Home>diy>Building & Construction>What Is A Stud In Construction

Building & Construction

What Is A Stud In Construction

Modified: January 23, 2024

Learn what a stud is in building construction and how it is essential for structural support. Discover the significance of studs in creating strong and durable buildings.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of construction, there are numerous components and materials that play a crucial role in building sturdy and durable structures. One such component is a stud, which is an essential element in construction projects.

In this article, we will explore what exactly a stud is in the context of construction, the different types of studs available, their common uses, the characteristics of an ideal stud, the installation process, challenges and considerations, as well as explore some alternatives to studs in construction.

Whether you are a professional in the construction industry or simply curious about the building process, this article will provide valuable insights into the world of studs and their significance in constructing strong and reliable structures.

Key Takeaways:

- Studs are essential vertical framing members that provide structural support, stability, and framework for walls, partitions, and other building elements. They play a crucial role in transferring loads and shaping the overall structure of a building.

- While traditional wood and metal studs are commonly used, alternative construction methods and materials, such as SIPs, metal framing systems, rammed earth walls, timber frame construction, CMUs, and composite panels, offer diverse options to meet specific project requirements and objectives.

Read more: What Is A Trimmer Stud In Construction

Definition of a Stud in Construction

In construction terminology, a stud refers to a vertical structural framing member that provides support to walls, partitions, and other elements of a building’s framework. Studs are typically made of wood or metal and are positioned vertically between the top and bottom plates.

Studs serve as the main load-bearing elements of a wall, distributing the weight of the structure evenly and providing stability and strength. They play a crucial role in transferring the load from the roof, floors, and other components to the foundation of the building.

Studs are typically spaced at regular intervals along the length of a wall, commonly 16 or 24 inches apart, and are fastened to the top and bottom plates using nails or screws. The precise spacing and installation of studs are determined by local building codes and structural engineering requirements.

In addition to providing structural support, studs also serve as a framework for attaching various building materials such as drywall, insulation, and exterior cladding. They create the structure and shape of the walls, allowing for the installation of windows, doors, electrical wiring, and plumbing.

Studs are an essential component of both interior and exterior walls, and their placement and alignment are critical for the overall stability and integrity of a building’s structure.

Types of Studs

Studs come in various types, each tailored to meet specific construction needs and building requirements. The two most common types of studs are wood studs and metal studs.

- Wood Studs: Wood studs are traditional and widely used in residential and commercial construction. They are typically made from lumber, such as pine or fir, and are available in various dimensions. The most common wood stud sizes are 2×4 (1.5 inches by 3.5 inches) and 2×6 (1.5 inches by 5.5 inches). Wood studs are known for their ease of installation, versatility, and affordability.

- Metal Studs: Metal studs, also known as steel studs, are gaining popularity in construction projects. They are made of galvanized steel and offer several advantages over wood studs. Metal studs are lightweight, non-combustible, resistant to rot, pests, and moisture, and have consistent dimensions. They are available in different gauges, indicating their thickness. Thinner gauges, such as 20 or 25, are commonly used for interior non-load bearing walls, while thicker gauges, such as 16 or 18, are used for load-bearing walls.

There are also specialized types of studs that serve specific purposes:

- Pressure-Treated Studs: These studs are treated with preservatives to resist rot, decay, and termite damage, making them suitable for below-grade applications or areas with potential moisture exposure.

- Fire-Rated Studs: These studs are designed to provide enhanced fire resistance. They are made with materials that can withstand high temperatures and are used in areas where fire-rated walls or partitions are required.

- Soundproof Studs: These studs feature additional insulation or sound-dampening materials, which help reduce sound transmission between rooms or buildings.

The choice of stud type depends on factors such as the building’s structural requirements, budget, environmental factors, and specific project needs.

Common Uses of Studs in Construction

Studs are a fundamental element in the construction industry and find extensive use in various applications. Let’s explore some of the common uses of studs in construction:

- Wall Construction: Studs are primarily used to construct walls, both interior and exterior. They provide the framework and support for attaching materials such as drywall, insulation, and sheathing. The studs create the structural integrity of the walls and allow for the installation of doors, windows, electrical outlets, and plumbing.

- Partition Walls: Studs are utilized to create partition walls that divide large spaces into smaller rooms or sections. These walls are commonly found in commercial buildings, offices, and residential spaces. Studs provide the necessary stability and framework for attaching wall finishes and other elements.

- Load-Bearing Walls: Studs play a vital role in load-bearing walls, which support the weight of the structure above, such as floors and roofs. Load-bearing walls are crucial for maintaining the structural integrity and stability of the building. Studs in load-bearing walls must be properly spaced and adequately sized to bear the weight they are subjected to.

- Interior Finishing: Studs are used to attach various interior finishes, such as drywall, paneling, and decorative elements. These finishes provide a polished and aesthetically pleasing appearance to the interior space.

- Exterior Cladding: Studs are essential for attaching exterior cladding materials, such as siding, brick veneer, or stucco. They provide the necessary framework and support for the cladding, ensuring a secure and visually appealing exterior finish.

- Ceiling and Roof Structures: Studs are utilized in the construction of ceilings and roof structures. They provide support for attaching materials such as ceiling joists, roof trusses, and rafters. Studs in roof structures are especially crucial for maintaining the integrity and strength of the roof system.

These are just a few examples of how studs are commonly used in construction. However, their versatility allows for various other applications and ensures the stability and durability of the overall structure.

Characteristics of an Ideal Stud

When it comes to selecting studs for construction projects, certain characteristics are crucial to ensure their effectiveness and reliability. Here are some key characteristics of an ideal stud:

- Strength: A high-quality stud should have sufficient strength to support the weight and structural loads it will be subjected to. It should be able to withstand both vertical and lateral forces, ensuring the stability and integrity of the building.

- Durability: An ideal stud should be durable and resistant to decay, rot, pests, and moisture. This is particularly important for studs used in exterior walls or areas prone to moisture exposure.

- Straightness: Straightness is a crucial characteristic for studs, as any curvature or bowing can affect the overall alignment and integrity of the walls. Straight studs ensure proper installation and reduce the risk of future structural issues.

- Consistent Dimensions: Whether it’s a wood stud or a metal stud, consistent dimensions are essential for a proper fit and alignment during installation. Consistency allows for accurate spacing and ensures the stability and reliability of the entire structure.

- Compatibility: Studs should be compatible with other building components and materials, such as fasteners, connectors, and finishes. This ensures a seamless construction process and optimizes the performance and longevity of the structure.

- Code Compliance: An ideal stud must meet local building code requirements and industry standards. It should be tested and certified to meet the necessary safety and performance standards, providing assurance that it meets or exceeds the required criteria.

- Ease of Installation: Finally, an ideal stud should be easy to install, saving time and effort during construction. Properly designed studs will have features that facilitate installation and ensure a secure and efficient construction process.

By considering these characteristics when selecting studs for construction projects, builders and contractors can ensure the reliability, longevity, and structural integrity of the building.

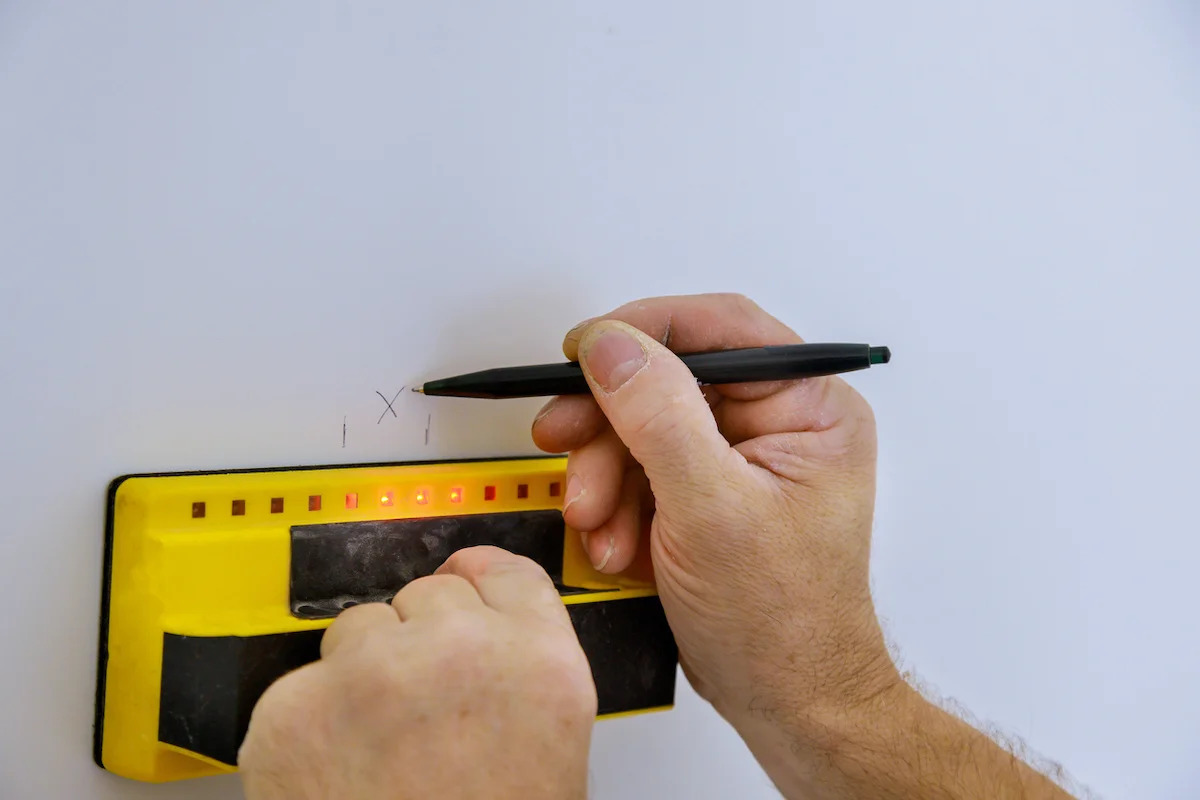

When locating a stud in construction, use a stud finder to accurately identify the vertical wooden or metal supports behind the wall. This will help ensure secure and stable installation of heavy items like shelves or cabinets.

Read more: What Size Studs For Interior Walls

Stud Installation Process

The installation of studs is a crucial step in the construction process, as it sets the foundation for the walls and overall structure of the building. Here is a general overview of the stud installation process:

- Prepare the Layout: Before installing the studs, the layout of the walls must be carefully planned and marked. This involves measuring and marking the locations of the studs on the floor and ceiling plates according to the building plans and local building codes.

- Cut the Studs: Once the layout is prepared, the studs are cut to the appropriate length. If using wood studs, they can be cut using a circular saw or a handsaw. Metal studs can be cut with aviation snips or a specialized metal-cutting tool.

- Align the Top and Bottom Plates: The top and bottom plates, which serve as the horizontal framing members, are installed first. They should be aligned properly and secured to the existing structure, such as the floor and ceiling joists, using nails or screws.

- Place and Secure the Studs: Starting from one end of the wall, the studs are placed vertically between the top and bottom plates according to the marked layout. They are positioned at regular intervals, typically 16 or 24 inches apart. Each stud is then secured to the plates using nails or screws, ensuring a tight fit.

- Check for Level and Plumb: As the installation progresses, it is important to regularly check the level and plumb of the studs. This ensures that the walls will be straight and properly aligned. Adjustments can be made by using shims, if necessary, to achieve the desired level and plumb.

- Install Blocking and Bracing: Blocking and bracing may be required in certain areas, such as around door or window openings, corners, or to provide additional support for shelves or fixtures. These additional framing elements are installed as necessary to enhance the overall strength and stability of the wall.

- Complete the Wall Assembly: With the studs in place, the wall assembly can be completed by attaching various building materials such as insulation, drywall, and exterior cladding. These materials are secured to the studs using appropriate fasteners and techniques.

It is important to follow local building codes and industry best practices throughout the stud installation process to ensure a structurally sound and code-compliant construction.

Challenges and Considerations with Studs in Construction

While studs are widely used in construction due to their versatility and strength, there are several challenges and considerations that builders and contractors must be aware of. These include the following:

- Load-Bearing Capacity: It is essential to ensure that the studs used in load-bearing walls are properly sized and spaced to support the required loads. Improperly sized or spaced studs can compromise the structural integrity and stability of the building.

- Thermal Bridging: Studs, especially metal studs, can create thermal bridges within the building envelope. Thermal bridging refers to the transmission of heat through materials with higher conductivity, resulting in energy loss and potential condensation issues. Proper insulation strategies and the use of thermal break materials can help mitigate this challenge.

- Sound Transmission: Studs can transmit sound vibrations between rooms and spaces. This can be a concern in residential or commercial buildings where sound privacy is important. Incorporating soundproofing materials or using specialized soundproof studs can help minimize sound transmission.

- Moisture and Rot: Wood studs, particularly when used in exterior walls or areas prone to moisture exposure, can be susceptible to rot, decay, and termite damage. Proper moisture management through the use of moisture barriers, flashing, and preservative-treated wood can help mitigate these issues.

- Fire Resistance: Studs made of combustible materials, such as wood, may contribute to the spread of fire. Fire-rated studs or the use of fire-resistant materials can help enhance the fire resistance of walls and provide additional protection in case of a fire.

- Installation Accuracy: Ensuring accurate installation of studs is crucial to maintaining wall alignment, preventing bowing or leaning, and avoiding issues with the installation of finishes and other building materials. Mistakes in stud placement or improper fastening can lead to structural issues or difficulties in subsequent construction phases.

- Environmental Impact: Both wood and metal studs have environmental considerations. Wood studs, although a renewable resource, may come from unsustainable logging practices. Metal studs require energy-intensive manufacturing processes. Builders should consider the environmental impact, availability, and sustainability of the chosen stud materials.

By taking these challenges and considerations into account, builders can implement appropriate strategies to address them and ensure the successful completion of a construction project.

Alternatives to Studs in Construction

While studs are commonly used in construction, there are alternative methods and materials that can be considered for specific projects or to address certain construction challenges. Here are a few alternatives to traditional studs:

- Structural Insulated Panels (SIPs): SIPs are prefabricated panels comprised of two layers of oriented strand board (OSB) or plywood, with a rigid insulation core sandwiched in between. SIPs offer excellent insulation, structural strength, and energy efficiency. They can be used as load-bearing walls, reducing the need for traditional stud framing.

- Metal Framing Systems: Metal framing systems, such as light gauge steel or aluminum, provide an alternative to wood studs. These materials offer durability, resistance to mold and pests, and can be prefabricated for efficient installation. Metal framing systems are often used in commercial construction or in projects that require non-combustible materials.

- Rammed Earth Walls: Rammed earth construction involves compacting layers of moistened earth into formwork to create solid, load-bearing walls. Rammed earth walls offer thermal mass, durability, and sustainability. They can be a suitable alternative for projects in regions with widely available earth materials.

- Timber Frame Construction: Timber frame construction involves using large wood beams and posts to create a skeleton structure. Unlike traditional stud framing, timber frame construction utilizes larger members that serve as both the structural support and the finish. Timber frame construction offers a visually appealing exposed wood aesthetic and can be used in both residential and commercial projects.

- Concrete Masonry Units (CMUs): CMUs, commonly known as concrete blocks, are large rectangular blocks made of concrete. CMUs are stacked and mortared together to create load-bearing walls. They offer strength, fire resistance, and soundproofing properties. CMUs are commonly used in commercial and industrial construction.

- Composite Panels: Composite panels, such as fiber cement panels or gypsum board systems, provide an alternative to traditional stud framing for cladding and interior walls. These panels offer ease of installation, durability, and a variety of design options.

The choice of an alternative to studs depends on various factors, including the project requirements, desired aesthetics, structural considerations, energy efficiency goals, and budget constraints. Consulting with architects, engineers, and construction professionals can help determine the most suitable alternative for a specific construction project.

Conclusion

Studs play an integral role in the construction industry, providing the framework and support for walls, partitions, and other structural elements. Whether made of wood or metal, studs serve as the backbone of a building, ensuring its stability, strength, and durability.

Throughout this article, we have explored the definition of a stud in construction, the various types of studs available, their common uses, the characteristics of an ideal stud, the installation process, challenges, and considerations, as well as alternative options. Understanding these aspects is crucial for builders, contractors, and anyone involved in the construction process.

From load-bearing walls to interior finishes, studs are a fundamental component in the construction of residential, commercial, and industrial buildings. Proper stud selection, installation, and attention to factors such as load-bearing capacity, thermal bridging, sound transmission, and moisture management are essential to ensure the overall structural integrity and performance of the building.

While studs are the traditional choice for framing, considering alternative methods and materials can offer advantages such as enhanced energy efficiency, durability, and sustainability. Structural insulated panels, metal framing systems, rammed earth walls, timber frame construction, concrete masonry units, and composite panels are all viable alternatives to studs, depending on specific project requirements and objectives.

In conclusion, studs are the backbone of construction, providing strength and stability while shaping the walls and overall structure of a building. With the right choice of studs, attention to installation details, and consideration of alternatives where applicable, builders can create resilient and functional spaces that stand the test of time.

Frequently Asked Questions about What Is A Stud In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Stud In Construction”