Home>diy>Building & Construction>What Is Construction Grout

Building & Construction

What Is Construction Grout

Modified: December 7, 2023

Learn about construction grout and its importance in building construction. Discover how this versatile material can enhance the strength and durability of your construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of construction grout, an essential component in building and construction projects. In this article, we will explore what construction grout is, its composition, functions, types, and how it is used. We will also discuss important factors to consider when selecting construction grout, its benefits and advantages, common applications, as well as potential issues and challenges.

Construction grout is a versatile material that plays a crucial role in the stability and durability of structures. Whether you are constructing a new building, repairing cracks in existing structures, or reinforcing load-bearing elements, construction grout is a key player in ensuring the integrity of your project.

From filling gaps and voids to providing structural support, construction grout proves its versatility in a wide range of applications. Whether it’s for residential, commercial, industrial, or infrastructure projects, understanding the different aspects of construction grout will help you make informed decisions and achieve successful outcomes.

So, let’s dive into the world of construction grout, its importance in the construction industry, and how it contributes to the stability and long-term performance of various structures.

Key Takeaways:

- Construction grout is a versatile material essential for stability and durability in construction. Understanding its functions, types, and applications is crucial for informed decision-making in building projects.

- When selecting construction grout, consider factors such as application, strength requirements, and environmental conditions. Addressing potential challenges through proper mixing, curing, and quality control ensures optimal grout performance.

Read more: What Is Grouting In Construction

Definition of Construction Grout

Construction grout, also known as grouting material, is a specialized form of concrete used to fill voids, gaps, and cavities in construction projects. It is primarily composed of cementitious materials, water, and aggregates that are carefully selected to achieve the desired properties and performance.

The primary purpose of construction grout is to provide structural stability and support. It is used to fill spaces between load-bearing elements, such as columns and foundations, to ensure proper load transfer and prevent the movement or settlement of the structure. Construction grout also acts as a bonding agent between adjacent elements, creating a monolithic connection that enhances the overall strength and integrity of the structure.

Unlike regular concrete, which is commonly used for structural purposes, construction grout is typically designed to have a higher fluidity or flowability. This allows it to effectively penetrate and fill even the narrowest gaps or voids, ensuring complete contact and bond with the surrounding surfaces.

Construction grout can be categorized into two main types: cementitious grout and epoxy grout. Cementitious grout is made from a mixture of cement, sand, and water, while epoxy grout is formulated using epoxy resin and a hardener. Each type has its unique properties and characteristics that make them suitable for different applications and conditions.

Overall, construction grout is an essential material in the building and construction industry, used to provide structural stability, fill voids, repair cracks, and enhance the performance and longevity of various structures.

Composition of Construction Grout

Construction grout is composed of several key components that work together to provide the desired properties and performance. The exact composition may vary depending on the specific application and requirements, but the following are the primary components commonly found in construction grout:

- Cementitious Materials: The main binder in construction grout is typically cement, such as Portland cement or blended cements. Cement provides strength and durability to the grout mixture. Various types of cement can be used depending on the project specifications.

- Aggregates: Aggregates, such as sand or fine gravel, are added to the grout mixture to enhance its strength and improve workability. They also help to fill voids and provide stability to the grout.

- Water: Water is a vital component in construction grout as it hydrates the cement and initiates the chemical reaction that forms a hardened structure. The amount of water used must be carefully controlled to achieve the desired consistency and strength.

- Chemical Additives: Various chemical additives may be incorporated into the grout mixture to modify its properties. These additives can enhance flowability, reduce shrinkage, improve adhesion, provide corrosion resistance, or increase chemical resistance, depending on the specific requirements of the project.

The proportions of these components in the construction grout mixture are crucial and must be carefully adjusted to achieve the desired characteristics. The right balance ensures that the grout mixture is easy to work with, has the required strength and durability, and meets the project’s specified performance criteria.

In addition to these primary components, construction grout may also contain admixtures, fibers, or other specialized additives depending on the specific application. These additional materials can enhance specific properties of the grout, such as improved crack resistance, increased flowability, or enhanced bonding strength.

Overall, the composition of construction grout is carefully engineered to provide the necessary strength, durability, and desired performance characteristics required for a particular construction project.

Functions of Construction Grout

Construction grout performs several critical functions that are vital for the structural stability and integrity of construction projects. Understanding these functions will help you appreciate the importance of grout in various applications. Here are the key functions of construction grout:

- Filling Voids and Gaps: One of the primary functions of construction grout is to fill voids, gaps, and cavities in structures. These voids can occur due to uneven surfaces, gaps between structural elements, or during the installation of anchor bolts or dowels. Grout fills these spaces, ensuring a tight, solid connection and preventing the movement or settling of structural elements.

- Providing Structural Support: Construction grout provides critical structural support by transferring loads between different elements of a structure. It fills the gaps between columns and foundations, ensuring load distribution and preventing the concentration of stress in specific areas. This helps maintain the stability and safety of the entire structure.

- Creating Monolithic Connections: Grout acts as a bonding agent, creating a monolithic connection between adjacent structural elements. It bonds surfaces together, resulting in a unified structure and enhancing overall strength and durability.

- Improving Load Transfer: Grout improves the load transfer capacity of structural elements such as columns by reducing the risk of differential settlement. It ensures that the load is evenly distributed, minimizing the potential for cracks or failures.

- Reinforcing and Repairing Cracks: Construction grout is also used to reinforce and repair cracks in existing structures. By injecting grout into cracks, it effectively fills and seals them, restoring structural integrity and preventing further damage or water infiltration.

- Enhancing Fire Resistance: Certain types of construction grout, particularly those containing additives and fibers, can enhance the fire resistance of structures. The grout acts as a barrier, delaying the spread of fire and providing valuable time for evacuation and firefighting efforts.

By performing these crucial functions, construction grout contributes to the overall stability, durability, and safety of structures. It ensures that loads are properly distributed, connections are secure, and potential weaknesses or gaps are addressed, resulting in robust and reliable construction.

Types of Construction Grout

Construction grout comes in various types, each with its own unique properties and suitability for different applications and conditions. Understanding the different types of construction grout will help you choose the right one for your specific project requirements. Here are the main types of construction grout:

- Cementitious Grout: Cementitious grout is the most common type of construction grout. It is made by combining cement, sand, and water to form a paste-like consistency. Cementitious grout is versatile and can be used for a wide range of applications, including filling voids, anchoring bolts, and repairing cracks. It cures to a hardened state and provides good compressive strength. However, it may be susceptible to shrinkage and cracking in certain conditions.

- Epoxy Grout: Epoxy grout is a two-component system that consists of epoxy resin and a hardener. It offers excellent chemical resistance, high strength, and resistant to moisture absorption. Epoxy grout is commonly used in applications where durability and stain resistance are critical, such as industrial environments, food processing areas, and medical facilities. It has a longer curing time compared to cementitious grout and requires proper surface preparation and careful mixing.

- Polymer-modified Grout: Polymer-modified grout is a cementitious grout that incorporates polymer additives. These additives improve the grout’s flexibility, adhesion, and resistance to cracking. Polymer-modified grout is commonly used in applications that require greater durability and flexibility, such as tile installations and exterior concrete repairs.

- Non-shrink Grout: Non-shrink grout, as the name suggests, is designed to minimize shrinkage during the curing process. It contains special additives that reduce the volume change, ensuring a tight fit and preventing the development of voids or gaps. Non-shrink grout is frequently used for high-strength applications, such as under heavy machine bases or for structural repairs.

- Precision Grout: Precision grout is a highly flowable grout that provides excellent depth and volume adjustment. It is commonly used in applications where large gaps or irregularities need to be filled, such as under machinery, precast concrete elements, or for bridge bearing grouting.

Each type of construction grout has its own specific advantages and is suitable for different conditions. It is important to carefully consider the requirements of your project and consult with professionals to determine the most appropriate type of construction grout to use.

Read more: What Grout To Use For Stone Veneer

How Construction Grout is Used

Construction grout is a versatile material that can be used in various applications to enhance the stability, strength, and durability of structures. Here are some common ways in which construction grout is used:

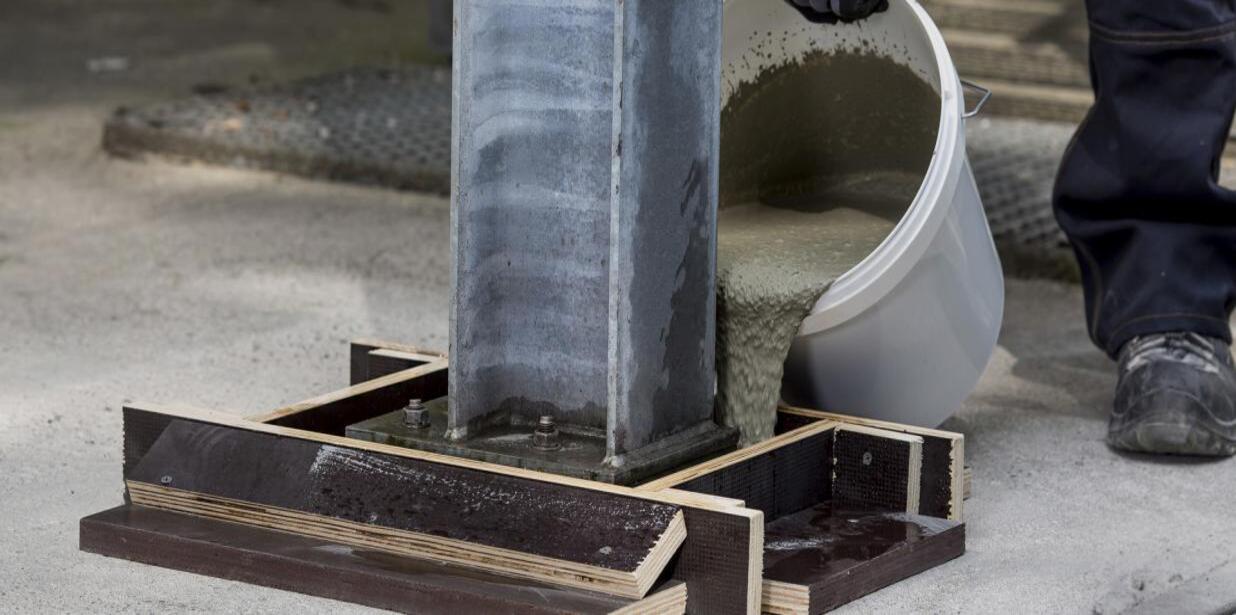

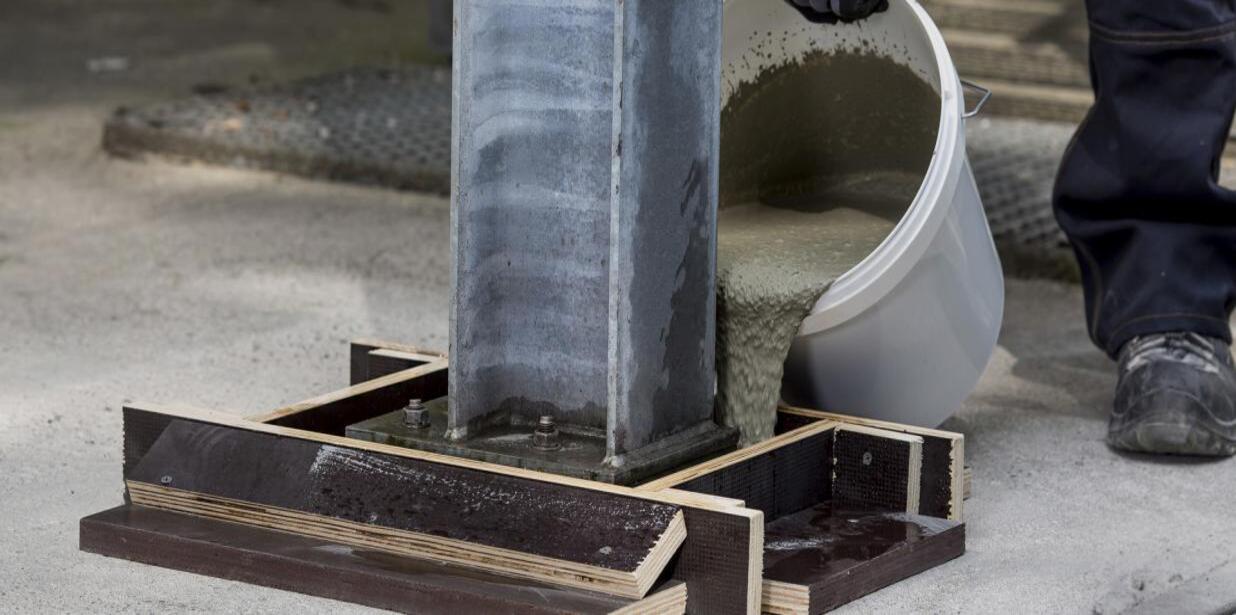

- Filling Voids and Cavities: Construction grout is commonly used to fill voids and cavities in structures. It is poured into gaps between load-bearing elements, such as columns and foundations, to ensure proper load transfer and prevent movement or settlement. Grout fills these spaces, creating a solid connection and enhancing structural stability.

- Anchoring and Doweling: Construction grout is frequently used for the anchoring and doweling of structural elements. It is poured around anchor bolts or dowels to provide a secure and stable connection between the embedded elements and the surrounding structure. This helps to distribute forces and loads effectively.

- Repairing Cracks: Grout is an effective material for repairing cracks in concrete structures. It is used to fill and seal cracks, restoring structural integrity and preventing further damage or water infiltration. Grout can be injected into the cracks to ensure complete filling and bonding of the damaged area.

- Tunnel and Mine Support: In underground construction, construction grout is used to provide support and reinforcement. It is injected into rock formations or soil to consolidate and strengthen the surrounding material, reducing the risk of collapse and ensuring the stability of tunnels, mines, and other underground structures.

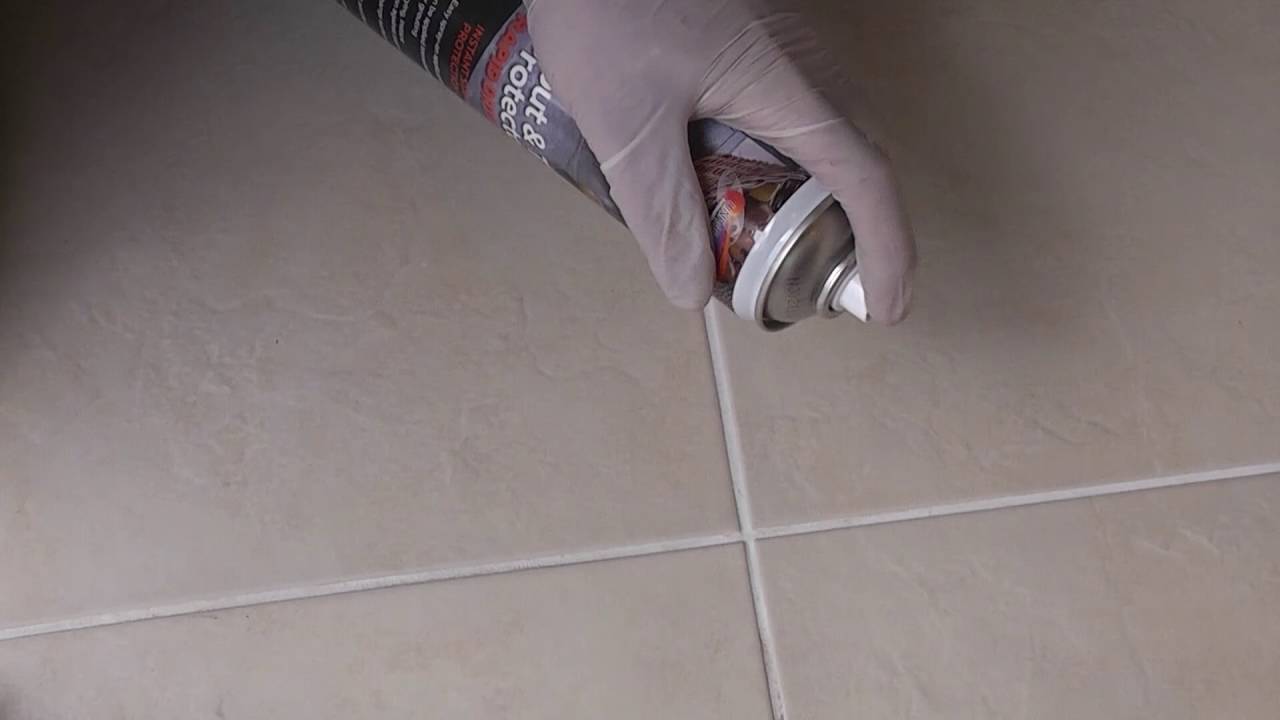

- Tile and Stone Installation: Construction grout is commonly used in tile and stone installations. It is applied in the gaps between tiles or stones to create a uniform and stable surface. Grout helps to prevent movement, fill voids, and provide a finished appearance to the installation.

- Precast Concrete Connection: Grout is used to create connections between precast concrete elements. It is poured into the joints between the precast elements, ensuring a solid and durable connection. Grout also helps to transfer loads and maintain the structural integrity of the precast elements.

These are just a few examples of how construction grout is used in the construction industry. The versatility and strength of grout make it an essential material for a wide range of applications, contributing to the stability and durability of various structures.

It’s important to note that the proper preparation and application of construction grout are crucial for achieving the desired results. Following manufacturer guidelines, consulting with professionals, and ensuring appropriate curing and curing conditions are essential for successful grout usage.

Construction grout is a mixture of cement, water, and sometimes sand and other additives. It is used to fill gaps, reinforce structures, and provide support for heavy equipment. When using construction grout, make sure to follow the manufacturer’s instructions for the proper mixing and application to ensure a strong and durable result.

Factors to Consider When Selecting Construction Grout

When selecting construction grout for your project, it is important to consider several factors to ensure that you choose the most suitable type of grout. Here are some key factors to keep in mind:

- Application: Understand the specific application of the construction grout. Different applications may require different types of grout with specific properties, such as high strength, flowability, or chemical resistance.

- Strength Requirements: Determine the required strength of the grout based on the project’s load-bearing capacity and structural design. Consider the compressive strength and bond strength needed to ensure the grout can withstand the intended loads and forces.

- Curing Time: Consider the desired curing time for the grout. Some projects may require a fast-setting grout for quicker construction progress, while others may allow for longer curing times to ensure proper bonding and strength development.

- Chemical Resistance: Assess the need for chemical resistance in the grout. For applications where exposure to chemicals or corrosive substances is expected, choose a grout that offers sufficient resistance to prevent degradation and maintain the integrity of the structure.

- Environmental Conditions: Take into account the environmental conditions at the project site. Factors such as temperature variations, moisture levels, or exposure to extreme weather conditions may influence the choice of grout. Ensure that the selected grout can withstand the specific environmental conditions to avoid degradation or performance issues.

- Compatibility: Consider the compatibility of the grout with the existing materials or substrates. Ensuring that the grout is compatible with the surrounding construction materials, such as concrete, tile, or stone, is crucial for achieving proper adhesion and minimizing the risk of cracking or delamination.

- Ease of Application: Evaluate the ease of mixing, application, and placement of the grout. Grouts that offer good flowability or self-leveling properties can simplify the installation process and ensure consistent coverage and filling of voids without significant effort.

- Budget: Take into account the project budget and cost of the grout. Balancing the project’s requirements with the available budget is essential. Consider the long-term benefits and performance of the grout to make an informed decision that aligns with both the project needs and financial constraints.

By considering these factors, you can select the most appropriate construction grout that meets the specific requirements of your project. Consulting with grout manufacturers, suppliers, or industry professionals can also provide valuable insights and guidance in choosing the right type of grout for your construction needs.

Benefits and Advantages of Construction Grout

Construction grout offers several benefits and advantages that make it an essential material in the construction industry. Here are some of the key benefits of using construction grout in your projects:

- Structural Stability: Construction grout improves the structural stability of buildings and structures by filling voids, providing support, and creating monolithic connections between structural elements. It helps distribute loads effectively, enhances load transfer, and minimizes the risk of settlement or movement.

- Enhanced Durability: Grout provides increased durability and resistance to external factors such as moisture, chemicals, and temperature variations. It helps protect and preserve the integrity of structures, ensuring long-term performance and reducing the need for costly repairs or maintenance.

- Improved Load-Bearing Capacity: Construction grout enhances the load-bearing capacity of structures by reinforcing weak areas and providing additional support. It helps to evenly distribute loads, preventing localized stress concentrations that can lead to cracks or failures.

- Versatility: Construction grout is a highly versatile material that can be used in various applications, such as filling voids, anchoring bolts, repairing cracks, and even installing tiles or stones. Its adaptability and flexibility make it suitable for a wide range of construction projects.

- Cost-Effectiveness: Using construction grout can be a cost-effective solution compared to alternative methods. Its ability to fill voids and repair cracks can extend the lifespan of structures, reducing the need for costly repairs or replacements. Additionally, its ease of application and compatibility with existing materials can help streamline the construction process, saving time and labor costs.

- Fire Resistance: Certain types of construction grout, particularly those with additives or fibers, offer enhanced fire resistance. This can help protect structures and provide valuable time for evacuation and firefighting efforts in the event of a fire.

- Improved Aesthetic Appeal: Construction grout can also contribute to the aesthetic appeal of structures. It can be available in different colors, allowing for creative design options or matching existing aesthetics. Grout used in tile or stone installations can ensure a uniform and attractive appearance.

These benefits highlight the importance and advantages of using construction grout in building and construction projects. The proper selection and application of grout can significantly enhance the structural integrity, longevity, and overall performance of structures, offering peace of mind to both builders and occupants.

Common Applications of Construction Grout

Construction grout is a versatile material that finds numerous applications in the construction industry. Its unique properties and capabilities make it suitable for a wide range of projects. Here are some common applications of construction grout:

- Foundation Repair: Construction grout is frequently used to repair and stabilize foundations. It can be injected into areas of settlement or cracks, filling voids and providing support to prevent further damage.

- Anchoring Bolts and Dowels: Grout is commonly used to anchor bolts and dowels in concrete, ensuring a secure and stable connection between structural elements.

- Tunnel and Mine Support: Construction grout is utilized in underground construction to provide support and reinforcement. It is injected into rock formations or soil to consolidate and strengthen the surrounding material, ensuring the stability of tunnels, mines, and other underground structures.

- Tile and Stone Installation: Grout is an essential component in tile and stone installations. It is used to fill the gaps between tiles or stones, providing a stable and aesthetically pleasing surface.

- Structural Columns and Beams: Construction grout is commonly used in the construction of columns, beams, and other load-bearing elements. It fills the voids around these elements, ensuring proper load transfer and stability.

- Precast Concrete Connection: Grout is used to create connections between precast concrete elements. It fills the joints and forms a solid bond, providing structural integrity.

- Highway and Bridge Deck Repair: Construction grout is employed for repairing damaged highway and bridge decks. It fills cracks and voids, restoring the strength and integrity of the concrete surface.

- Curtain Wall Construction: Grout is used to anchor curtain wall systems, ensuring their stability and secure attachment to the building structure.

- Machinery and Equipment Foundations: Construction grout is commonly used to provide stable and level foundations for heavy machinery and equipment. It helps distribute the weight, reduces vibrations, and ensures proper functioning.

- Repairing Concrete Spalls and Deteriorated Surfaces: Grout is used to repair and fill concrete spalls, deteriorated surfaces, and other damaged areas, improving the appearance and structural integrity.

- Joint Sealing: Construction grout is employed to seal joints between concrete elements, preventing water penetration, minimizing the risk of corrosion, and maintaining the structural integrity of the joints.

These are just a few examples of the common applications of construction grout. Its versatility, strength, and adaptability make it an indispensable material in various construction projects, ensuring stability, durability, and performance.

Read more: What Grout To Use For Outdoor Tile

Potential Issues and Challenges with Construction Grout

While construction grout is a valuable material with numerous benefits, there are potential issues and challenges that should be considered during its selection and application. Understanding these challenges will help ensure the proper use and maximize the effectiveness of construction grout. Here are some potential issues and challenges:

- Shrinkage and Cracking: Construction grout can be prone to shrinkage and cracking if not properly managed. Factors such as high water content, improper mixing, or inadequate curing can contribute to these issues. Proper proportioning, control of water content, use of additives, and following manufacturer recommendations can help minimize shrinkage and cracking.

- Poor Adhesion: In some cases, construction grout may exhibit poor adhesion to substrates or surfaces. This can lead to reduced bond strength and potential failure. It is crucial to ensure proper surface preparation, including cleaning and roughening, to promote good adhesion between the grout and the substrate.

- Improper Flowability: Construction grout that lacks the desired flowability or self-leveling properties can make it challenging to properly fill voids and gaps. Inadequate flowability can lead to incomplete filling and compromised performance. Choosing grouts with appropriate flow characteristics for specific applications is important to achieve optimal performance.

- Incorrect Mixing: Improper mixing of construction grout can result in inconsistent properties, such as reduced strength or poor workability. It is essential to follow the manufacturer’s instructions and ensure thorough mixing of all components to achieve a homogeneous mixture and desired performance.

- Inadequate Curing: Inadequate curing can negatively impact the strength and durability of the grout. Insufficient curing time or improper curing conditions can result in reduced compressive strength and compromised bond strength. Adhering to the recommended curing procedures, such as proper moisture and temperature control, is crucial for achieving the desired performance of the grout.

- Incompatibility: Construction grout may not be compatible with certain materials or environments. For example, certain grouts may contain additives that react poorly with certain substrates or chemicals. Prior to application, it is important to check for compatibility between the grout and the surrounding materials to avoid potential issues such as staining, corrosion, or degradation.

- Environmental Factors: Environmental conditions, such as extreme temperatures, moisture, or exposure to chemicals, can impact the performance of construction grout. Consider these factors during the selection process and choose grouts specifically designed to withstand the anticipated environmental conditions.

- Quality Control: Ensuring consistent quality of construction grout can be a challenge, particularly when dealing with bulk deliveries or multiple batches. Regular testing, adherence to quality control measures, and utilizing reputable suppliers can help maintain consistency and minimize variations in grout quality.

By being aware of these potential issues and challenges, and taking appropriate measures to address them, the effectiveness and reliability of construction grout can be optimized. Consulting with experts and following industry best practices will help mitigate these challenges and ensure successful grout applications in construction projects.

Conclusion

Construction grout is a valuable and versatile material that plays a crucial role in the stability, durability, and performance of various structures. Whether it’s filling voids, providing support, or reinforcing connections, construction grout enhances the integrity of buildings and infrastructure. By understanding its functions, types, and applications, you can make informed decisions when selecting the appropriate grout for your project.

When choosing construction grout, consider factors such as the application, strength requirements, curing time, environmental conditions, and compatibility with surrounding materials. Evaluating these factors will ensure that you select the right grout that meets the specific needs of your project.

Construction grout offers numerous benefits, including improved structural stability, enhanced durability, increased load-bearing capacity, and fire resistance. Its versatility allows for various applications, such as foundation repair, anchoring bolts, tunnel and mine support, and tile installation.

However, it is essential to be aware of potential challenges associated with construction grout, such as shrinkage, poor adhesion, improper flowability, and inadequate curing. By addressing these challenges through proper mixing, surface preparation, curing, and quality control, you can overcome potential issues and ensure optimal grout performance.

In conclusion, construction grout is a fundamental element in building and construction projects. Its ability to fill voids, provide structural support, and enhance durability makes it essential for achieving long-lasting, resilient structures. By considering the factors, selecting the right type, and adhering to best practices, you can ensure successful and efficient grout applications, contributing to the overall success of your construction endeavors.

Frequently Asked Questions about What Is Construction Grout

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Construction Grout”