Articles

How To Resurface Fireplace

Modified: January 23, 2024

Learn how to resurface your fireplace with helpful articles. Transform your outdated fireplace into a stunning focal point in your home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the comprehensive guide on how to resurface your fireplace. Whether you want to update the look of your fireplace or repair any damage, resurfacing can be a cost-effective and satisfying project to undertake. By following the steps outlined in this article, you will be able to transform your fireplace and give it a fresh new appearance.

A fireplace is often the focal point of a room, providing both warmth and ambiance. Over time, however, the surface of the fireplace may become worn, cracked, or outdated. Resurfacing allows you to rejuvenate the look of your fireplace, giving it a modern and stylish makeover. It is a process that involves preparing the surface, repairing any damage, and applying a new layer of material for a smooth and refined finish.

Before you begin, it is important to gather all the necessary materials and tools for the project. This will ensure that you have everything you need within reach, saving you time and frustration later on. The specific materials required may vary depending on the condition and type of your fireplace, so it is advisable to consult with a professional or refer to the instructions provided by the manufacturer of the resurfacing product.

Once you have gathered all the materials, the next step is to properly prepare the fireplace for resurfacing. This involves cleaning the surface and removing any loose debris, such as dirt, dust, or old paint. It is crucial to start with a clean and smooth surface to ensure proper adhesion of the new resurfacing material.

If there are any damaged areas on your fireplace, such as cracks or chips, it is important to repair them before applying the new surface. This will ensure that the final result is seamless and free from imperfections. Depending on the extent of the damage, you may need to use a filler or patching compound to level the surface and create a solid foundation for the resurfacing material.

Once the preparation and repairs are complete, it is time to apply the resurfacing material to the fireplace. There are various options to choose from, including brick veneer, stone veneer, or tile. The choice will depend on your personal preference and the desired aesthetic. It is essential to follow the manufacturer’s instructions when applying the resurfacing material to ensure a successful and durable finish.

After applying the resurfacing material, it is important to smooth and finish the surface to achieve a professional-looking result. This may involve sanding, buffing, or polishing depending on the chosen material. Taking the time to refine the surface will not only enhance its appearance but also improve its durability and longevity.

Finally, once the resurfacing process is complete, adding the final touches can elevate the overall look of the fireplace. This may include painting or staining, adding decorative trim or accessories, or even updating the mantel. These additional elements can personalize the fireplace and make it a unique feature in your home.

With proper maintenance and care, your resurfaced fireplace can provide years of enjoyment and beauty. Regular cleaning and avoiding harsh chemicals or abrasive materials will help preserve the integrity of the surface. By following this comprehensive guide, you will have all the necessary knowledge and steps to successfully resurface your fireplace and transform it into a stunning centerpiece for your living space.

Key Takeaways:

- Transform your fireplace with resurfacing, a cost-effective and satisfying project. Gather materials, prep the fireplace, apply the resurfacing material, and add final touches for a stunning centerpiece in your home.

- Achieve a professional and visually appealing resurfaced fireplace by following the comprehensive guide. Clean, repair, apply, smooth, and maintain for long-lasting beauty and warmth in your living space.

Read more: How To Resurface Rotors With Sandpaper

Step 1: Gather Materials

Before you begin the process of resurfacing your fireplace, it is essential to gather all the necessary materials. Having everything you need at hand will ensure a smooth and efficient project. The specific materials required may vary depending on the type of resurfacing material you choose and the condition of your fireplace. Here is a general list of materials commonly used for fireplace resurfacing:

- Resurfacing material: This can include brick veneer, stone veneer, tile, or any other material that suits your desired look.

- Adhesive: The type of adhesive will depend on the resurfacing material you choose. Make sure to choose a high-quality adhesive that is suitable for indoor use and designed to bond to your fireplace surface.

- Trowel: A trowel is necessary for applying the adhesive and smoothing the resurfacing material. Select a trowel with the appropriate size and shape for your specific project.

- Sanding block or sandpaper: This is essential for smoothing the surface of the fireplace before applying the resurfacing material. Choose sandpaper with different grits to achieve the desired level of smoothness.

- Primer (if necessary): Depending on the type of resurfacing material and the condition of your fireplace surface, a primer may be required. The primer will help the adhesive bond more effectively to the fireplace.

- Paint or stain (optional): If you plan to paint or stain the resurfaced fireplace, gather the appropriate paint or stain in your desired color or finish. Make sure to choose a high-quality, heat-resistant product suitable for use on fireplaces.

- Protective gear: It is important to prioritize safety during any home improvement project. Gather safety goggles, gloves, and a mask to protect yourself from potential hazards such as dust or chemicals.

- Cleaning supplies: Before resurfacing your fireplace, you will need to thoroughly clean the surface. Gather a vacuum or broom to remove loose dirt and debris, as well as a mild cleaning solution and a sponge or cloth for washing the surface.

- Drop cloths or plastic sheets: To protect the surrounding area from dust, debris, and any potential spills, lay down drop cloths or plastic sheets. This will make cleanup easier and prevent damage to your flooring or furniture.

- Tools: Depending on the specific requirements of your project, you may need additional tools such as a hammer, chisel, level, utility knife, or caulking gun. Consult the instructions provided with your resurfacing material to determine if any specialized tools are needed.

Once you have gathered all the necessary materials, double-check to ensure you have everything you need before starting the resurfacing process. This will save you time and frustration by avoiding unnecessary trips to the store during the project.

Remember, each resurfacing project is unique, so the materials required may vary. It is always advisable to consult with a professional or refer to the manufacturer’s instructions for your chosen resurfacing material to ensure you have all the appropriate tools and materials for a successful fireplace transformation.

Step 2: Prep the Fireplace

Before you can proceed with resurfacing your fireplace, it is crucial to properly prepare the surface. Prepping the fireplace ensures that the resurfacing material adheres well and provides a smooth, even finish. Follow these steps to prepare your fireplace for resurfacing:

- Clear the area: Start by removing any furniture, decorations, or objects in the vicinity of the fireplace. This will allow you to have a clear workspace and prevent any damage or obstructions during the preparation process.

- Protect surrounding surfaces: Use drop cloths or plastic sheets to cover the surrounding floor, walls, and furniture. This will protect them from dust, debris, and any potential spills or splatters.

- Clean the fireplace: Thoroughly clean the fireplace surface to remove any dirt, dust, soot, or old paint. Use a vacuum or broom to remove loose debris, and then wash the surface with a mild cleaning solution. Scrub with a sponge or cloth to remove any stubborn stains or residue. Rinse with clean water and allow the surface to dry completely.

- Inspect for damage: Carefully inspect the fireplace surface for any damage, such as cracks, chips, or loose bricks or tiles. Addressing these issues before resurfacing will ensure a more durable and visually appealing result. If you encounter any major structural damage, it is advisable to consult with a professional before proceeding further.

- Repair minor damage: If you notice any minor cracks or chips, it is important to repair them before applying the resurfacing material. Use a suitable filler or patching compound to level the damaged areas and create a smooth surface. Follow the manufacturer’s instructions for the specific product you are using, and allow sufficient time for the repairs to dry and cure.

- Remove old paint (if necessary): If your fireplace has been previously painted, you may need to remove the old paint before proceeding with resurfacing. Use a paint stripper or scraper to gently remove the paint, following the instructions provided with the product. Ensure proper ventilation while working with paint strippers and wear appropriate protective gear.

- Smoothen rough surfaces: Use a sanding block or sandpaper to smoothen any rough or uneven areas on the fireplace surface. This will create a better bonding surface for the resurfacing material. Start with a coarse grit sandpaper and gradually switch to finer grits for a smoother finish.

- Wipe down the surface: After sanding, wipe down the fireplace surface with a damp cloth to remove any dust or debris. This will ensure a clean surface for optimal adhesion of the resurfacing material.

Properly prepping the fireplace is essential for a successful resurfacing project. Taking the time to clean, repair, and smoothen the surface will result in a more professional-looking finish. It will also help the resurfacing material bond securely to the fireplace, ensuring a long-lasting and visually appealing transformation.

Step 3: Clean the Surface

Once you have prepped the fireplace, the next step in the resurfacing process is to thoroughly clean the surface. Cleaning the fireplace surface is crucial to remove any remaining dirt, dust, or residue that could hinder the adherence of the resurfacing material. Follow these steps to ensure a clean surface for optimal results:

- Remove loose debris: Use a vacuum, broom, or brush to remove any loose debris, such as dirt, dust, or cobwebs, from the fireplace surface. Pay special attention to the corners and crevices where debris can accumulate.

- Use a mild cleaning solution: Prepare a mild cleaning solution by mixing warm water with a gentle soap or detergent. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface of the fireplace.

- Apply the cleaning solution: Dip a sponge or cloth into the cleaning solution and gently scrub the fireplace surface, working in small sections. Pay attention to any areas with stubborn stains or residue, and apply a bit more pressure if needed. Be mindful of the type of fireplace material you are cleaning, as some materials may require specific cleaning methods or products.

- Rinse with clean water: After scrubbing, rinse the fireplace surface with clean water to remove the cleaning solution and any remaining residue. Use a damp cloth or sponge to wipe away any excess water.

- Dry the surface: Allow the fireplace surface to air dry completely before proceeding with the resurfacing process. Make sure there is proper ventilation to facilitate the drying process. Avoid using heat sources or fans to speed up the drying, as they can affect the adhesion of the resurfacing material.

Ensuring a clean surface is essential for the resurfacing material to adhere properly and provide a smooth and even finish. Any dirt, dust, or residue left on the surface can create barriers that compromise the bonding process. By taking the time to clean the fireplace surface thoroughly, you will set the stage for a successful resurfacing project.

It is worth noting that the cleaning process may vary depending on the type of fireplace material you are working with. Always refer to the manufacturer’s instructions or consult with professionals if you are unsure about the appropriate cleaning method for your specific fireplace.

Step 4: Repair Any Damage

Before you can proceed with resurfacing your fireplace, it is essential to address any damage present on the surface. Repairing any cracks, chips, or other imperfections will ensure a smooth and visually appealing finish. Here are the steps to follow to repair any damage on your fireplace:

- Inspect the fireplace surface: Carefully examine the entire surface of your fireplace to identify any cracks, chips, loose bricks or tiles, or other types of damage. It’s crucial to address these issues before applying the resurfacing material.

- Clean the damaged areas: Clean the damaged areas using a mild cleaning solution. Use a sponge or cloth to remove any dirt, dust, or debris from the cracks or chips. Make sure the surface is dry before proceeding with the repairs.

- Fill cracks and chips: Depending on the size and severity of the cracks or chips, select an appropriate filler or patching compound. Apply the compound to the damaged areas using a putty knife or a trowel. Smooth it out evenly, ensuring that it is level with the surrounding surface. Follow the manufacturer’s instructions for drying and curing times.

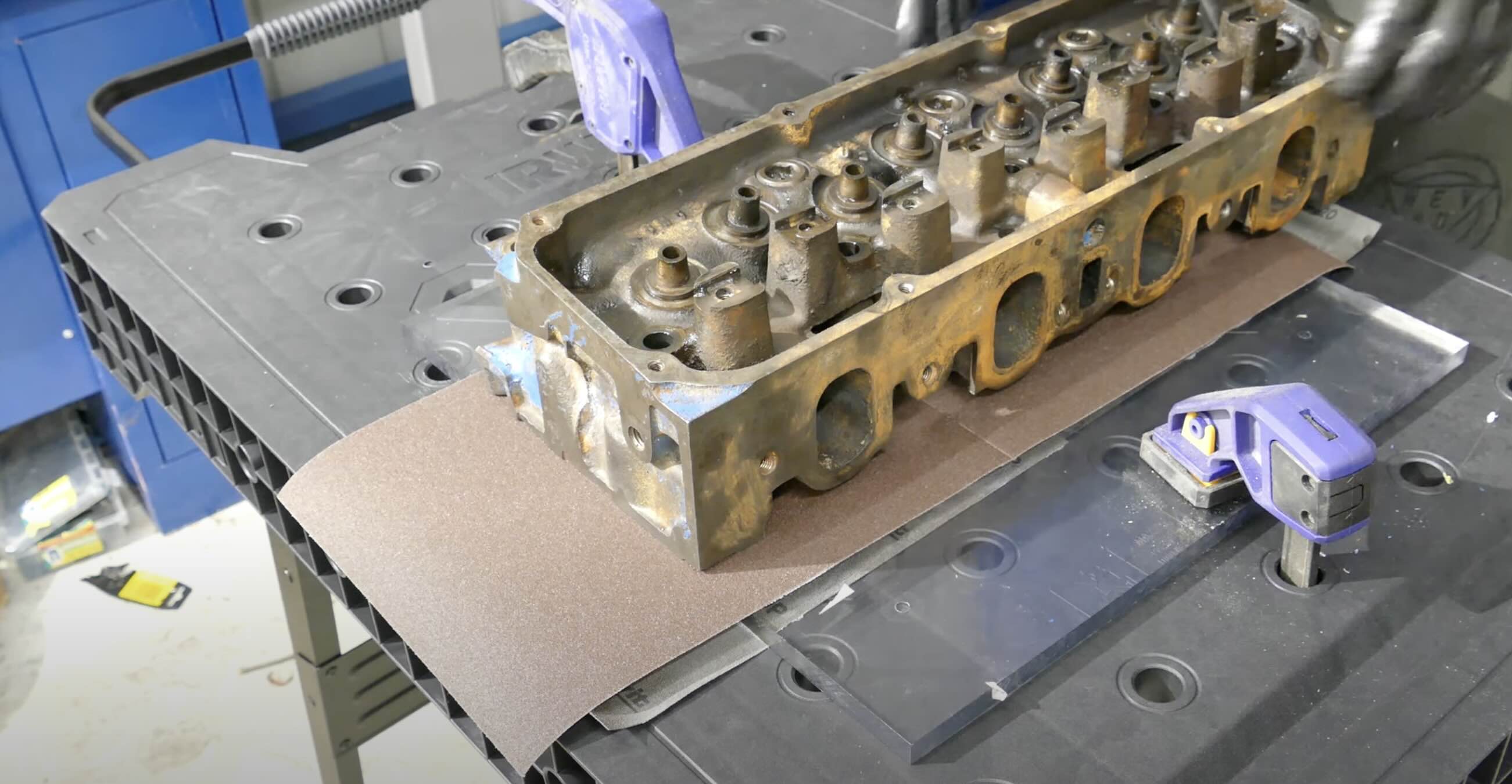

- Sand the repaired areas: Once the filler or patching compound is fully dry and cured, use sandpaper or a sanding block to smooth the repaired areas. Start with a coarse grit sandpaper and gradually move to finer grits until the surface is smooth and even. This will create a seamless transition between the repaired areas and the rest of the fireplace surface.

- Remove excess dust: After sanding, wipe away any dust or debris from the repaired areas using a damp cloth or sponge. This will ensure a clean and debris-free surface for the resurfacing material to adhere properly.

Repairing any damage on your fireplace is crucial for achieving a flawless resurfacing result. It ensures that the surface is even and provides a solid foundation for the resurfacing material to bond effectively. Taking the time to address cracks, chips, or other imperfections will enhance the durability and longevity of your fireplace’s newly resurfaced appearance.

If you encounter any major structural damage during the inspection process, it is advisable to consult with a professional before attempting any repairs. They can provide the necessary expertise and guidance to ensure the safety and integrity of your fireplace.

When resurfacing a fireplace, be sure to thoroughly clean the surface before applying any new materials. This will ensure better adhesion and a longer-lasting finish.

Read more: How To Resurface A Cement Patio

Step 5: Apply Resurfacing Material

With the surface prepared and any damage repaired, it’s time to apply the resurfacing material to transform the look of your fireplace. The specific resurfacing material you choose will depend on your desired aesthetic and the overall style of your space. Follow these steps to apply the resurfacing material to your fireplace:

- Prepare the resurfacing material: Read and follow the manufacturer’s instructions to properly prepare the resurfacing material. This may involve mixing certain components or allowing the material to acclimate to the room’s temperature.

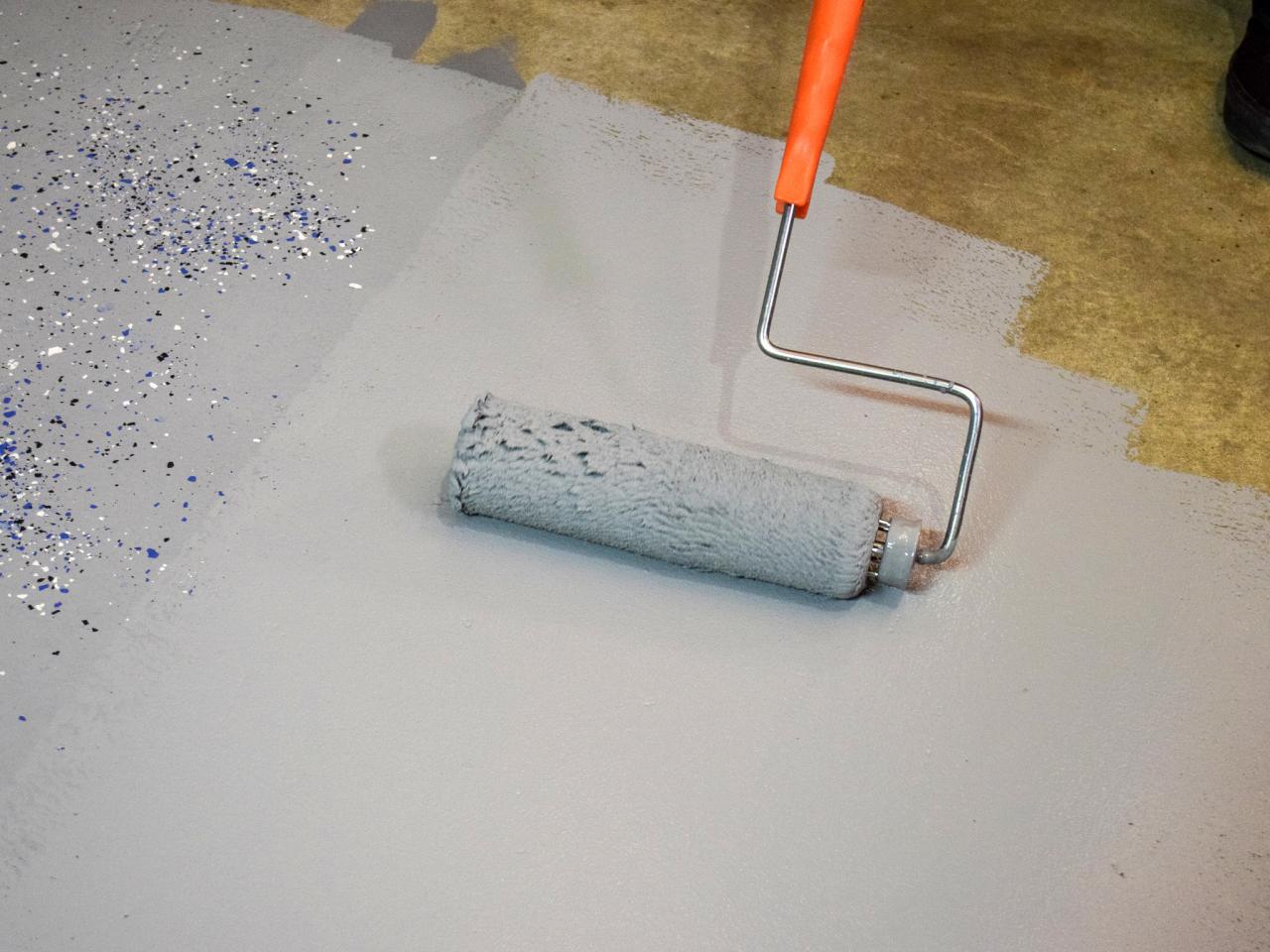

- Apply the adhesive: If required, apply the adhesive according to the manufacturer’s instructions. Use a trowel to spread an even layer of adhesive onto the surface, ensuring full coverage in all areas where the resurfacing material will be applied.

- Start applying the resurfacing material: Begin applying the resurfacing material onto the adhesive-coated surface. Work in small sections at a time, using a trowel or a putty knife to spread the material evenly. Press the material firmly into place, ensuring it adheres well to the adhesive and the surface of the fireplace.

- Continue to apply the material: Move systematically across the fireplace surface, working from one section to another. Pay attention to the manufacturer’s recommended thickness for the resurfacing material and ensure a consistent application throughout.

- Shape and smooth the material: While the resurfacing material is still wet, use a trowel or other appropriate tool to shape and smooth it as desired. This will help achieve the desired texture and finish. Follow the manufacturer’s instructions for specific guidelines on shaping and smoothing techniques.

- Clean up excess material: As you work, periodically remove any excess material or smudges around the edges or joints. Wipe away the excess carefully using a damp cloth or sponge for a clean and polished look.

- Allow the material to dry: Allow the applied resurfacing material to dry completely according to the manufacturer’s instructions. This may involve a specific curing time or recommending a particular environmental condition, such as proper ventilation or humidity levels. Avoid touching or disturbing the drying material during this time.

It’s important to note that the application process may vary depending on the type of resurfacing material you choose. Always refer to the manufacturer’s instructions to ensure proper application and adhere to any specific guidelines or precautions for your chosen material.

By carefully applying the resurfacing material, you can achieve a beautiful and refreshed look for your fireplace. The process requires patience and attention to detail, but the end result will be a stunning transformation that enhances the overall aesthetic of your space.

Step 6: Smooth and Finish the Surface

Once the resurfacing material has dried, it’s time to focus on smoothing and finishing the surface of your fireplace. This step is crucial to achieve a professional and polished look. Follow these steps to ensure a smooth and beautifully finished outcome:

- Inspect the resurfaced surface: Carefully examine the resurfaced surface for any rough patches, uneven areas, or imperfections. Note any areas that require additional attention before moving forward.

- Sanding the surface: Use sandpaper or a sanding block to gently sand the entire resurfaced surface. Start with a coarse grit sandpaper and gradually switch to finer grits to achieve a smooth finish. Sanding will not only remove any roughness but also help blend any seams or edges for a seamless appearance.

- Remove sanding residue: After sanding, wipe away any sanding residue or dust from the surface using a damp cloth or sponge. This will ensure a clean surface for the next step of the finishing process.

- Apply a sealer (if necessary): Depending on the type of resurfacing material you have used, it may be necessary to apply a sealer to protect and enhance the surface. Follow the manufacturer’s instructions regarding the use of sealers, as some materials may not require this step.

- Paint or stain the surface (optional): If desired, you can further customize the appearance of your resurfaced fireplace by painting or staining the surface. Choose a paint or stain that is specifically formulated for use on fireplaces and follow the manufacturer’s instructions for proper application. Apply multiple coats as needed, allowing each coat to dry thoroughly before applying the next.

- Polish or buff the surface (if applicable): Some resurfacing materials may benefit from polishing or buffing to achieve a glossy or satin finish. Follow the manufacturer’s recommendations and use appropriate tools or products to achieve the desired level of shine.

- Final inspection: Once the finishing touches are complete, inspect the surface for any remaining flaws or areas that require touch-ups. Address any issues to ensure a flawless final result.

By taking the time to smooth and finish the surface of your resurfaced fireplace, you can achieve a refined and professional look. This step will help enhance the visual appeal and ensure a durable and long-lasting finish for your fireplace.

Remember to refer to the manufacturer’s instructions for any specific guidelines or recommendations regarding the finishing process. Each resurfacing material may have unique requirements, and following the instructions will help you achieve the best possible outcome.

Step 7: Final Touches and Maintenance

With your fireplace beautifully resurfaced, there are a few final touches and maintenance steps to ensure its long-lasting beauty and functionality:

- Paint or stain touch-ups: Inspect the resurfaced fireplace for any areas that may require touch-ups in the paint or stain. Carefully apply the appropriate touch-up product to ensure a consistent and seamless appearance.

- Protective coatings (if applicable): Depending on the type of resurfacing material used, applying a protective coating may be beneficial. Check with the manufacturer’s instructions to determine whether a protective sealant or coating should be applied to enhance durability and longevity.

- Clean and maintain the resurfaced fireplace: Regular cleaning is essential to keep your resurfaced fireplace looking its best. Use a soft cloth or sponge and mild cleaning solution to remove any dirt or debris. Avoid using abrasive cleaners or tools that may damage the surface. Additionally, be mindful of any specific cleaning instructions provided by the manufacturer for your chosen resurfacing material.

- Monitor for signs of wear or damage: Over time, your resurfaced fireplace may experience wear or minor damage. Keep an eye out for any cracks, chips, or areas that may require repair. Promptly address any issues to prevent further damage and maintain the appearance of your fireplace.

- Follow proper maintenance guidelines: Follow any specific maintenance guidelines provided by the manufacturer of the resurfacing material. This may include recommendations for cleaning, refinishing, or applying protective coatings. Adhering to these guidelines will help prolong the life and appearance of your resurfaced fireplace.

- Enjoy your newly resurfaced fireplace: With proper care and maintenance, your resurfaced fireplace will continue to enhance the ambiance and aesthetics of your space. Take the time to enjoy its beauty and the warmth it brings to your home.

By incorporating these final touches and adopting a regular maintenance routine, you can ensure that your resurfaced fireplace remains a stunning focal point in your living space. Regular cleaning, vigilant monitoring, and prompt repairs will help maintain its appearance and functionality for years to come.

Remember, if you have any specific questions or concerns regarding the maintenance or care of your resurfaced fireplace, consult the manufacturer’s instructions or seek advice from professionals in the field.

Conclusion

Resurfacing your fireplace can be a rewarding and transformative project that breathes new life into your living space. By following the steps outlined in this comprehensive guide, you have learned how to gather the necessary materials, prepare the fireplace surface, clean it, repair any damage, apply the resurfacing material, smooth and finish the surface, and add the final touches. Each step plays a vital role in achieving a professional and visually appealing result.

Remember, the success of your resurfacing project relies on careful preparation, attention to detail, and the use of high-quality materials. Take the time to thoroughly clean and inspect your fireplace before starting the resurfacing process. Repair any damage and apply the resurfacing material with precision and care, ensuring an even and durable finish. Smooth and finish the surface, paying attention to the specific recommendations for your chosen resurfacing material, and consider adding protective coatings or performing regular maintenance to keep your fireplace looking its best for years to come.

Throughout the resurfacing process, be sure to follow the manufacturer’s instructions for the specific resurfacing material you have chosen. They will provide valuable guidance and ensure that you achieve the desired results. If you encounter any major structural issues or are unsure about any aspect of the project, it is always advisable to consult with professionals who can provide expert advice and assistance.

By taking the time and effort to resurface your fireplace, you can create a stunning centerpiece that adds charm and character to your home. Enjoy the warmth and ambiance it provides while reveling in the visual transformation you have accomplished. So go ahead, get started on your fireplace resurfacing project and witness the incredible difference it can make in your living space.

Frequently Asked Questions about How To Resurface Fireplace

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Resurface Fireplace”