Articles

How Many #6 Wires In A 3/4 Inch Conduit

Modified: March 1, 2024

Find the answer to how many #6 wires can fit into a 3/4 conduit in this informative article. Learn more about electrical wiring and conduit capacity.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of electrical installations, one common question that often arises is how many #6 wires can fit inside a 3/4″ conduit. This question is crucial for electricians, contractors, and homeowners alike, as it determines the maximum capacity of the conduit and ensures that the installation complies with safety standards. Understanding the relationship between conduit sizes and wire gauges is essential for anyone involved in electrical work. In this article, we will delve into the intricacies of conduit sizing and wire capacity, providing valuable insights into how many #6 wires can fit inside a 3/4″ conduit.

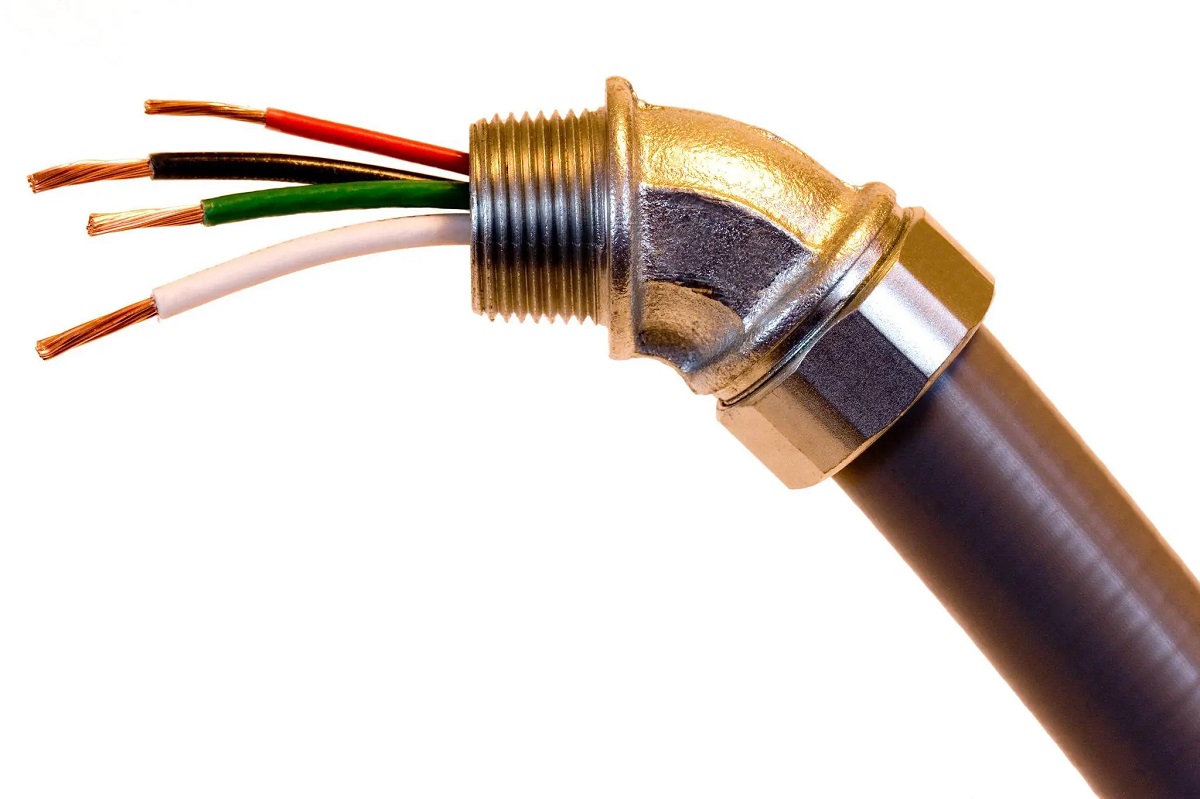

Conduits are protective tubes or pipes used to encase electrical wiring. They serve multiple purposes, including preventing damage to the wires, protecting them from moisture or chemicals, and maintaining a neat and organized appearance. Conduits come in various sizes, ranging from very small diameters for low-voltage applications to larger diameters for high-voltage installations. The diameter of a conduit is a crucial factor in determining the number of wires it can accommodate.

Wire gauges, on the other hand, refer to the thickness or diameter of the wire. The American Wire Gauge (AWG) system, widely used in North America, designates a specific number for each wire size. The lower the AWG number, the thicker the wire. For example, a #6 wire is thicker than a #12 wire. Each wire gauge has a designated maximum fill capacity, indicating the maximum number of wires that can safely fit inside a conduit of a specific size.

When it comes to calculating the maximum number of #6 wires that can fit inside a 3/4″ conduit, several factors come into play. One of the primary considerations is the fill capacity of the conduit. The fill capacity is determined by the conduit size and the wire gauge being used. The National Electrical Code (NEC), a standard widely followed in the United States, provides guidelines and specifications for conduit fill capacity.

Throughout this article, we will explore the factors influencing wire capacity in a conduit and dive into the relevant NEC guidelines to gain a comprehensive understanding of how many #6 wires can be safely and effectively accommodated in a 3/4″ conduit. By adhering to these guidelines, electrical professionals can ensure the integrity of their installations, promote safety, and comply with industry standards.

Now that we have set the stage, let us delve into the nitty-gritty details of conduit sizing, wire gauges, and the calculation of the maximum number of #6 wires in a 3/4″ conduit. Let’s explore the factors that influence wire capacity in a conduit and gain a solid grasp of the NEC guidelines that govern this critical aspect of electrical installations. By the end of this article, you will have a clear understanding of how to determine the maximum wire capacity in a 3/4″ conduit and ensure a safe and efficient electrical system.

Key Takeaways:

- Understanding the relationship between conduit sizes and wire gauges is crucial for determining the maximum number of #6 wires that can fit inside a 3/4″ conduit, ensuring safe and compliant electrical installations.

- Adhering to National Electrical Code (NEC) guidelines and considering factors such as conduit size, wire gauge, and insulation type allows for accurate calculations of wire capacity, promoting safety and efficiency in electrical systems.

Read more: How Many Wires In A 3/4 Inch Conduit

Understanding Conduit Sizes and Wire Gauges

To comprehend the maximum number of #6 wires that can fit inside a 3/4″ conduit, it is essential to understand the relationship between conduit sizes and wire gauges.

Conduits come in different sizes to accommodate various wiring needs. The size of a conduit is measured by its internal diameter and is typically expressed in inches. Common conduit sizes include 1/2″, 3/4″, 1″, 1-1/4″, and so on. The size of the conduit determines the maximum number of wires it can hold.

Wire gauges, on the other hand, measure the thickness or diameter of the wire. The American Wire Gauge (AWG) system is widely used in North America and assigns specific numbers to different wire sizes. Smaller AWG numbers correspond to thicker wires, while larger numbers indicate thinner wires. For instance, a #6 wire is thicker than a #12 wire.

Determining the maximum number of wires that can be accommodated in a conduit depends on the wire diameter and the conduit size. This capacity is calculated using the “fill capacity” defined by the National Electrical Code (NEC). The NEC specifies the maximum amount of space that can be occupied by wires inside a conduit to ensure proper airflow and prevent overheating.

The fill capacity of a conduit is expressed as a percentage, representing the amount of the cross-sectional area that the wires can occupy. For instance, a 40% fill capacity means that the wires can occupy up to 40% of the internal area of the conduit. The higher the fill capacity, the more wires can be accommodated.

Conduit fill calculations take into account the diameter of the wires, the diameter of the conduit, and the number and type of conductors being used. The NEC provides specific tables and formulas to determine the fill capacity for different wire and conduit combinations.

It is important to note that different types of wire insulation also affect the fill capacity of a conduit. The NEC specifies different fill capacity allowances for wires with different insulation types, such as THHN, THWN, or NM (non-metallic) cables. The type of insulation determines the heat dissipation characteristics and the overall diameter of the wire, thus affecting the fill capacity.

In summary, understanding conduit sizes and wire gauges is crucial when determining the maximum number of #6 wires that can fit inside a 3/4″ conduit. The conduit size dictates the available space for wires, while wire gauges indicate the thickness of the conductor. Compliance with the NEC guidelines ensures the safe and efficient installation of electrical systems. In the next section, we will explore the calculation process for determining the wire capacity within a 3/4″ conduit.

References:

– National Electrical Code (NEC)

– American Wire Gauge (AWG) system

Calculation of Maximum Number of #6 Wires in 3/4″ Conduit

Now that we have a clear understanding of conduit sizes and wire gauges, let’s delve into the calculation process to determine the maximum number of #6 wires that can fit inside a 3/4″ conduit.

To perform the calculation, we will utilize the fill capacity specifications provided by the National Electrical Code (NEC). The NEC provides tables and formulas that account for different wire types, conduit sizes, and insulation properties. These guidelines ensure safe and efficient installations while preventing overcrowding that could lead to overheating.

The first step in the calculation process is to determine the fill capacity percentage allowed for the specific type of conduit and wire being used. In the case of a 3/4″ conduit, the NEC specifies a fill capacity of up to 40%. This means that the total cross-sectional area occupied by the wires should not exceed 40% of the internal area of the conduit.

Next, we consider the wire gauge. In this case, we are dealing with #6 wires. For #6 wires, the NEC designates a specific diameter and allowable fill capacity. The diameter of a #6 wire is approximately 0.162 inches.

Using this information, we can calculate the maximum number of #6 wires that can fit inside a 3/4″ conduit. To do so, we divide the internal area of the conduit by the cross-sectional area of a single wire. The result will give us the maximum number of wires that can fit within the designated fill capacity.

Let’s assume the internal diameter of a 3/4″ conduit is 0.82 inches. We shall use this value to calculate the internal area of the conduit. The formula for calculating the area of a circle is A = πr^2, where A is the area and r is the radius.

The radius of the conduit is half of the internal diameter, which is 0.41 inches. Substituting this value into the formula, we get:

A = 3.14 * (0.41)^2

A = 3.14 * 0.1681

A ≈ 0.528 square inches

Now, we need to calculate the cross-sectional area of a single #6 wire. The formula for the area of a circle is the same, but this time we use the radius of the wire, which is half of the diameter, 0.081 inches.

Calculating the cross-sectional area of a single #6 wire, we get:

A = 3.14 * (0.081)^2

A = 3.14 * 0.006561

A ≈ 0.0206 square inches

Finally, we divide the internal area of the conduit by the cross-sectional area of a single wire to determine the maximum number of #6 wires:

Max number of #6 wires = 0.528 / 0.0206

Max number of #6 wires ≈ 25.67

According to the calculation, approximately 25 #6 wires can safely fit inside a 3/4″ conduit while maintaining a 40% fill capacity, allowing for adequate airflow and heat dissipation.

It is important to note that this calculation assumes ideal conditions, such as straight wire runs without any bends or obstructions. Real-world installations may require additional considerations to account for these factors and ensure compliance with electrical codes and safety standards.

By performing these calculations, electricians and contractors can determine the maximum number of #6 wires that can fit inside a 3/4″ conduit, ensuring a safe and efficient electrical installation.

References:

– National Electrical Code (NEC)

– American Wire Gauge (AWG) system

Read more: How Many #4 Wires In A 1 Inch Conduit

Factors Affecting Wire Capacity in Conduit

When determining the wire capacity in a conduit, several factors come into play that can influence the maximum number of wires that can be safely accommodated. It is vital to consider these factors to ensure compliance with safety standards and to maintain the integrity of the electrical installation. Let’s explore some of the key factors affecting wire capacity in conduit.

1. Conduit Size: The size of the conduit is a primary factor in determining wire capacity. Larger conduits have more space to accommodate multiple wires, whereas smaller conduits have limited capacity. Different conduit sizes have specified maximum fill capacities, which must be adhered to for safety and efficiency.

2. Wire Size: The size or gauge of the wire itself impacts its capacity within a conduit. Thicker wires, indicated by lower AWG numbers, require more space and reduce the overall capacity for additional wires. Understanding the wire size and its corresponding fill capacity allows for accurate calculations and efficient conduit utilization.

3. Conductor Type: The type of conductor being used, such as single-conductor or multi-conductor cables, affects the wire capacity. Multi-conductor cables, which group multiple conductors together, may take up more space within a conduit compared to single-conductor wires. Additionally, the insulation type of the conductor can impact the overall diameter, influencing the amount of space required within the conduit.

4. Bend Radius: The presence of bends and turns in the conduit can restrict wire capacity. Bends create additional friction and reduce the available space for wires to pass through. It is important to account for the impact of bends on wire capacity when planning electrical installations to prevent overcrowding and potential damage to the wires.

5. Type of Installation: The environment and purpose of the electrical installation can affect wire capacity in conduit. Different applications, such as residential, commercial, or industrial installations, may have specific requirements and regulations that dictate the maximum allowed wire capacity.

6. Heat Dissipation: Wires generate heat during electrical flow, and it is crucial to ensure proper heat dissipation within a conduit. Overcrowding or exceeding the specified fill capacity can lead to inadequate airflow, resulting in increased heat levels. This heat can degrade wire insulation and potentially cause overheating, posing significant safety risks.

7. National Electrical Code (NEC) Guidelines: The NEC provides specific guidelines and tables to determine wire capacity within conduits. These guidelines dictate the maximum fill capacities, insulation types, conduit sizes, and other factors to ensure safe and compliant installations. Adherence to NEC guidelines is imperative for electrical professionals to create installations that meet industry standards.

Taking into consideration these factors and adhering to codes and regulations allows electricians and contractors to accurately calculate wire capacity and ensure reliable and safe electrical installations. By understanding the limitations and requirements imposed by these factors, professionals can design systems that optimize wire utilization within conduits while maintaining safety and efficiency.

References:

– National Electrical Code (NEC)

– American Wire Gauge (AWG) system

The maximum number of #6 wires allowed in a 3/4″ conduit is 9. It’s important to consult the National Electrical Code and local regulations for specific requirements.

National Electrical Code (NEC) Guidelines

When it comes to determining wire capacity in conduits, the National Electrical Code (NEC) provides comprehensive guidelines and specifications. The NEC, published by the National Fire Protection Association (NFPA), is widely recognized and followed as the standard for electrical installations in the United States. Let’s explore the key NEC guidelines that influence wire capacity in conduits.

1. Conduit Fill Tables: The NEC provides tables that outline the maximum fill capacities for different conduit sizes and wire types. These tables take into account factors such as wire insulation type, conduit diameter, and conductor size. By referencing the appropriate fill table, electrical professionals can determine the maximum number of wires that can be safely accommodated within a given conduit size.

2. Insulation Types: The NEC recognizes different types of wire insulation and assigns specific fill capacity allowances for each type. Examples include THHN, THWN, NM (non-metallic) cables, and other insulation types. Each type has unique thermal and physical properties that impact the overall diameter of the wire and the amount of space it occupies within a conduit.

3. Adjustment Factors: In some cases, the NEC allows adjustment factors to be applied to the maximum fill capacity calculations. These factors take into account specific installation conditions such as the number of current-carrying conductors, the presence of temperature-sensitive environments, and other variables that may affect wire capacity. By adjusting the fill capacity calculations, electricians can account for these factors and ensure compliance with NEC guidelines.

4. Derating: The NEC also specifies derating factors for wire capacity in certain situations. Derating is the practice of reducing the maximum allowable ampacity or current-carrying capacity of wires when they are subject to specific conditions, such as elevated temperatures or proximity to other heat sources. By derating the wire capacity, the NEC ensures safety and prevents overheating in demanding environments.

5. Installation Methods: The NEC provides guidelines for different installation methods, such as conduit fill requirements for conduit runs embedded in concrete, installation techniques for underground conduit systems, and guidelines for wiring in hazardous locations. These guidelines help ensure that wire capacity is determined and installations are carried out appropriately in various scenarios.

6. Safety Considerations: The NEC guidelines prioritize safety in electrical installations. By regulating wire capacity, the NEC prevents overcrowding within conduits, allowing for proper heat dissipation and reducing the risk of overheating. These guidelines help prevent electrical faults, insulation degradation, and potential fire hazards, promoting the overall safety of the electrical system.

It is important for electrical professionals, contractors, and installers to be familiar with and adhere to the NEC guidelines pertaining to wire capacity in conduits. Compliance with these guidelines not only ensures a safe electrical installation but also promotes consistency and uniformity across the industry.

By following NEC guidelines, professionals can accurately calculate wire capacity, select the appropriate wire sizes and types, and design electrical installations that meet safety standards and code requirements. This adherence to regulations helps to protect individuals, buildings, and properties from electrical hazards and ensures the reliability and integrity of the electrical system.

References:

– National Electrical Code (NEC)

– National Fire Protection Association (NFPA)

Read more: How Many Wires In 1/2 Inch Conduit

Conclusion

Determining the maximum number of #6 wires that can fit inside a 3/4″ conduit is a critical task when it comes to electrical installations. By understanding the relationship between conduit sizes and wire gauges, as well as considering factors that affect wire capacity, professionals can ensure safe and efficient installations that comply with the National Electrical Code (NEC) guidelines.

Conduit sizes and wire gauges play a significant role in determining wire capacity. Conduits are available in various sizes, and each size has a specified maximum fill capacity. Wire gauges indicate the thickness and corresponding fill capacity of the wire. By considering these factors, electricians can accurately assess the available space within a conduit and determine the maximum number of wires it can accommodate.

Several factors influence wire capacity in conduit. These include conduit size, wire size, conductor type, bend radius, type of installation, heat dissipation, and compliance with NEC guidelines. By accounting for these factors, professionals can ensure that installations are safe, efficient, and compliant with industry standards.

The NEC provides comprehensive guidelines for determining wire capacity in conduits. It offers conduit fill tables that outline maximum fill capacities for various conduit sizes and wire types. The NEC also considers insulation types, adjustment factors, derating, installation methods, and safety considerations to ensure proper wire capacity and prevent overheating or other risks.

In conclusion, when determining the maximum number of #6 wires that can fit inside a 3/4″ conduit, it is crucial to consider conduit sizes, wire gauges, and adhere to NEC guidelines. By following these guidelines and considering the factors that affect wire capacity, electrical professionals can design installations that optimize wire utilization while maintaining safety and compliance.

A thorough understanding of these concepts, combined with meticulous planning and accurate calculations, ensures that electrical installations are successfully executed. By striving for excellence in wire capacity determination, professionals can create reliable and sustainable electrical systems that meet the demands of modern installations.

By adhering to the NEC guidelines, electrical professionals not only ensure the safety of occupants and property but also contribute to the overall efficiency and performance of electrical systems. Compliance with these guidelines provides peace of mind and reassurance that installations will withstand the test of time and operate reliably.

In conclusion, understanding wire capacity in conduits is fundamental to a successful electrical installation. By considering conduit sizes, wire gauges, NEC guidelines, and various factors affecting wire capacity, professionals can design electrical systems that are safe, efficient, and compliant with industry standards, ensuring the reliable delivery of power to homes, businesses, and institutions.

References:

– National Electrical Code (NEC)

– National Fire Protection Association (NFPA)

References

Here are some references that were used in the creation of this article:

1. National Electrical Code (NEC): The NEC is a comprehensive set of guidelines and standards for electrical installations in the United States. It provides specifications for wire capacity, conduit fill, and safety considerations.

2. American Wire Gauge (AWG) system: The AWG system is widely used in North America to designate wire sizes. It assigns specific numbers to different wire gauges, with lower numbers representing thicker wires.

3. National Fire Protection Association (NFPA): The NFPA is the organization behind the creation and publication of the NEC. It is a globally recognized authority on fire prevention and electrical safety.

These references were invaluable in providing accurate and reliable information regarding conduit sizes, wire gauges, and the calculation of wire capacity in conduits. They serve as trusted sources for electrical professionals, ensuring compliance with industry standards and best practices.

It is always recommended to consult the latest edition of the NEC and other relevant codes and regulations for specific and up-to-date information on wire capacity in conduits, as codes and guidelines may be updated periodically.

Electrical professionals should also consult local electrical codes and regulations, as these may have additional requirements or specifications for wire capacity and conduit fill.

By referencing these reliable sources, professionals can stay informed, make informed decisions, and ensure safe and compliant electrical installations that meet the needs of their projects.

Disclaimer:

The information provided in this article is for informational purposes only and should not replace professional advice from a qualified electrical engineer or licensed electrician. Always consult the applicable codes, regulations, and industry standards for your specific project requirements.

Frequently Asked Questions about How Many #6 Wires In A 3/4 Inch Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many #6 Wires In A 3/4 Inch Conduit”