Home>Gardening & Outdoor>Outdoor Recreation & Activities>How To Make Cornhole Boards Slick

Outdoor Recreation & Activities

How To Make Cornhole Boards Slick

Modified: March 2, 2024

Learn how to make your cornhole boards slick for a better outdoor recreation and activities experience. Discover the best methods for achieving a smooth playing surface.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

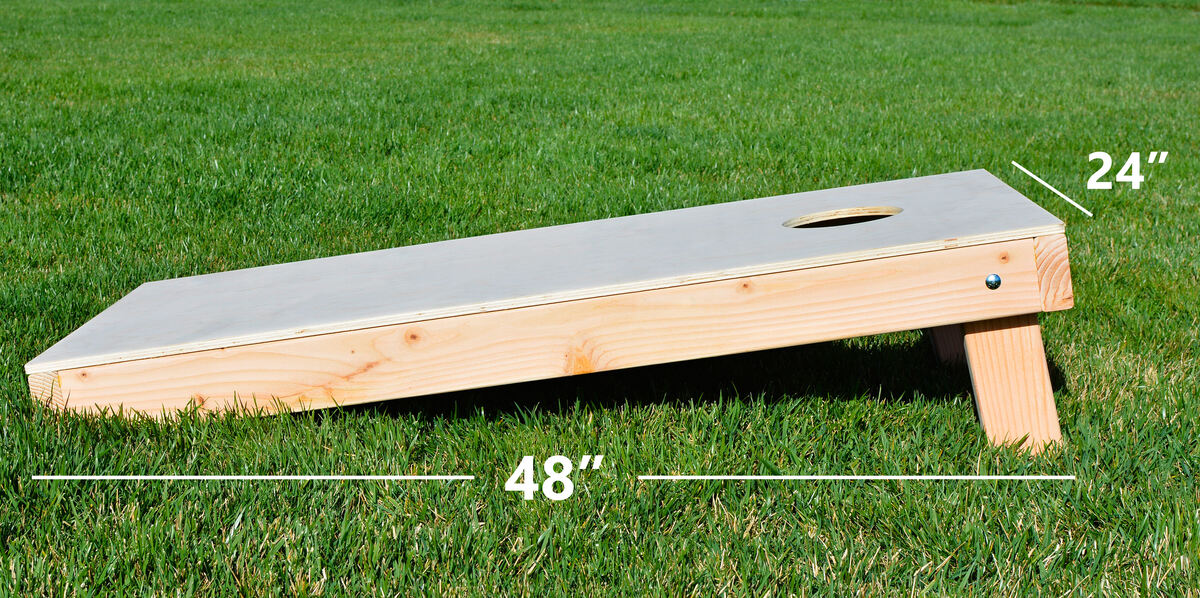

Welcome to the exciting world of cornhole! Whether you're a seasoned player or just getting started, having a high-quality set of cornhole boards is essential for a great game. One crucial factor that significantly impacts gameplay is the slickness of the cornhole boards. Achieving the ideal level of slickness ensures that the bags slide smoothly and consistently, adding to the enjoyment and competitiveness of the game.

In this guide, we'll walk you through the process of making your cornhole boards slick. From the materials and tools needed to the step-by-step procedures, we've got you covered. You'll learn how to sand the boards to a smooth finish and apply the perfect sealant to achieve the desired level of slickness. Additionally, we'll provide tips on caring for your cornhole boards to maintain their slick surface for countless games to come.

So, grab your boards, roll up your sleeves, and let's dive into the wonderful world of making cornhole boards slick!

Key Takeaways:

- Achieving the ideal slickness for cornhole boards involves sanding with varying grits and applying a high-quality sealant, ensuring smooth gameplay and durability for countless games.

- To maintain slick cornhole boards, regular cleaning, proper storage, occasional touch-ups, and protective transportation are essential, ensuring endless fun and competitive gameplay.

Read more: How To Make A Cornhole Board

Materials and Tools Needed

Before you begin the process of making your cornhole boards slick, it’s essential to gather the necessary materials and tools. Here’s what you’ll need:

Materials:

- High-quality wood boards for the cornhole platform

- Sandpaper of varying grits (coarse, medium, fine)

- Tack cloth or microfiber cloths for cleaning

- Quality wood sealant or polyurethane finish

- Paintbrush or paint sprayer for applying the sealant

- Painter's tape (if applying any designs or paint to the boards)

- Disposable gloves for protection

- Protective mask for sanding and applying the sealant

- Well-ventilated workspace or outdoor area

Tools:

- Electric sander or sanding block

- Hand sanding pad for reaching edges and corners

- Screwdriver (if removing hardware from the boards)

- Worktable or sawhorses for securing the boards during sanding and finishing

- Clean, dry cloth for wiping off excess sealant

Having these materials and tools at your disposal will ensure a smooth and efficient process as you work to achieve the perfect level of slickness for your cornhole boards.

Sanding the Boards

Once you have gathered all the necessary materials and tools, it’s time to prepare the boards for the finishing process. Sanding the boards is a critical step in achieving the desired level of slickness. Follow these steps to ensure a smooth and even surface:

- Preparation: Start by setting up your workspace in a well-ventilated area. If your boards have any hardware such as handles or latches, use a screwdriver to remove them. Place the boards on a stable worktable or sawhorses, ensuring that they are secure and won’t shift during sanding.

- Coarse Sanding: Begin with coarse-grit sandpaper to remove any rough spots, imperfections, or old finish from the surface of the boards. Use an electric sander or sanding block to cover the entire surface, working in the direction of the wood grain. Pay extra attention to the edges and corners, ensuring that they are smooth and free of splinters.

- Medium Sanding: Switch to medium-grit sandpaper to further smooth out the surface. This step helps to eliminate any remaining roughness and prepares the boards for the final sanding stage. Again, work in the direction of the wood grain to maintain a consistent finish.

- Fine Sanding: Use fine-grit sandpaper for the final sanding stage. This step is crucial for achieving a silky-smooth surface that will contribute to the slickness of the boards. Take your time to ensure that the entire surface is uniformly smooth, paying attention to detail and maintaining a steady hand.

- Clean the Boards: Once the sanding process is complete, use a tack cloth or microfiber cloth to thoroughly clean the boards, removing any dust and debris. It’s essential to start the finishing process with a clean surface to achieve optimal results.

By following these steps and taking the time to sand the boards thoroughly, you’ll be well on your way to achieving the ideal level of slickness for your cornhole boards.

Read more: How To Make Cornhole Board Legs

Applying the Finish

With the boards expertly sanded to perfection, it’s time to apply the finish that will enhance their slickness and durability. Follow these steps to achieve a professional-quality finish:

- Choose the Right Sealant: Select a high-quality wood sealant or polyurethane finish that is suitable for outdoor use. Consider a clear, glossy finish to achieve the desired slickness while showcasing the natural beauty of the wood.

- Prepare the Workspace: Set up your workspace in a well-ventilated area, preferably outdoors. Ensure that the boards are placed on a stable surface and are free from any dust or debris that could affect the finish.

- Apply the Sealant: Using a paintbrush or paint sprayer, apply a thin, even coat of the sealant to the surface of the boards. Work in the direction of the wood grain to achieve a uniform finish. Pay attention to any intricate designs or patterns on the boards, ensuring that the sealant reaches all areas for consistent coverage.

- Allow for Drying Time: Follow the manufacturer’s instructions regarding drying time between coats. Typically, you’ll need to allow the first coat to dry completely before applying additional coats. This process may involve light sanding between coats to ensure a smooth and flawless finish.

- Apply Additional Coats (If Needed): Depending on the type of sealant used, you may need to apply multiple coats to achieve the desired level of slickness and protection. Each additional coat contributes to the durability and smoothness of the boards, so be patient and thorough in this process.

- Final Inspection: Once the final coat has been applied and allowed to dry, inspect the boards carefully for any imperfections or uneven areas. Touch up any spots as needed to ensure a flawless finish that will contribute to the slickness of the boards.

By following these steps and taking the time to apply the finish meticulously, you’ll enhance the slickness of your cornhole boards, elevating your game to a new level of enjoyment and competitiveness.

To make cornhole boards slick, apply a thin coat of polyurethane or a slick surface sealant. Sand the boards smooth before applying the sealant for best results.

Caring for Your Cornhole Boards

After investing time and effort into making your cornhole boards slick, it’s essential to maintain their optimal condition for long-lasting enjoyment. Proper care and maintenance will ensure that your boards retain their slick surface, allowing for countless games and endless fun. Here are some tips for caring for your cornhole boards:

- Regular Cleaning: Keep your cornhole boards clean by wiping them down with a clean, dry cloth after each use. This helps remove any dirt, debris, or moisture that could affect the slickness of the boards.

- Storage: When not in use, store your cornhole boards in a dry, covered area to protect them from the elements. If storing them outdoors, consider using a protective cover to shield the boards from rain, sun, and other environmental factors.

- Inspect and Touch Up: Periodically inspect the boards for any signs of wear or damage to the finish. Touch up any areas that may have become worn or scuffed to maintain the slickness and overall appearance of the boards.

- Reapply Sealant (As Needed): Over time, the slickness of the boards may diminish due to regular use and exposure to the elements. If you notice a decrease in slickness, consider reapplying a thin coat of sealant to restore the smooth surface and enhance the gameplay experience.

- Protective Storage: When transporting your cornhole boards, use protective cases or bags to prevent scratches, dings, or other damage. Proper storage and transportation help maintain the slickness and overall condition of the boards.

- Enjoy and Share: Lastly, enjoy your newly slicked cornhole boards to the fullest! Share the excitement of the game with friends and family, and take pride in knowing that your carefully maintained boards contribute to unforgettable moments and friendly competition.

By incorporating these care and maintenance practices into your routine, you’ll ensure that your cornhole boards remain slick and ready for action, providing endless entertainment for players of all skill levels.

Frequently Asked Questions about How To Make Cornhole Boards Slick

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make Cornhole Boards Slick”