Articles

What Size Co2 Tank Does A Kegerator Use

Modified: August 27, 2024

Looking for articles on what size CO2 tank a kegerator uses? Find all the information you need and more in our comprehensive guide.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of kegerators! If you’re a beer enthusiast or looking to tap into the joys of draft beer at home, then you’ve come to the right place. Kegerators are an excellent way to enjoy a cold and refreshing pint straight from the keg, just like at your favorite bar or brewery.

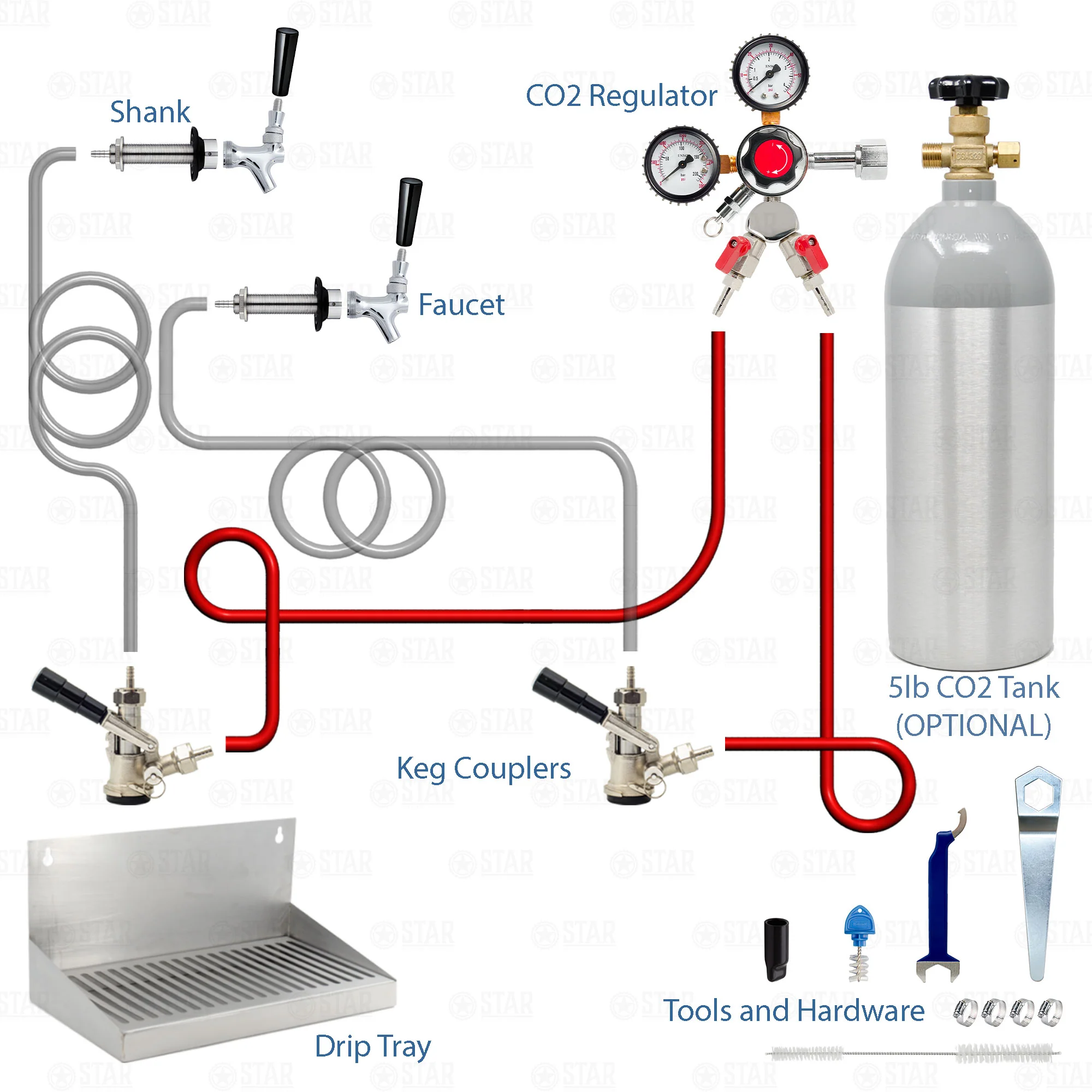

One key component of a kegerator is the CO2 tank. CO2, or carbon dioxide, is a crucial element in the process of dispensing beer from a keg. It provides the necessary pressure to push the beer out of the keg and into your glass, ensuring that it maintains its carbonation and freshness.

In this article, we will delve into the world of kegerators and explore the importance of CO2 tanks in these beer dispensing systems. We will also discuss the various factors you need to consider when choosing the size of a CO2 tank for your kegerator and provide you with some helpful tips for optimizing CO2 usage.

So, let’s raise our glasses and dive into the fascinating world of CO2 tanks in kegerators!

Key Takeaways:

- Choosing the right size CO2 tank for your kegerator is crucial for maintaining carbonation, controlling dispensing pressure, and preserving freshness. Consider factors like usage frequency and keg size to make an informed decision.

- To optimize CO2 usage, regularly check for leaks, maintain appropriate dispensing pressure, and avoid overcarbonation. These practices ensure efficient carbonation and dispensing, maximizing the life of your CO2 tank for a satisfying beer-drinking experience.

Read more: What Size Co2 Tank For A Kegerator Nostalgia

Understanding CO2 in Kegerators

Before we dive into the specifics of CO2 tanks in kegerators, it’s important to have a basic understanding of how CO2 works in this context. Carbon dioxide is a colorless and odorless gas that is naturally produced during the fermentation process of beer.

When beer is stored in a keg, it is typically under pressure to maintain its carbonation. This pressure is provided by the CO2 gas stored in a separate tank and regulated by a regulator attached to the kegerator. The CO2 gas is then released into the keg, creating the necessary force to dispense the beer.

CO2 tanks for kegerators come in various sizes and types, each with its own capacity and pressure rating. The most common type of CO2 tank used in kegerators is the aluminum tank, which is lightweight and easy to handle. These tanks are equipped with a valve that allows for easy refilling and pressure regulation.

It’s important to note that CO2 tanks are not only used for dispensing beer but also for carbonating and serving other beverages like soda, wine, and cold brew coffee. They are versatile tools that ensure a consistent and enjoyable drinking experience.

Now that we have a basic understanding of CO2’s role in kegerators, let’s explore the importance of CO2 tanks in more detail.

Importance of CO2 Tanks in Kegerators

CO2 tanks play a vital role in the functionality and performance of kegerators. Here are a few key reasons why CO2 tanks are important:

Maintain Carbonation Levels:

CO2 is responsible for maintaining the carbonation levels in your beer. When the CO2 gas is released into the keg, it pressurizes the beer and keeps it carbonated. Without a proper supply of CO2, your beer would become flat and lose its desired effervescence.

Control Dispensing Pressure:

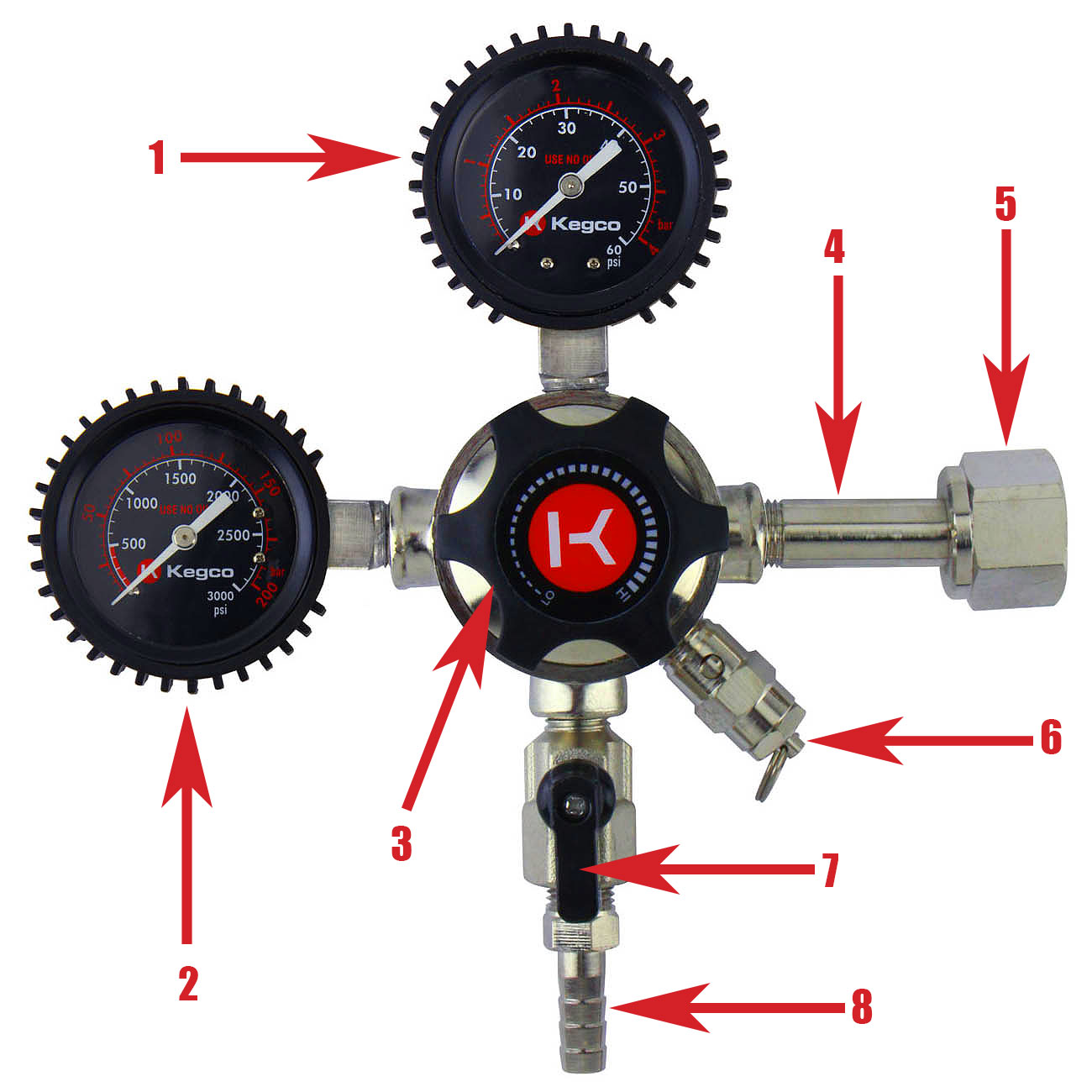

CO2 tanks allow you to control the pressure at which the beer is dispensed. Different beer styles require different dispensing pressures to achieve optimal carbonation levels and the desired head on the beer. CO2 tanks with regulators enable you to adjust the pressure to match the specific requirements of your beer.

Read more: How To Change Co2 Tank In Kegerator

Preserve Freshness:

CO2 helps to preserve the freshness and flavor of your beer. By maintaining proper carbonation, the CO2 gas acts as a barrier, preventing oxygen from entering the keg. Oxygen can degrade the quality and taste of beer, causing it to go stale or develop off-flavors. With a reliable CO2 supply, you can enjoy your beer at its best.

Ensure Smooth Dispensing:

CO2 provides the necessary force to push beer out of the keg and through the dispensing system. It ensures a smooth and consistent flow of beer, preventing clogging or uneven dispensing. This ensures that every pint you pour is as satisfying as the last.

In summary, CO2 tanks are essential components of kegerators as they maintain carbonation, control dispensing pressure, preserve freshness, and ensure smooth dispensing. Choosing the right size of CO2 tank for your kegerator is crucial to ensure optimal performance and an enjoyable beer-drinking experience. In the next section, we will discuss the factors to consider when selecting the size of a CO2 tank for your kegerator.

Factors to Consider When Choosing the Size of a CO2 Tank

When it comes to selecting the size of a CO2 tank for your kegerator, there are several important factors to consider. These factors will help determine the appropriate size that will meet your needs and provide an optimal experience. Let’s take a closer look at these factors:

Usage Frequency:

Consider how often you will be using your kegerator and dispensing beer. If you are a casual drinker or only use the kegerator occasionally, a smaller CO2 tank may be sufficient. However, if you entertain frequently or have a high demand for beer, a larger tank will ensure you have an ample supply of CO2.

Keg Size:

The size of the kegs you plan to use in your kegerator is another crucial factor. Different keg sizes require different amounts of CO2 to maintain proper carbonation. For example, a standard half-barrel keg (15.5 gallons) will require more CO2 than a smaller quarter-barrel keg (7.75 gallons). Consider the keg size you will be predominantly using and choose a CO2 tank size accordingly.

Space Constraints:

Take into account the available space in your kegerator for the CO2 tank. Larger tanks will require more space, so ensure your kegerator has enough room to accommodate the size you choose without hindering other components or functionality.

Convenience and Portability:

If portability is a priority for you, consider opting for a smaller CO2 tank that is lightweight and easy to transport. This is especially important if you plan on taking your kegerator to outdoor events or parties. However, keep in mind that smaller tanks may need to be refilled more frequently.

By considering these factors, you can make an informed decision about the size of CO2 tank that will best suit your needs. In the next section, we will explore the common sizes of CO2 tanks for kegerators, giving you a better idea of the options available.

Common Sizes of CO2 Tanks for Kegerators

When it comes to choosing a CO2 tank for your kegerator, there are several common sizes to choose from. These sizes are based on the capacity of the tank and can vary depending on your specific needs. Let’s take a look at the most common sizes of CO2 tanks for kegerators:

- 5 lb Tank: The 5 lb CO2 tank is the most popular size for home kegerators. It’s compact, lightweight, and can easily fit into most kegerator systems. This size is ideal for casual beer drinkers or those with limited space.

- 10 lb Tank: The 10 lb CO2 tank is a step up from the 5 lb tank and provides a larger supply of CO2. This size is perfect for those who entertain frequently or have a higher beer consumption. It offers a longer-lasting supply of CO2 before needing a refill.

- 20 lb Tank: The 20 lb CO2 tank is a large-size option suitable for commercial or heavy usage. It’s commonly used in bars, restaurants, or for large-scale events. This size provides a significant amount of CO2 and requires less frequent refills compared to smaller tanks.

- Other Sizes: In addition to the commonly used sizes mentioned above, there are also smaller and larger CO2 tank options available. Smaller tanks, such as 2.5 lb or 3 lb tanks, are often used for portable kegerators or for smaller keg sizes. Larger tanks, such as 50 lb or 100 lb tanks, are primarily used for commercial applications.

When selecting the size of your CO2 tank, consider your usage frequency, keg size, space constraints, and portability needs. It’s important to choose a size that provides an adequate supply of CO2 while fitting comfortably in your kegerator setup.

Next, we will discuss how to determine the right size of CO2 tank for your kegerator based on your specific requirements.

Read also: 8 Amazing Co2 Tank For Kegerator For 2025

How to Determine the Right Size of CO2 Tank for Your Kegerator

Choosing the right size of CO2 tank for your kegerator can be a little tricky, but with a few considerations, you can determine the perfect fit. Here’s how:

Calculate Your Average Beer Consumption:

Start by estimating your average beer consumption. Consider how often you entertain guests or how frequently you enjoy a pint at home. If you’re unsure, it’s better to overestimate rather than underestimate.

Determine the CO2 Usage per Keg:

Research the typical CO2 usage per keg based on your beer style and carbonation preferences. This information can usually be found in the kegging instructions provided by the brewery or homebrew supplier. This will give you an idea of how much CO2 you’ll need for each keg.

Calculate the Maximum Kegs per Tank:

To determine the maximum number of kegs you can dispense with a single CO2 tank, divide the capacity of the tank (in pounds) by the estimated CO2 usage per keg (in pounds). For example, if you have a 10 lb CO2 tank and your estimated CO2 usage per keg is 1 lb, you can dispense approximately 10 kegs before needing a refill.

Consider Refill Frequency:

Think about how often you’re willing to refill your CO2 tank. If you prefer less frequent refills, opt for a larger tank. Keep in mind that bigger tanks are heavier and take up more space. Balancing your desired refill frequency with practicality is key.

Evaluate Space Constraints:

Assess the available space you have in your kegerator setup. Make sure the CO2 tank, along with other components, can fit comfortably without hindering functionality or causing any obstructions.

By considering these factors and doing some calculations, you can determine the right size of CO2 tank for your kegerator. Remember, it’s always a good idea to consult with your local homebrew shop or supplier for more specific guidance based on your unique setup and needs.

In the next section, we will share some tips for optimizing CO2 usage in your kegerator, helping you make the most out of your CO2 tank and ensuring a fantastic beer-drinking experience.

Tips for Optimizing CO2 Usage in Your Kegerator

Efficient use of CO2 in your kegerator not only helps extend the life of your CO2 tank but also ensures optimal carbonation and dispensing. Here are some tips to optimize CO2 usage:

Check for Leaks Regularly:

Leaks in your kegerator system can lead to unnecessary CO2 loss. Regularly inspect all connections, fittings, and hoses for any signs of leaks. Apply a mixture of soap and water to the connections and look for bubbles. Tighten or replace any faulty components to minimize CO2 wastage.

Read more: How To Use A Kegerator Co2 Regulator

Maintain Appropriate Dispensing Pressure:

Ensure that your CO2 regulator is set to the correct pressure for your specific beer style. Too much pressure can result in excess CO2 consumption, while too little pressure may lead to under-carbonation. Adjust the pressure according to the keg’s requirements to optimize carbonation and minimize CO2 waste.

Avoid Overcarbonation:

Overcarbonated beer can lead to excessive foaming and wasted CO2. Follow recommended carbonation guidelines for your beer style and adjust the PSI (pounds per square inch) on the regulator accordingly. It’s better to slightly undercarbonate and gradually increase the pressure if needed.

Reduce Line Lengths:

Long beer lines can contribute to excessive foam and the need for higher dispensing pressure. Consider using shorter beer lines to reduce the distance between the keg and the faucet. This allows for better dispensing control, resulting in less CO2 waste.

Keep Your Kegerator at the Optimal Temperature:

Maintaining the proper temperature inside your kegerator is essential for minimizing CO2 usage. Carbonation and dispensing efficiency are influenced by temperature, so ensure that your kegerator is set to the recommended temperature for the style of beer you are serving.

Avoid Constant Opening and Closing of the Kegerator:

Frequent opening and closing of the kegerator door can cause temperature fluctuations, leading to unnecessary CO2 consumption. Try to minimize the number of times you open the door to maintain a consistent temperature inside and preserve the carbonation.

By implementing these optimization tips, you can maximize the usage of your CO2 tank and enjoy a well-carbonated beer without wasting CO2. Remember to keep an eye on your CO2 levels and refill as needed to ensure uninterrupted beer enjoyment.

Now, let’s wrap up our discussion on CO2 tanks in kegerators.

Conclusion

CO2 tanks are an essential component of kegerators, providing the necessary pressure to dispense beer from kegs while maintaining carbonation and freshness. Choosing the right size of a CO2 tank for your kegerator is crucial to ensure optimal performance and a satisfying beer-drinking experience.

When selecting a CO2 tank, consider factors such as your usage frequency, keg size, space constraints, and portability needs. This will help you determine the appropriate size that meets your specific requirements.

Common sizes of CO2 tanks for kegerators include 5 lb, 10 lb, and 20 lb tanks, each catering to different usage scenarios. Smaller tanks are ideal for casual drinkers or those with limited space, while larger tanks are suitable for frequent entertainers or commercial use.

To optimize CO2 usage in your kegerator, regularly check for leaks, maintain appropriate dispensing pressure, avoid overcarbonation, reduce line lengths, and keep your kegerator at the optimal temperature. These practices help minimize CO2 waste and ensure efficient carbonation and dispensing.

Remember, for more specific guidance based on your unique setup and needs, consult with your local homebrew shop or supplier.

Now that you have a better understanding of the importance of CO2 tanks in kegerators and how to choose the right size, it’s time to raise a glass and enjoy the pleasure of a perfectly poured draft beer at home. Cheers!

Frequently Asked Questions about What Size Co2 Tank Does A Kegerator Use

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Size Co2 Tank Does A Kegerator Use”