Home>Furniture>Kitchen Furniture>What To Do If Your Kegerator Runs Out Of Co2

Kitchen Furniture

What To Do If Your Kegerator Runs Out Of Co2

Modified: March 1, 2024

If your kegerator runs out of CO2, don't panic! Read our articles for expert tips on how to handle this situation and get your beer flowing again.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the wonderful world of kegerators! These beer dispensing systems are a great addition to any home or commercial space, allowing you to enjoy draft beer at its freshest. However, one of the frustrating situations kegerator owners may encounter is running out of CO2. When that happens, you may find yourself wondering what to do next. In this article, we’ll explore the steps you can take to resolve this issue and get your kegerator back up and running.

But first, let’s have a quick overview of how CO2 functions in a kegerator. Carbon dioxide, or CO2, is an essential component of a kegerator that allows the beer to be carbonated and dispensed under pressure. The CO2 is stored in a tank, which is connected to the kegerator system through a regulator. The regulator controls the flow of CO2, ensuring that the beer is dispensed at the desired carbonation level.

Now that we understand the role of CO2 in a kegerator, let’s dive into the signs that indicate your CO2 might be running low.

Key Takeaways:

- Regularly monitor CO2 levels, check for leaks, and bleed air from the system to maintain optimal carbonation and dispensing in your kegerator. Safety and diligence are crucial for a delightful beer experience.

- If DIY troubleshooting steps don’t resolve CO2 issues, seek professional help for expert diagnostics and efficient solutions. Ensure a steady supply of CO2 for a smooth and enjoyable kegerator experience.

Read more: How To Build A Co2 Kegerator

Understanding CO2 in a Kegerator

Before we discuss how to handle a kegerator running out of CO2, it’s essential to have a good understanding of how CO2 operates within the system.

As mentioned earlier, CO2 is responsible for carbonating and pressurizing the beer in the kegerator. When the keg is connected to the system, the regulator allows CO2 to flow into the keg, creating the desired level of carbonation. The pressure from the CO2 also helps to push the beer out of the keg and through the faucet.

CO2 is stored in a tank, typically made of aluminum or steel. The tank is pressurized, allowing the gas to remain in a liquid form. The gas is then released from the tank as needed, passing through the regulator, which controls the pressure and flow rate.

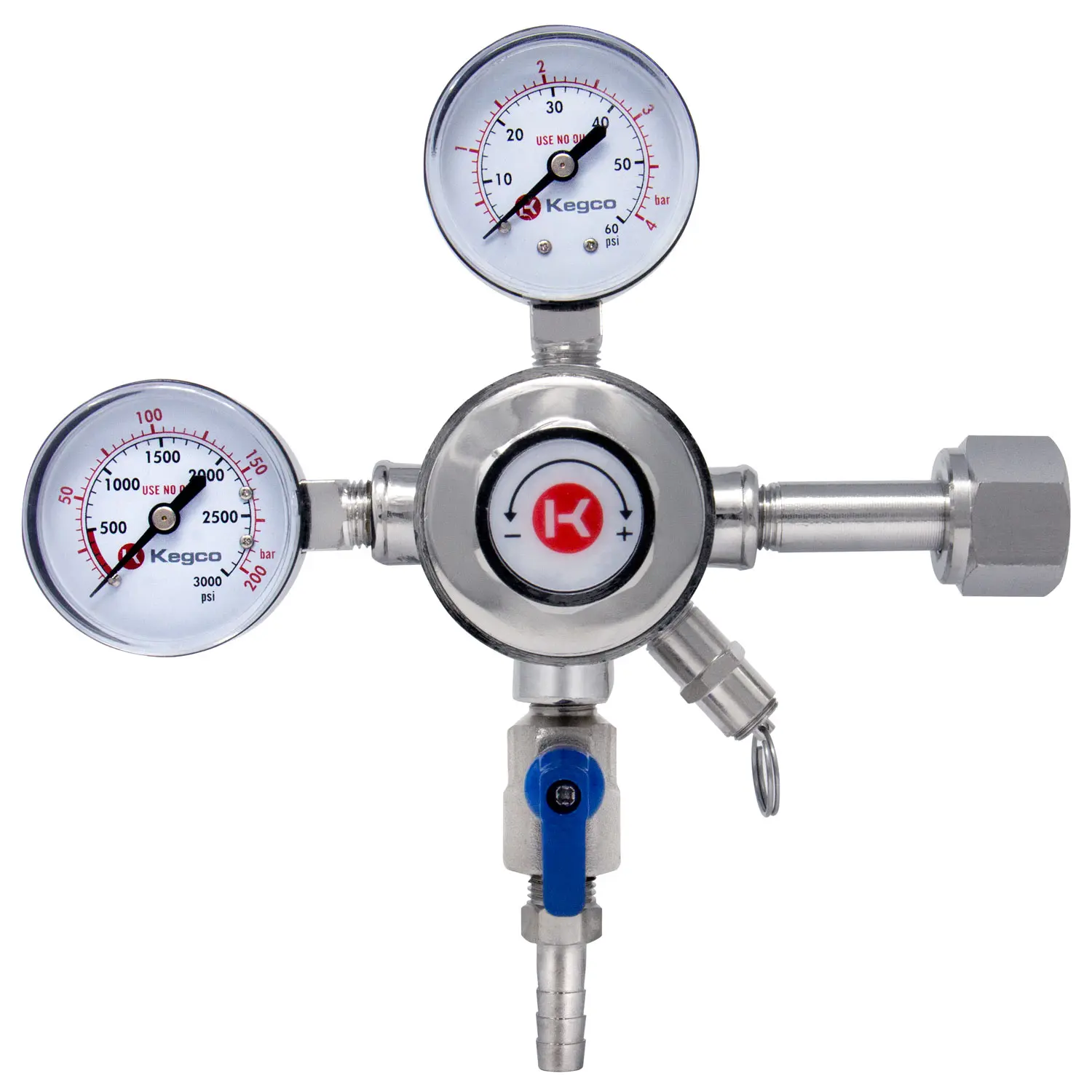

The regulator is an essential component of the kegerator. It attaches to the CO2 tank and has a gauge that displays the pressure level. It also has an adjustment knob that allows you to increase or decrease the pressure as needed. The regulator ensures that the right amount of CO2 is delivered to the keg, resulting in proper carbonation and dispensing of the beer.

It’s important to handle CO2 tanks with care, as they are under pressure. Proper storage and handling are necessary to ensure safety. CO2 tanks should always be securely mounted to prevent them from falling or rolling. Additionally, they should be kept away from heat sources and direct sunlight to avoid potential damage.

Now that we have a better understanding of how CO2 works in a kegerator, let’s move on to discussing the signs that indicate your CO2 might be running low.

Signs of CO2 Running Out

When your kegerator runs out of CO2, there are a few key signs that you can look out for. Recognizing these signs early on will help you address the issue promptly and ensure a continuous supply of refreshing draft beer.

1. Flat or Low Carbonation: One of the most obvious signs that your CO2 is running out is when the beer lacks carbonation. If you notice that the beer coming out of the faucet is flat, without any bubbles or foam, it’s a clear indication that the keg is not receiving enough pressure to carbonate the beer properly. Low carbonation can result in a lackluster drinking experience and diminish the overall flavor profile of the beer.

2. Slow Dispensing: Another sign of a dwindling CO2 supply is when the beer takes a longer time to pour. If you find that the beer is trickling out of the faucet rather than flowing smoothly, it’s a sign that the pressure in the system is decreasing. This slow dispensing can be frustrating, especially when you’re serving multiple guests or trying to fill up your glass.

3. Pressure Gauge Reading: Your kegerator’s regulator is equipped with a pressure gauge that indicates the amount of CO2 remaining in the tank. Regularly checking the gauge will give you a good idea of the CO2 levels and when it’s time to consider refilling or replacing the tank. If the pressure gauge shows a significant drop in pressure or reaches the red zone, it’s a clear signal that your CO2 supply is running low.

4. Shorter Duration Between Refills: If you find yourself refilling your CO2 tank more frequently than usual, it’s a strong indication that it’s running out faster than before. Pay attention to how often you need to replenish the CO2 and compare it to the average duration between refills. A shorter time frame between refills suggests that your CO2 usage has increased or that there may be a leak in the system.

5. Strange Noises: If you hear unusual sounds coming from your kegerator, such as hissing or leaking noises, it could be a sign of a CO2 leak. When CO2 is leaking from the system, you not only lose precious gas, but it can also affect the pressure and carbonation levels in the keg. Identifying and addressing leaks promptly can help conserve your CO2 supply and prevent further complications.

Now that we’ve discussed the signs of a CO2 running out, let’s move on to troubleshooting steps to get your kegerator back in action.

Troubleshooting Steps

If you’ve determined that your kegerator is running out of CO2, there are several troubleshooting steps you can take to address the issue. These steps will help you identify the cause and resolve the problem, allowing you to enjoy your favorite draft beer once again.

1. Check CO2 Tank: The first step is to inspect the CO2 tank. Ensure that the tank is not completely empty by checking the pressure gauge. If the gauge shows low pressure or is in the red zone, it’s time to either refill or replace the CO2 tank.

2. Inspect CO2 Lines: Examine the CO2 lines for any visible signs of damage or leaks. Look for cracks, loose connections, or hissing sounds that might indicate CO2 escaping from the system. Tighten any loose connections and replace damaged lines if necessary.

3. Verify CO2 Regulator: Check the CO2 regulator to ensure it is working correctly. Make sure the adjustment knob is properly set, allowing the right amount of pressure to flow into the keg. If necessary, adjust the regulator to achieve the desired carbonation levels. If the regulator is faulty or not functioning properly, it may need to be replaced.

4. Bleed Air from the System: There may be air trapped in the lines or keg, affecting the carbonation and dispensing process. To remove this air, you can bleed the system. Start by turning off the CO2 supply, then slowly release the pressure in the keg by opening the relief valve or tapping the keg’s pressure release. Once the pressure is released, close the valve and turn on the CO2 supply again.

5. Conduct Leak Test: To identify any potential leaks in the system, you can perform a leak test. Mix a solution of water and dish soap and apply it to the connections, valve stems, and regulator. If you see bubbles forming, it indicates a leak. Tighten the connection or replace any faulty parts to resolve the issue.

6. Seek Professional Help: If you’ve gone through the troubleshooting steps and are still experiencing issues with your kegerator, it may be time to seek professional assistance. A professional technician can inspect and diagnose the problem more thoroughly, ensuring a proper resolution.

By following these troubleshooting steps, you’ll have a better chance of identifying and resolving the issue causing your kegerator to run out of CO2. Remember, it’s always best to address the problem as soon as possible to avoid any further disruption to your beer enjoyment.

In the next sections, we’ll delve into specific options you can take, starting with replacing or refilling your CO2 tank.

Option 1: Replacing or Refilling CO2 Tank

When your kegerator runs out of CO2, one of the first and most straightforward options is to replace or refill the CO2 tank. This ensures a fresh supply of gas that will allow you to properly carbonate and dispense your beer.

If you have a spare CO2 tank on hand, you can simply swap out the empty tank with a filled one. This is a quick and convenient solution, especially if you regularly keep a backup CO2 tank. Make sure to securely attach the new tank to the regulator, taking care to tighten the connections properly.

On the other hand, if you don’t have a spare CO2 tank, you’ll need to get the empty tank refilled. To do this, you can visit a local gas supplier, homebrew supply store, or even some liquor stores that offer CO2 tank refilling services. They will have the necessary equipment to safely refill your CO2 tank to the appropriate pressure level.

When getting your CO2 tank refilled, it’s essential to follow safety protocols. Ensure the tank is inspected and certified for a safe refill. Avoid overfilling the tank, as this can cause pressure-related hazards. And always securely fasten the tank to the kegerator, taking precautions to prevent any accidental falls or damage.

It’s also a good idea to keep track of your CO2 tank’s usage and refill schedule. This will help you plan ahead and ensure that you have a continuous supply of CO2 for your kegerator. Regularly check the pressure gauge on the regulator to monitor the remaining CO2 levels and refill as needed to avoid any unexpected shortages.

Now that you’re familiar with the option of replacing or refilling your CO2 tank, let’s move on to another troubleshooting step: checking for CO2 leaks in the system.

If your kegerator runs out of CO2, you can temporarily dispense beer using a hand pump or CO2 cartridge system. However, it’s best to refill the CO2 tank as soon as possible to maintain the quality of your beer.

Read more: How Adjust Co2 Kegerator

Option 2: Checking for CO2 Leaks

If your kegerator is running out of CO2 faster than usual or experiencing a decline in pressure, there may be a CO2 leak in the system. Identifying and resolving leaks is crucial to ensure a steady supply of CO2 and the optimal functioning of your kegerator.

Here are the steps to check for CO2 leaks in your kegerator:

1. Prepare a Soap Solution: Mix a solution of water and dish soap in a spray bottle or bowl. Ensure the solution is well-mixed and ready for use.

2. Turn Off CO2 Supply: Before starting the leak check, make sure to turn off the CO2 supply to eliminate any potential risks or accidents.

3. Inspect Connections: Begin by inspecting all the connections in the kegerator system. Check the connection between the CO2 tank and the regulator, as well as the connections between the regulator and the CO2 lines. Look for any visible signs of leaking gas, such as bubbles or hissing sounds.

4. Apply Soap Solution: Using the soap solution you prepared earlier, spray or apply it to the connections, valve stems, and regulator. Be thorough in covering all the potential areas where leaks may occur.

5. Observe for Bubbles: After applying the soap solution, carefully observe the areas you treated. If there is a CO2 leak, you will see bubbles forming, indicating the presence of escaping gas. Pay special attention to the connections and valves, as these are common areas where leaks tend to occur.

6. Tighten or Replace: If you detect any leaks, tighten the connections as necessary to seal them properly. If tightening the connections doesn’t resolve the issue, it may be necessary to replace faulty parts, such as damaged lines or worn-out seals. Addressing leaks promptly will prevent further CO2 wastage and will ensure that your kegerator operates efficiently.

Remember, even small leaks can result in a significant loss of CO2 over time, affecting the carbonation and pressure levels in the keg. It’s essential to conduct regular leak checks to minimize CO2 wastage and maximize the enjoyment of your draft beer.

If you’ve performed the leak check and resolved any issues, but your kegerator is still running out of CO2, consider the next troubleshooting step: bleeding air from the system.

Option 3: Bleeding Air from the System

If you’re experiencing issues with your kegerator’s CO2 levels, such as inconsistent carbonation or slow dispensing, there may be trapped air in the system. Bleeding air from the system is a simple yet effective way to restore proper CO2 flow and resolve these problems.

Here’s how you can go about bleeding air from your kegerator:

1. Prepare a Container: To catch any liquid that may be released during the process, place a container or towel underneath the relief valve or pressure release on the keg.

2. Turn Off CO2 Supply: Before bleeding air from the system, make sure to turn off the CO2 supply to prevent any unexpected release of gas or pressure.

3. Release Pressure: Locate the relief valve or pressure release on the keg. Slowly open the valve to release the pressure from the keg. You may hear a hissing sound as the CO2 escapes. Keep the valve open until all the pressure has been released.

4. Close Valve: Once the pressure has been released, close the relief valve or pressure release. Ensure it is tightly closed to prevent any further air from entering the system.

5. Turn On CO2 Supply: After successfully bleeding the air from the system, you can now turn on the CO2 supply again. Slowly open the valve to allow CO2 to flow into the system. Be cautious not to introduce too much pressure to avoid over-carbonating the beer.

By bleeding air from the kegerator system, you are helping to eliminate any trapped air pockets that can interfere with proper carbonation and dispensing. This process allows the CO2 to effectively penetrate the beer, ensuring the desired levels of carbonation and a smoother pouring experience.

If bleeding air from the system doesn’t resolve the CO2 issues in your kegerator, consider the next option: adjusting the CO2 regulator.

Option 4: Adjusting CO2 Regulator

If your kegerator is experiencing issues with CO2 levels, such as over-carbonation or under-carbonation, adjusting the CO2 regulator might be the solution. The CO2 regulator controls the amount of pressure applied to the keg, which directly affects the carbonation level of the beer. By making the necessary adjustments, you can achieve the desired carbonation for a perfect pint.

Here’s how you can adjust the CO2 regulator on your kegerator:

1. Understand the Ideal Carbonation Level: Before making any adjustments, it’s important to know the optimal carbonation level for the style of beer you’re serving. Different beer styles have varying levels of carbonation, ranging from light and crisp to heavy and fizzy. Consult a reliable source or beer style guidelines to determine the appropriate carbonation level.

2. Turn Off CO2 Supply: Ensure that the CO2 supply to the kegerator is turned off before you make any adjustments to the regulator. This eliminates any potential risks or sudden release of gas.

3. Locate the Adjustment Knob: The CO2 regulator is equipped with an adjustment knob that controls the pressure. It is usually located on top of the regulator. Familiarize yourself with the knob for the next step.

4. Adjust the Pressure: To increase the carbonation level, start by turning the adjustment knob clockwise. Make small adjustments, a quarter-turn at a time, and allow some time for the pressure to stabilize before making further changes. If you want to decrease the carbonation level, turn the adjustment knob counterclockwise in small increments.

5. Monitor Carbonation: After each adjustment, observe the carbonation level by pouring a small sample of beer into a glass. Take note of the resulting carbonation level and taste. Continue making adjustments until you reach the desired carbonation level.

6. Be Patient: It’s important to be patient when adjusting the CO2 regulator. Carbonation changes take time to fully develop. Allow the beer to sit for a while after each adjustment before evaluating the carbonation level. This will ensure accurate assessment of the changes made.

Remember, it’s crucial to make gradual adjustments to avoid over-carbonation or sudden changes in pressure. Take your time and be attentive to achieve the perfect carbonation level for your specific beer style.

If adjusting the CO2 regulator doesn’t address the CO2 issues in your kegerator, it may be necessary to consider the final troubleshooting option: seeking professional help.

Option 5: Seeking Professional Help

If you’ve tried the previous troubleshooting steps and are still experiencing issues with your kegerator’s CO2 supply, it may be time to consider seeking professional help. An experienced technician can provide expert guidance, diagnose the problem accurately, and offer the most appropriate solution for your specific situation.

Here are the benefits of seeking professional help for your kegerator:

1. Expert Knowledge: Professional technicians specialize in kegerator maintenance and repair, and they have extensive knowledge of the inner workings of these systems. They understand the complexities of CO2 systems, including regulators, valves, and connections. By relying on their expertise, you can be confident that the issue will be properly diagnosed and resolved.

2. Proper Equipment: Professional technicians have access to specialized tools and equipment that are necessary for thorough diagnostics and repairs. They can quickly and accurately identify any leaks, pressure problems, or component malfunctions within your kegerator.

3. Time and Cost Efficiency: While attempting to troubleshoot and repair your kegerator on your own may seem like a cost-saving measure, it can be time-consuming and may result in further damage if not done correctly. By turning to a professional, you can save time and avoid costly mistakes. Their expertise allows them to efficiently pinpoint the problem and provide a precise solution, ultimately saving you both time and money in the long run.

4. Peace of Mind: By seeking professional help, you gain peace of mind knowing that a skilled technician is handling the issue. They will ensure that your kegerator is functioning optimally, allowing you to enjoy your favorite beer without any worries or frustrations.

When reaching out to a professional technician, it’s helpful to provide them with detailed information about the symptoms you’ve experienced, the troubleshooting steps you’ve already taken, and any other relevant details. This will assist them in diagnosing the problem more efficiently and accurately.

Remember, seeking professional help is a valuable option if the DIY troubleshooting steps have not resolved the CO2 issues in your kegerator. Their expertise and specialized equipment can provide a comprehensive solution and help restore your kegerator to its optimal performance.

As we conclude this article, we hope that the troubleshooting steps and options discussed have empowered you to address CO2-related issues in your kegerator. Remember, proper maintenance and regular checks will help you maintain a consistent supply of CO2 and ensure a delightful draft beer experience.

Read more: Where To Get Co2 For A Kegerator

Conclusion

Running out of CO2 in your kegerator can be a frustrating experience, but it’s important to remember that there are solutions to get your system back up and running smoothly. By following the troubleshooting steps outlined in this article, you can identify and address the issues affecting your kegerator’s CO2 supply.

We started by understanding the role of CO2 in a kegerator and the signs that indicate it’s running low. From there, we explored several options for troubleshooting. You can replace or refill the CO2 tank, check for leaks in the system, bleed any trapped air from the system, adjust the CO2 regulator, or seek professional help if needed.

Each option offers a potential solution to the CO2 supply problem, and it’s important to be diligent and patient when troubleshooting. By taking the time to properly diagnose and address the issue, you can ensure that your kegerator continues to deliver perfectly carbonated and refreshing draft beer.

Remember, safety should always be a top priority when handling CO2 tanks. Proper storage, securely mounting the tanks, and following safety protocols for refills are crucial to avoid accidents or damage to the kegerator system.

Whether you’re a homebrew enthusiast or a commercial establishment with a kegerator, maintaining a steady supply of CO2 is vital for an enjoyable beer experience. By being proactive in monitoring CO2 levels, conducting routine checks, and promptly addressing any issues, you can keep your kegerator running smoothly for years to come.

If you’re unsure about troubleshooting steps or need assistance, don’t hesitate to seek professional help. Experienced technicians can provide expertise, proper diagnostics, and the right solutions for your specific kegerator needs.

We hope that this article has provided you with valuable insights into handling CO2-related issues in your kegerator. Cheers to keeping your beer flowing and your glass always full!

Frequently Asked Questions about What To Do If Your Kegerator Runs Out Of Co2

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What To Do If Your Kegerator Runs Out Of Co2”