Home>Articles>When Replacing A Water Pump What Else Should You Replace?

Articles

When Replacing A Water Pump What Else Should You Replace?

Modified: February 27, 2024

Discover the important components to replace when replacing a water pump. Read our informative articles and ensure a thorough replacement process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

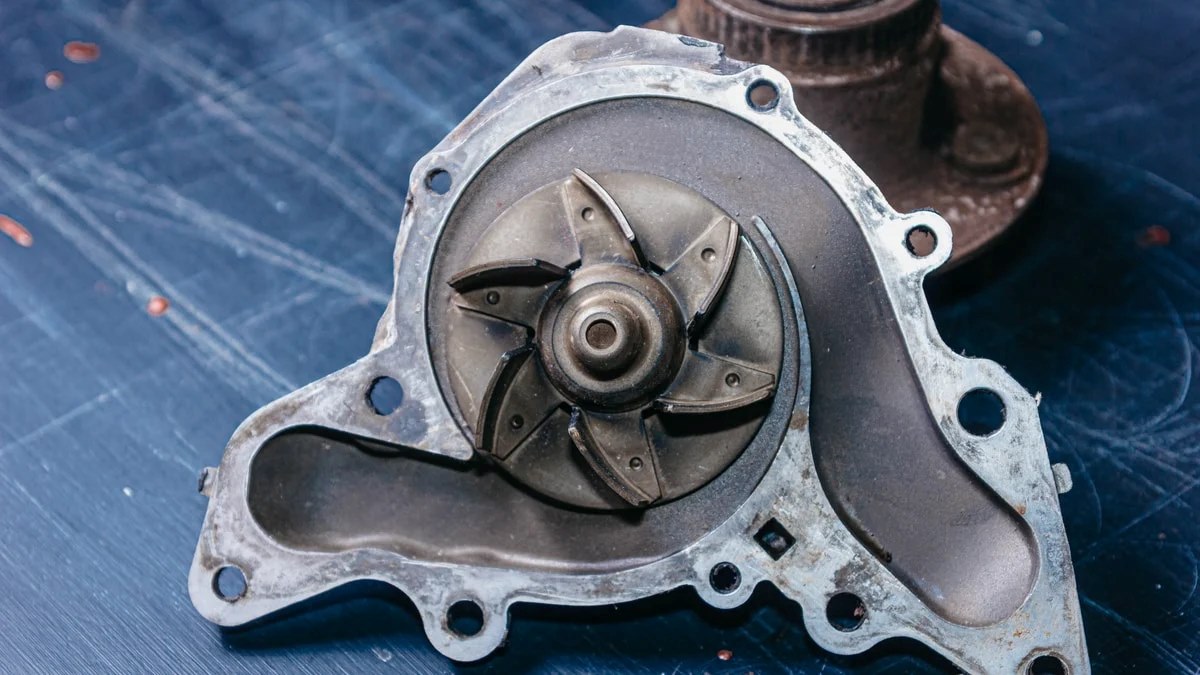

Replacing a water pump is a common maintenance task that vehicle owners may need to undertake at some point. The water pump plays a critical role in the cooling system of a vehicle, ensuring that the engine operates at optimal temperatures. However, when replacing a water pump, it is important to consider other components that are closely related and may require attention as well.

In this article, we will explore the importance of replacing a water pump and discuss the components that should be addressed when undertaking this maintenance task. By understanding the interdependencies between these components, you can ensure the longevity and efficiency of your vehicle’s cooling system.

So, let’s dive in and discover why it’s essential to consider more than just the water pump when completing this repair.

Key Takeaways:

- Don’t overlook related components when replacing a water pump. Belts, thermostat, coolant, hoses, radiator, and timing belt/chain are crucial for optimal cooling system performance and engine longevity.

- Addressing belts, coolant, hoses, and more during water pump replacement ensures efficient cooling and prevents potential engine damage. Regular maintenance of related components is key to a healthy vehicle cooling system.

Importance of Water Pump Replacement

The water pump is a vital component of a vehicle’s cooling system. Its primary function is to circulate coolant throughout the engine, allowing it to maintain optimal operating temperatures. Over time, water pumps can wear out, leading to leaks, decreased performance, and even engine damage. Therefore, replacing a faulty water pump is essential to ensure the proper functioning of the cooling system and prevent potential costly repairs.

When a water pump fails, it can result in overheating, which can cause severe damage to the engine. The engine relies on the cooling system to transfer heat away from vital components, such as the cylinders and cylinder heads. A malfunctioning water pump can disrupt this process, leading to increased friction and potential engine failure.

Furthermore, a faulty water pump can cause coolant leaks. Coolant, also known as antifreeze, is essential for maintaining appropriate engine temperatures. Leaks can lead to a loss of coolant, resulting in inadequate cooling and increased risk of overheating. Additionally, coolant leaks can contaminate other engine components and lead to corrosion and further damage.

By promptly replacing a malfunctioning water pump, you can prevent these potential issues from occurring and keep your vehicle running smoothly. Regularly inspecting the water pump for any signs of wear or leaks and addressing issues promptly can help avoid costly repairs and engine damage in the future.

However, simply replacing the water pump may not be enough to ensure the optimal functioning of the cooling system. Several other components work in sync with the water pump, and neglecting them during the replacement process can result in decreased efficiency and potential issues down the line.

Components Related to the Water Pump

When replacing a water pump, it is essential to consider other components that are closely related to its operation. Neglecting these components can compromise the overall efficiency and performance of the cooling system. Let’s take a closer look at these key components:

- Belts and Pulleys: The water pump is typically driven by a belt connected to the engine’s crankshaft. During the replacement process, it is crucial to inspect the condition of the belt and pulleys. Worn or damaged belts can cause slippage, leading to decreased water pump performance or failure. It is advisable to replace the belt if there are any signs of excessive wear or cracking. Additionally, inspect the pulleys for any signs of misalignment or damage, as this can affect the tension and operation of the belt.

- Thermostat: The thermostat regulates the flow of coolant through the engine based on its temperature. A malfunctioning thermostat can lead to improper coolant circulation, resulting in insufficient cooling or overheating. It is recommended to replace the thermostat when replacing the water pump to ensure optimal cooling system performance.

- Coolant: Coolant, or antifreeze, plays a crucial role in maintaining proper engine temperatures. When replacing the water pump, it is an ideal time to flush and replace the coolant. Over time, coolant can become contaminated or lose its effectiveness, leading to decreased cooling efficiency. Follow the manufacturer’s recommendations for the appropriate coolant type and ensure proper mixture ratios.

- Hoses: Inspect the hoses connected to the water pump for signs of wear, leaks, or damage. Over time, hoses can deteriorate, leading to coolant leaks or restricted flow. Replace any worn hoses to prevent potential issues in the future.

- Radiator: The radiator works in conjunction with the water pump to dissipate heat from the coolant. It is essential to inspect the radiator for any signs of corrosion, leaks, or blockages. Over time, debris and sediment can accumulate, hindering proper heat transfer. A compromised radiator can lead to overheating and engine damage. Consider flushing or replacing the radiator if necessary.

- Timing Belt/Chain: In some vehicles, the timing belt or chain is driven by the water pump. If the timing belt or chain is due for replacement, it is wise to address it along with the water pump replacement. Neglecting this component can lead to catastrophic engine failure if it fails while driving.

By considering and addressing these components alongside the water pump replacement, you can ensure the optimal functionality and longevity of your vehicle’s cooling system. Regular maintenance and inspection of these components can prevent costly repairs and keep your vehicle running smoothly.

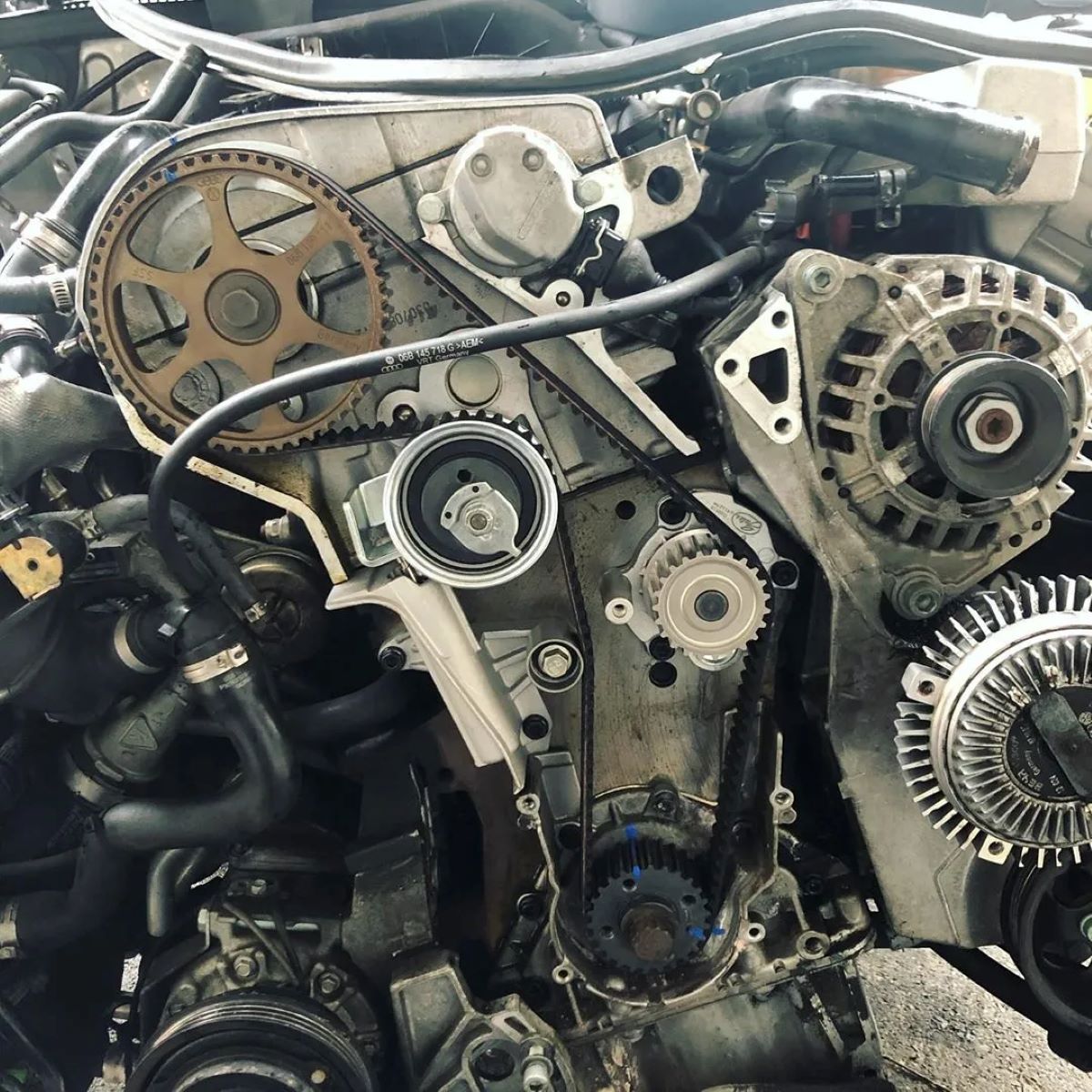

Belts and Pulleys

When replacing a water pump, it is important to pay close attention to the condition of the belts and pulleys associated with its operation. The water pump is typically driven by a belt connected to the engine’s crankshaft. This belt, commonly known as the serpentine belt, is responsible for transmitting power to various engine components, including the water pump.

Over time, belts can wear out or become damaged due to exposure to heat, friction, and age. Cracks, fraying, or signs of excessive wear are indications that the belt may need to be replaced. A worn-out serpentine belt can cause slippage or even failure, resulting in diminished performance of the water pump and other engine accessories.

In addition to inspecting the belt, it’s crucial to assess the condition of the pulleys. Pulleys are responsible for maintaining the tension and proper alignment of the belt. Any misalignment or damage to the pulleys can lead to belt slippage and decreased performance. Visually inspect the pulleys for any signs of wear, cracks, or misalignment. If any issues are detected, it is advisable to replace the pulleys to ensure optimal functionality.

During the water pump replacement process, it is recommended to replace the belt if there are any signs of wear or damage. It is a good preventive measure to avoid potential issues in the near future. Additionally, it is crucial to ensure the proper tension of the new belt. The correct tension prevents slippage and ensures the optimal operation of the water pump and other engine accessories.

To ensure a smooth replacement process, consult your vehicle’s manual or a trusted mechanic for the correct specifications and procedures for changing the serpentine belt. Consider using a belt tensioner tool to achieve the appropriate tension during installation.

Remember, neglecting the condition of the belts and pulleys when replacing the water pump can lead to decreased performance, decreased lifespan of the new water pump, and potential damage to other engine components. By inspecting and replacing the belt and addressing any issues with the pulleys, you can ensure the longevity and efficiency of your vehicle’s cooling system.

Thermostat

When replacing a water pump, it is essential to consider the condition of the thermostat. The thermostat plays a crucial role in regulating the flow of coolant through the engine based on its temperature. A malfunctioning thermostat can disrupt the proper operation of the cooling system, leading to issues such as overheating or insufficient cooling.

Over time, the thermostat can become stuck in the closed or open position, causing coolant flow problems. If the thermostat remains closed, coolant circulation is restricted, leading to inadequate cooling and potential overheating. On the other hand, if the thermostat remains open, coolant flows continuously, preventing the engine from reaching its optimal operating temperature. Both scenarios can negatively impact engine performance and efficiency.

During the water pump replacement process, it is advisable to replace the thermostat. By doing so, you ensure that the coolant flow is properly regulated and the engine remains at the optimal temperature. A new thermostat helps maintain consistent engine temperatures, preventing potential issues such as engine overheating or decreased fuel economy.

When selecting a thermostat, be sure to choose one that fits the manufacturer’s specifications for your particular vehicle make and model. Consult your vehicle’s manual or a trusted mechanic for guidance on the appropriate thermostat replacement.

To replace the thermostat, locate it on the engine. It is usually situated in the thermostat housing, which is connected to the upper radiator hose. Remove the housing, take out the old thermostat, and install the new one. Be sure to follow the manufacturer’s instructions for installation and any necessary bleeding procedures.

As a preventive measure, it is also recommended to consider replacing any associated gaskets or seals during the thermostat replacement process. This helps ensure a proper seal and prevent coolant leaks.

By addressing the thermostat when replacing the water pump, you can maintain proper coolant circulation and regulate the engine’s temperature effectively. This contributes to the overall efficiency and longevity of your vehicle’s cooling system.

When replacing a water pump, it’s a good idea to also replace the thermostat and gasket to ensure optimal performance and prevent future issues.

Read more: When Should Water Pump Be Replaced

Coolant

When replacing a water pump, it is essential to consider the condition of the coolant in your vehicle’s cooling system. Coolant, also known as antifreeze, plays a crucial role in maintaining proper engine temperatures and preventing overheating. Over time, coolant can become contaminated, lose its effectiveness, or develop acidic properties, which can compromise the performance of the cooling system.

During the water pump replacement process, it is a good opportunity to flush and replace the coolant. Flushing the system involves removing the old coolant and any accumulated debris or contaminants from the radiator, engine block, and hoses. This helps improve the efficiency of the cooling system and keeps your engine running optimally.

When selecting a coolant replacement, it is essential to choose the right type and follow the manufacturer’s recommendations for your vehicle. Different vehicles may require specific coolant formulations, such as ethylene glycol-based or propylene glycol-based coolants. Consult your vehicle’s manual or a trusted mechanic to determine the appropriate coolant for your specific make and model.

It is also important to ensure the correct mixture ratio when filling the cooling system with new coolant. Most coolants are typically mixed with water, usually in a 50/50 ratio, to achieve the optimum balance of coolant properties. This helps prevent freezing in cold weather and protects against overheating in hot conditions. Follow the manufacturer’s instructions for the proper mixing ratio and use distilled or deionized water for the best results.

Regularly checking the coolant level and quality in your vehicle is crucial for maintaining the cooling system’s efficiency. Over time, coolant can become contaminated or diluted, reducing its effectiveness in regulating engine temperatures. It is recommended to have the coolant checked and replaced at regular intervals or as specified by the manufacturer.

Additionally, inspecting the coolant reservoir and radiator for any signs of leaks, blockages, or corrosion is important during the water pump replacement process. Coolant leaks can lead to a loss of coolant and hinder the proper functioning of the cooling system. Addressing any issues promptly can prevent further damage and ensure optimal cooling system performance.

By replacing the coolant during the water pump replacement and maintaining regular coolant checks and replacements, you can effectively preserve the efficiency and longevity of your vehicle’s cooling system. Proper coolant care is essential for preventing overheating, protecting engine components, and ensuring optimal engine performance.

Hoses

When replacing a water pump, it is crucial to inspect the condition of the hoses connected to the cooling system. The hoses play a vital role in circulating coolant between the water pump, radiator, and engine, ensuring proper cooling functionality. Over time, hoses can deteriorate, develop leaks, or become weakened, compromising the efficiency and performance of the cooling system.

During the water pump replacement process, carefully inspect all the hoses for signs of wear, cracks, bulges, or soft spots. These are indications that the hoses may be nearing the end of their lifespan and need to be replaced. Additionally, pay attention to the hose clamps and ensure they are tight and secure.

Replacing the hoses when replacing the water pump is a smart preventative measure. By installing new hoses, you can eliminate the risk of sudden hose failure and coolant leaks that can lead to overheating and potential engine damage.

When selecting replacement hoses, it is essential to choose hoses that are compatible with your specific vehicle make and model. Hoses are available in different materials, such as rubber or silicone, and varying sizes to fit different cooling system configurations. Referring to your vehicle’s manual or consulting a trusted mechanic can help you select the correct hoses for your vehicle.

During hose replacement, it is advisable to apply a thin layer of coolant-safe lubricant to the hose ends and connections. This facilitates easier installation and ensures a proper seal to prevent coolant leaks.

After installing new hoses, it is crucial to check the coolant level and monitor for any signs of leaks or abnormalities. Coolant leaks can indicate issues with the hose connections or clamps, and should be addressed promptly to prevent further damage to the cooling system.

In addition to regular inspections during water pump replacement, it is wise to periodically check the hoses for any signs of wear or damage. Inspecting the hoses as part of routine maintenance can help catch any issues early and prevent potential coolant leaks or overheating.

By replacing worn or damaged hoses during the water pump replacement process and regularly inspecting them, you can ensure the proper functioning of your vehicle’s cooling system. Well-maintained hoses contribute to efficient coolant circulation, preventing overheating and protecting the engine from potential damage.

Radiator

When replacing a water pump, it is crucial to consider the condition of the radiator. The radiator plays a vital role in the cooling system by dissipating heat from the coolant. Over time, the radiator can develop issues such as corrosion, leaks, or blockages, which can hinder its ability to effectively cool the engine.

During the water pump replacement process, it is recommended to inspect the radiator for any signs of damage or deterioration. Look for corrosion on the metal fins or tubes, as well as any visible leaks or blockages. Corrosion can weaken the radiator structure and reduce heat transfer efficiency, while leaks can cause coolant loss and decrease the cooling system’s effectiveness. Blockages, such as debris or sediment buildup, can restrict coolant flow and lead to inadequate cooling.

If any issues are detected, it is advisable to address them promptly to maintain proper cooling system functionality. Depending on the extent of the damage, you may need to either repair or replace the radiator.

Repairing minor radiator damage, such as small leaks, can be done using products specifically designed for radiator repairs. These products act as sealants to fix minor leaks and improve the radiator’s integrity. However, it is important to note that while these sealants can be effective for temporary repairs, they may not be a long-term solution. If the damage to the radiator is more severe or the leaks persist, replacement may be necessary.

When replacing the radiator, consider selecting a high-quality, OEM (Original Equipment Manufacturer) or aftermarket radiator that is designed to fit your specific vehicle make and model. OEM radiators are made to the manufacturer’s specifications, ensuring proper fit and performance, while aftermarket radiators provide an alternative option that may offer improved cooling capabilities or other features.

During the radiator replacement, it is also important to flush the cooling system to remove any debris or sediment. Flushing helps to maintain optimal coolant flow and prevent future blockages that can lead to radiator and cooling system issues.

Regular maintenance of the radiator is crucial for the overall health of the cooling system. This includes inspecting the radiator periodically for any signs of damage or leaks, ensuring proper coolant levels, and performing recommended radiator flushes. By properly maintaining the radiator, you can ensure efficient heat dissipation, prevent overheating, and prolong the life of your vehicle’s cooling system.

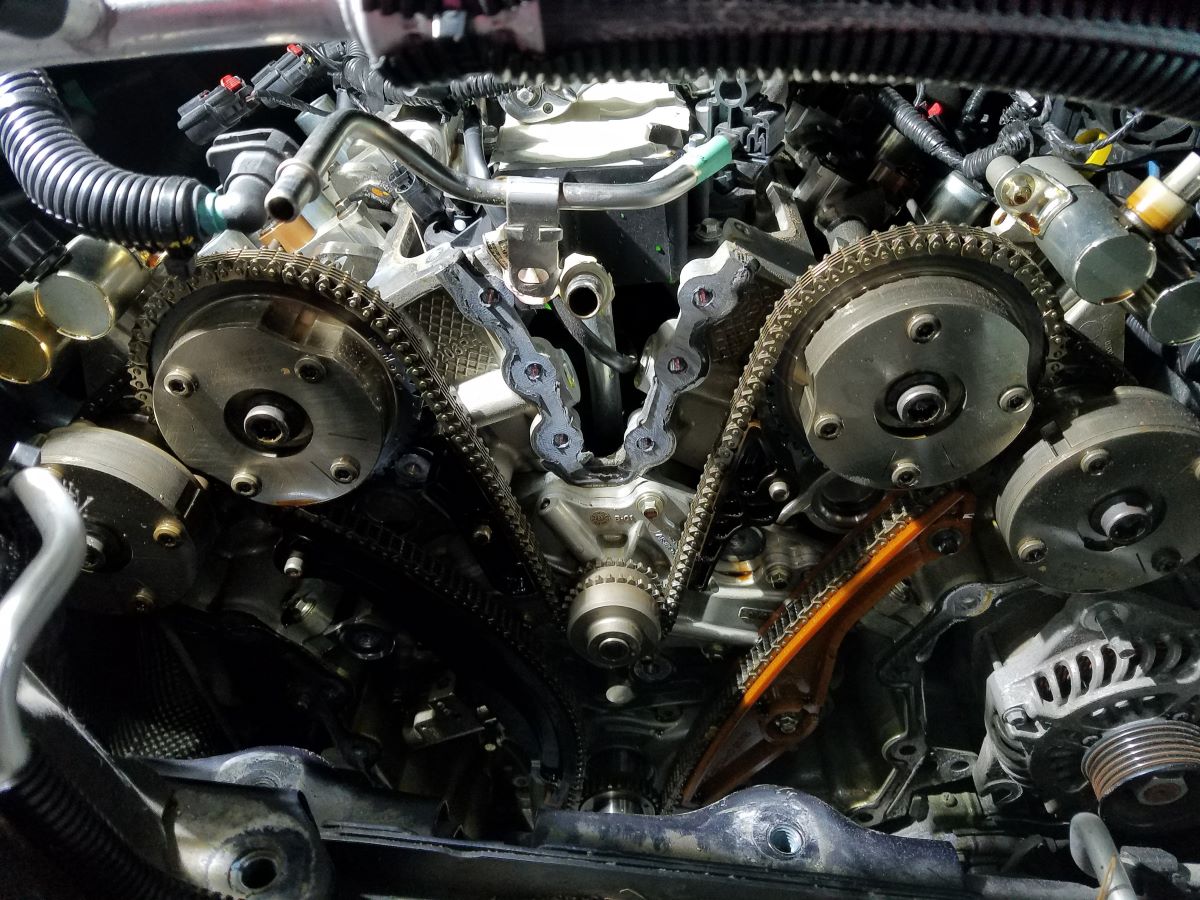

Timing Belt/Chain

When replacing a water pump, it is important to consider the condition of the timing belt or chain. While not directly related to the water pump, the timing belt/chain is often connected to the water pump and plays a vital role in the engine’s operation. Neglecting to address the timing belt/chain during the water pump replacement can result in serious engine damage if it fails unexpectedly.

The timing belt/chain synchronizes the rotation of the engine’s crankshaft and camshaft(s), ensuring that the valves open and close at the correct time in relation to the position of the pistons. This precise coordination is essential for the engine to operate smoothly. However, timing belts and chains can wear out over time, leading to potential failure and catastrophic engine damage.

Timing belts are typically made of rubber with reinforcing materials, while timing chains are metal. Both can degrade due to factors such as age, high mileage, and exposure to heat and contaminants. Signs of a worn-out timing belt/chain include cracking, fraying, or a loose or noisy chain. It is essential to follow the manufacturer’s recommendation for timing belt/chain replacement intervals, which can vary depending on the vehicle make and model.

If the timing belt/chain is due for replacement or shows signs of wear during the water pump replacement process, it is highly advisable to address it. Since the water pump is often located near the timing belt/chain, replacing it provides an opportune time to inspect and replace the timing belt/chain if necessary.

Replacing the timing belt/chain is a complex task that typically requires specialized knowledge and tools. It is recommended to have this procedure performed by a professional mechanic to ensure it is done correctly. A qualified mechanic will also inspect and replace any associated components, such as tensioners, pulleys, and seals, as needed.

By addressing the timing belt/chain during the water pump replacement, you can prevent unexpected belt/chain failure and avoid severe engine damage. Keeping up with the recommended timing belt/chain replacement intervals and following the manufacturer’s guidelines for maintenance can help ensure the longevity and reliability of your vehicle’s engine.

Read more: When Should You Replace Water Heater

Conclusion

Replacing a water pump is a crucial maintenance task that ensures the proper functioning and longevity of a vehicle’s cooling system. However, it is important to consider other components that are closely related to the water pump and its operation.

Components such as belts and pulleys, thermostat, coolant, hoses, radiator, and timing belt/chain are interconnected and play crucial roles in the cooling system. Neglecting these components during the water pump replacement can lead to decreased performance, inefficient cooling, and potential engine damage.

Inspecting and addressing the condition of belts and pulleys is essential to ensure the optimal operation of the water pump and other engine accessories. The thermostat regulates coolant flow, and replacing it during the water pump replacement process helps maintain the engine’s ideal operating temperature.

Regularly flushing and replacing coolant prevents contaminants from compromising the cooling system’s performance. Inspecting and replacing worn or damaged hoses prevents coolant leaks and ensures proper coolant circulation. The radiator dissipates heat, and maintaining its integrity is crucial for effective heat transfer.

Lastly, addressing the timing belt/chain during the water pump replacement can prevent unexpected failures that can cause severe engine damage. Proper maintenance and following recommended replacement intervals for the timing belt/chain are essential for engine reliability.

In conclusion, replacing a water pump is not just about the pump itself. It is vital to consider and address other components that work in harmony with the water pump. By doing so, you can maintain the efficiency, performance, and longevity of your vehicle’s cooling system, providing peace of mind and avoiding costly repairs down the road.

Frequently Asked Questions about When Replacing A Water Pump What Else Should You Replace?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “When Replacing A Water Pump What Else Should You Replace?”