Home>Articles>Understanding Power Hand Tools To Refine Your Skills

Articles

Understanding Power Hand Tools To Refine Your Skills

Modified: October 31, 2024

Discover the best articles about power hand tools to enhance your experience. Learn tips and tricks from experts and find the perfect tools for your projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of hand tools! Whether you are a DIY enthusiast or a professional tradesperson, having a solid understanding of hand tools is essential. These versatile tools can help you tackle a wide range of tasks, from simple repairs to complex projects. They are portable, easy to use, and require no power source, making them a convenient choice in various situations.

In this article, we will dive into the world of hand tools and explore everything you need to know to have a powerful hand tools experience. We will cover topics such as selecting the right hand tools, understanding hand tool safety, basic hand tool techniques, maintaining hand tools, advanced hand tool techniques, and troubleshooting common issues.

So, whether you are a beginner looking to build your toolkit or a seasoned professional seeking to refine your skills, this guide will provide you with valuable insights and practical tips to optimize your hand tool usage.

Let’s get started by understanding the importance of selecting the right hand tools for your needs.

Key Takeaways:

- Selecting the right hand tools, understanding safety measures, mastering basic and advanced techniques, maintaining tools, and troubleshooting issues are essential for a powerful hand tools experience.

- By prioritizing safety, investing in quality tools, and continuously improving skills, individuals can confidently tackle projects and achieve professional-level results with hand tools.

Selecting the Right Hand Tools

Choosing the right hand tools is crucial for efficiency, effectiveness, and safety. With a myriad of options available in the market, it can be overwhelming to make the best selection. However, considering a few key factors can help simplify the process.

The first step in selecting hand tools is to assess your needs. Consider the types of projects you commonly work on and the tasks you need to accomplish. This will help you determine which tools are essential and which ones you can prioritize.

Next, consider the quality of the tools. Investing in high-quality hand tools is a wise decision in the long run. They are designed to withstand regular use and offer better performance, durability, and precision. Look for reputable brands and read reviews to ensure you are making a wise investment.

Another important aspect to consider is ergonomics. Hand tools that are comfortable to use can minimize fatigue and prevent injuries. Look for tools with non-slip handles and ergonomic grips that fit well in your hand.

Furthermore, it is essential to consider the materials used in the construction of the hand tools. Opt for tools made from durable materials like stainless steel or aluminum, as they offer better longevity and performance.

Consider the size and weight of the tools as well. Depending on the tasks at hand, you may need different sizes of tools. Lightweight tools are preferred for prolonged use, while heavier ones may offer more stability and power.

Finally, take into account your budget. While it is important to invest in quality tools, it is also crucial to stay within your budget. Look for tools that strike a balance between quality and affordability.

By considering these factors when selecting hand tools, you can ensure that you have the right tools for the job, enhance your productivity, and achieve the best results. Now that you have selected your tools, let’s move on to understanding the importance of hand tool safety.

Understanding Hand Tool Safety

When it comes to working with hand tools, safety should always be a top priority. Understanding and following proper safety guidelines is essential to prevent accidents and injuries. Here are some key tips to ensure hand tool safety:

1. Wear Protective Gear: Always wear appropriate personal protective equipment (PPE) when using hand tools. This can include safety goggles, gloves, ear protection, and even a dust mask, depending on the task at hand. PPE helps protect you from potential hazards such as flying debris, sharp edges, and loud noises.

2. Inspect Tools: Before using any hand tool, inspect it for any signs of damage or wear. Check the handles for cracks or splinters, ensure the blades are sharp and secure, and verify that all moving parts are in good working condition. Never use damaged or defective tools, as they can pose a safety risk.

3. Follow Manufacturer’s Instructions: Familiarize yourself with the manufacturer’s instructions for each hand tool. Pay attention to any warnings, recommended usage guidelines, and maintenance instructions. Following these instructions will help you use the tools safely and extend their lifespan.

4. Use Tools for Their Intended Purpose: Each hand tool is designed for a specific task. Avoid using tools for purposes they were not intended for, as this can lead to accidents. For example, using a screwdriver as a chisel can result in the tool slipping and causing injury.

5. Maintain a Secure Work Area: Keep your work area clean and organized. Remove any clutter, debris, or tripping hazards to prevent accidents. Ensure that you have sufficient lighting and a stable work surface for better visibility and stability.

6. Use Proper Techniques: Learn and practice the correct techniques for using each hand tool. This includes gripping the tool firmly but not too tightly, maintaining control and balance, and using smooth, controlled motions. Avoid using excessive force, as this can lead to loss of control and accidents.

7. Store Tools Properly: When not in use, store your hand tools in a designated area, such as a toolbox or wall-mounted organizer. This helps prevent accidents caused by tools lying around or being misplaced. Keep sharp tools separate from others, and use blade protectors or sheaths to prevent accidental injuries.

By following these safety guidelines, you can minimize the risk of accidents and injuries while using hand tools. Remember, safety should always come first. Now that you understand hand tool safety, let’s move on to learning some basic hand tool techniques.

Basic Hand Tool Techniques

Mastering basic hand tool techniques is essential for effectively using these tools and achieving the desired results. Here are some fundamental techniques that will serve as a great foundation for your hand tool skills:

1. Measuring and Marking: Accurate measurements and markings are crucial for precise work. Use a tape measure, ruler, or combination square to measure and mark your materials before cutting or drilling. Use a pencil or marking gauge to make clear and visible marks.

2. Cutting and Shaping: Hand tools like hand saws, chisels, and planes are used for cutting and shaping materials such as wood or metal. Practice proper hand placement and apply controlled pressure to achieve clean and accurate cuts or shaping.

3. Fastening: Hand tools such as screwdrivers, wrenches, and pliers are used for fastening materials together. Develop good grip and leverage when using these tools. Ensure that the fasteners are tightened securely without over-tightening, which can cause damage.

4. Striking and Hammering: Hammers and mallets are essential hand tools for striking and hammering tasks. Learn proper striking techniques and use the correct type of hammer for each job, whether it’s driving nails or chiseling wood.

5. Holding and Clamping: Hand tools like clamps, vises, and holding devices are used to secure materials in place during work. Use these tools to hold materials securely and prevent movement or shifting while you work on them.

6. Sanding and Finishing: Sanding blocks and rasps are used to smooth surfaces and remove imperfections. Learn the proper sanding techniques to achieve a smooth finish and apply appropriate finishes like varnish or paint for protection and aesthetics.

7. Extracting and Removing: Hand tools like screw extractors or pry bars are used to remove nails, screws, or other fasteners. Learn how to use these tools safely and effectively to avoid damaging the surrounding materials.

Remember, practice makes perfect. Take the time to learn and refine these basic hand tool techniques. As you build your confidence and skill, you can move on to more advanced hand tool techniques.

When using power hand tools, always wear appropriate safety gear such as goggles, gloves, and ear protection. This will help protect you from potential injuries and long-term damage to your senses.

Maintaining Hand Tools

Proper maintenance of hand tools is essential for their longevity, performance, and safety. Taking care of your hand tools will not only save you money in the long run but also ensure that they are always ready for use. Here are some tips for maintaining your hand tools:

1. Clean Regularly: After each use, clean your hand tools to remove any dirt, debris, or residue. Use a brush or cloth to wipe away the dirt and grime, and use a mild detergent or tool cleaner if necessary. Dry the tools thoroughly to prevent rust and corrosion.

2. Lubricate Moving Parts: Moving parts such as hinges, locks, and adjustable components should be lubricated periodically to ensure smooth operation. Use a light machine oil or silicone spray to lubricate these parts, and wipe away any excess oil before storing the tools.

3. Sharpen Blades and Cutting Edges: Maintaining sharp blades and cutting edges is crucial for optimal performance. Regularly inspect the blades and sharpen them using a sharpening stone or file as needed. This will ensure clean and efficient cuts and reduce the risk of accidents caused by dull blades.

4. Store Properly: Store your hand tools in a clean, dry, and organized manner. Use toolboxes, racks, or pegboards to keep them neatly arranged and protected. Avoid storing them in humid or damp areas to prevent rust formation.

5. Handle with Care: Treat your hand tools with care to prevent damage. Avoid dropping them, using excessive force, or using them for tasks they are not designed for. Proper handling will extend their lifespan and maintain their functionality.

6. Inspect and Replace Parts: Regularly inspect your hand tools for signs of wear, damage, or loose components. Replace any worn-out or broken parts to maintain the tool’s effectiveness and prevent accidents. Replace worn-out handles or grips to maintain a comfortable and secure grip.

7. Keep an Eye on Rust: Rust can negatively impact the performance and appearance of hand tools. Regularly check your tools for any signs of rust, especially on metal surfaces. Use a rust remover or light abrasive material to gently remove the rust before applying a rust inhibitor or coating to protect the tool.

By following these maintenance tips, you can ensure that your hand tools stay in top shape and offer optimal performance whenever you need them. Now that you know how to maintain your tools, let’s move on to exploring some advanced hand tool techniques.

Read more: What Are Non-Powered Hand Tools

Advanced Hand Tool Techniques

Once you’ve mastered the basic hand tool techniques, you can move on to more advanced skills that will expand your capabilities and allow you to tackle more complex projects. Here are some advanced hand tool techniques to enhance your craftsmanship:

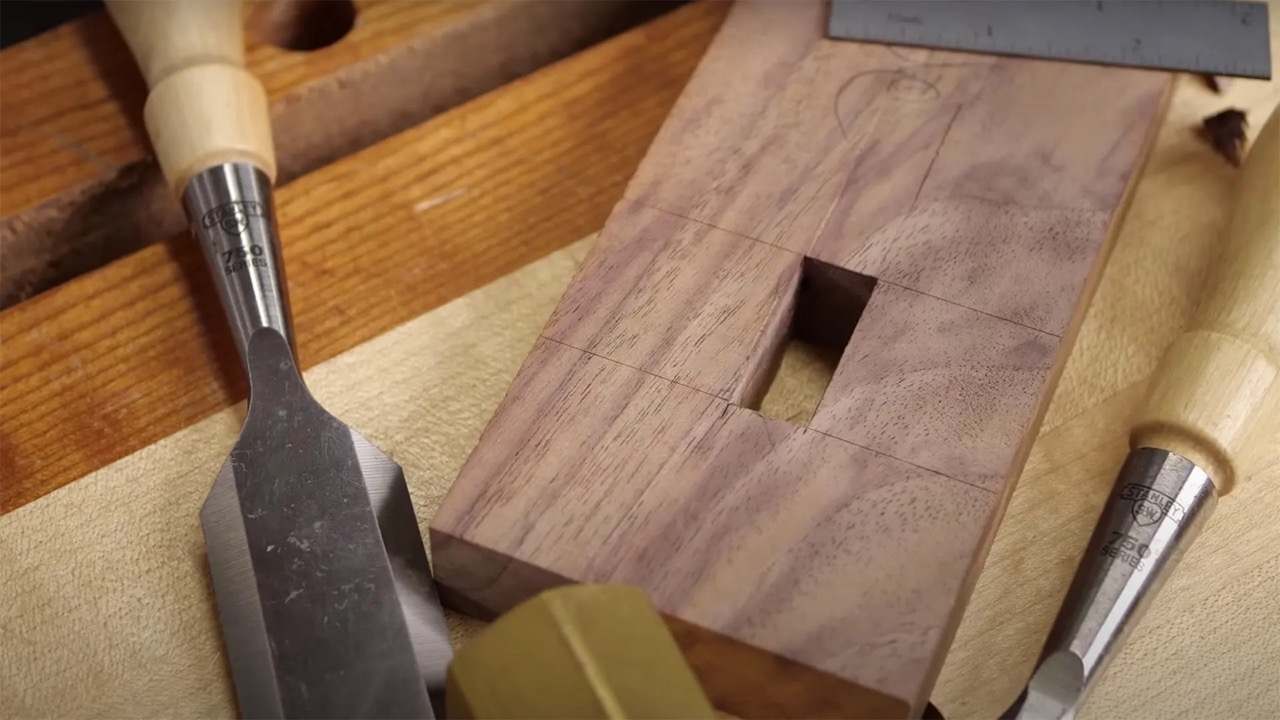

1. Joinery Techniques: Joinery involves connecting and securing pieces of wood together. Advanced hand tool techniques such as mortise and tenon joints, dovetail joints, and finger joints add strength and visual appeal to your woodworking projects. Practice these techniques to create precise and beautiful joints.

2. Carving and Sculpting: Hand carving and sculpting involves shaping wood or other materials with chisels, gouges, and carving knives. Develop your skills in creating intricate designs, textures, and details that bring life to your creations. The art of carving requires patience and precision, so be sure to practice and refine your techniques.

3. Inlay and Marquetry: Inlay and marquetry are decorative techniques where pieces of contrasting materials, such as wood, metal, or mother-of-pearl, are carefully fitted into a base material to create intricate patterns or designs. Tools like coping saws, chisels, and veneer saws are used in these techniques. This advanced skill adds a touch of elegance and sophistication to your woodworking projects.

4. Advanced Finishing Techniques: Enhance the appearance of your projects by mastering advanced finishing techniques. This includes techniques such as French polishing, staining, distressing, and grain filling. Learn to use different varnishes, oils, or shellacs to achieve the desired finish and protect the surface of your work.

5. Precision Cutting and Shaping: Take your cutting and shaping skills to the next level by refining your precision. This can involve intricate joinery cuts, delicate shaping of curves and contours, or precise trimming of materials. Utilize tools like coping saws, scroll saws, and precision hand planes to achieve accurate and smooth cuts.

6. Leatherworking Techniques: Hand tools are commonly used in leatherworking to cut, punch, and shape leather. Advanced techniques include saddle stitching, decorative tooling, and leather lacing. With practice, you can create durable and visually appealing leather goods.

7. Complex Metalworking Techniques: Hand tools like files, saws, and taps can be used in advanced metalworking techniques. This includes intricate metal sculpting, creating precise threads, or even fabricating custom metal parts. Developing these skills will allow you to work with metal and accomplish complex metal projects.

Remember, advanced hand tool techniques require practice, patience, and a willingness to challenge yourself. Keep honing your skills and exploring new techniques to expand your capabilities as a craftsman.

Troubleshooting Hand Tools

Even with proper maintenance and care, hand tools may encounter issues from time to time. Being able to troubleshoot and fix common problems will save you time, money, and frustration. Here are some troubleshooting tips for common hand tool issues:

1. Loose Handles or Grips: If the handle or grip of a hand tool becomes loose, it can affect the tool’s performance and make it unsafe to use. To fix this issue, tighten any screws or fasteners that secure the handle or grip. If necessary, apply a layer of adhesive or epoxy to reinforce the connection.

2. Dull Cutting Edges: Over time, cutting edges on tools such as saws, chisels, or blades may become dull. To restore their cutting ability, sharpen the edges using a sharpening stone or file. It’s essential to maintain proper bevel angles and remove any nicks or burrs that may affect the tool’s performance.

3. Stuck or Jammed Moving Parts: If a hand tool has moving parts that become stuck or jammed, it could hinder its functionality. Begin by cleaning any debris or dirt that may be causing the problem. If the issue persists, apply a few drops of lubricating oil to the affected area and work the parts back and forth to loosen them.

4. Rust or Corrosion: If you notice rust or corrosion on the metal surfaces of your hand tools, it’s important to address it promptly. Use a rust remover or light abrasive material to gently remove the rust. Afterward, apply a rust inhibitor or protective coating to prevent further corrosion.

5. Misaligned Cutting Blades: When the blades on tools like hand saws or planes become misaligned, it can lead to uneven or inaccurate cuts. Check the alignment of the blades and adjust them as needed. Some tools may have adjustment screws or mechanisms that allow for easy alignment.

6. Damaged or Broken Handles: If a handle on a hand tool becomes damaged or breaks, it can render the tool unusable or unsafe. In this case, it may be necessary to replace the handle. Look for replacement handles specifically designed for your tool and follow the manufacturer’s instructions for installation.

7. Worn Out or Faulty Parts: With prolonged use, certain parts of a hand tool may become worn out or fail. It’s important to identify the faulty part and replace it with a compatible and high-quality replacement. Whether it’s a blade, spring, or locking mechanism, ensuring that all parts are in good working condition is crucial for the tool’s performance and safety.

By troubleshooting and addressing these common issues, you can extend the lifespan of your hand tools and maintain their optimal functionality. Regular inspection and timely repairs will keep your tools in top shape and ready for any task at hand.

Conclusion

Having a comprehensive understanding of hand tools is essential for anyone looking to embark on DIY projects or pursue a career in a trade. By selecting the right hand tools, understanding hand tool safety, mastering basic and advanced techniques, maintaining your tools, and troubleshooting common issues, you can have a powerful hand tools experience.

Choosing the right hand tools involves considering your needs, quality, ergonomics, materials, size, and budget. By making wise selections, you can ensure that you have the tools necessary for your projects.

Understanding hand tool safety is crucial for preventing accidents and injuries. Wearing protective gear, inspecting tools, following manufacturer’s instructions, and practicing proper techniques contribute to a safe working environment.

Mastering basic hand tool techniques, such as measuring and marking, cutting and shaping, fastening, holding and clamping, sanding and finishing, and extracting and removing, allows you to accomplish a wide range of tasks with precision and efficiency.

Maintaining hand tools through regular cleaning, lubrication, sharpening, proper storage, and careful handling prolongs their lifespan and ensures optimal performance.

Once you’ve mastered the basics, advanced hand tool techniques, like joinery, carving and sculpting, inlay and marquetry, precision cutting and shaping, leatherworking, and complex metalworking, allow you to take your skills to the next level and create intricate and impressive projects.

Troubleshooting common hand tool issues, such as loose handles or grips, dull cutting edges, stuck or jammed moving parts, rust or corrosion, misaligned blades, damaged or broken handles, and worn-out parts, enables you to address problems and keep your tools in working order.

By following these guidelines and continuously improving your hand tool skills, you can confidently tackle a variety of projects, unleash your creativity, and achieve professional-level results.

So, embrace the power of hand tools and enjoy the satisfaction of creating, repairing, and building with your own hands. Remember to always prioritize safety, invest in quality tools, and strive for continuous improvement. Happy crafting!

Frequently Asked Questions about Understanding Power Hand Tools To Refine Your Skills

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Understanding Power Hand Tools To Refine Your Skills”