Home>Technology>Smart Home Devices>How Long Does It Take For A 3D Printer To Print

Smart Home Devices

How Long Does It Take For A 3D Printer To Print

Published: January 22, 2024

Discover the printing time for 3D objects with a smart home device. Learn how long it takes for a 3D printer to complete a print job. Explore more about smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Introduction

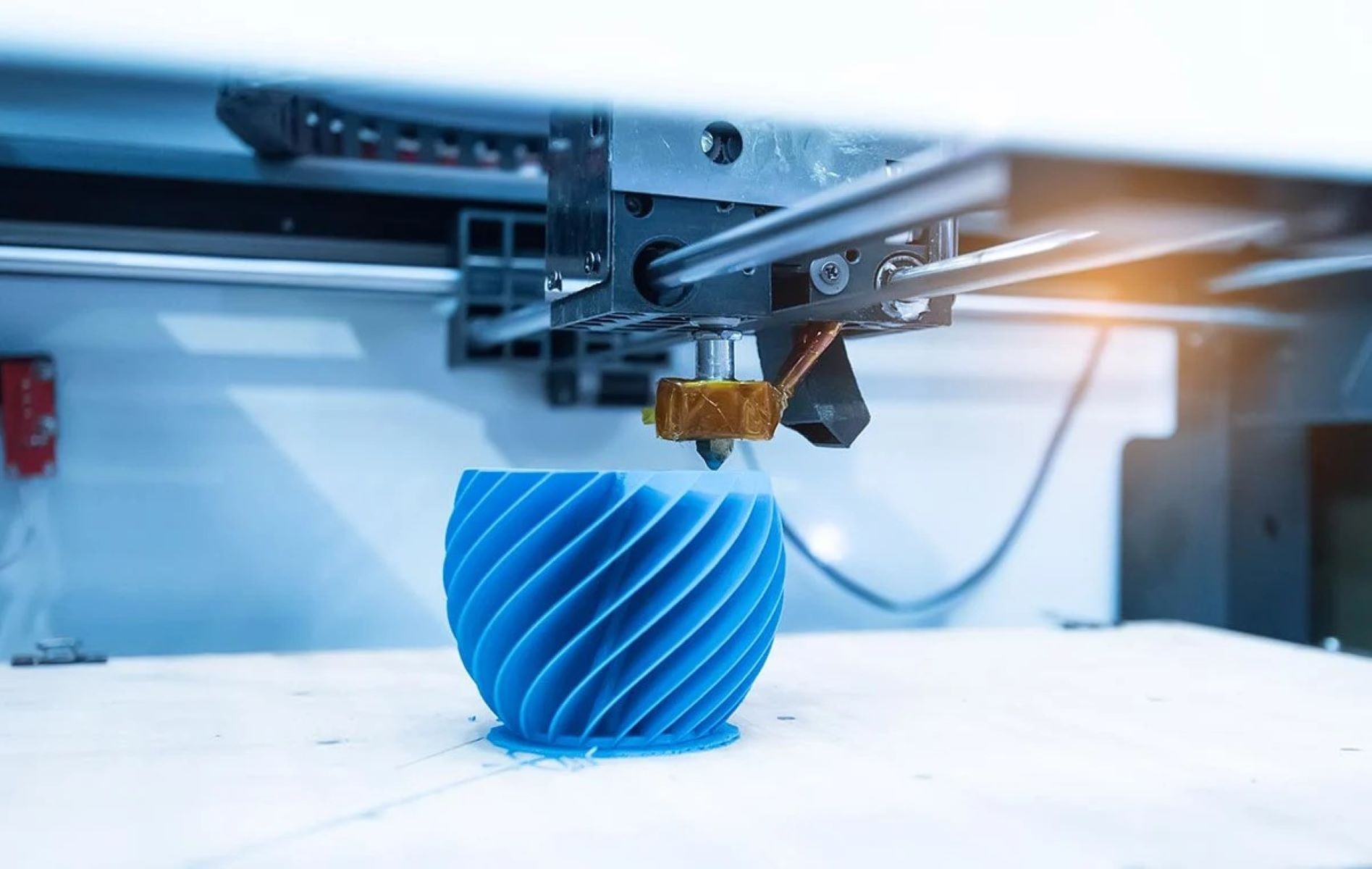

Welcome to the world of 3D printing, where the boundaries of creativity and innovation are continually being pushed. The ability to transform digital designs into physical objects has revolutionized various industries, from manufacturing and healthcare to architecture and fashion. As 3D printing technology advances, it's essential to understand the factors that influence the time required to complete a 3D printing project.

In this article, we will delve into the intricacies of 3D printing and explore the variables that impact the duration of the printing process. From print speed and quality to material composition and complexity, each element plays a crucial role in determining how long it takes for a 3D printer to bring your designs to life.

Whether you're a seasoned 3D printing enthusiast or a newcomer eager to explore this cutting-edge technology, gaining insights into the time considerations of 3D printing will empower you to make informed decisions and optimize your printing endeavors. Let's embark on a journey through the realm of 3D printing and unravel the fascinating dynamics that govern its temporal dimensions.

Factors Affecting 3D Printing Time

Key Takeaways:

- 3D printing time is influenced by factors like print speed, material complexity, and size. Balancing speed and quality, choosing the right material, and optimizing size and resolution are crucial for efficient printing.

- Understanding the interplay of factors like speed, material, and size is key to optimizing 3D printing time. Striking a balance between quality and efficiency empowers users to unlock the full potential of this innovative technology.

Factors Affecting 3D Printing Time

When embarking on a 3D printing venture, it’s crucial to comprehend the multifaceted nature of the process and the diverse factors that influence the duration of a print job. Several key elements contribute to the overall printing time, and understanding these variables is essential for optimizing efficiency and achieving desired outcomes.

Print speed and quality, material composition and complexity, as well as size and resolution, are among the primary factors that significantly impact the time required for a 3D printer to complete a project. Let’s explore each of these factors in detail to gain a comprehensive understanding of their influence on the temporal dimensions of 3D printing.

Print Speed and Quality

Read more: How To Remove Print From A 3D Printer

Print Speed and Quality

Print speed and quality are pivotal considerations in the realm of 3D printing, directly impacting the time required to bring a digital design to fruition. The speed at which a 3D printer operates is influenced by various factors, including the chosen printing technology, layer height, and infill density.

While faster print speeds can expedite the printing process, they can also compromise the quality and precision of the final output. Balancing speed and quality is a delicate art, as achieving optimal print speed without sacrificing the integrity of the printed object is paramount. Additionally, the complexity of the design and the intricacy of details can influence the printer’s speed, as intricate patterns and fine details may necessitate slower printing to ensure accuracy.

Moreover, the quality of the printed object is intrinsically linked to the chosen print settings, such as layer height, infill density, and print temperature. Fine-tuning these parameters can significantly enhance the overall quality of the print, albeit at the expense of increased printing time. Conversely, reducing print quality settings can expedite the printing process but may result in a less refined final product.

It’s essential to strike a harmonious balance between print speed and quality, taking into account the specific requirements of each printing project. By optimizing print settings and leveraging advanced printing technologies, it’s possible to achieve remarkable print quality without unduly prolonging the printing duration.

Next, let’s delve into the impact of material composition and complexity on 3D printing time.

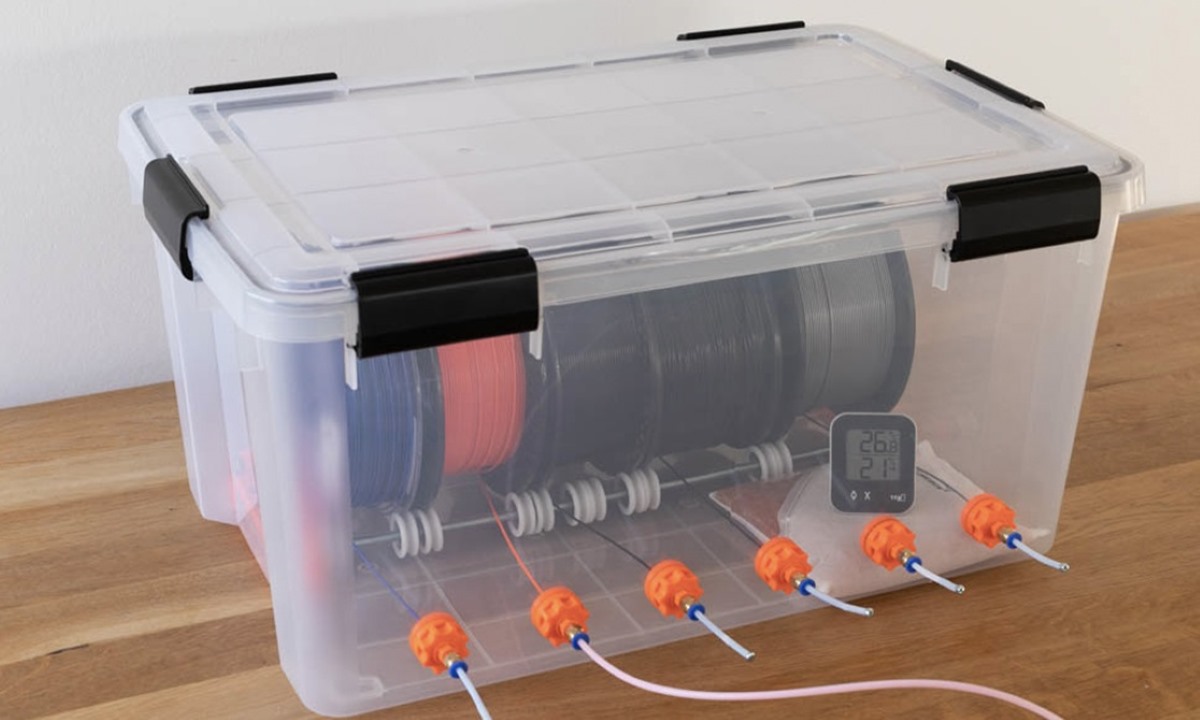

Material and Complexity

Material composition and the complexity of the design are pivotal factors that significantly influence the time required for 3D printing. The choice of printing material, such as PLA, ABS, PETG, or specialized filaments, directly impacts the printing duration due to varying material properties and printing parameters.

Complex designs, characterized by intricate geometries and intricate details, often necessitate longer printing times to ensure precision and structural integrity. The intricacy of the design affects the printer’s movements and the amount of material deposition, directly impacting the temporal dimensions of the printing process. Moreover, intricate designs may require additional support structures to prevent deformation during printing, further contributing to the overall printing time.

Furthermore, the material’s cooling and solidification properties influence the printing duration, particularly for designs with intricate overhangs and intricate features. Some materials may necessitate slower printing speeds to facilitate adequate cooling and minimize the risk of warping or deformation, thereby extending the overall printing time.

Optimizing material selection and design complexity is essential for balancing printing time with the desired structural integrity and visual appeal of the printed object. By leveraging advanced slicing software and material-specific parameters, it’s possible to streamline the printing process while ensuring exceptional quality and durability.

Now, let’s explore the impact of size and resolution on the temporal dimensions of 3D printing.

Size and Resolution

The size and resolution of a 3D printed object are critical determinants of the printing time, exerting a profound impact on the temporal dimensions of the printing process. Larger objects inherently require more material deposition and intricate layering, thereby extending the printing duration. Additionally, larger prints often necessitate the use of support structures to maintain structural stability, further contributing to the overall printing time.

Moreover, the chosen resolution significantly influences the intricacy and level of detail in the printed object. Higher resolutions, characterized by finer layer heights and enhanced precision, often entail longer printing times due to the increased number of layers and the meticulous nature of the printing process. Conversely, lower resolutions may expedite the printing process but can result in reduced surface quality and diminished detail.

Furthermore, the intricacy of the design, coupled with the chosen resolution, directly impacts the temporal dimensions of 3D printing. Complex designs with intricate details and fine features demand higher resolutions to faithfully capture the design’s nuances, consequently prolonging the printing time. Balancing design intricacy with the desired resolution is essential for optimizing printing time without compromising the visual fidelity and structural integrity of the printed object.

Additionally, leveraging advanced slicing software enables users to strategically adjust the printing resolution based on specific design elements, thereby optimizing printing time while preserving the desired level of detail and precision.

Understanding the interplay between size, resolution, and design intricacy is paramount for effectively managing 3D printing time and achieving exceptional print quality. By carefully considering these factors and implementing strategic optimizations, individuals and businesses can harness the full potential of 3D printing technology while maximizing efficiency and productivity.

The time it takes for a 3D printer to print depends on the size and complexity of the object. Smaller, simpler objects can take a few hours, while larger, more intricate objects can take several days.

Conclusion

As we conclude our exploration of the temporal dimensions of 3D printing, it’s evident that a myriad of factors intricately shape the duration of the printing process. Print speed and quality, material composition and complexity, as well as size and resolution, collectively influence the temporal dynamics of 3D printing, underscoring the multifaceted nature of this innovative technology.

Optimizing print speed and quality involves striking a delicate balance between expediency and precision, leveraging advanced printing technologies and fine-tuning print settings to achieve remarkable outcomes within reasonable timeframes. Material selection and design complexity play a pivotal role in shaping printing time, necessitating thoughtful considerations to ensure optimal structural integrity and visual appeal without unduly prolonging the printing process.

Furthermore, the size and resolution of a printed object are critical determinants of printing time, warranting strategic adjustments and meticulous planning to achieve the desired level of detail and quality while managing printing duration effectively.

As 3D printing technology continues to evolve, it’s imperative for enthusiasts, innovators, and businesses to harness a comprehensive understanding of the temporal dimensions of 3D printing. By embracing the interplay of these factors and implementing strategic optimizations, individuals and industries can unlock the full potential of 3D printing while achieving exceptional efficiency and productivity.

Whether embarking on intricate prototyping projects, manufacturing bespoke components, or exploring creative expressions, the insights gleaned from our exploration will empower practitioners to navigate the temporal intricacies of 3D printing with confidence and ingenuity.

As we look toward the future of 3D printing, it’s evident that a nuanced understanding of the temporal dimensions will serve as a cornerstone for innovation, creativity, and transformative advancements across diverse domains.

Frequently Asked Questions about How Long Does It Take For A 3D Printer To Print

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Does It Take For A 3D Printer To Print”