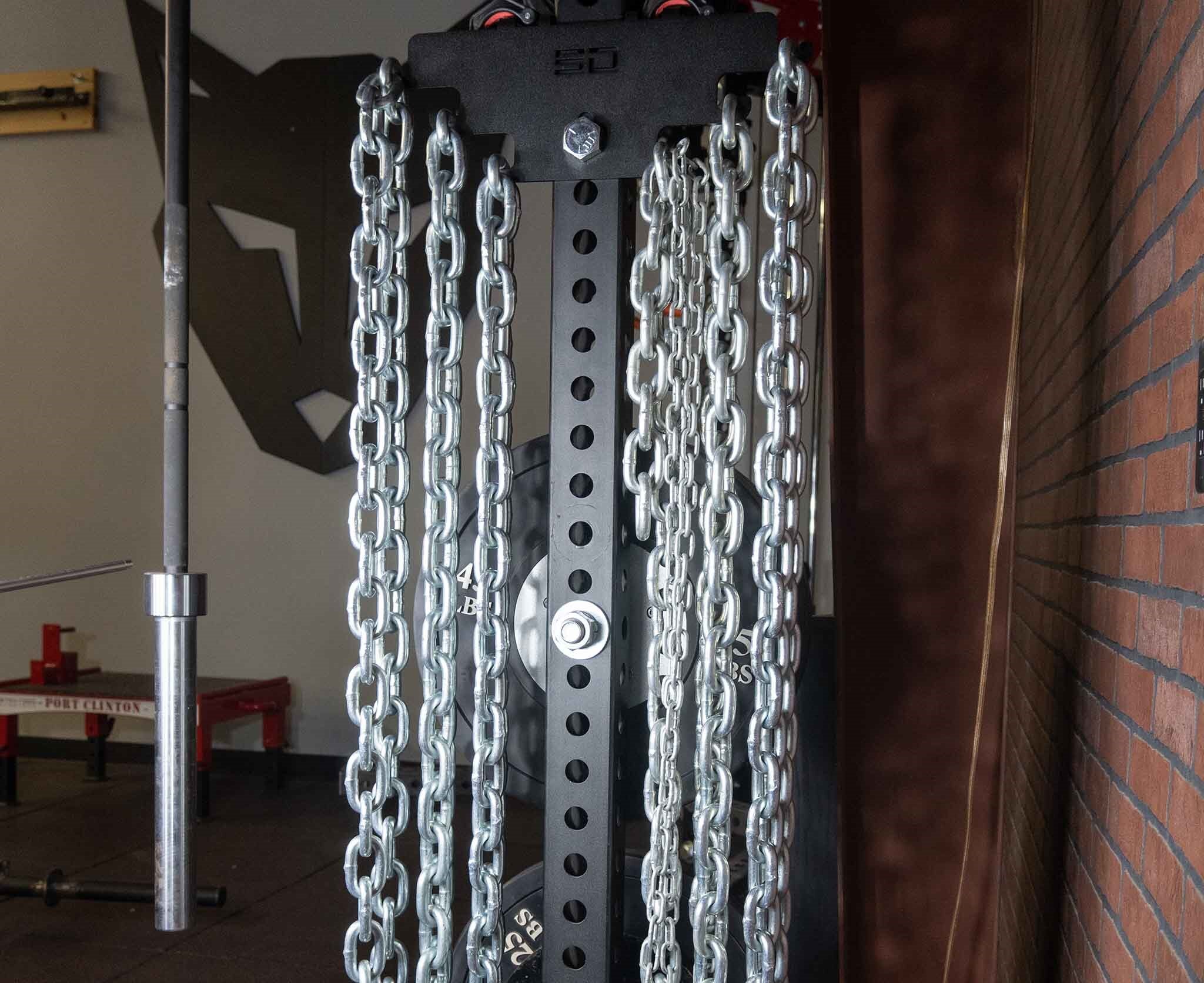

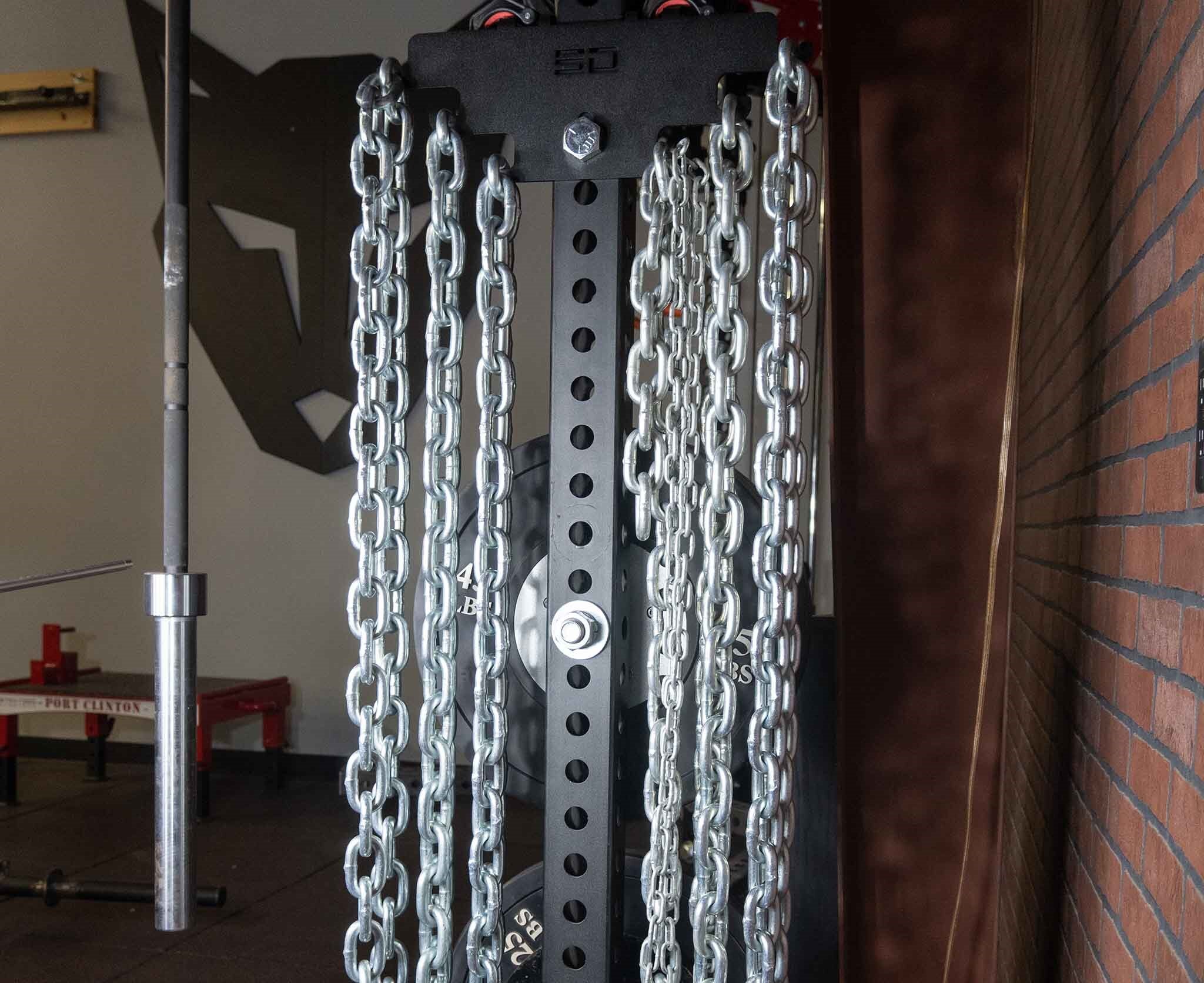

- Hang Chains: If you have the space and appropriate storage equipment, consider hanging the chains vertically to minimize the chance of tangling. Use hooks or hangers specifically designed for chains to ensure they are securely suspended.

- Regularly Check and Straighten: Periodically check the stored chains to ensure they have not become tangled or knotted over time. If you notice any tangles or knots, gently straighten them out to prevent further entanglement.

- Organize by Size or Type: Group and store chains of similar sizes or types together. This will make it easier to locate and retrieve specific chains without disturbing the others, reducing the risk of tangling.

By implementing these preventive measures, you can significantly reduce the occurrence of tangling and knotting, ensuring that your chains remain organized and easily manageable. Now that we’ve covered preventing tangling and knotting, let’s move on to labeling and organizing chains.

Labeling and Organizing Chains

Labeling and organizing your chains is crucial for easy identification, efficient retrieval, and overall organization. Proper labeling and organization will save you time and effort when you need to locate a specific chain. Here are some techniques to label and organize your chains effectively:

- Use Clear Labels: Attach clear labels to each storage container or compartment. Include important information such as the type, size, and purpose of the chains stored inside. Use waterproof or durable labels to ensure they remain legible over time.

- Color Coding: Consider implementing a color-coding system for different types, sizes, or applications of chains. Assign specific colors to each category and use colored labels, tapes, or tags to distinguish between them. This makes it easier to quickly identify the desired chain visually.

- Inventory List: Create an inventory list that provides a detailed record of the chains you have and their respective storage locations. Include relevant information such as chain specifications, quantities, and storage container details. Keep the inventory list readily accessible for quick reference.

- Divide by Category: Group chains by category or purpose and store them in separate containers or compartments. For example, separate lifting chains from securing chains or divide chains based on their weight capacities. This helps maintain organization and facilitates easy retrieval based on specific needs.

- Arrange by Frequency of Use: If you have chains that are used more frequently or have time-sensitive applications, place them in easily accessible locations within the storage area. This saves time when retrieving frequently used chains and ensures efficiency in daily operations.

- Label Hanging Hooks or Racks: If you use hanging hooks or racks to store your chains, consider labeling them. Attach small labels or tags indicating the type or size of chains hanging from each hook or rack. This simplifies the process of locating and selecting the desired chain.

- Periodic Reviews and Updates: Regularly review and update your labeling and organization system. As you acquire new chains or make changes to your inventory, adjust the labels and storage locations accordingly. This helps to maintain an accurate and up-to-date organization system.

- Accessible Labeling Tools: Keep labeling tools such as markers, label makers, or adhesive labels within reach of the storage area. This allows for quick and convenient label creation or modification when needed.

By implementing effective labeling and organization techniques, you can ensure that your chains are well-organized, easily identifiable, and efficiently stored. Now that we have covered labeling and organizing chains, let’s move on to the importance of regular maintenance and inspection.

Read more: How To Stretch A Chain Link Fence

Regular Maintenance and Inspection

Regular maintenance and inspection of your chains are essential to ensure their continued performance and longevity. By implementing a routine maintenance schedule, you can identify and address any potential issues before they escalate into major problems. Here are some key points to consider for regular maintenance and inspection:

- Cleaning and Lubrication: Regularly clean the chains to remove dirt, debris, and contaminants that can cause corrosion or hinder their functionality. After cleaning, apply appropriate lubrication to keep the chains well-maintained and operating smoothly.

- Visual Inspection: Periodically inspect the chains visually for any signs of damage, wear, or deformation. Look for bent or twisted links, elongated openings, or signs of corrosion. If you notice any issues, address them promptly to prevent further damage or compromise in chain strength.

- Load Testing: For chains used in critical applications or under heavy load, consider periodic load testing to ensure their strength and integrity. This involves subjecting the chains to a controlled test load to ensure they can handle the expected weight capacities. Consult manufacturer guidelines or seek professional advice for proper load testing procedures.

- Check Connections: Inspect hooks, shackles, or other connections used with the chains. Ensure they are properly secured and free from wear or deformation. Loose or damaged connections can compromise the effectiveness and safety of the entire chain system.

- Monitor Wear and Tear: Keep track of the wear and tear on your chains over time. Note any areas that show excessive wear or signs of stress, such as elongated openings or significant thinning of the metal. Replace chains that have reached their service limits or show signs of compromised integrity.

- Keep Records: Maintain records of inspection dates, maintenance activities, and any repairs or replacements undertaken. This provides a historical record of the maintenance history and can be useful for future reference or audits.

- Follow Manufacturer Guidelines: Refer to the manufacturer’s guidelines and recommendations for maintenance and inspection procedures specific to your chains. These guidelines often provide valuable insights on the recommended frequency of maintenance, lubrication requirements, and other maintenance best practices.

- Training and Education: Ensure that you and your team are trained in proper chain inspection techniques and maintenance procedures. Stay informed about industry standards and best practices to ensure you are equipped with the knowledge necessary to maintain and inspect your chains effectively.

By implementing regular maintenance and inspection practices, you can proactively identify and address any issues with your chains, ensuring they remain in optimal condition and reducing the risk of unexpected failures. Now that we’ve covered regular maintenance and inspection, let’s wrap up the article.

Conclusion

Properly storing and maintaining your chains is crucial for their longevity, functionality, and safety. By following the best practices outlined in this article, you can ensure that your chains remain in optimal condition and are ready for use when needed. Here’s a recap of the key points covered:

First, choosing the right storage area is important. Opt for an indoor, climate-controlled area that is secure, spacious, and free from potential hazards. Cleaning and preparing the chains involve inspecting, removing dirt and debris, and applying appropriate lubrication.

Selecting appropriate containers is essential for organizing and protecting your chains. Choose durable, sealable containers that provide ample space and allow for easy access and identification. Arrange the chains neatly to prevent tangling and utilize dividers or hanging hooks for added organization.

Storing chains in a climate-controlled environment helps prevent rust and corrosion. Maintain stable temperature and humidity levels, ensure proper air circulation, and monitor the storage area regularly. Protecting the chains from moisture and corrosion entails using protective coatings, keeping them dry, and controlling the storage environment.

To prevent tangling and knotting, straighten and align the chains, use dividers or spools, and secure the ends. Labeling and organizing the chains facilitate easy identification and retrieval. Use clear labels, implement color coding, and maintain a comprehensive inventory list for efficient organization.

Regular maintenance and inspection are vital to maintaining the performance and integrity of the chains. Clean and lubricate them regularly, visually inspect for damage, conduct load testing when necessary, and monitor wear and tear. Keeping records of maintenance activities and following manufacturer guidelines are also important.

By implementing these measures, you can ensure that your chains are stored properly, protected from damage, and in optimal condition for use. Regular maintenance and inspection practices will help identify and address any issues early on, ensuring the safety and reliability of your chains.

Remember, the proper storage and maintenance of your chains not only increases their lifespan but also contributes to the overall efficiency and effectiveness of your operations. By investing the time and effort into implementing these best practices, you can ensure that your chains are always ready to perform when you need them.

By following these guidelines, you can become an expert in storing chains and maintain their longevity, functionality, and safety. So, go ahead and apply these tips to your chain storage practices and witness the difference they make!

Frequently Asked Questions about How To Store Chains

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Chains”