Home>Home Appliances>Lighting Appliances>Where To Cut LED Strips

Lighting Appliances

Where To Cut LED Strips

Modified: January 5, 2024

Looking for the best place to trim LED light strips? Discover the top options for cutting LED strips with our helpful guide on lighting appliances!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

LED strips are versatile lighting solutions that have gained popularity in recent years. They are widely used in various applications, from home decor to commercial lighting. One of the advantages of LED strips is that they can be easily cut to the desired length to fit any space. However, cutting LED strips requires careful consideration to ensure the best results.

In this article, we will explore the factors to consider before cutting LED strips, the tools and materials needed, and provide a step-by-step guide on how to cut LED strips. We will also discuss precautions and safety measures, common mistakes to avoid, and offer tips for achieving clean cuts.

Before you start cutting your LED strips, it’s important to understand the impact it may have on their functionality and appearance. LED strips are designed to work as a continuous circuit, and cutting them may affect their electrical conductivity, brightness, and even color consistency. Therefore, it’s crucial to proceed with caution and follow the correct methods to ensure optimal performance.

Let’s dive into the essential factors to consider before embarking on the process of cutting LED strips.

Key Takeaways:

- Customize LED strips to fit any space by considering factors like purpose, power supply, and cutting points. Gather the right tools, follow a step-by-step guide, and prioritize safety for clean and precise cuts.

- Avoid common mistakes and follow tips for achieving professional cuts when working with LED strips. Prioritize safety, take your time, and double-check cutting points for optimal results.

Read more: How To Connect Cut LED Strips

Factors to consider before cutting LED strips

Before you grab your cutting tools and begin chopping away at your LED strips, there are several important factors to keep in mind. These factors will help ensure that you make the right decisions and achieve the desired results.

1. Purpose and design

Consider the purpose of the LED strips and how they fit into your overall design scheme. Are you using them for ambient lighting, accent lighting, or task lighting? Understanding the intended use will determine the length and placement of the strips, and subsequently, the cuts you need to make.

2. Power supply and voltage

LED strips typically require a power supply to operate. It’s crucial to understand the voltage requirements of your LED strips and ensure that your power supply matches. Cutting the LED strip in the wrong place might result in an unsuitable voltage distribution, leading to fluctuations in brightness or even damage to the LED chips.

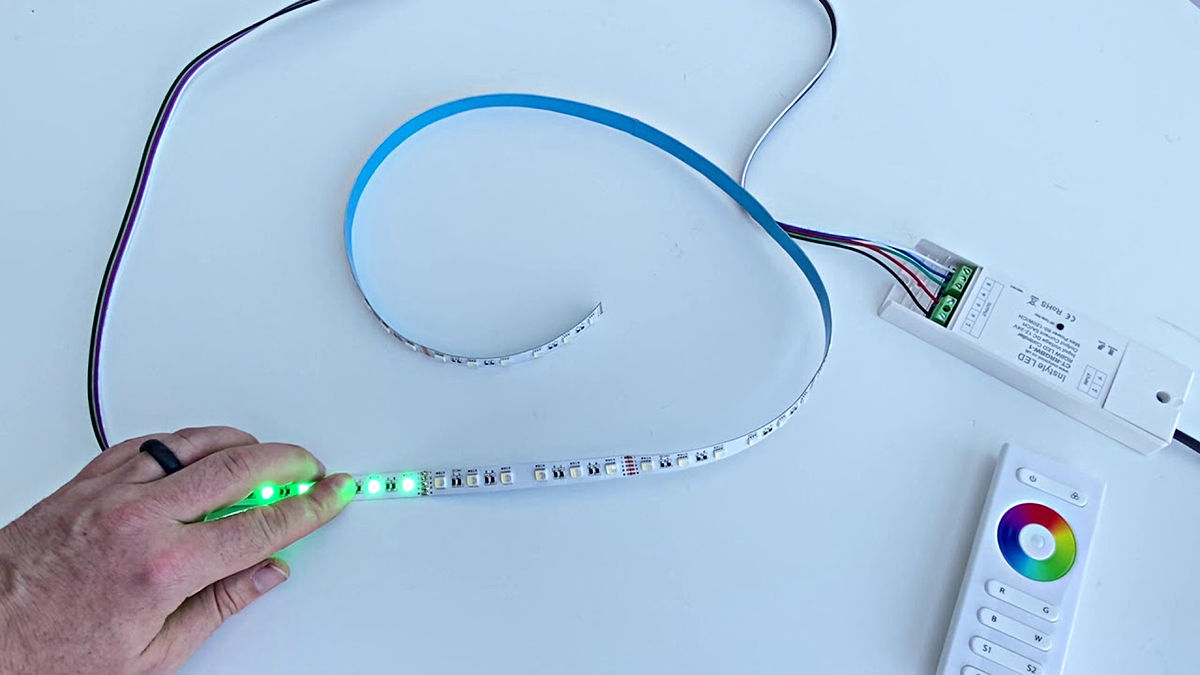

3. Cutting points

LED strips are usually marked with cutting points, indicating where it is safe to trim them. These cutting points are typically spaced at specific intervals, such as every few inches or centimeters. It’s important to identify these cutting points to ensure clean, precise cuts without damaging the circuit.

Read more: Where To Put LED Strips In A Room

4. Heat dissipation

LEDs generate heat, and proper heat dissipation is essential for their longevity and performance. Cutting the LED strip at the wrong point can disrupt the heat dissipation mechanism, leading to increased temperatures that could potentially harm the LEDs. Consider consulting the manufacturer’s guidelines or seeking professional advice on cutting the strips to avoid any heat-related issues.

5. Waterproof or non-waterproof

LED strips are available in both waterproof and non-waterproof variants. If you plan to use the LED strips in an environment where they may come into contact with moisture or water, such as bathrooms or outdoor applications, it’s crucial to choose the appropriate type. Waterproof LED strips have a protective covering that seals the circuit and protects it from moisture damage. Cutting the strip at the wrong point in a waterproof variant might compromise its waterproofing capabilities.

6. Flexibility and bend radius

LED strips come in various levels of flexibility, ranging from rigid to highly flexible types. The flexibility of the strip affects the ease of cutting and installation. It’s essential to assess the bend radius required for your installation and ensure that the LED strip can accommodate it. Cutting at the wrong point might hinder the strip’s ability to bend smoothly, affecting its overall appearance.

By considering these factors before cutting your LED strips, you can ensure that you make informed decisions, avoid potential issues, and achieve the desired lighting effect. Armed with the right knowledge, let’s move on to discussing the tools and materials you’ll need for cutting LED strips.

Tools and materials needed

Before you embark on cutting your LED strips, it’s important to gather the necessary tools and materials. Having the right equipment on hand will ensure a smooth and successful cutting process.

Read more: How To Solder RGB LED Strips

1. Measuring tape or ruler

To accurately measure the length of the LED strip you need, a measuring tape or ruler is indispensable. This will help you determine the exact cutting points and ensure precise cuts.

2. Sharp scissors or utility knife

To make clean and accurate cuts, you’ll need a sharp pair of scissors or a utility knife. Ensure that the blades are sharp enough to cut through the LED strip without damaging the circuit or the LED chips.

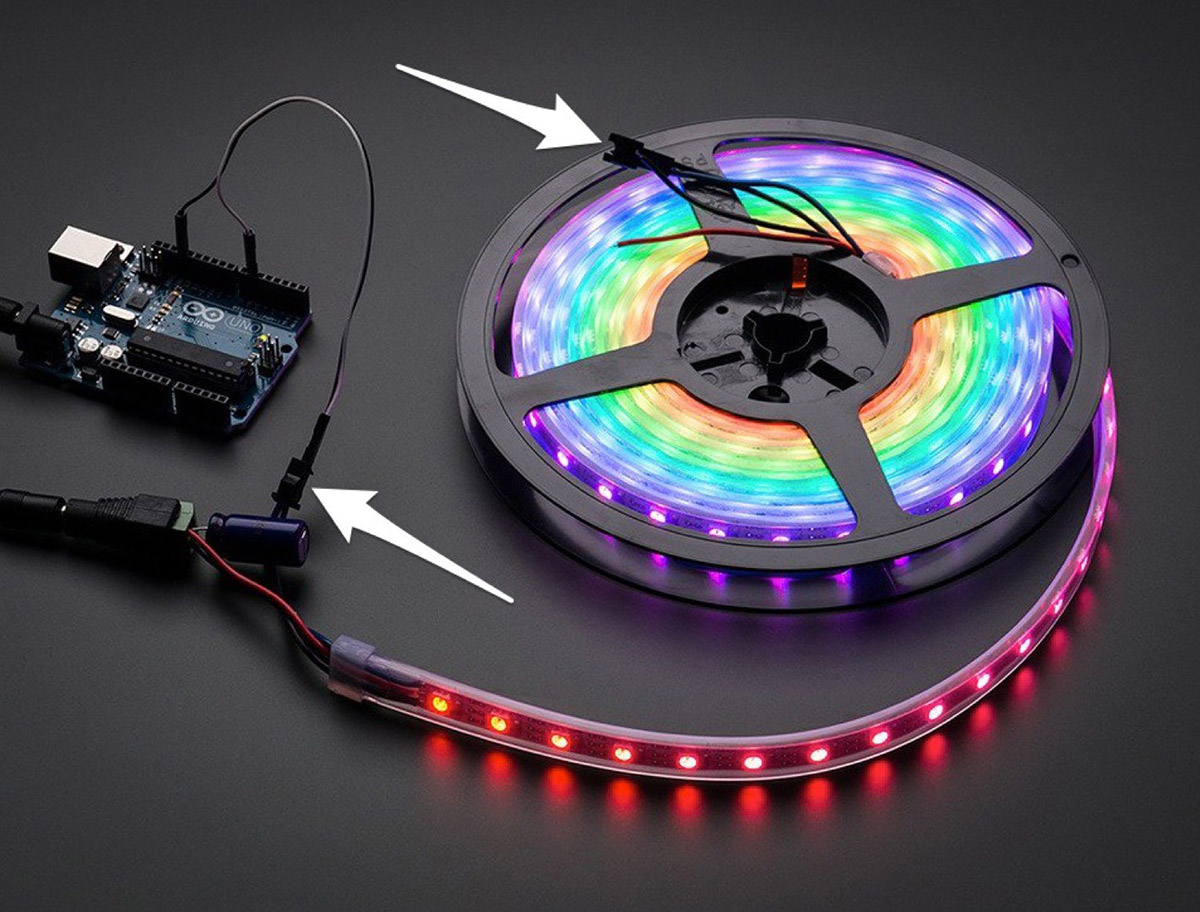

3. Soldering iron and soldering wire (optional)

If you need to reconnect or extend the cut sections of the LED strip, a soldering iron and soldering wire may be necessary. This equipment allows you to create secure connections and ensure proper electrical conductivity.

4. Wire strippers (optional)

If you’re working with LED strips that have exposed wires at the cutting points, wire strippers can come in handy. They allow you to remove the insulation from the wires, making it easier to connect or extend the strips if needed.

Read more: How To Install LED Strips Around Corners

5. Heat shrink tubing (optional)

Heat shrink tubing can be used to provide additional protection and insulation when reconnecting or extending LED strips. It is placed over the soldered or connected area and heated to shrink and create a tight seal.

6. Safety equipment

While cutting LED strips is generally safe, it’s always a good idea to wear safety goggles and gloves as a precautionary measure. This will protect your eyes from any flying debris or sharp edges, and your hands from accidental cuts or injuries.

By ensuring you have the right tools and materials at your disposal, you can confidently proceed with cutting your LED strips. In the next section, we will provide a step-by-step guide on how to cut LED strips, so stay tuned!

Step-by-step guide on cutting LED strips

Now that you have gathered the necessary tools and materials, it’s time to delve into the step-by-step process of cutting LED strips. By following these instructions carefully, you can achieve clean and precise cuts.

1. Measure and mark

Using a measuring tape or ruler, measure the desired length of the LED strip you need. Make sure to account for any connectors or extensions if required. Once you have determined the length, use a marker or pen to mark the cutting point on the LED strip.

Read more: How LED Strips Work

2. Cut along the designated line

With your sharp scissors or utility knife, carefully cut along the previously marked line. Apply gentle pressure to avoid damaging the LED chips or circuit. For more rigid LED strips, you may need to use a little more force, but be cautious not to compromise the circuit.

3. Inspect the cut section

After making the cut, examine the newly cut section to ensure that the circuit remains intact and that none of the wires are exposed or damaged. This will help prevent any potential electrical issues later on.

4. Reconnect or extend (if necessary)

If you need to reconnect or extend the LED strip, this is the stage where you would utilize the soldering iron and soldering wire. Ensure that the soldering iron is heated to the appropriate temperature and carefully solder the necessary connections, securing the wires together. If you prefer not to solder, you can use connectors specifically designed for LED strips.

5. Optional: Use heat shrink tubing

If you have soldered or connected the LED strip, you may choose to slide a heat shrink tubing over the soldered area to provide additional protection and insulation. Heat the tubing with a heat gun or lighter to shrink it around the connection, creating a secure seal.

6. Test the LED strip

Before fully installing the cut LED strip, it’s crucial to test its functionality. Connect the strip to the power supply and ensure that all the LEDs light up properly. This will help identify any issues or faulty connections that need to be addressed before installation.

By following these step-by-step instructions, you can confidently cut and customize your LED strips to fit your desired length and design. However, it’s important to keep in mind the precautions and safety measures associated with cutting LED strips, which we will discuss in the next section.

Precautions and safety measures

While cutting LED strips is a relatively safe task, it’s essential to take certain precautions to ensure your safety and protect the integrity of the strips. Here are some key precautions and safety measures to keep in mind:

1. Disconnect the power supply

Before you start cutting or working with LED strips, always disconnect the power supply to avoid any risk of electric shock or damage to the circuit. This includes unplugging the LED strip from the power source.

2. Wear safety goggles and gloves

When handling cutting tools or sharp objects, it’s essential to wear safety goggles to protect your eyes from any flying debris. Additionally, wearing gloves can provide an extra layer of protection against accidental cuts or injuries.

Read more: How To Remove LED Strips From The Wall

3. Use sharp and suitable cutting tools

Ensure that your cutting tools, such as scissors or a utility knife, are sharp and suitable for the task at hand. Dull blades can lead to uneven cuts and potential damage to the LED chips or circuit. Choose a tool that allows for precise and clean cuts.

4. Cut at designated cutting points

LED strips are typically marked with designated cutting points. It’s crucial to cut at these specified points to avoid damaging the circuit. Cutting in the wrong place can result in non-functioning sections or even complete failure of the strip.

5. Take care when soldering or connecting

If you need to solder or connect the cut sections of the LED strip, take care to follow proper soldering techniques. Ensure the soldering iron is heated to the correct temperature and that the connections are secure and insulated. Avoid touching the hot soldering iron or inhaling fumes from the soldering process.

6. Consider professional assistance

If you are unsure about cutting or working with LED strips, or if your project involves complex installations, it’s advisable to seek professional assistance. Electricians or lighting experts have the knowledge and experience to handle LED strips safely and effectively.

By following these precautions and safety measures, you can minimize the risk of accidents, ensure the longevity of your LED strips, and maintain a safe working environment. Next, let’s explore some common mistakes to avoid when cutting LED strips.

Read more: How To Connect To LED Strips

Common mistakes to avoid

When cutting LED strips, there are several common mistakes that you should avoid. Being aware of these mistakes will help you achieve better results and prevent potential issues. Here are some common mistakes to watch out for:

1. Cutting at the wrong location

The most crucial mistake to avoid is cutting the LED strip at the wrong location. LED strips are designed with designated cutting points, and cutting outside of these points can lead to circuit disruption, uneven brightness, or non-functioning sections. Always identify and cut at the appropriate cutting points indicated on the strip.

2. Damaging the LED chips or circuit

Applying too much pressure or using unsuitable cutting tools can result in damage to the LED chips or circuit. Make sure to use sharp and appropriate cutting tools to ensure clean cuts without causing any harm to the LEDs or the circuit within the strip.

3. Ignoring voltage requirements

Each LED strip has specific voltage requirements, and cutting the strip at the wrong location can disrupt the voltage distribution. Ignoring the voltage requirements can lead to fluctuating brightness, color inconsistencies, or even complete failure of the LED strip. Always consider the voltage requirements and ensure that the power supply matches accordingly.

Read more: How To Connect Multiple Govee LED Strips

4. Skipping testing before installation

It’s essential to test the functionality of the cut LED strip before fully installing it. Skipping this step can result in discovering issues or faulty connections after installation, leading to unnecessary rework or replacements. Always connect and test the cut strip to ensure all the LEDs light up properly.

5. Neglecting heat dissipation

LEDs generate heat, and proper heat dissipation is crucial for their performance and longevity. Neglecting heat dissipation can result in increased temperatures that may damage the LEDs. Avoid cutting or obstructing sections of the LED strip that play a critical role in heat dissipation. Consult the manufacturer’s guidelines or seek professional advice if unsure.

6. Rushing the cutting process

Take your time when cutting LED strips. Rushing the process can lead to mistakes, uneven cuts, or damaged components. Be patient and meticulous, ensuring that each cut is precise and meets the requirements of your project.

By avoiding these common mistakes, you can ensure a successful and professional outcome when cutting LED strips. Now, let’s explore some tips to help you achieve clean and professional cuts.

Tips for achieving clean cuts

To achieve clean and professional-looking cuts when working with LED strips, it’s important to follow these helpful tips. These tips will ensure that your cuts are precise, minimize the risk of damaging the strip, and result in a clean and polished appearance.

Read more: How To Attach Two LED Strips

1. Use a sharp cutting tool

Ensure that you are using a sharp cutting tool, such as scissors or a utility knife, that is specifically designed for the material of the LED strip. A dull blade can lead to uneven cuts or damage to the LED chips. Replace the blade if it becomes dull to maintain clean cuts.

2. Work slowly and steadily

Take your time when cutting LED strips to avoid rushing and making mistakes. Work slowly and steadily, applying gentle and even pressure along the cutting line. This will help you achieve cleaner cuts and ensure the integrity of the LED strip is maintained.

3. Double-check the cutting points

Before making any cuts, double-check the designated cutting points marked on the LED strip. Cutting at the wrong location can disrupt the circuit and cause functionality issues. Ensure that you are cutting at the correct points to achieve seamless connections.

4. Use a straight edge as a guide

If you find it challenging to cut a straight line freehand, you can use a straight edge, such as a ruler or a piece of sturdy material, as a guide. Place the straight edge along the desired cutting line and carefully cut along the edge to ensure a straight and even cut.

Read more: Why Are My LED Strips Flashing

5. Take precautions during soldering or connecting

If you need to solder or connect the cut sections of the LED strip, take precautions to ensure clean and secure connections. Use a soldering iron with the appropriate temperature to avoid damaging the strip. Apply solder carefully and ensure it adheres well to the wires or connectors. Use heat shrink tubing to insulate and protect the soldered area, if necessary.

6. Inspect the cut section

After making the cut, inspect the newly cut section of the LED strip. Check for any signs of damage, exposed wires, or loose connections. If you notice any issues, address them before installing the strip to ensure optimal performance and safety.

By following these tips, you can achieve clean and professional cuts when working with LED strips. Remember to prioritize safety and precision throughout the cutting process. With proper care and attention, you can create custom lengths of LED strips that seamlessly integrate into your lighting design.

Now that you have a better understanding of how to achieve clean cuts, let’s wrap up this article.

Conclusion

Cutting LED strips can be a simple and effective way to customize their length and fit them into your desired space. However, it’s crucial to approach the cutting process with thoughtful consideration, proper tools, and safety precautions to ensure optimal results.

Before cutting LED strips, take into account the purpose and design, power supply and voltage requirements, cutting points, heat dissipation, and whether the strips are waterproof or non-waterproof. These factors will guide you in making informed decisions and avoiding potential issues.

Gather the necessary tools and materials, including a measuring tape or ruler, sharp scissors or utility knife, soldering iron and soldering wire, wire strippers (if needed), heat shrink tubing (if desired), and safety equipment such as goggles and gloves.

Follow the step-by-step guide to cutting LED strips, ensuring precise measurements, using sharp cutting tools, inspecting the cut section, and testing the strip before installation. Be mindful of the precautions and safety measures, such as disconnecting the power supply, wearing safety gear, and taking care during soldering or connecting.

Avoid common mistakes like cutting at the wrong location, damaging the LED chips or circuit, ignoring voltage requirements, skipping testing, neglecting heat dissipation, or rushing the cutting process.

By implementing these tips and best practices, you can achieve clean and professional cuts when working with LED strips. Whether you’re installing LED strips for home decor, accent lighting, or commercial applications, taking the time to cut them accurately will ensure a seamless and visually appealing lighting display.

Remember, if you’re unsure about cutting LED strips or if your project involves complex installations, it’s always a good idea to seek professional assistance to ensure the best results and maintain safety standards.

Now armed with the knowledge and understanding of cutting LED strips, you can confidently embark on your lighting project and create a unique and personalized lighting solution that elevates any space.

Frequently Asked Questions about Where To Cut LED Strips

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Where To Cut LED Strips”