Home>Technology>Smart Home Devices>How To Reuse 3D Printer Filament

Smart Home Devices

How To Reuse 3D Printer Filament

Modified: August 20, 2024

Learn how to reuse 3D printer filament to create innovative smart home devices. Reduce waste and save money with these practical tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of 3D printing, where creativity knows no bounds, and innovation thrives. One of the key components of 3D printing is the filament, a material used to create the physical objects layer by layer. As the 3D printing community continues to expand, the need for sustainable practices becomes increasingly important. In this article, we will explore the art of reusing 3D printer filament, delving into the methods, precautions, and considerations associated with this eco-friendly approach.

Reusing 3D printer filament not only aligns with environmental consciousness but also offers cost-effective benefits. By understanding the different types of filaments and the methods for reusing them, you can contribute to a more sustainable 3D printing ecosystem while optimizing your resources.

So, let's embark on a journey to unravel the possibilities of reusing 3D printer filament, empowering you to make informed decisions that benefit both the environment and your creative endeavors.

Key Takeaways:

- Embrace sustainability and creativity in 3D printing by reusing filament through methods like joining, recycling, and experimental blending. Make informed decisions to minimize waste and maximize resources.

- Understand filament types, consider precautions, and navigate challenges to contribute to a more sustainable and efficient 3D printing ecosystem. Embrace reusability for a mindful and innovative approach.

Read more: How To Store 3D Printer Filament

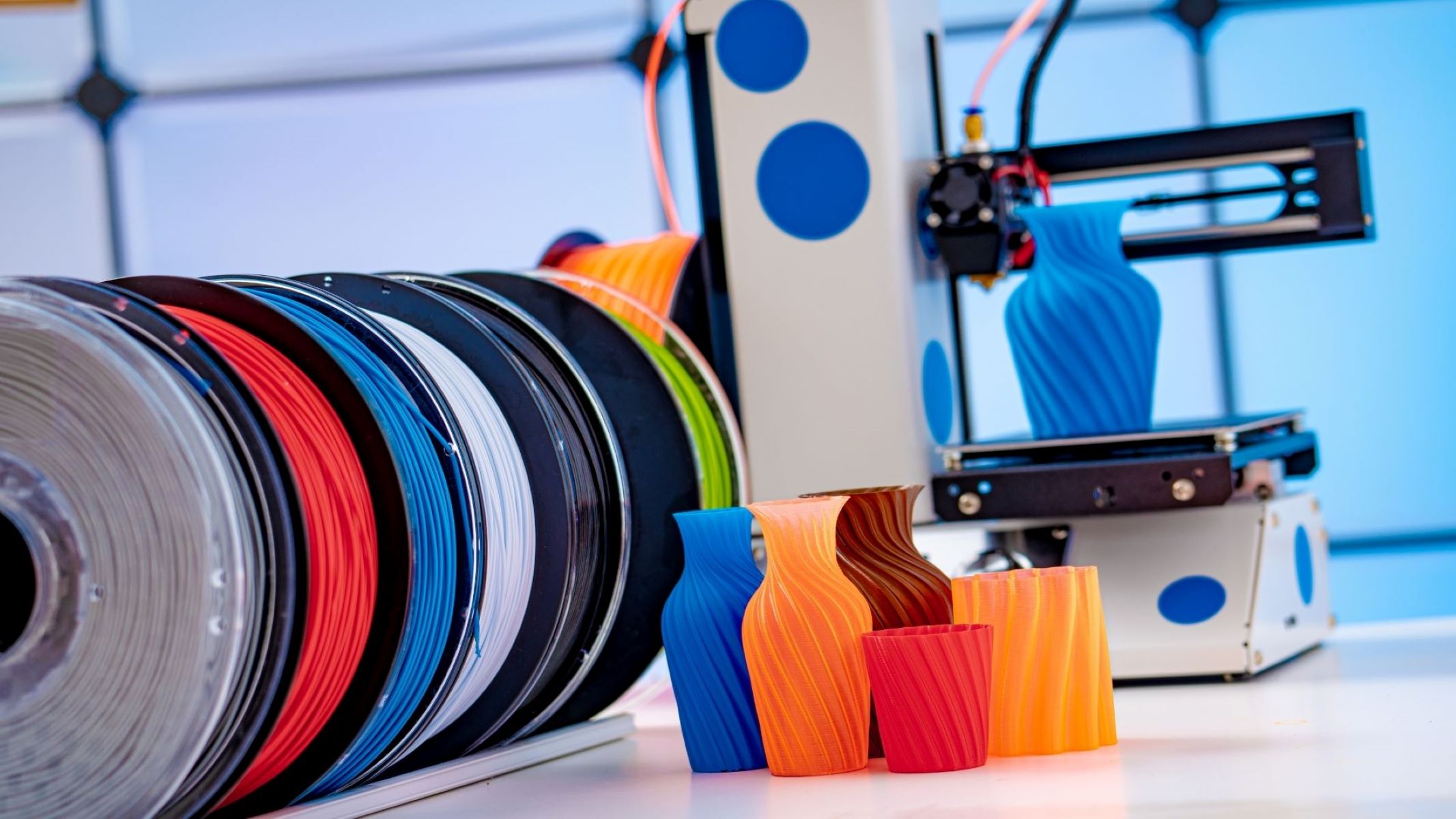

Understanding 3D Printer Filament

Before delving into the methods for reusing 3D printer filament, it’s essential to understand the different types of filaments commonly used in 3D printing. Each type of filament possesses unique properties that cater to specific printing needs and preferences.

1. PLA (Polylactic Acid): PLA is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. It is renowned for its environmental friendliness and ease of use, making it a popular choice among 3D printing enthusiasts.

2. ABS (Acrylonitrile Butadiene Styrene): ABS is a petroleum-based thermoplastic known for its durability and impact resistance. It is commonly used in industrial applications and is favored for its ability to withstand higher temperatures compared to PLA.

3. PETG (Polyethylene Terephthalate Glycol): PETG combines the strength of ABS with the ease of use of PLA. It is known for its transparency, impact resistance, and chemical resistance, making it suitable for a wide range of applications.

4. TPU (Thermoplastic Polyurethane): TPU is a flexible filament with excellent elasticity and abrasion resistance. It is often used to create flexible and durable prints, such as phone cases and footwear.

5. Nylon: Nylon is a versatile filament known for its strength, flexibility, and durability. It is commonly used in industrial and engineering applications due to its high impact resistance and ability to withstand wear and tear.

Each type of filament requires specific printing parameters and post-processing techniques to achieve optimal results. Understanding the unique characteristics of each filament type is crucial when considering the potential for reusing 3D printer filament, as certain types may lend themselves more readily to the reusability process.

Now that we have gained insight into the diverse world of 3D printer filaments, let’s explore the methods for reusing these materials to minimize waste and maximize their potential.

Methods for Reusing 3D Printer Filament

Reusing 3D printer filament presents an opportunity to minimize waste and maximize the utility of these valuable materials. Several methods can be employed to effectively repurpose and reuse filament, contributing to a more sustainable approach to 3D printing.

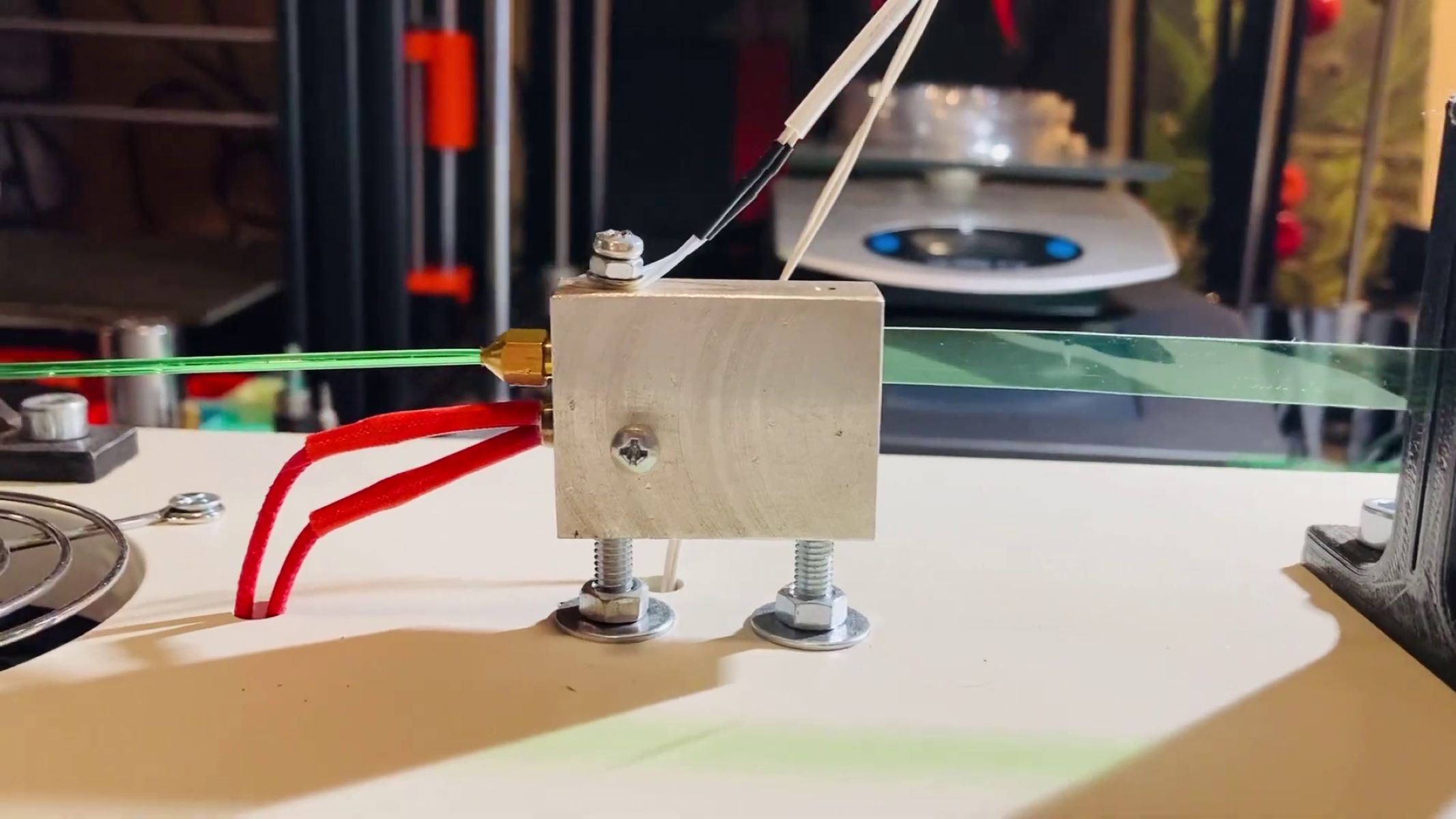

1. Filament Joining: When 3D printing projects result in partial spools of filament, filament joining offers a practical solution to combine leftover segments into longer strands. This process involves carefully aligning and fusing the ends of the filaments using a heat source, such as a soldering iron or a specialized filament joining tool. Once joined, the filament can be used for future printing projects, reducing the need to discard shorter segments.

2. Filament Recycling: Filament recycling involves melting down used or failed prints to create new filament spools. This process typically requires a filament extruder, which heats and extrudes the recycled material into a new filament strand. By recycling 3D printer waste, such as failed prints or support structures, into fresh filament, this method promotes a closed-loop approach to filament utilization.

3. Experimental Blending: Experimenting with filament blending allows for the creation of custom filament compositions by combining different types of filaments. By blending compatible filaments with varying properties, such as PLA and TPU, creators can tailor the characteristics of the resulting filament to suit specific printing requirements. This method opens the door to innovative material combinations and unique printing capabilities.

4. Multi-Material Printing: Some 3D printers support multi-material printing, enabling the simultaneous use of multiple filaments to create intricate and multi-colored prints. By strategically planning and utilizing multiple filaments within a single print, creators can optimize the use of existing filament spools and minimize waste while achieving captivating visual effects.

5. Reclaimed Filament: Reclaimed filament refers to the process of salvaging and repurposing filament from failed or discarded prints. By carefully collecting and processing the unused filament from failed prints, creators can reclaim and reuse the material for future projects, reducing material waste and maximizing resource efficiency.

By embracing these methods for reusing 3D printer filament, creators can actively contribute to sustainable practices within the 3D printing community. These approaches not only minimize material waste but also foster creativity and resourcefulness, empowering individuals to explore new possibilities while reducing their environmental footprint.

Consider using a filament dryer to remove moisture and improve the quality of reused filament. This can help prevent clogs and improve print quality.

Precautions and Considerations

While the prospect of reusing 3D printer filament holds promise for sustainable and cost-effective 3D printing, it is essential to approach the reusability of filament with careful consideration and awareness of potential challenges. By acknowledging the precautions and considerations associated with reusing filament, creators can navigate this eco-friendly practice with confidence and foresight.

1. Filament Compatibility: When blending or joining filaments, it is crucial to consider the compatibility of the materials being combined. Different filaments may have varying melting points, adhesion properties, and cooling requirements, which can impact the success of the reusability process. Understanding the compatibility of filaments ensures that the resulting blends or joined filaments exhibit desirable printing characteristics and structural integrity.

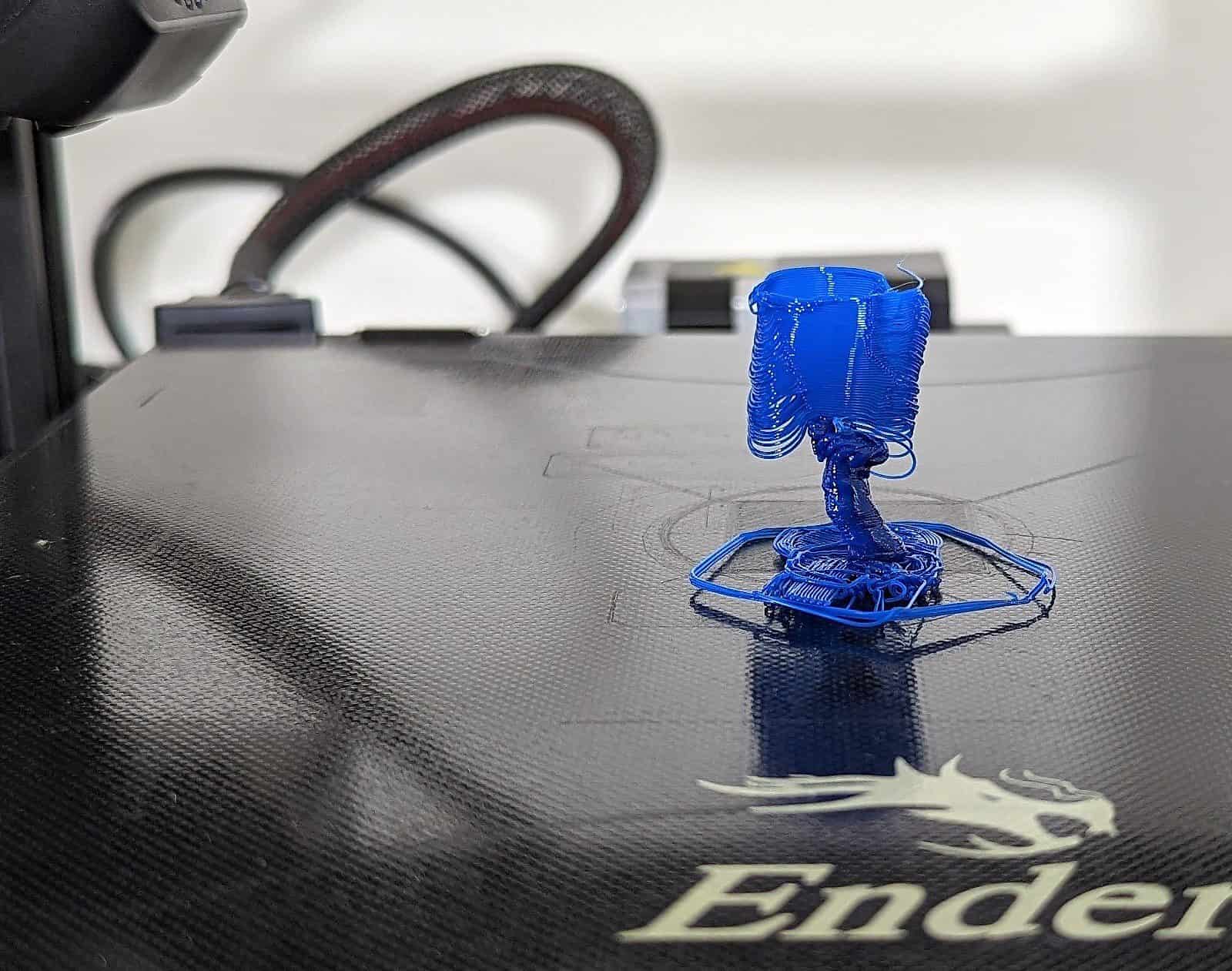

2. Quality Control: Reused filament may exhibit inconsistencies in color, diameter, or material properties, particularly when derived from recycled or reclaimed sources. Implementing stringent quality control measures, such as filament diameter monitoring and visual inspection, can help identify and address potential irregularities, ensuring the reliability and performance of the reused filament during printing.

3. Printer Settings and Calibration: When using reclaimed or experimental filament blends, it is essential to recalibrate printer settings, including nozzle temperature, extrusion rate, and cooling parameters, to accommodate the unique characteristics of the reused filament. Adapting printer settings ensures optimal print quality and adhesion, mitigating the risk of printing issues arising from variations in the reused filament.

4. Material Properties: Different filament types possess distinct material properties, such as flexibility, strength, and heat resistance. When reusing filament, creators should consider the intended application and environmental conditions the printed objects will encounter. Selecting the appropriate reused filament based on its material properties ensures that the resulting prints meet the desired functional and aesthetic requirements.

5. Environmental Impact: While reusing filament contributes to waste reduction, it is important to remain mindful of the environmental impact throughout the filament reusability process. Proper disposal of unusable filament remnants and adherence to recycling best practices further support sustainable 3D printing practices, reinforcing the holistic approach to environmental stewardship.

By conscientiously addressing these precautions and considerations, creators can harness the potential of reusing 3D printer filament while upholding quality standards and environmental responsibility. Embracing a thoughtful and informed approach to filament reusability fosters a sustainable and innovative ethos within the 3D printing community, paving the way for conscientious and resource-efficient practices.

Conclusion

As we conclude our exploration of reusing 3D printer filament, it becomes evident that the 3D printing community holds the power to embrace sustainable practices while nurturing creativity and resourcefulness. The methods for reusing filament, from joining and recycling to experimental blending and reclaimed filament, exemplify the ingenuity and commitment to minimizing waste within the realm of 3D printing.

By understanding the diverse landscape of 3D printer filaments, including PLA, ABS, PETG, TPU, and nylon, creators can tailor their reusability efforts to align with the unique properties and characteristics of each filament type. This knowledge empowers individuals to make informed decisions when repurposing filament, ultimately contributing to a more sustainable and efficient 3D printing ecosystem.

Furthermore, the precautions and considerations associated with reusing filament underscore the significance of quality control, material compatibility, and environmental mindfulness. By approaching filament reusability with attentiveness and foresight, creators can navigate the challenges and opportunities inherent in sustainable 3D printing practices, ensuring that reusing filament remains a viable and impactful endeavor.

As the 3D printing landscape continues to evolve, the ethos of reusing filament encapsulates the spirit of innovation, environmental stewardship, and community collaboration. Embracing this ethos fosters a collective commitment to minimizing material waste, maximizing resource efficiency, and promoting sustainable creativity within the 3D printing domain.

In essence, the journey of reusing 3D printer filament transcends mere material repurposing; it embodies a collective vision for a more sustainable and conscientious approach to 3D printing. By integrating reusability into the fabric of 3D printing practices, we honor the principles of innovation, environmental responsibility, and community-driven progress, shaping a future where creativity and sustainability harmoniously converge.

As you embark on your 3D printing endeavors, may the spirit of reusing filament inspire you to explore new frontiers of creativity, all while championing a sustainable and mindful approach to material utilization. Together, we can redefine the possibilities of 3D printing, one filament at a time.

Frequently Asked Questions about How To Reuse 3D Printer Filament

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Reuse 3D Printer Filament”