Home>Technology>Smart Home Devices>How Long Can You Leave A 3D Printer Running

Smart Home Devices

How Long Can You Leave A 3D Printer Running

Modified: February 18, 2024

Learn about the safety and practical considerations of leaving your 3D printer running continuously. Discover tips for managing your smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Have you ever wondered about the optimal duration for running a 3D printer? As the popularity of 3D printing continues to soar, it's essential to understand the factors that determine how long you can leave a 3D printer operational. Whether you're an experienced enthusiast or a newcomer to the world of 3D printing, this article will provide valuable insights to help you make informed decisions about printer usage.

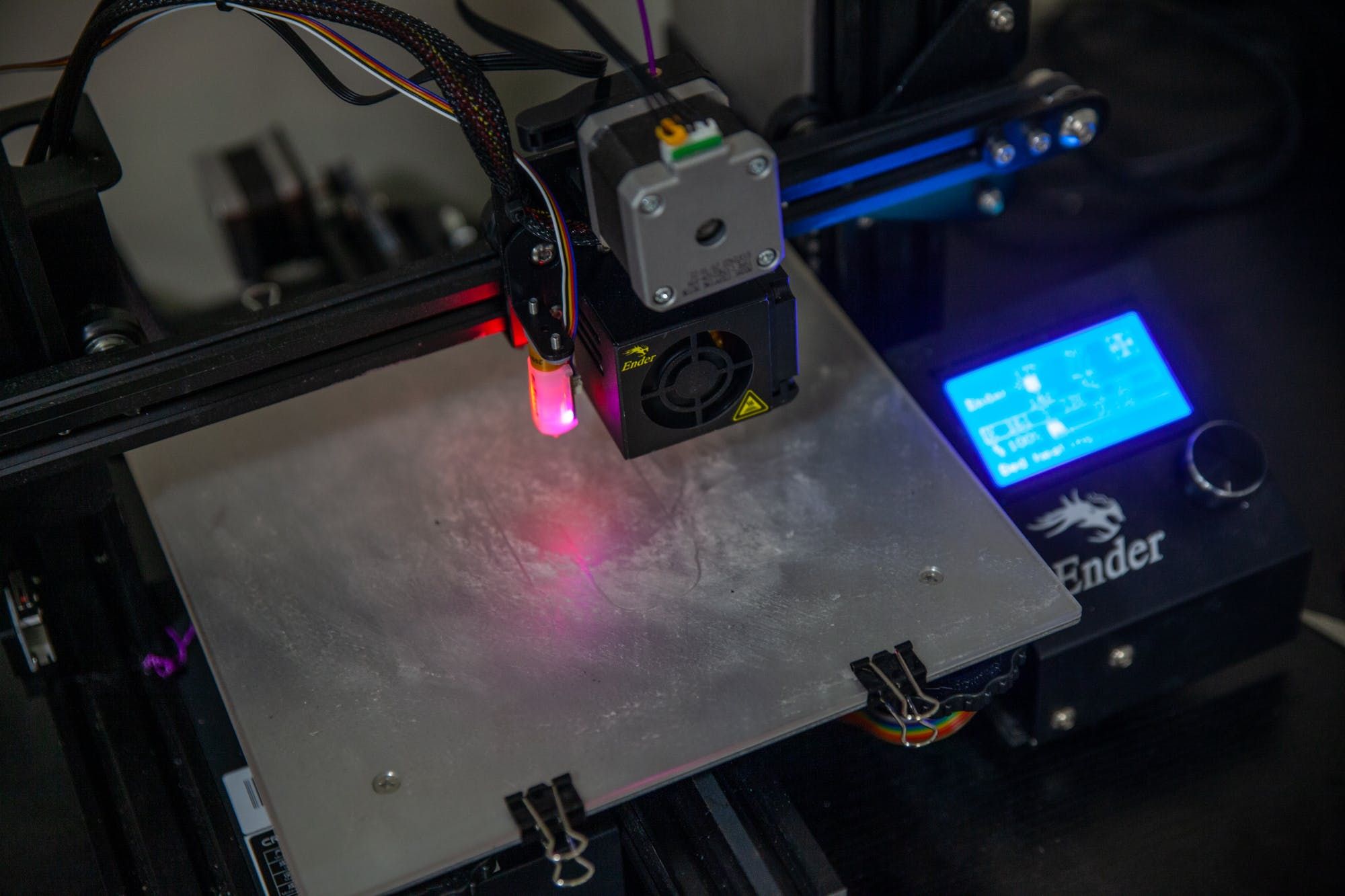

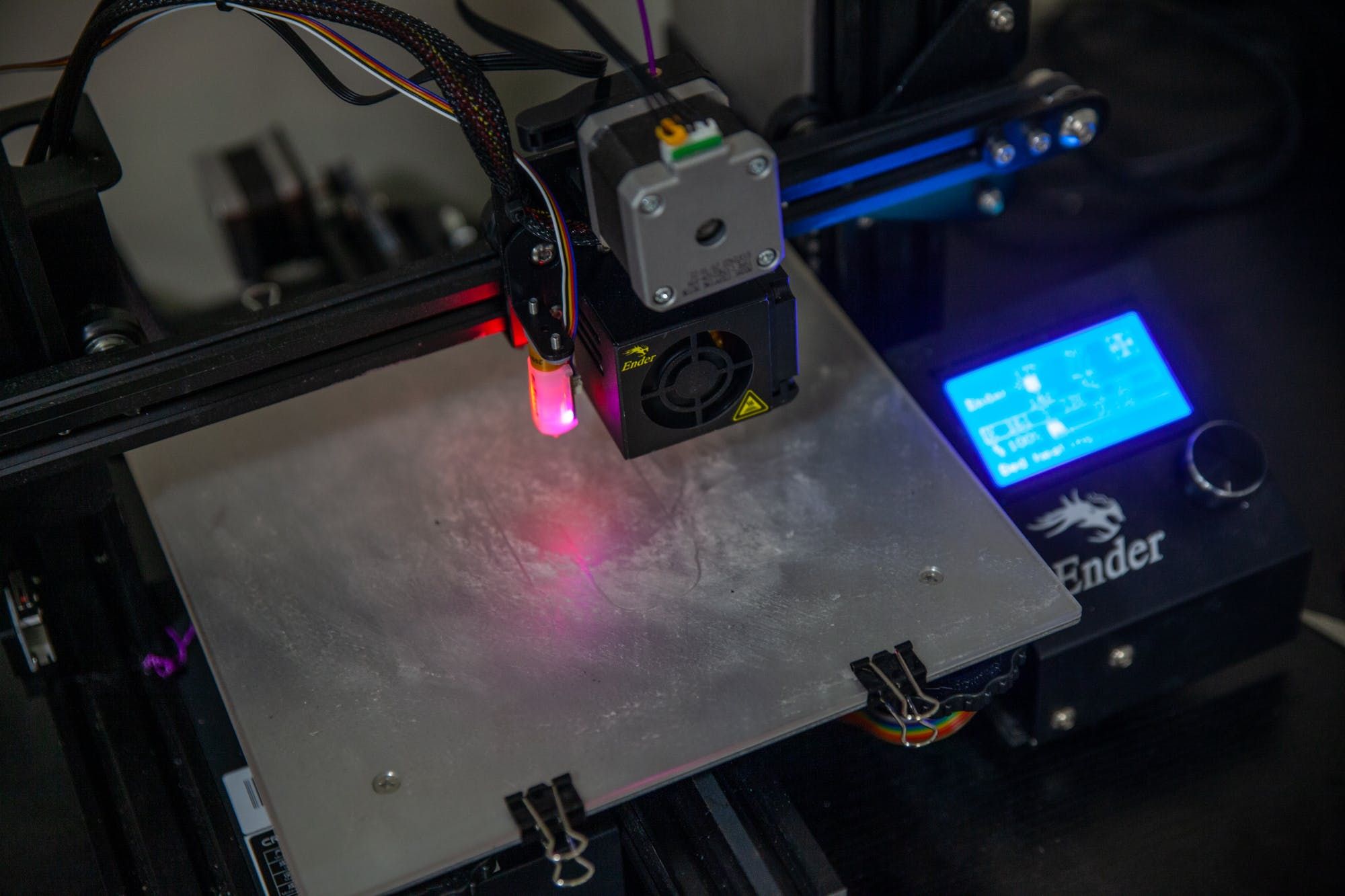

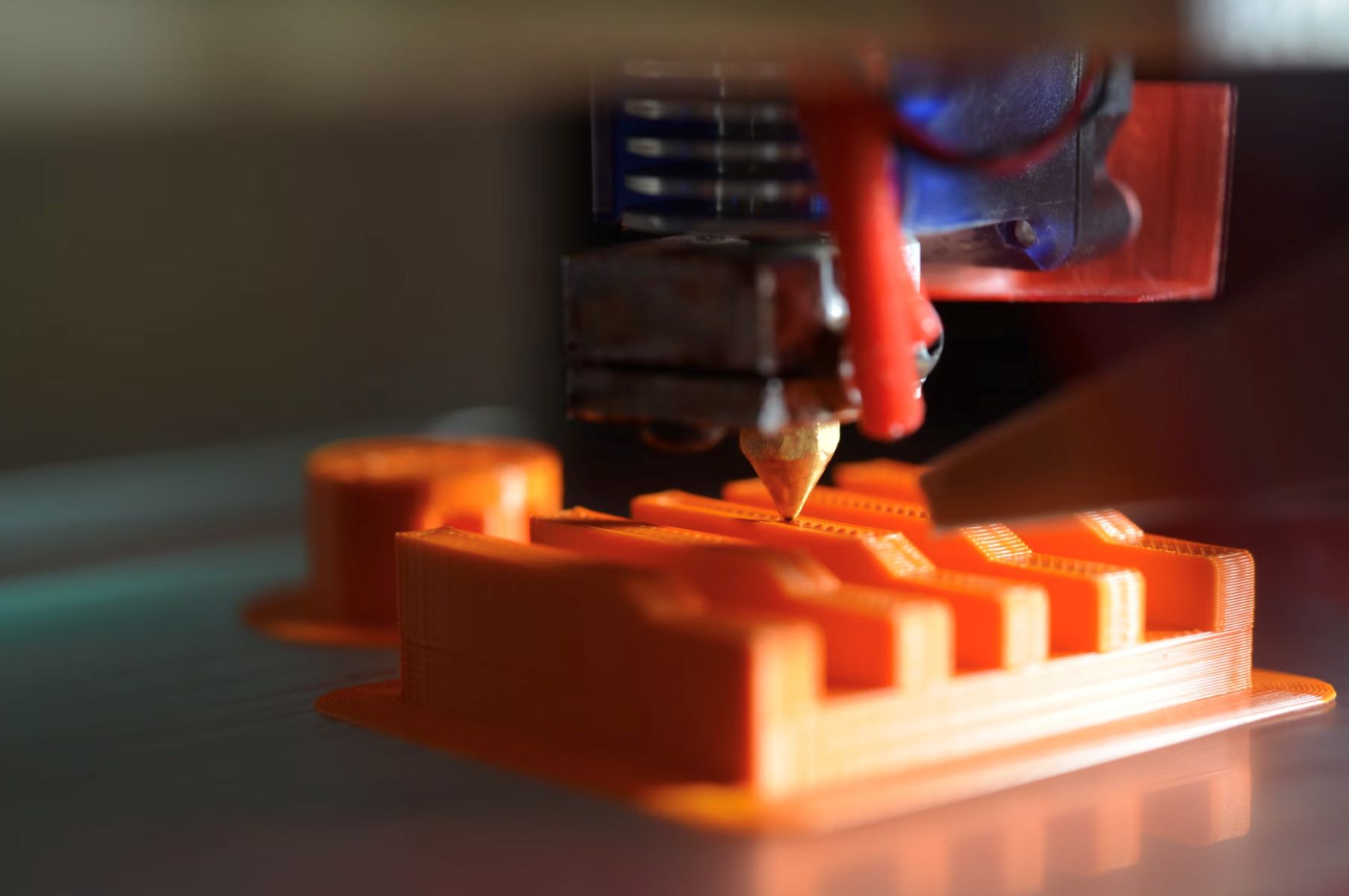

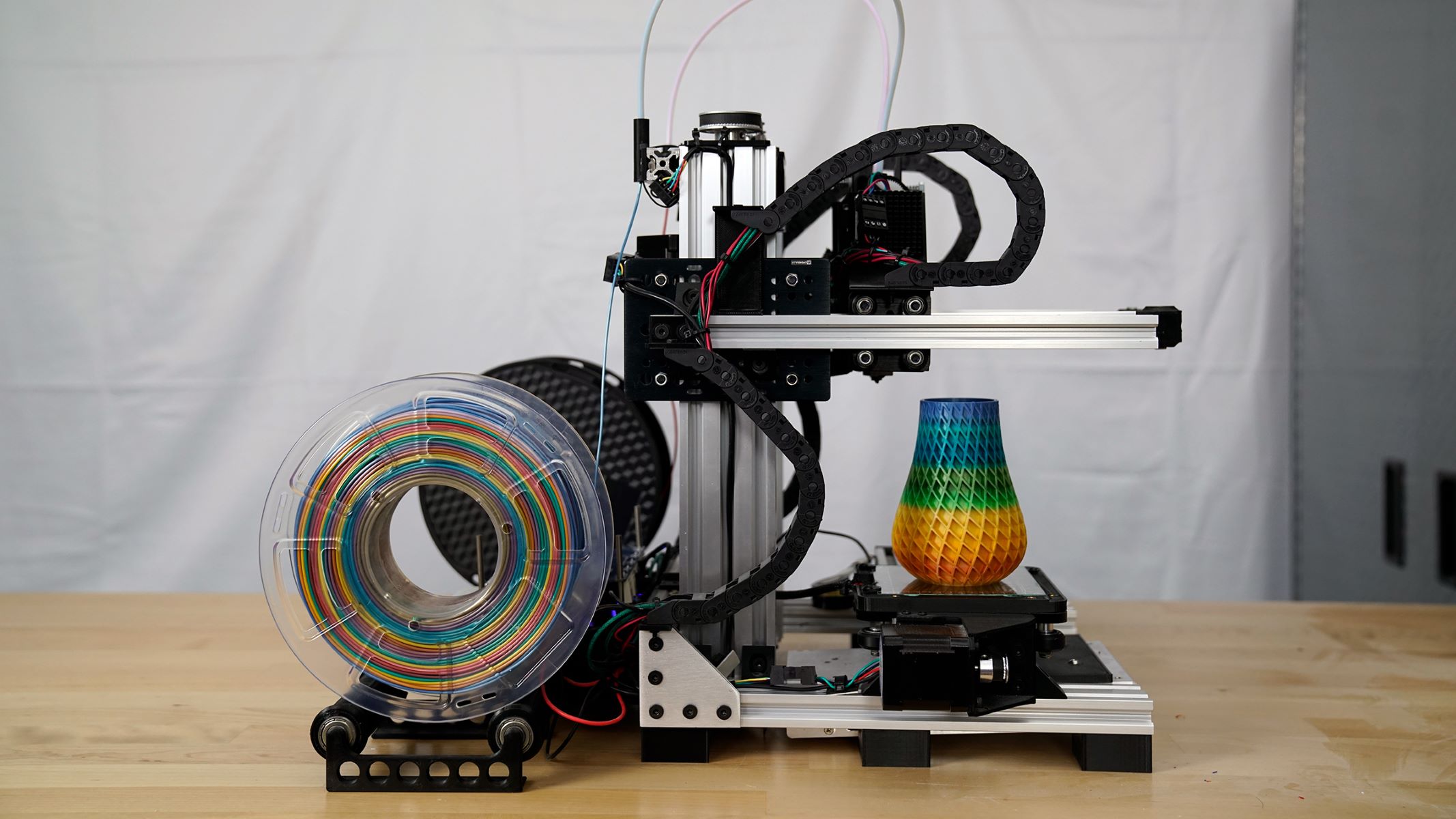

3D printing, also known as additive manufacturing, has revolutionized various industries, from prototyping and manufacturing to art and design. The process involves creating three-dimensional objects by depositing material layer by layer based on a digital model. As 3D printing technology evolves, the capabilities of printers expand, allowing for more complex and precise creations.

In this article, we'll delve into the factors that influence the duration for which a 3D printer can safely and effectively operate. From safety precautions and potential risks to maintenance and monitoring, we'll explore essential considerations to ensure optimal printer performance and user safety. So, let's embark on this insightful journey to uncover the intricacies of 3D printer usage and maintenance.

Key Takeaways:

- Running a 3D printer for extended periods requires considering factors like printer model, material, and safety precautions to ensure optimal performance and safety.

- Regular maintenance, monitoring, and awareness of potential risks are crucial for sustaining reliable 3D printing operations and minimizing operational disruptions.

Read more: What Can You Make On A 3D Printer

Factors to Consider

When determining how long you can leave a 3D printer running, several critical factors come into play. Understanding and addressing these factors is essential for optimizing the printer’s performance and ensuring safe operation. Let’s explore the key considerations:

- Printer Model and Specifications: The specific model of your 3D printer and its technical specifications significantly influence its operational capabilities. Higher-end models with robust construction and advanced cooling systems may be designed to handle longer print durations compared to entry-level printers.

- Print Material and Complexity: The type of filament or resin used for printing, along with the complexity of the design, can impact the duration of a print job. Certain materials may require precise temperature control and exhibit varying behaviors during extended printing, affecting the overall print quality and reliability.

- Heat Management: Efficient heat dissipation is crucial for prolonged 3D printing sessions. Printers equipped with effective cooling mechanisms, such as fans and heat sinks, are better equipped to manage heat buildup during extended operation, reducing the risk of malfunctions and ensuring consistent print quality.

- Power Supply Stability: A stable and reliable power supply is essential for uninterrupted printing. Sudden power fluctuations or outages can disrupt print jobs, leading to potential defects in the printed object. Using a surge protector or uninterruptible power supply (UPS) can safeguard the printer against power-related issues.

- Print Bed Adhesion and Calibration: Proper adhesion of the print to the bed and accurate calibration are critical for successful, uninterrupted printing. Inadequate adhesion or calibration errors can result in print failures, especially during long printing sessions, leading to wasted time and resources.

By considering these factors, you can make informed decisions regarding the duration for which your 3D printer can safely operate. Addressing these aspects proactively contributes to a smoother printing experience and enhances the overall reliability of your 3D printing endeavors.

Safety Precautions

Ensuring the safety of both the 3D printer and its operators is paramount when contemplating extended printing durations. Implementing appropriate safety measures minimizes the risk of accidents, malfunctions, and potential hazards. Let’s explore essential safety precautions to observe when leaving a 3D printer running for an extended period:

- Fire Safety: 3D printers generate heat during operation, and certain components, such as hot ends and heated beds, can pose fire hazards if not properly managed. To mitigate this risk, it’s crucial to keep flammable materials away from the printer and have fire extinguishing equipment readily accessible in the vicinity.

- Smoke and Fume Extraction: Some printing materials emit fumes or particles during the printing process, potentially posing health risks if inhaled. Implementing adequate ventilation or utilizing a fume extractor helps minimize exposure to airborne contaminants, promoting a safer printing environment.

- Overheating Prevention: Monitoring the printer’s temperature throughout extended printing sessions is essential to prevent overheating. Ensure that the printer’s cooling systems are functioning optimally and avoid obstructing ventilation openings to facilitate heat dissipation.

- Operational Supervision: While longer print durations may be necessary for certain projects, it’s advisable to periodically check on the printer to monitor its progress and detect any anomalies. This proactive approach allows for timely intervention in the event of issues such as filament jams or mechanical malfunctions.

- Electrical Safety: Safeguard the printer against electrical hazards by using grounded outlets and appropriate power cables. Regularly inspect the power supply and associated components for signs of damage or wear, and refrain from overloading electrical circuits with multiple high-power devices.

By adhering to these safety precautions, you can significantly reduce the likelihood of accidents and operational disruptions when leaving your 3D printer running for extended periods. Prioritizing safety not only protects the equipment and surrounding environment but also promotes a secure and reliable 3D printing environment for all involved.

It is generally safe to leave a 3D printer running unattended for a few hours, but it is not recommended to leave it running for extended periods of time, especially overnight or when you are not at home. Always follow the manufacturer’s guidelines and monitor the printer for any signs of malfunction.

Potential Risks

While 3D printing technology offers remarkable capabilities, it is essential to be aware of the potential risks associated with prolonged printer operation. Understanding these risks empowers users to proactively mitigate them and maintain a safe and efficient printing environment. Let’s delve into the potential risks of leaving a 3D printer running for extended durations:

- Component Wear and Tear: Extended printing sessions can subject the printer’s components to increased wear and tear. Moving parts, such as belts, bearings, and extruder mechanisms, may experience accelerated degradation, potentially leading to diminished print quality and reliability over time.

- Filament or Resin Depletion: Lengthy print jobs consume significant amounts of filament or resin. Inadvertently running out of material mid-print can result in incomplete objects and wasted time. Monitoring material levels and ensuring sufficient supply before initiating long print sessions mitigates this risk.

- Print Failures: The longer a print job runs, the higher the probability of encountering print failures. Factors such as filament jams, power fluctuations, or mechanical issues can disrupt the printing process, leading to incomplete or flawed objects. Regular monitoring and preemptive maintenance help minimize the likelihood of such failures.

- Environmental Considerations: Extended 3D printing can impact the surrounding environment, particularly in terms of heat generation and airborne particle emissions. Adequate ventilation and temperature control are essential to mitigate these effects and maintain a comfortable and safe workspace.

- Operational Fatigue: Continuous operation of a 3D printer without sufficient intervals for maintenance and cooling can contribute to operational fatigue. This may manifest as reduced print quality, increased error rates, and heightened susceptibility to malfunctions, emphasizing the importance of periodic rest periods for the printer.

By recognizing and understanding these potential risks, 3D printer operators can take proactive measures to mitigate them and optimize the overall printing experience. Implementing regular maintenance, monitoring material consumption, and addressing operational fatigue are integral to minimizing the impact of these risks and sustaining reliable 3D printing operations.

Maintenance and Monitoring

Effective maintenance and diligent monitoring are pivotal for ensuring the longevity, performance, and safety of a 3D printer, particularly during extended operation. By adhering to a proactive maintenance regimen and implementing vigilant monitoring practices, users can mitigate potential issues and sustain optimal printing conditions. Let’s explore the essential aspects of maintenance and monitoring for prolonged 3D printer operation:

- Regular Cleaning and Lubrication: Periodic cleaning of the printer’s components, such as the print bed, extruder, and guide rails, helps prevent the accumulation of debris and residues that can impede smooth operation. Additionally, applying appropriate lubricants to moving parts minimizes friction and reduces wear, contributing to prolonged component lifespan.

- Firmware and Software Updates: Keeping the printer’s firmware and associated software up to date is crucial for leveraging performance enhancements, bug fixes, and compatibility improvements. Regularly checking for updates and applying them in a timely manner ensures the printer operates with optimal stability and functionality.

- Calibration and Quality Checks: Regular calibration of the printer’s components, including the extruder, print bed, and axis alignments, is essential for maintaining print accuracy and consistency. Conducting quality checks on printed objects helps identify any deviations from expected specifications, enabling timely adjustments and optimizations.

- Material and Consumables Management: Monitoring filament or resin levels and ensuring a consistent supply of printing materials is crucial for uninterrupted printing. Additionally, proper storage and handling of consumables, such as filament spools and resin cartridges, preserve material integrity and prevent printing issues stemming from degraded or contaminated materials.

- Temperature and Environmental Control: Maintaining a stable and suitable operating environment for the printer is essential for consistent print quality and component longevity. Monitoring ambient temperature, humidity levels, and airflow ensures that the printer operates within optimal conditions, reducing the likelihood of print defects and equipment stress.

By prioritizing regular maintenance and vigilant monitoring, 3D printer operators can uphold the printer’s performance, extend its lifespan, and minimize the risk of operational disruptions. These proactive measures contribute to a reliable and efficient 3D printing environment, fostering consistent output quality and user satisfaction.

Read more: What Can You Make With A 3D Printer

Conclusion

As the realm of 3D printing continues to evolve, the question of how long a 3D printer can be safely left running becomes increasingly relevant. By considering a multitude of factors, implementing safety precautions, understanding potential risks, and embracing diligent maintenance and monitoring practices, users can navigate extended printing durations with confidence and prudence.

It is evident that the specific model and technical specifications of a 3D printer, the materials being used, and the operational environment collectively influence the printer’s capacity for prolonged operation. By acknowledging these factors, users can make informed decisions regarding the duration for which their printers can reliably function, while optimizing print quality and equipment longevity.

Safety precautions play a pivotal role in mitigating potential hazards associated with extended 3D printer operation. From fire safety and fume extraction to electrical considerations, prioritizing safety measures fosters a secure printing environment for both the equipment and its operators.

Understanding the potential risks of prolonged printing sessions empowers users to proactively address wear and tear, material consumption, and operational fatigue. By recognizing these risks and taking preemptive measures, users can minimize the impact of potential issues and sustain consistent print quality and operational reliability.

Furthermore, the significance of proactive maintenance and vigilant monitoring cannot be overstated. Regular cleaning, lubrication, firmware updates, calibration, and consumables management are integral to sustaining optimal printer performance and mitigating operational disruptions during extended printing sessions.

In conclusion, the duration for which a 3D printer can be safely left running is contingent upon a myriad of factors, safety precautions, risk awareness, and maintenance practices. By embracing these considerations and best practices, 3D printer operators can navigate extended printing durations with confidence, ensuring reliable performance and fostering a secure and efficient printing environment.

Frequently Asked Questions about How Long Can You Leave A 3D Printer Running

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Can You Leave A 3D Printer Running”