Home>Technology>Smart Home Devices>Why Should I Get A 3D Printer

Smart Home Devices

Why Should I Get A 3D Printer

Modified: August 20, 2024

Discover the benefits of 3D printing for your smart home devices. Learn why a 3D printer can enhance your home automation setup.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

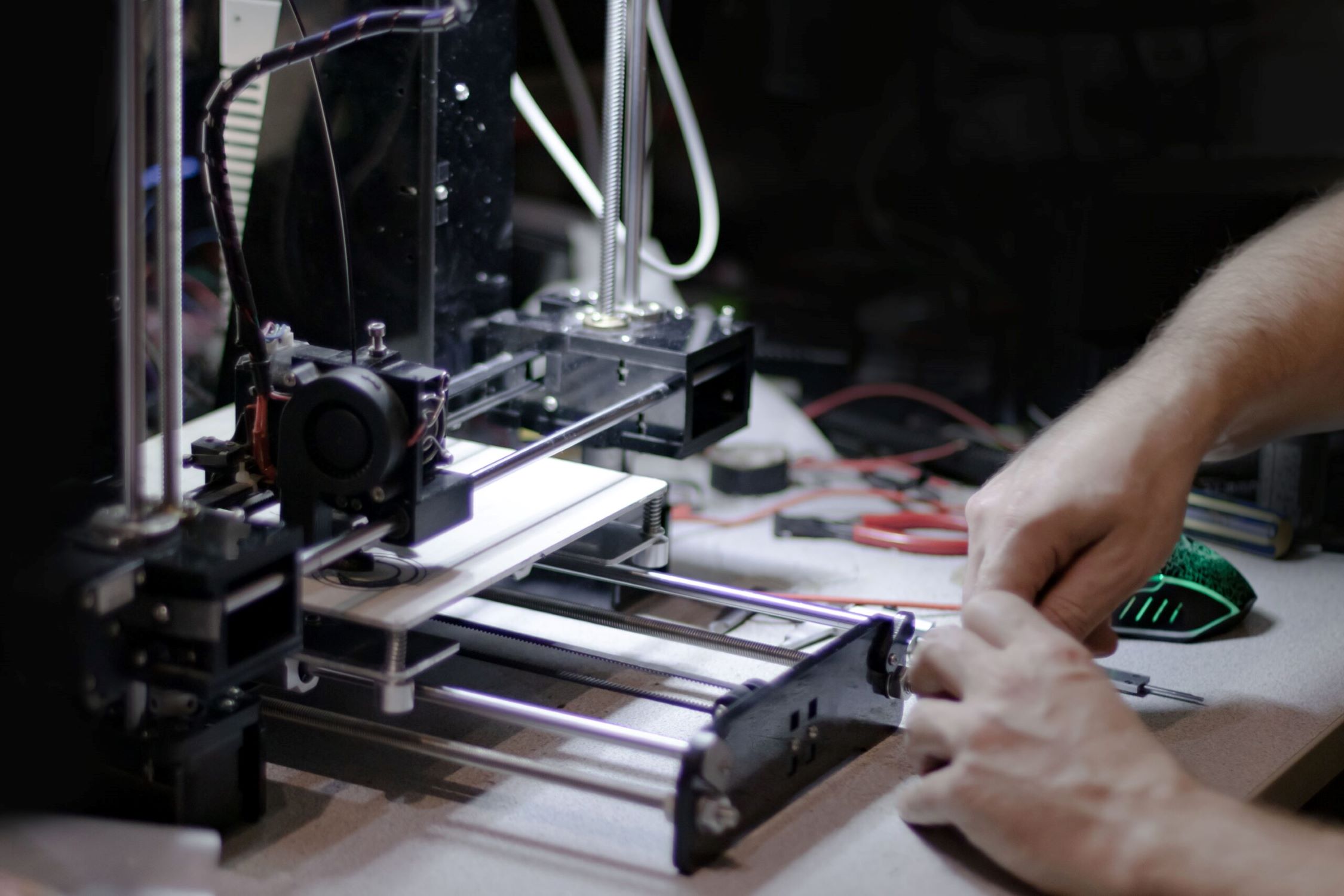

Welcome to the world of 3D printing, where innovation and creativity converge to revolutionize the way we conceptualize and materialize objects. The advent of 3D printing technology has paved the way for a myriad of possibilities, empowering individuals and businesses to bring their ideas to life in a tangible and cost-effective manner. Whether you are a hobbyist, an entrepreneur, or an educator, the allure of 3D printing lies in its ability to transcend traditional manufacturing constraints and unlock a realm of endless opportunities.

Throughout this article, we will explore the compelling reasons why 3D printing has become a game-changer in various domains, from cost efficiency and customization to rapid prototyping and educational enrichment. By delving into these facets, you will gain a comprehensive understanding of the profound impact that 3D printing can have on your personal and professional endeavors. So, let’s embark on this enlightening journey into the realm of 3D printing and uncover the myriad benefits that await those who embrace this cutting-edge technology.

Key Takeaways:

- 3D printing offers cost-efficient and customizable solutions, making it accessible to businesses, hobbyists, and educators. It minimizes waste and streamlines production, fostering a culture of affordability and innovation.

- 3D printing accelerates innovation and learning by enabling rapid prototyping and hands-on experimentation. It enhances education, fosters interdisciplinary collaboration, and democratizes the creation of personalized products, shaping a future of inclusive and sustainable production.

Read more: Why Is My 3D Printer Clicking

Cost Efficiency

One of the most compelling aspects of 3D printing is its remarkable cost efficiency. Unlike traditional manufacturing methods that often entail substantial setup costs and minimum production runs, 3D printing offers a more economical approach to bringing designs to fruition. With 3D printing, you have the flexibility to produce objects on demand, eliminating the need for large-scale production runs that can result in excess inventory and associated costs.

Furthermore, 3D printing enables the utilization of a diverse range of materials, including thermoplastics, metals, and composite filaments, allowing for cost-effective experimentation and prototyping. This versatility in material options empowers designers and engineers to iterate and refine their designs without incurring exorbitant expenses typically associated with traditional manufacturing processes.

Moreover, the ability to create intricate and complex geometries with 3D printing can lead to significant material savings. Traditional subtractive manufacturing methods often generate a substantial amount of waste material, whereas 3D printing adds material only where necessary, minimizing waste and optimizing material usage.

From a business perspective, 3D printing can yield substantial cost savings by streamlining the production process, reducing lead times, and mitigating the expenses associated with maintaining large inventories. This is particularly advantageous for small to medium-sized enterprises seeking to minimize upfront investment and production overheads while retaining the capacity for agile and on-demand manufacturing.

Ultimately, the cost efficiency of 3D printing extends beyond the realm of business and industry, permeating into the realm of personal creativity and DIY projects. Enthusiasts and hobbyists can harness the power of 3D printing to materialize their imaginative designs without breaking the bank, fostering a culture of accessibility and affordability in the realm of fabrication and craftsmanship.

Customization and Personalization

3D printing heralds a new era of customization and personalization, empowering individuals to tailor products and designs to their specific preferences and requirements. Unlike mass-produced items that offer limited variations, 3D printing allows for unparalleled customization, enabling the adaptation of designs to suit individualized needs.

From personalized smartphone cases and jewelry to bespoke prosthetics and orthodontic devices, 3D printing facilitates the creation of unique and tailored products that align with the distinct anatomical, aesthetic, and functional specifications of the end user. This level of customization transcends the constraints of traditional manufacturing, where achieving such personalized intricacies would be logistically challenging and cost-prohibitive.

Furthermore, the advent of parametric design and generative algorithms has augmented the scope of customization in 3D printing, enabling the creation of designs that respond dynamically to user input and environmental factors. This dynamic approach to design fosters a symbiotic relationship between the user and the product, allowing for personalized modifications that cater to evolving needs and preferences.

For businesses, the ability to offer customizable products through 3D printing can be a competitive differentiator, fostering brand loyalty and customer satisfaction. Whether it’s personalized promotional merchandise or tailored industrial components, 3D printing facilitates the seamless integration of customization into the production process, enhancing the value proposition for both businesses and consumers.

Moreover, 3D printing serves as a catalyst for artistic expression and creative exploration, enabling designers and artists to materialize their visionary concepts with unprecedented freedom. The capacity to iterate and refine designs in a digital environment before translating them into physical objects empowers creators to push the boundaries of conventional aesthetics and functionality, resulting in truly unique and personalized artifacts.

Ultimately, the fusion of customization and personalization in 3D printing transcends the realm of mere fabrication; it embodies a paradigm shift towards a future where products are not just manufactured, but meticulously tailored to resonate with the individuality of each user, fostering a profound sense of connection and ownership.

Rapid Prototyping

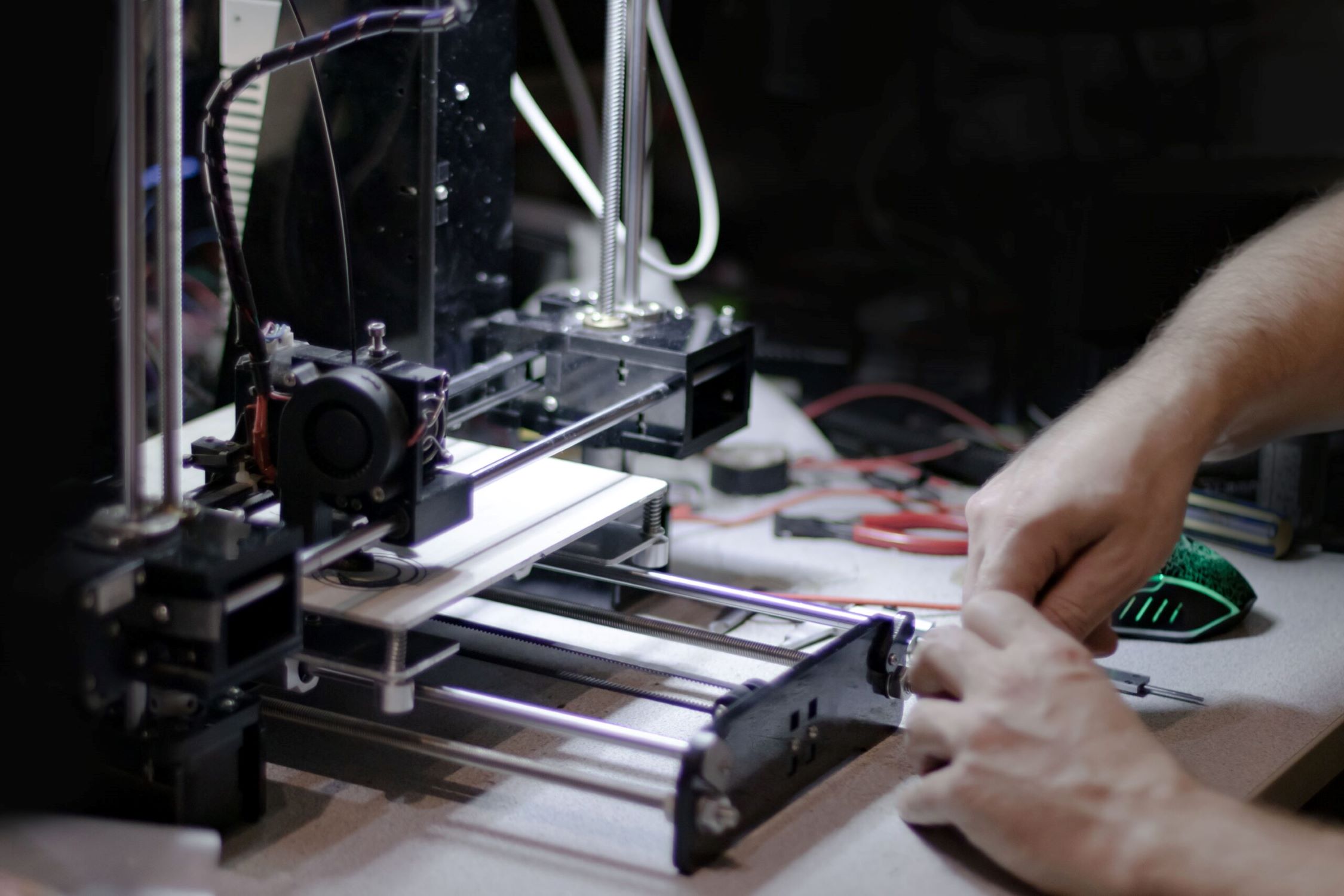

3D printing has revolutionized the landscape of product development and innovation through its unparalleled capability for rapid prototyping. Traditionally, the process of prototyping involved extensive lead times, exorbitant costs, and logistical complexities. However, 3D printing has redefined this paradigm by enabling swift and cost-effective iteration of designs, thereby expediting the product development lifecycle.

By harnessing the power of 3D printing, designers and engineers can swiftly translate digital designs into physical prototypes, allowing for tangible evaluation and refinement of concepts at an unprecedented pace. This agility in prototyping not only accelerates the design iteration process but also fosters a culture of experimentation and innovation, where ideas can swiftly evolve from conception to realization.

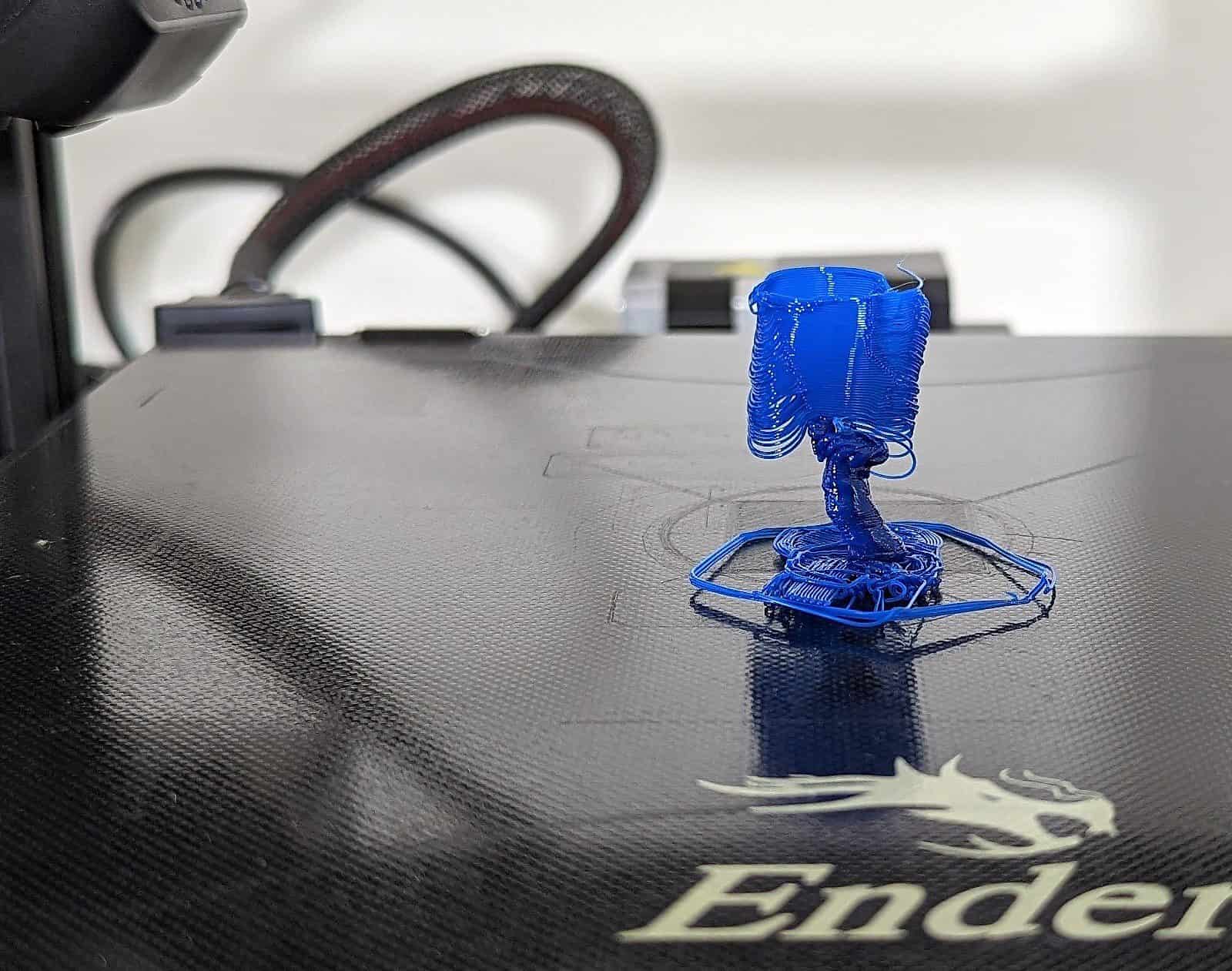

Furthermore, 3D printing facilitates the creation of functional prototypes that closely emulate the properties and performance of the final products, enabling comprehensive testing and validation prior to mass production. This capability to produce prototypes with intricate geometries and diverse material properties empowers designers to simulate real-world conditions and performance metrics, thereby enhancing the robustness and reliability of the final products.

From a cost perspective, 3D printing mitigates the financial risks associated with traditional prototyping methods, where tooling and setup costs for each iteration can accumulate substantial expenses. With 3D printing, designers can iterate designs on-demand, minimizing upfront investment and unlocking the potential for a higher number of iterations within a given timeframe.

Moreover, the agility of 3D printing in prototyping extends beyond industrial applications, permeating into the realms of education and DIY projects. Students and enthusiasts can leverage 3D printing to materialize their ideas and concepts, gaining hands-on experience in the iterative design process and fostering a culture of creativity and ingenuity.

Ultimately, 3D printing’s capacity for rapid prototyping transcends the confines of traditional manufacturing, ushering in a new era of accelerated innovation and design iteration. By democratizing the prototyping process and amplifying the pace of ideation to realization, 3D printing serves as a catalyst for transformative advancements across diverse domains, from product development to academic research.

Consider the practical uses of a 3D printer, such as creating prototypes, customizing products, and learning about technology. It can also be a fun and educational tool for all ages.

Educational and Learning Opportunities

3D printing has emerged as a transformative tool in education, offering a myriad of learning opportunities that extend beyond traditional pedagogical approaches. By integrating 3D printing into educational curricula, students are exposed to a dynamic and experiential learning environment that fosters creativity, problem-solving, and interdisciplinary exploration.

One of the primary educational benefits of 3D printing lies in its capacity to materialize abstract concepts and theoretical principles into tangible, three-dimensional objects. This tangible representation enhances conceptual understanding and spatial visualization, enabling students to grasp complex ideas with greater clarity and depth. Whether it’s visualizing molecular structures in chemistry or exploring geometric concepts in mathematics, 3D printing bridges the gap between theory and practical application, enhancing the learning experience.

Moreover, 3D printing nurtures a culture of hands-on experimentation and iterative design, empowering students to engage in the entire product development lifecycle, from ideation and prototyping to testing and refinement. This holistic approach to learning instills essential skills such as critical thinking, design thinking, and problem-solving, fostering a mindset of innovation and resilience that transcends academic boundaries.

Furthermore, 3D printing serves as a conduit for interdisciplinary collaboration, where students from diverse fields such as engineering, design, biology, and art converge to explore cross-disciplinary projects. This interdisciplinary synergy mirrors real-world collaborative dynamics, preparing students for the complexities of modern workplaces and societal challenges, where multifaceted solutions are imperative.

From a vocational standpoint, integrating 3D printing into educational curricula equips students with practical skills that are increasingly relevant in today’s technological landscape. By familiarizing students with 3D modeling software, additive manufacturing processes, and design optimization techniques, educational institutions cultivate a talent pool that is adept at leveraging cutting-edge technologies to drive innovation and progress.

Moreover, 3D printing transcends the confines of formal education, permeating into the realm of lifelong learning and skill development. Enthusiasts, hobbyists, and lifelong learners can harness the educational potential of 3D printing to explore new frontiers of creativity, craftsmanship, and technological literacy, fostering a culture of continuous learning and personal growth.

Ultimately, 3D printing’s educational impact extends far beyond the fabrication of objects; it embodies a paradigm shift in learning methodologies, fostering a generation of inquisitive, adaptable, and resourceful individuals who are poised to shape the future through their innovative prowess and interdisciplinary acumen.

Read more: How To Get A Free 3D Printer

Accessibility and Convenience

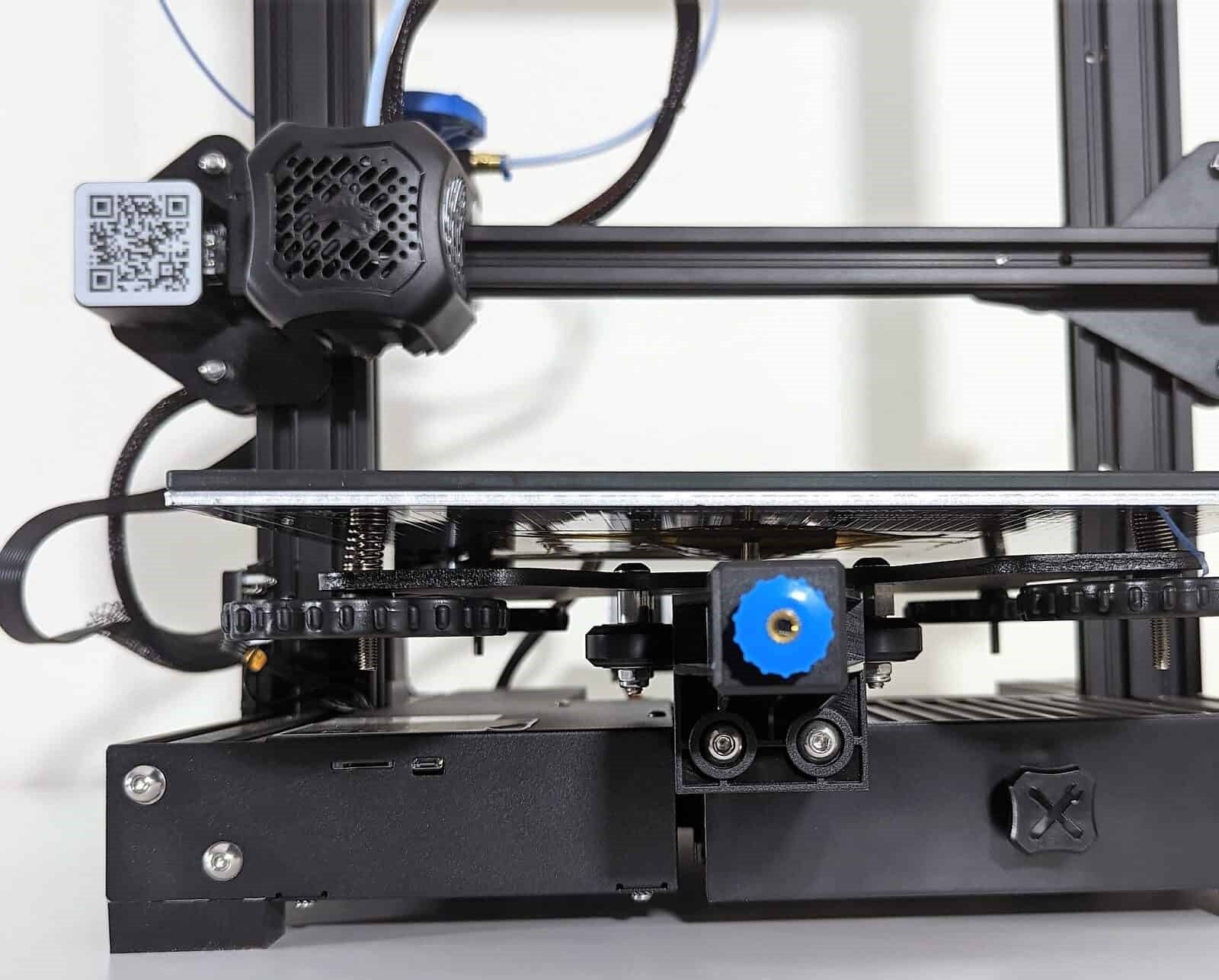

3D printing has democratized the realm of fabrication and manufacturing, rendering the process of creating physical objects more accessible and convenient than ever before. Unlike traditional manufacturing methods that often entail logistical complexities and geographic constraints, 3D printing transcends these barriers, offering a decentralized and user-centric approach to fabrication.

One of the hallmark features of 3D printing is its accessibility to a diverse spectrum of users, ranging from hobbyists and enthusiasts to entrepreneurs and educators. With the advent of user-friendly 3D printers and intuitive design software, individuals with varying levels of technical expertise can engage in the process of 3D printing, unleashing their creativity and innovation without being encumbered by steep learning curves or specialized skill sets.

Furthermore, the accessibility of 3D printing extends to its capacity for on-demand production, eliminating the need for large-scale manufacturing infrastructure and extensive supply chains. This on-demand paradigm fosters a culture of localized and sustainable production, where objects can be fabricated closer to the point of use, reducing transportation costs and carbon footprint while enhancing supply chain resilience.

From a consumer standpoint, 3D printing engenders unparalleled convenience by offering bespoke and personalized solutions that cater to individual needs and preferences. Whether it’s custom-fit orthotics, personalized home decor, or tailored fashion accessories, 3D printing empowers consumers to procure products that align with their unique tastes and requirements, transcending the limitations of mass-produced commodities.

Moreover, the advent of distributed manufacturing networks and online 3D printing services has further augmented the accessibility and convenience of 3D printing. Users can seamlessly upload their designs to online platforms and have them fabricated and delivered to their doorstep, fostering a seamless and frictionless experience that epitomizes the convergence of digital design and physical production.

Additionally, 3D printing serves as a catalyst for innovation and problem-solving in regions with limited access to traditional manufacturing infrastructure. Whether it’s addressing local healthcare needs through the production of medical devices or fostering economic empowerment through small-scale entrepreneurship, 3D printing amplifies accessibility and convenience, catalyzing positive socio-economic impact.

Ultimately, the accessibility and convenience of 3D printing transcend the realm of mere fabrication; they embody a paradigm shift towards a future where the power of creation is decentralized, inclusive, and seamlessly integrated into the fabric of everyday life, fostering a culture of empowerment, customization, and sustainable production.

Conclusion

The realm of 3D printing stands as a testament to the transformative potential of technology, offering a tapestry of opportunities that transcend traditional manufacturing paradigms. From cost efficiency and customization to rapid prototyping, educational enrichment, and accessibility, the impact of 3D printing reverberates across diverse domains, catalyzing innovation, creativity, and empowerment.

As we navigate the landscape of 3D printing, it becomes evident that this technology has transcended the confines of industrial applications, permeating into the realms of education, entrepreneurship, and personal creativity. The cost efficiency of 3D printing has democratized manufacturing, empowering businesses and individuals to materialize their ideas with unprecedented agility and affordability.

Moreover, the fusion of customization and personalization in 3D printing has engendered a culture of bespoke solutions, where products are meticulously tailored to resonate with the individuality of each user. This paradigm shift fosters a profound sense of connection and ownership, amplifying the intrinsic value of the objects we interact with on a daily basis.

Furthermore, the rapid prototyping capabilities of 3D printing have accelerated the pace of innovation, expediting the design iteration process and fostering a culture of experimentation and resilience. This agility in prototyping transcends industrial applications, permeating into the realms of education and DIY projects, catalyzing transformative advancements and creative exploration.

Education has emerged as a cornerstone of 3D printing’s impact, offering a dynamic and experiential learning environment that nurtures creativity, critical thinking, and interdisciplinary collaboration. By integrating 3D printing into educational curricula, institutions cultivate a talent pool that is adept at leveraging cutting-edge technologies to drive innovation and progress.

Lastly, the accessibility and convenience of 3D printing have democratized the process of fabrication, rendering the creation of physical objects more inclusive and user-centric. This decentralized approach fosters a culture of localized and sustainable production, offering bespoke and personalized solutions that cater to individual needs and preferences.

In essence, 3D printing epitomizes a future where the power of creation is decentralized, inclusive, and seamlessly integrated into the fabric of everyday life. As we continue to explore the frontiers of 3D printing, it is imperative to embrace its transformative potential and leverage its capabilities to shape a future where innovation, creativity, and empowerment converge to redefine the way we conceptualize and materialize objects.

Frequently Asked Questions about Why Should I Get A 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Should I Get A 3D Printer”