Home>diy>Architecture & Design>What Is A Step File CAD

Architecture & Design

What Is A Step File CAD

Modified: December 7, 2023

Learn what a Step File CAD is and how it is used in architecture design. Explore the benefits and key features of this file format.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A Step File CAD, also known as a Standard for the Exchange of Product Data, is a file format used in computer-aided design (CAD) software. It is widely used for transferring 3D model data between different CAD systems. A Step file contains detailed information about the geometry, topology, and attributes of a 3D model, making it an essential tool for architects, engineers, and designers.

In this article, we will explore the concept of a Step File CAD, its history, how it works, popular software programs that use it, as well as the advantages, limitations, and common applications of Step File CAD.

So, let’s dive in and discover the world of Step File CAD!

Key Takeaways:

- Step File CAD revolutionizes design and manufacturing by enabling seamless collaboration and interoperability among different CAD software applications, enhancing efficiency and accuracy in the design process.

- Despite challenges, Step File CAD’s interoperability, standardization, and ability to preserve design data make it an invaluable tool for architects, engineers, and designers across various industries.

Read more: What Are CAD Files

Definition of a Step File CAD

A Step File CAD is a standardized file format used in computer-aided design to exchange 3D model data between different software applications. It is an industry-neutral format that allows for the seamless transfer of complex 3D models, ensuring compatibility and interoperability.

A Step File CAD contains a complete representation of the 3D model’s geometry, topology, and attributes. It encapsulates information such as solid and surface geometry, color, material properties, assembly structure, and metadata. These files are typically generated by CAD systems and can be opened and edited by other software programs that support the Step format.

The Step format, also known as ISO 10303, was developed by the International Organization for Standardization (ISO) in the early 1990s. It was created as a means to overcome the interoperability issues that arose due to the multitude of proprietary file formats used by different CAD systems. By adopting the Step format, CAD software vendors could ensure seamless data exchange between their products, enabling collaborative design and reducing the need for model translation.

Step Files CAD are widely used across various industries, including automotive, aerospace, architecture, and manufacturing. They have become the de facto standard for sharing 3D models between different CAD systems, ensuring accurate representation and consistency throughout the design and manufacturing process.

Now that we have a clear understanding of what a Step File CAD is, let’s delve into its history and evolution.

History of Step File CAD

The history of Step File CAD dates back to the early 1990s when the need for a standardized format for exchanging 3D model data became apparent. Prior to the introduction of the Step format, CAD software vendors each had their own proprietary file formats, making it challenging to share models between different systems without encountering compatibility issues.

In response to this challenge, the International Organization for Standardization (ISO) developed the Step format, formally known as ISO 10303. The Step format was designed to be an industry-neutral, platform-independent format that could be implemented by various CAD software vendors.

The development of Step File CAD was a collaborative effort involving experts from different industries and CAD software vendors. The aim was to create a standardized format that would facilitate seamless data exchange and interoperability between different CAD systems.

The initial version of the Step format, released in 1994, focused primarily on the exchange of product data. It provided a standardized way to represent and exchange 3D geometric data, as well as other relevant information such as materials, product structure, and manufacturing properties.

Over the years, the Step format has evolved and expanded to incorporate additional functionalities and support for different types of data. Updated versions of the Step format have introduced features like assembly structures, kinematics, and electrical systems, making the format more comprehensive and versatile.

Today, the Step format is widely adopted by CAD software vendors and is supported by most major CAD systems. It has become the industry standard for 3D model exchange, enabling seamless collaboration and data interoperability between different design and manufacturing software applications.

Now that we understand the history of Step File CAD, let’s explore how this format works and how it facilitates the exchange of 3D model data.

How Step File CAD Works

Step File CAD works by encapsulating 3D model data in a standardized format that can be read and interpreted by different CAD software applications. This ensures that the model’s geometry, topology, and attributes are accurately represented when transferred between systems.

The Step format utilizes a structured ASCII text file or a binary encoding to store the 3D model data. The file consists of a series of entities that describe various aspects of the model, such as geometries, surfaces, assemblies, and materials. Each entity is defined by a unique identifier and contains specific parameters that define its characteristics.

When a Step file is imported into a CAD software program, the software reads the file and reconstructs the 3D model based on the information provided. The software interprets the entity parameters and recreates the model’s geometry, including curves, surfaces, and solids.

In addition to the geometric information, the Step format also supports the inclusion of attributes such as color, material properties, and assembly structures. This allows for a comprehensive representation of the 3D model and ensures that important design data is preserved during the exchange process.

Step File CAD supports not only the transfer of individual 3D models but also the exchange of complex assemblies and hierarchical structures. This means that entire product designs can be shared, including the relationships between individual components and their spatial arrangements.

To ensure compatibility and interoperability, CAD software applications that support Step File CAD adhere to the ISO 10303 standard. This ensures that the software reads and interprets the Step file data correctly, regardless of the software’s native file format or vendor.

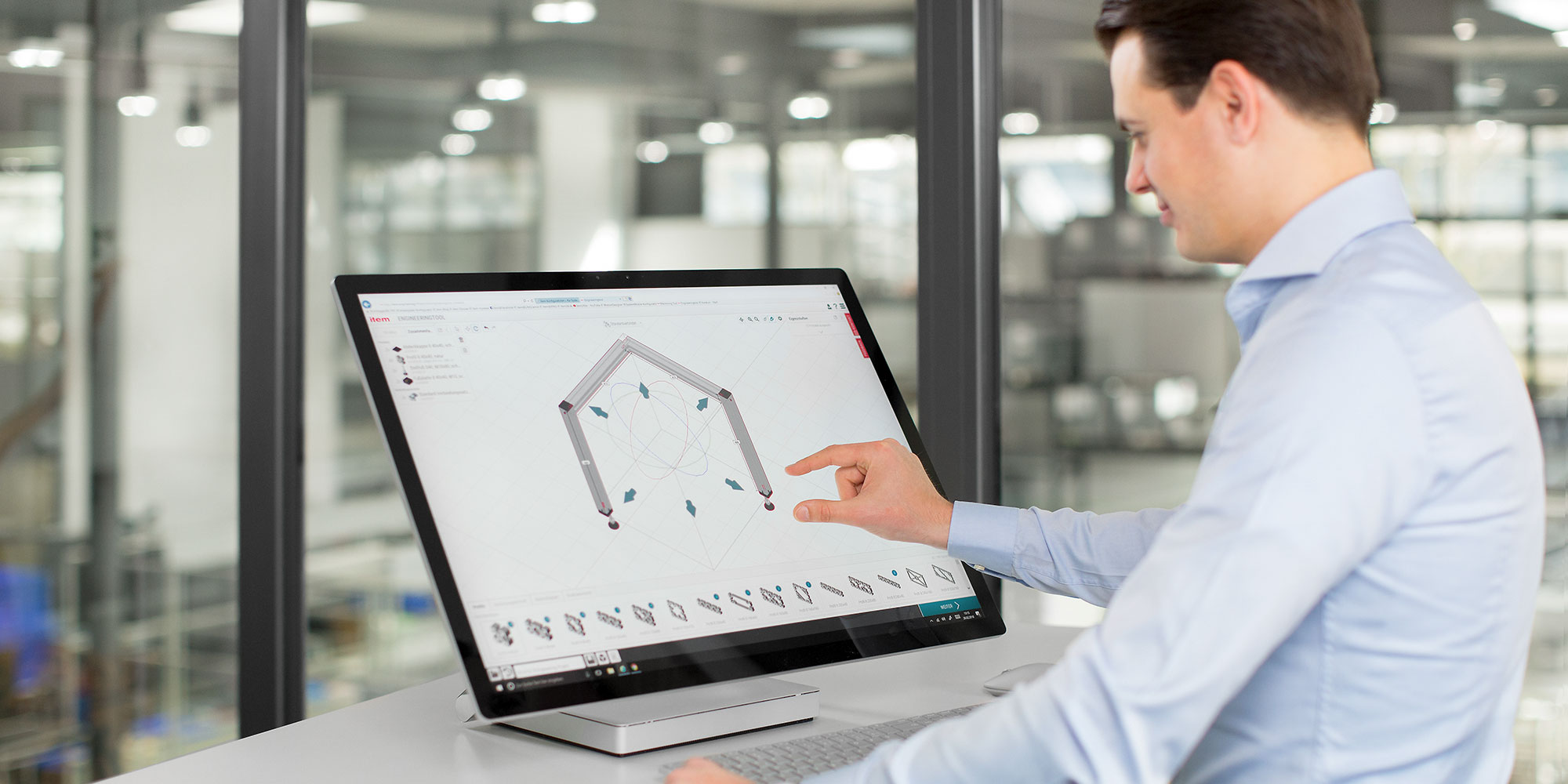

Overall, Step File CAD simplifies the process of exchanging 3D models between different CAD software applications. It eliminates the need for manual redesign, reduces errors caused by translation issues, and enables seamless collaboration between design teams using different software systems.

Now that we understand how Step File CAD works, let’s explore some popular software programs that utilize this file format.

Popular Software Programs that Use Step File CAD

Step File CAD is widely supported by various CAD software programs, making it a versatile format for exchanging 3D model data. Let’s take a look at some of the popular software programs that utilize Step File CAD:

- AutoCAD: AutoCAD is a leading CAD software program used for 2D drafting and 3D modeling. It has built-in support for Step files, allowing users to import and export models seamlessly. AutoCAD’s compatibility with Step File CAD makes it a preferred choice for architects, engineers, and designers.

- SolidWorks: SolidWorks is a powerful CAD software program known for its robust 3D modeling capabilities. It supports the Step format, enabling users to import Step files and work with them seamlessly. SolidWorks offers advanced tools for designing and modifying Step models, making it a popular choice among mechanical engineers and product designers.

- CATIA: CATIA is a comprehensive CAD and product lifecycle management (PLM) software used in industries such as aerospace, automotive, and manufacturing. It provides robust support for the Step format, allowing users to collaborate and exchange 3D models across different CAD systems.

- Fusion 360: Fusion 360 is a cloud-based CAD software program that combines 3D modeling, rendering, and simulation capabilities. It supports the Step format, making it easy to import and modify Step files. Fusion 360’s cloud-based nature enables seamless collaboration and data sharing, making it a popular choice for teams working on Step models.

- Siemens NX: Siemens NX is a comprehensive CAD/CAM/CAE software program used in industries such as automotive, aerospace, and machinery. It fully supports the Step format, allowing for the import and export of Step files. Siemens NX offers advanced features for working with Step models, making it a preferred choice for complex engineering designs.

These are just a few examples of the popular CAD software programs that support Step File CAD. In addition to these, many other CAD applications, including Rhino 3D, Creo, and Inventor, also offer support for the Step format.

Now that we know the popular software programs that utilize Step File CAD, let’s explore the advantages and benefits of using this file format.

A STEP file (Standard for the Exchange of Product model data) is a common CAD file format used for sharing 3D models between different CAD software. It’s a neutral file format that preserves the design’s geometry and can be easily exchanged between different programs.

Read more: How To Open CAD Files

Advantages and Benefits of Step File CAD

Step File CAD offers numerous advantages and benefits that contribute to its popularity and widespread adoption. Let’s explore some of the key advantages of using Step File CAD:

- Interoperability: Step File CAD ensures interoperability between different CAD software programs. It allows for the seamless exchange of 3D model data, eliminating the need for time-consuming translations or redesigns. This promotes collaboration and streamlines the design and manufacturing process.

- Standardization: Step File CAD follows the ISO 10303 standard, providing a uniform format for exchanging 3D models. The standardization eliminates the risk of compatibility issues between different CAD systems, ensuring accurate representation and consistent data interpretation.

- Preservation of Design Data: Step files encapsulate not only the geometric properties of a 3D model but also its attributes, such as colors, materials, and assembly structures. This ensures that vital design data is preserved during the exchange process, improving the integrity and accuracy of the shared models.

- Reduced Design Iterations: By using Step File CAD, design iterations can be reduced significantly. Designers and engineers can exchange models seamlessly, allowing for early collaboration, faster feedback, and fewer revision cycles. This results in streamlined design workflows and faster time-to-market.

- Compatibility with Multiple Software Programs: Step files are supported by a wide range of CAD software programs, including industry-leading applications like AutoCAD, SolidWorks, and CATIA. This compatibility allows designers and engineers using different software systems to collaborate seamlessly, regardless of their preferred CAD platforms.

- Enhanced Data Security: Step files can be encrypted and password-protected, ensuring the security of sensitive design data. This feature is particularly important when sharing models with external partners or during the transfer of intellectual property across organizational boundaries.

The advantages and benefits of Step File CAD make it an essential tool for architects, engineers, and designers across various industries. Its interoperability, standardization, and ability to preserve design data contribute to improved efficiency, collaboration, and accuracy in the design and manufacturing process.

Next, let’s explore some of the challenges and limitations associated with Step File CAD.

Challenges and Limitations of Step File CAD

While Step File CAD offers many advantages, it is important to be aware of its challenges and limitations. Understanding these can help users make informed decisions when working with Step files. Here are some of the key challenges and limitations:

- File Size and Performance: Step files can become large in size, especially for complex 3D models. This can impact file loading and processing times, leading to slower performance in CAD software. It is important to optimize models and manage file sizes to ensure smoother workflows.

- Loss of Application-Specific Data: Step files provide a standardized representation of 3D models, but they may not fully capture all the specialized information or functionalities of certain CAD software applications. Complex features, proprietary materials, or specialized operations may be lost or simplified when exporting to Step format.

- Complex Geometry Representation: Step files primarily handle geometric representation, but advanced geometries such as NURBS surfaces, splines, or parametric features may be difficult to fully represent in the Step format. This can result in a loss of precision or detail when transferring such models between CAD systems.

- Assembly Structure Complexity: Step files support assembly structures, but the representation of complex hierarchical relationships or assembly constraints may not be fully preserved. This can require additional work to recreate or modify assemblies accurately in the receiving CAD system.

- Data Integrity and Translation Errors: Although Step File CAD aims to ensure accurate data exchange, there is still a potential for translation errors or data corruption during the import/export process. It is essential to validate the integrity and accuracy of Step files when transferring between different CAD software programs.

- Compatibility with Older Versions: Since Step File CAD has evolved over the years, there can be compatibility issues when moving between different versions of the format. Some older CAD software programs may not fully support the latest version of the Step format, leading to potential data loss or inaccuracies.

Despite these challenges and limitations, Step File CAD remains a widely used and valuable format for sharing 3D models between different CAD software applications. By understanding these limitations and implementing best practices, users can mitigate potential issues and maximize the benefits of Step File CAD.

Now, let’s explore some common applications of Step File CAD in various industries.

Common Applications of Step File CAD

Step File CAD finds applications in various industries where 3D modeling and data exchange are essential. Let’s explore some of the common applications of Step File CAD:

- Automotive Industry: Step File CAD is widely used in the automotive industry for designing and manufacturing vehicles. It enables the exchange of 3D models between different design teams, suppliers, and manufacturers, facilitating collaboration and streamlining the production process.

- Aerospace Industry: The aerospace industry relies heavily on Step File CAD for designing aircraft and spacecraft components. It enables the transfer of complex 3D models between different teams involved in design, analysis, and manufacturing, ensuring accurate representation and seamless integration of various components.

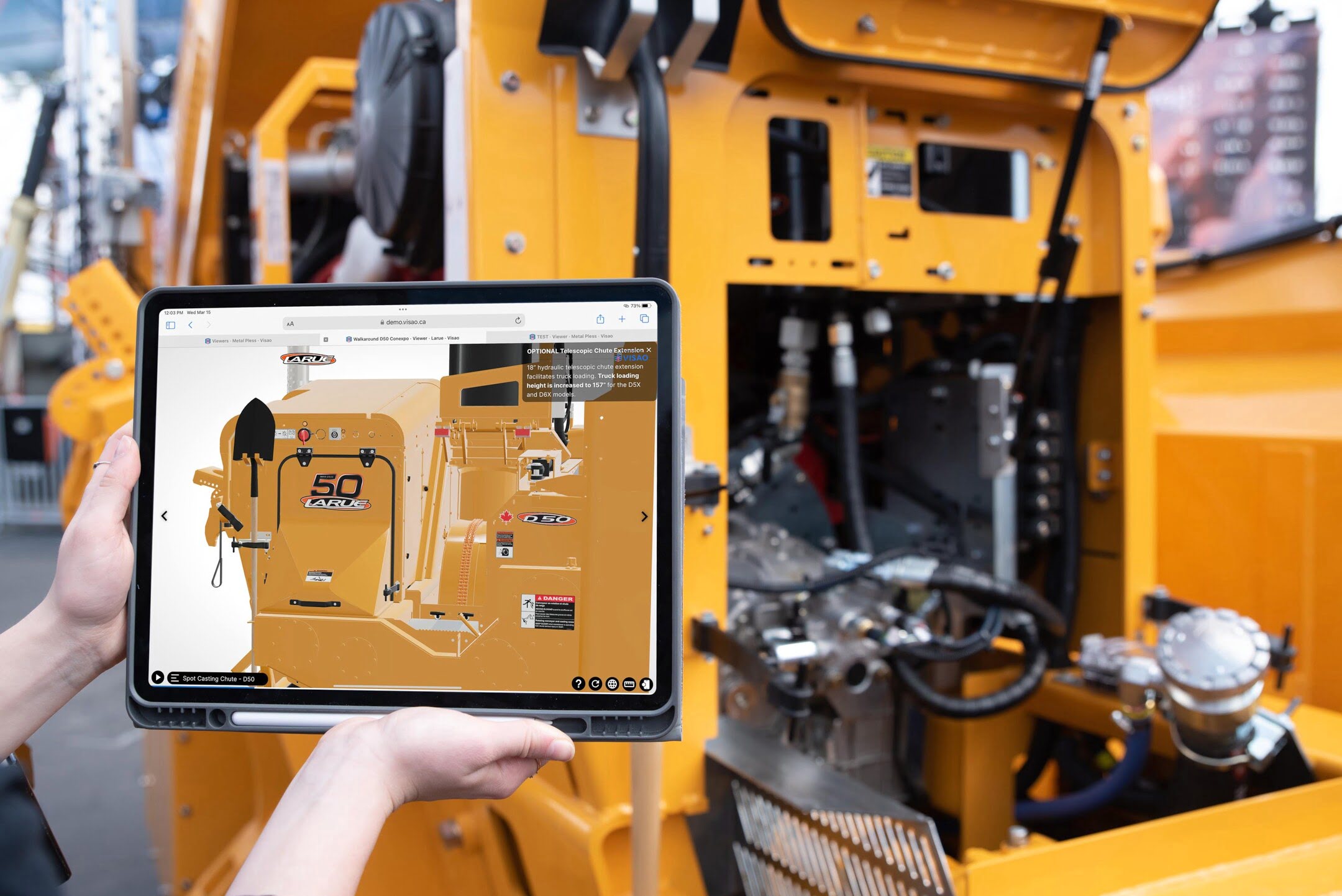

- Architectural Design: Step File CAD plays a crucial role in architectural design, allowing architects to exchange 3D models with structural engineers and contractors. It enables effective collaboration and coordination among different professionals involved in the design and construction process.

- Manufacturing and Machinery: Step File CAD is extensively used in manufacturing and machinery industries for designing and producing complex machinery and equipment. It enables manufacturers to exchange 3D models with suppliers, ensuring accurate representation and smooth integration of components.

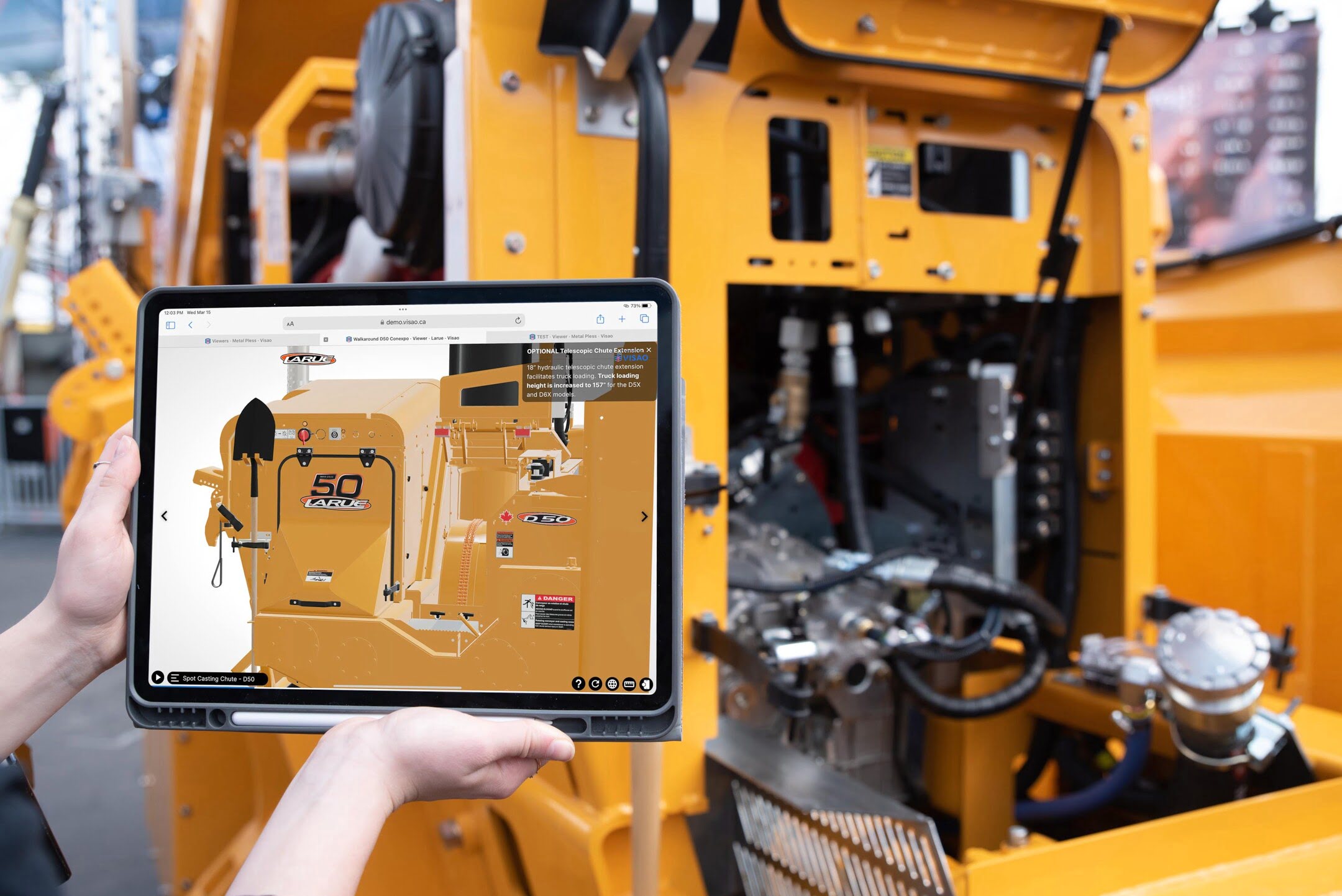

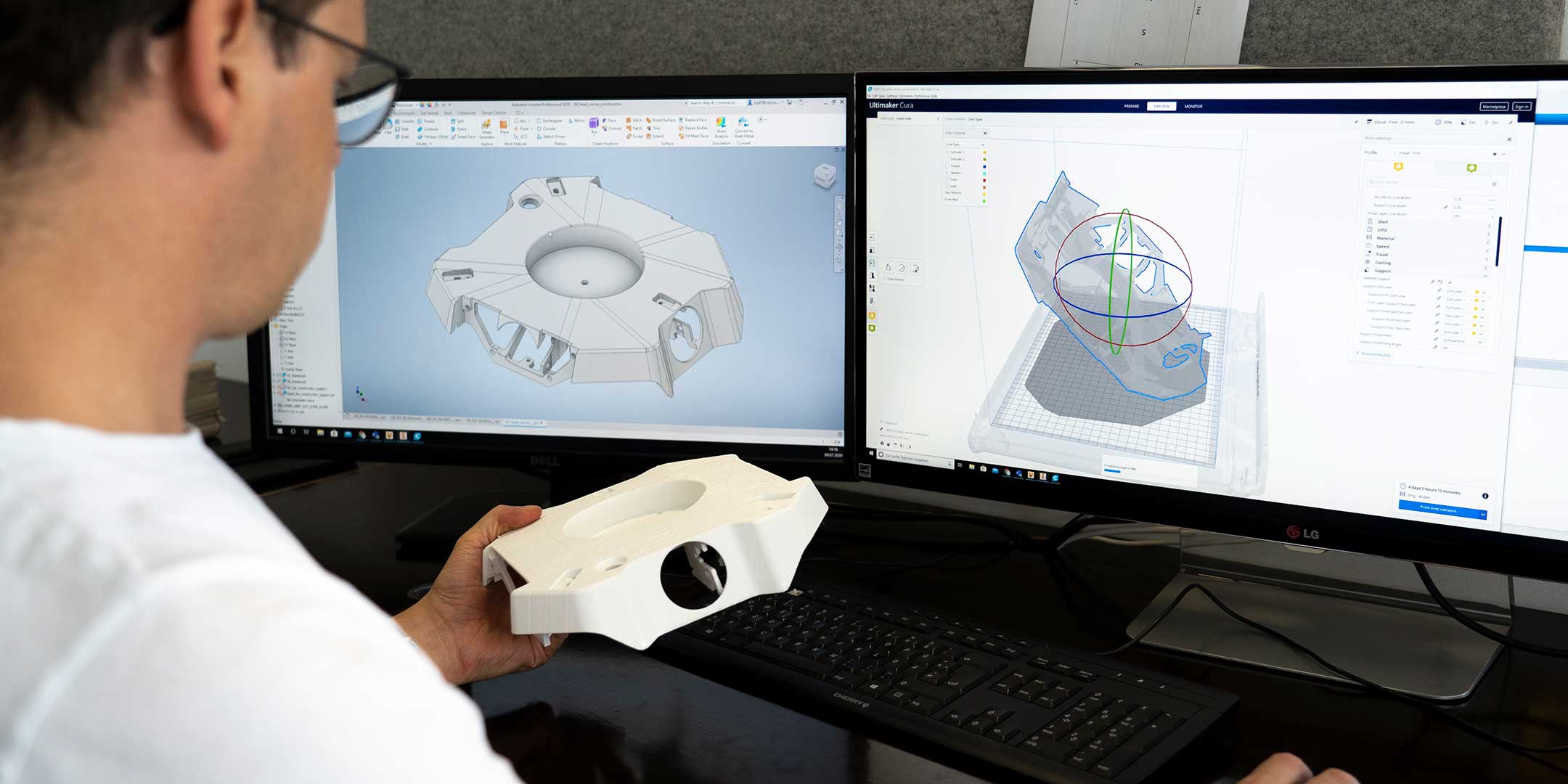

- Product Design and Prototyping: Step File CAD is an invaluable tool in product design and prototyping. It allows designers to create 3D models and easily transfer them to prototyping software or 3D printers. This enables rapid prototyping and testing of product designs, reducing time-to-market.

- Medical and Biotechnology: Step File CAD is utilized in the medical and biotechnology fields for designing medical devices, prosthetics, and other healthcare-related products. It enables the exchange of 3D models between manufacturers, clinicians, and researchers, facilitating innovation and advancements in healthcare technology.

These are just a few examples of the industries where Step File CAD finds common applications. Its versatility and compatibility with various CAD software programs make it a valuable asset in the design, manufacturing, and engineering fields.

Now let’s conclude our exploration of Step File CAD.

Conclusion

Step File CAD, or Standard for the Exchange of Product Data, is a standardized file format that facilitates the transfer of 3D model data between different CAD software applications. It has revolutionized the design and manufacturing industry by enabling seamless collaboration and interoperability among various teams and software systems.

In this article, we have explored the definition of Step File CAD, its history, how it works, popular software programs that utilize it, as well as the advantages, challenges, and common applications associated with this file format.

The advantages of Step File CAD, such as interoperability, standardization, and preserving design data, have made it an invaluable tool for architects, engineers, and designers. The format’s ability to ensure accurate representation and consistent data interpretation across different CAD systems enhances collaboration and streamlines the design and manufacturing process.

While there are challenges and limitations, such as file size, loss of application-specific data, and assembly complexity, understanding these limitations and implementing best practices can help mitigate potential issues when working with Step files.

Step File CAD finds widespread applications in industries such as automotive, aerospace, architecture, manufacturing, medical, and more. It plays a crucial role in exchanging 3D models, facilitating collaboration, and accelerating the design-to-manufacturing process.

In conclusion, Step File CAD is an essential tool for the CAD community, enabling seamless data exchange, reliable collaboration, and efficient design workflows. As technology continues to evolve, Step File CAD will continue to adapt and play a vital role in the future of design and manufacturing.

Frequently Asked Questions about What Is A Step File CAD

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Step File CAD”