Home>Technology>Smart Home Devices>How Hot Should My 3D Printer Bed Be

Smart Home Devices

How Hot Should My 3D Printer Bed Be

Modified: August 20, 2024

Find out the ideal bed temperature for your 3D printer and ensure optimal performance for your smart home devices. Get expert tips and recommendations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Welcome to the exciting world of 3D printing, where creativity knows no bounds, and the possibilities are endless. One of the key elements in achieving high-quality 3D prints is ensuring the optimal temperature of the print bed. The bed temperature plays a crucial role in the adhesion and overall success of your 3D printing projects. In this article, we will delve into the significance of bed temperature in 3D printing, explore the factors that influence it, and provide guidance on determining the right bed temperature for different filaments. Whether you are a seasoned 3D printing enthusiast or a newcomer to the craft, understanding the nuances of bed temperature will undoubtedly elevate your printing experience and the quality of your creations. So, let's embark on this illuminating journey into the world of 3D printing bed temperatures.

**

Key Takeaways:

- Maintaining the right bed temperature is crucial for successful 3D printing, preventing issues like warping and ensuring strong adhesion. Different filaments require different temperatures, so it’s important to follow manufacturer guidelines and conduct tests to find the optimal setting.

- Experimentation and observation are key to determining the best bed temperature for your 3D printing needs. By using calibration prints and temperature towers, you can fine-tune the temperature to achieve consistent and high-quality prints.

Read more: Why Is My 3D Printer Clicking

Importance of Bed Temperature in 3D Printing

**

The bed temperature in 3D printing is a critical factor that significantly influences the outcome of your prints.

First and foremost, bed temperature directly impacts the adhesion of the first layer of the print to the build surface. When the bed is heated to the appropriate temperature, it helps the filament to adhere firmly to the surface, preventing warping and ensuring that the print stays securely in place throughout the printing process. This is particularly important for prints with large surface areas or those that have intricate details, as proper adhesion at the initial stage sets the foundation for a successful print.

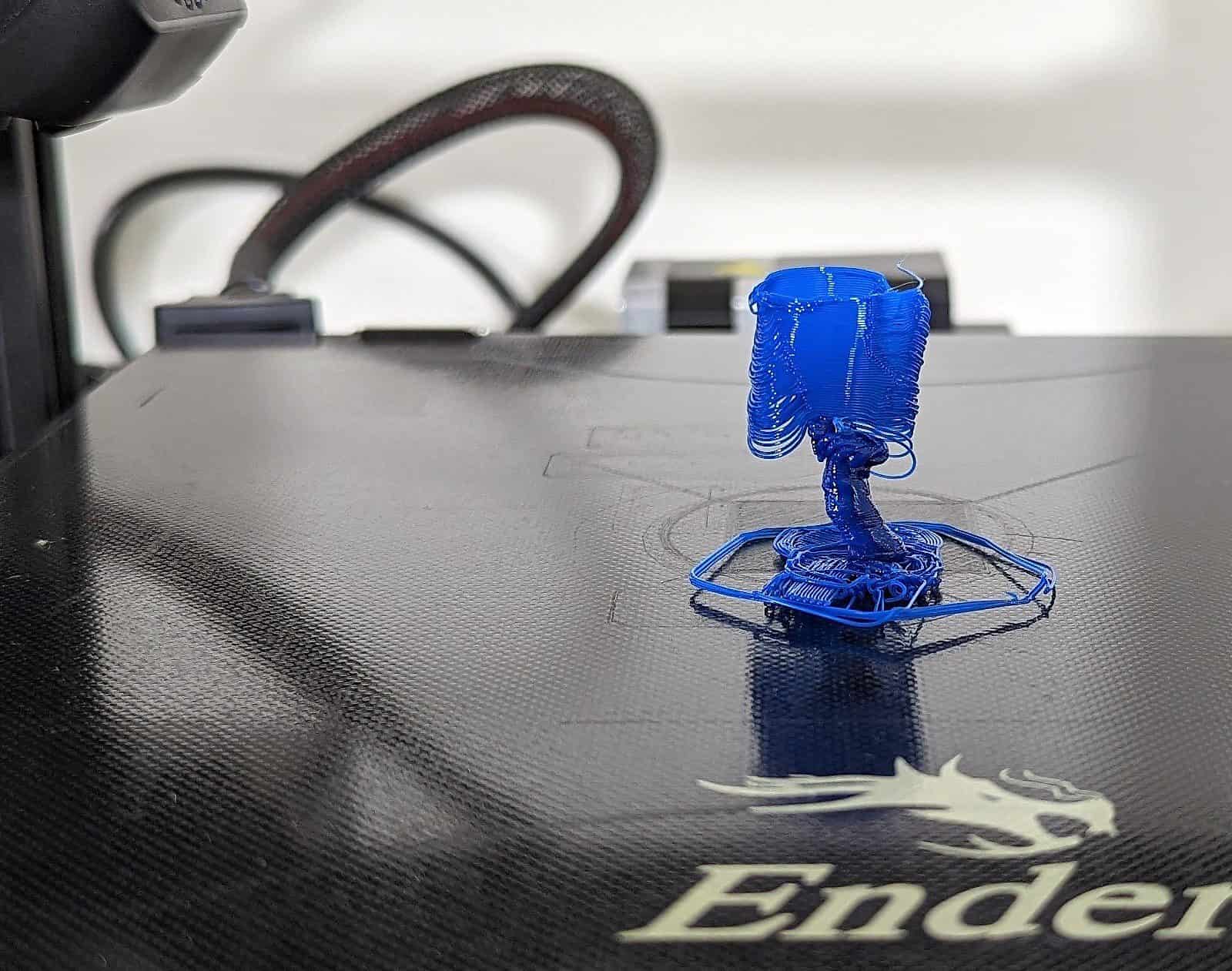

Furthermore, maintaining the correct bed temperature can mitigate issues such as curling, lifting, and warping of the printed object. These problems commonly arise when the bed temperature is too low, causing the material to cool unevenly and contract, leading to deformities in the print. By optimizing the bed temperature, you can minimize these issues and achieve smoother, more precise prints.

In addition to adhesion and print quality, bed temperature also plays a role in preventing delamination. Delamination occurs when the layers of the print do not bond properly, resulting in a weak and structurally unsound object. By ensuring the bed temperature is at the appropriate level, you can promote strong interlayer adhesion, enhancing the overall durability and integrity of the printed item.

Moreover, certain filaments, such as ABS and PETG, benefit from a heated bed to reduce the likelihood of warping and improve print quality. The thermal expansion and contraction characteristics of these materials make them particularly sensitive to variations in bed temperature. By maintaining a consistent and suitable bed temperature, you can harness the full potential of these filaments and produce high-quality prints with minimal defects.

Ultimately, the bed temperature is a fundamental parameter that directly impacts the success and quality of 3D prints. By understanding its importance and mastering its control, you can elevate your 3D printing capabilities and unlock the full potential of your creativity.

**

Factors Affecting Bed Temperature

**

Several factors influence the optimal bed temperature for 3D printing, and understanding these variables is essential for achieving consistent and high-quality prints.

- Filament Type: Different filaments have varying requirements when it comes to bed temperature. For instance, ABS typically benefits from a higher bed temperature compared to PLA, as the elevated heat helps prevent warping and ensures better adhesion. On the other hand, PLA, a commonly used filament, generally performs well with a lower bed temperature. It is crucial to refer to the manufacturer’s recommendations for the specific filament you are using to determine the ideal bed temperature.

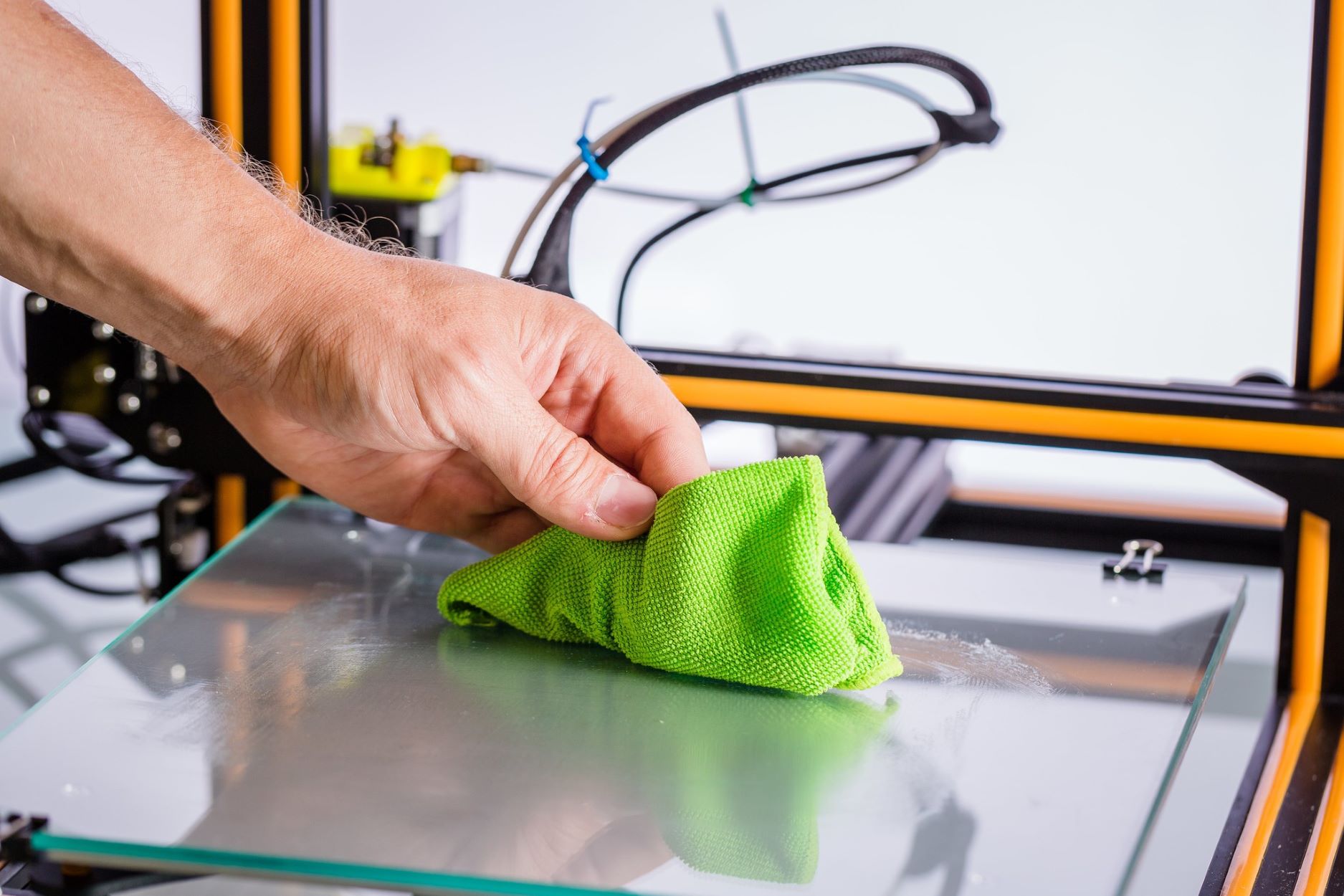

- Print Surface Material: The type of material used for the print surface can impact the bed temperature. For example, glass beds may necessitate a different temperature compared to build surfaces coated with specialized materials such as PEI (Polyetherimide) or BuildTak. The surface material’s thermal conductivity and adhesion properties can influence the required bed temperature for successful printing.

- Print Environment: The ambient temperature and humidity in the printing environment can affect the bed temperature needed to achieve optimal print adhesion and quality. In colder environments, the bed may require slightly higher temperatures to compensate for heat loss, while in warmer settings, adjustments may be necessary to prevent overheating and potential print deformities.

- Printer Model and Settings: The specific 3D printer model and its settings, including the build plate material, insulation, and heating mechanisms, can impact the ideal bed temperature. Additionally, factors such as layer height, print speed, and infill density may influence the recommended bed temperature for different prints.

By considering these factors and conducting thorough experimentation and calibration, you can determine the optimal bed temperature for your specific printing setup and the filaments you use. Fine-tuning the bed temperature based on these variables will contribute to consistent and successful 3D prints, minimizing adhesion issues, warping, and other common printing challenges.

**

The recommended bed temperature for 3D printing varies depending on the type of filament you are using. For PLA, a bed temperature of 60-70°C is sufficient, while for ABS, a bed temperature of 90-110°C is recommended. Always refer to the filament manufacturer’s guidelines for the best results.

Recommended Bed Temperatures for Different Filaments

**

When it comes to 3D printing, achieving the ideal bed temperature for different filaments is crucial for ensuring successful adhesion and print quality. Here are the recommended bed temperatures for some commonly used filaments:

- PLA (Polylactic Acid): PLA is known for its ease of use and generally adheres well to print surfaces. A bed temperature in the range of 50°C to 60°C is often sufficient for reliable adhesion and minimal warping. However, some PLA formulations may perform well at lower temperatures, so it is advisable to experiment within this temperature range to find the optimal setting for your specific PLA filament.

- ABS (Acrylonitrile Butadiene Styrene): ABS benefits from a higher bed temperature to minimize warping and promote adhesion. A bed temperature of approximately 90°C to 100°C is commonly recommended for printing with ABS. The elevated temperature helps mitigate the material’s tendency to shrink and curl during the printing process, resulting in more stable and precise prints.

- PETG (Polyethylene Terephthalate Glycol): PETG generally requires a bed temperature ranging from 75°C to 85°C to ensure proper adhesion and reduce the risk of warping. The slightly elevated temperature compared to PLA accommodates the material’s characteristics and contributes to successful prints with PETG filament.

- TPU (Thermoplastic Polyurethane): TPU filaments, known for their flexibility and elasticity, typically adhere well to print surfaces with a bed temperature of approximately 40°C to 60°C. The lower bed temperature helps maintain adhesion while preventing excessive softening of the material during printing.

- Nylon: Nylon filaments often require a bed temperature in the range of 70°C to 90°C for optimal adhesion and print quality. The elevated temperature assists in reducing the likelihood of warping and delamination, contributing to the successful printing of nylon-based objects.

It is important to note that these recommended bed temperatures serve as starting points, and fine-tuning may be necessary based on specific printer models, environmental conditions, and filament variations. Additionally, always refer to the manufacturer’s guidelines and conduct test prints to determine the most suitable bed temperature for your unique 3D printing setup.

By understanding and implementing the appropriate bed temperatures for different filaments, you can enhance the adhesion, quality, and overall success of your 3D printing projects, unlocking the full potential of various materials and expanding your creative horizons.

**

How to Determine the Right Bed Temperature

**

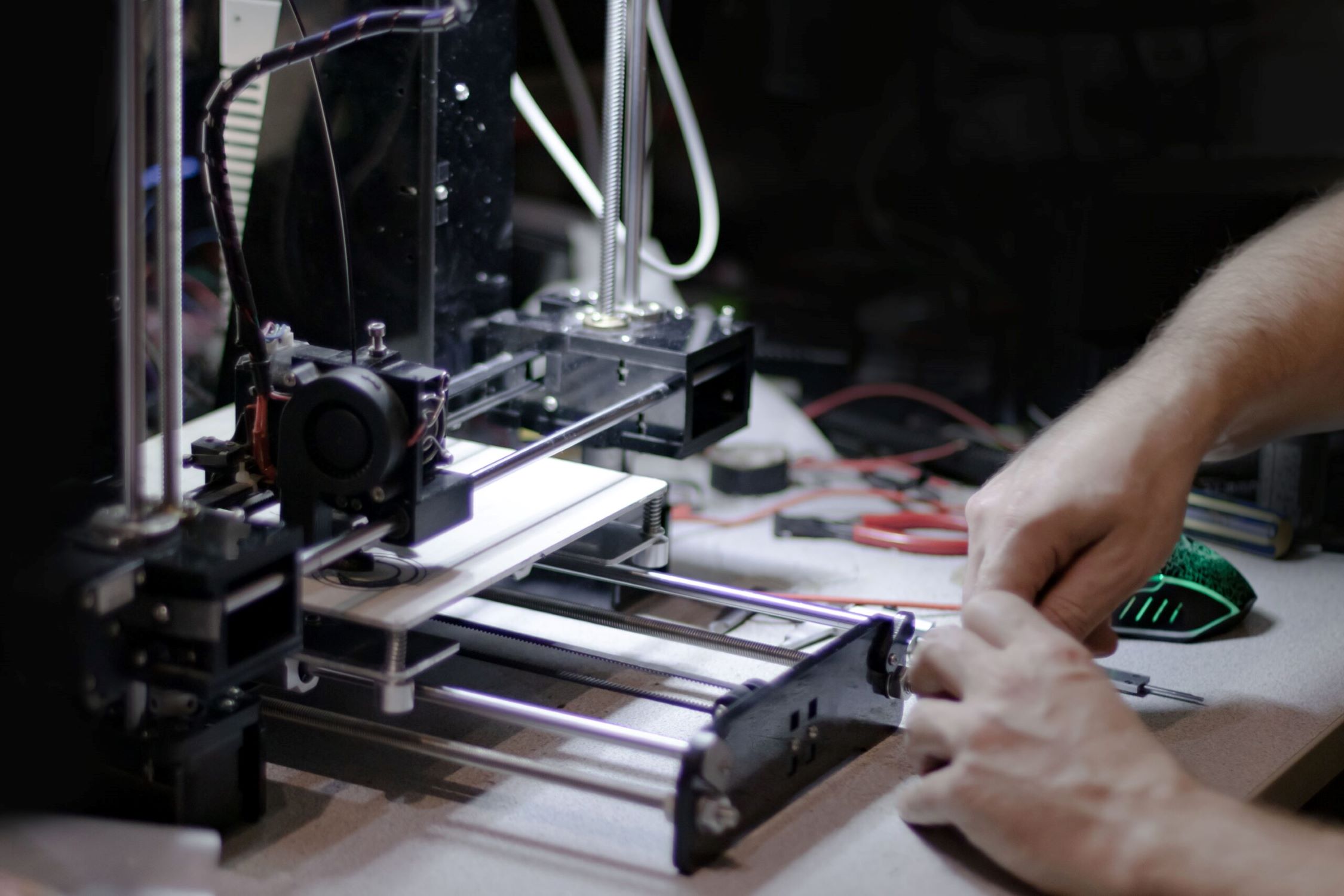

Achieving the optimal bed temperature for 3D printing involves a combination of experimentation, observation, and adherence to best practices. Here are some steps to help you determine the right bed temperature for your specific printing needs:

- Refer to Manufacturer Guidelines: Start by consulting the recommended bed temperatures provided by the filament manufacturer. These guidelines serve as valuable initial references and can offer insights into the ideal temperature range for successful printing with a particular filament.

- Calibration Prints: Conduct calibration prints with varying bed temperatures to assess the adhesion, warping, and overall print quality. Begin with the manufacturer’s recommended temperature and gradually adjust in small increments, observing the impact on print adhesion and surface finish. This iterative process allows you to identify the temperature that yields the best results for your specific filament and printing environment.

- Utilize Temperature Towers: Temperature towers, also known as temperature calibration or temperature gradient tests, are specialized models that feature sections printed at different bed temperatures. Printing and examining these structures enable you to visually assess the impact of temperature variations on print quality, aiding in the selection of the optimal bed temperature for your filament and printer setup.

- Monitor Print Adhesion and Warping: Throughout the experimentation process, pay close attention to the adhesion of the initial layer to the print bed and observe for any signs of warping or lifting during printing. These visual cues provide valuable insights into the effectiveness of the bed temperature and guide you in determining the temperature that promotes stable adhesion and minimizes print deformities.

- Record and Analyze Results: Keep detailed records of the bed temperatures used for different prints and their corresponding outcomes. Analyzing these results enables you to identify trends, understand the impact of temperature adjustments, and refine your approach to determining the right bed temperature for various filaments and printing conditions.

By leveraging these methods and embracing a systematic approach to bed temperature determination, you can fine-tune your 3D printing process and optimize the bed temperature to suit the specific requirements of different filaments and printing scenarios.

**

Read more: What To Clean 3D Printer Bed With

Conclusion

**

In the realm of 3D printing, the bed temperature stands as a pivotal factor that significantly influences the adhesion, quality, and overall success of prints. By understanding the importance of bed temperature and the factors that impact it, as well as the recommended temperatures for different filaments, you can elevate your 3D printing capabilities and achieve exceptional results.

The process of determining the right bed temperature involves a blend of manufacturer guidelines, iterative testing, and astute observation. Through calibration prints, temperature towers, and meticulous monitoring, you can pinpoint the optimal bed temperature for your specific filament and printing environment, paving the way for consistent and high-quality prints.

As you embark on your 3D printing journey, remember that the bed temperature is not just a numerical setting but a critical element that empowers you to unleash the potential of diverse filaments and bring your creative visions to life. By mastering the art of bed temperature control, you can conquer challenges such as warping, delamination, and adhesion issues, and embark on a seamless and rewarding printing experience.

So, embrace the nuances of bed temperature, experiment with confidence, and let your creations manifest with precision and finesse. With the right bed temperature as your ally, the world of 3D printing becomes a canvas for boundless innovation and impeccable craftsmanship. Here’s to harnessing the power of bed temperature and unlocking the extraordinary possibilities of 3D printing.

Frequently Asked Questions about How Hot Should My 3D Printer Bed Be

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Hot Should My 3D Printer Bed Be”