Home>Technology>Smart Home Devices>What Does A 3D Printer Use For Material

Smart Home Devices

What Does A 3D Printer Use For Material

Published: January 10, 2024

Discover the materials used by 3D printers and their applications in smart home devices. Learn about the latest advancements in 3D printing technology.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of 3D printing, where innovation and creativity converge to bring ideas to life. 3D printing, also known as additive manufacturing, has revolutionized various industries, from manufacturing and healthcare to art and culinary arts. At the core of this innovative technology lies the question: What materials can a 3D printer use to bring digital designs into the physical realm?

In this comprehensive guide, we will explore the diverse range of materials utilized in 3D printing, shedding light on the unique properties and applications of each. Whether you're an enthusiast, a professional in a specific industry, or simply curious about the possibilities of 3D printing, this exploration will provide valuable insights into the materials that fuel this groundbreaking technology.

Join us as we embark on a journey through the world of 3D printing materials, uncovering the versatility and potential of plastic filament, resin, metal, ceramic, and even food as essential elements in the 3D printing process. Let's delve into the intricate details and discover the remarkable ways in which these materials are harnessed to transform digital concepts into tangible objects.

Key Takeaways:

- 3D printing materials, including plastic filament, resin, metal, ceramic, and even food, have revolutionized manufacturing, healthcare, and culinary arts, offering limitless possibilities for creativity and innovation.

- Plastic filament empowers 3D printing enthusiasts with versatility and affordability, while resin elevates precision and detail. Metal 3D printing offers unparalleled design freedom, ceramic 3D printing unlocks new dimensions in advanced manufacturing, and food 3D printing revolutionizes culinary artistry and personalized nutrition.

Read more: What File Does 3D Printer Use

Plastic Filament

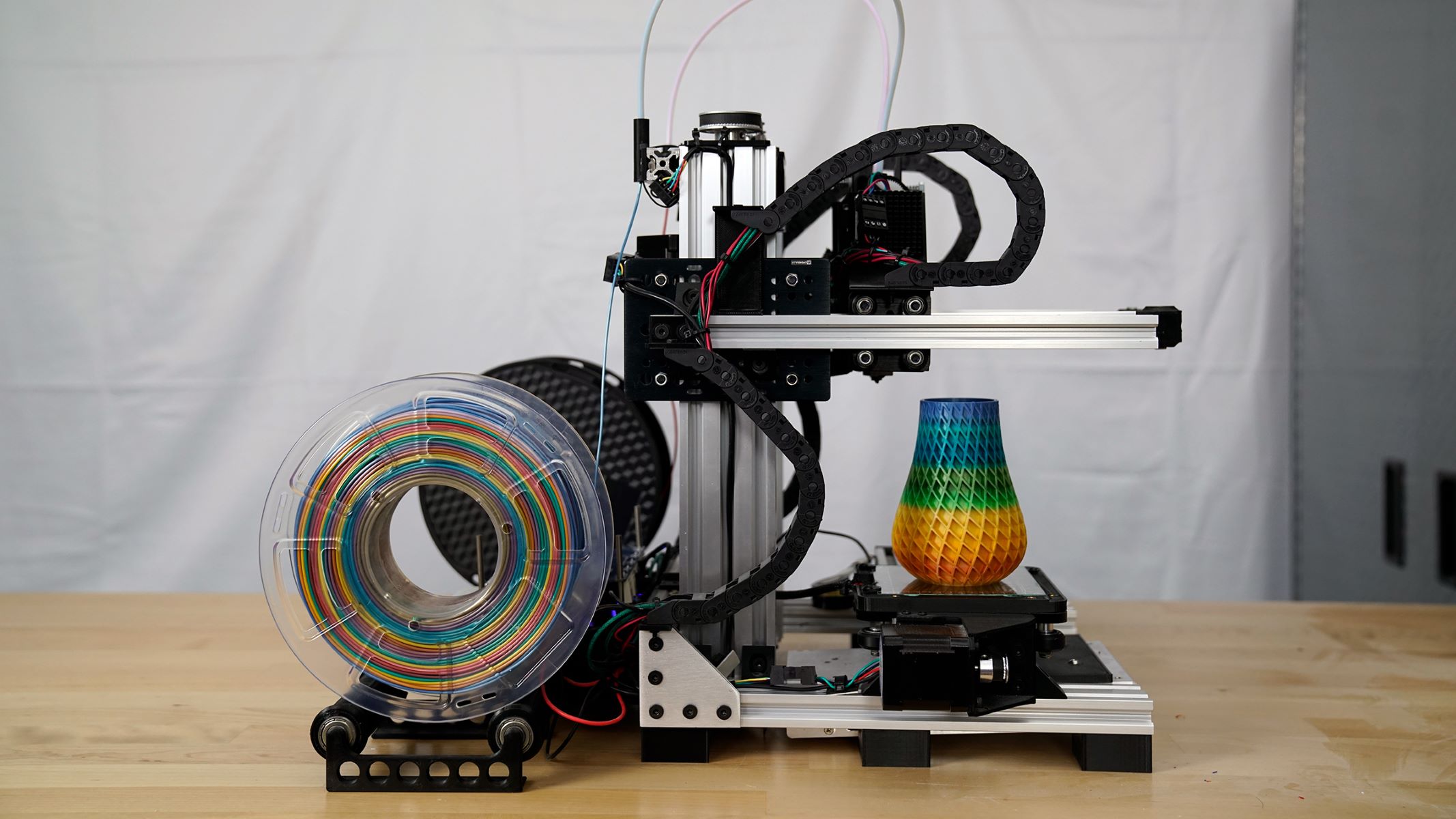

Plastic filament is one of the most commonly used materials in 3D printing, prized for its versatility, affordability, and wide range of applications. Typically made from thermoplastics such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), plastic filament offers a diverse array of colors and properties, making it suitable for various projects and industries.

PLA, derived from renewable resources such as cornstarch or sugarcane, is celebrated for its eco-friendly nature and biodegradability. It is often favored for creating prototypes, consumer products, and intricate models due to its low warping and ease of use. On the other hand, ABS boasts superior strength and durability, making it a preferred choice for functional parts, automotive components, and industrial prototypes.

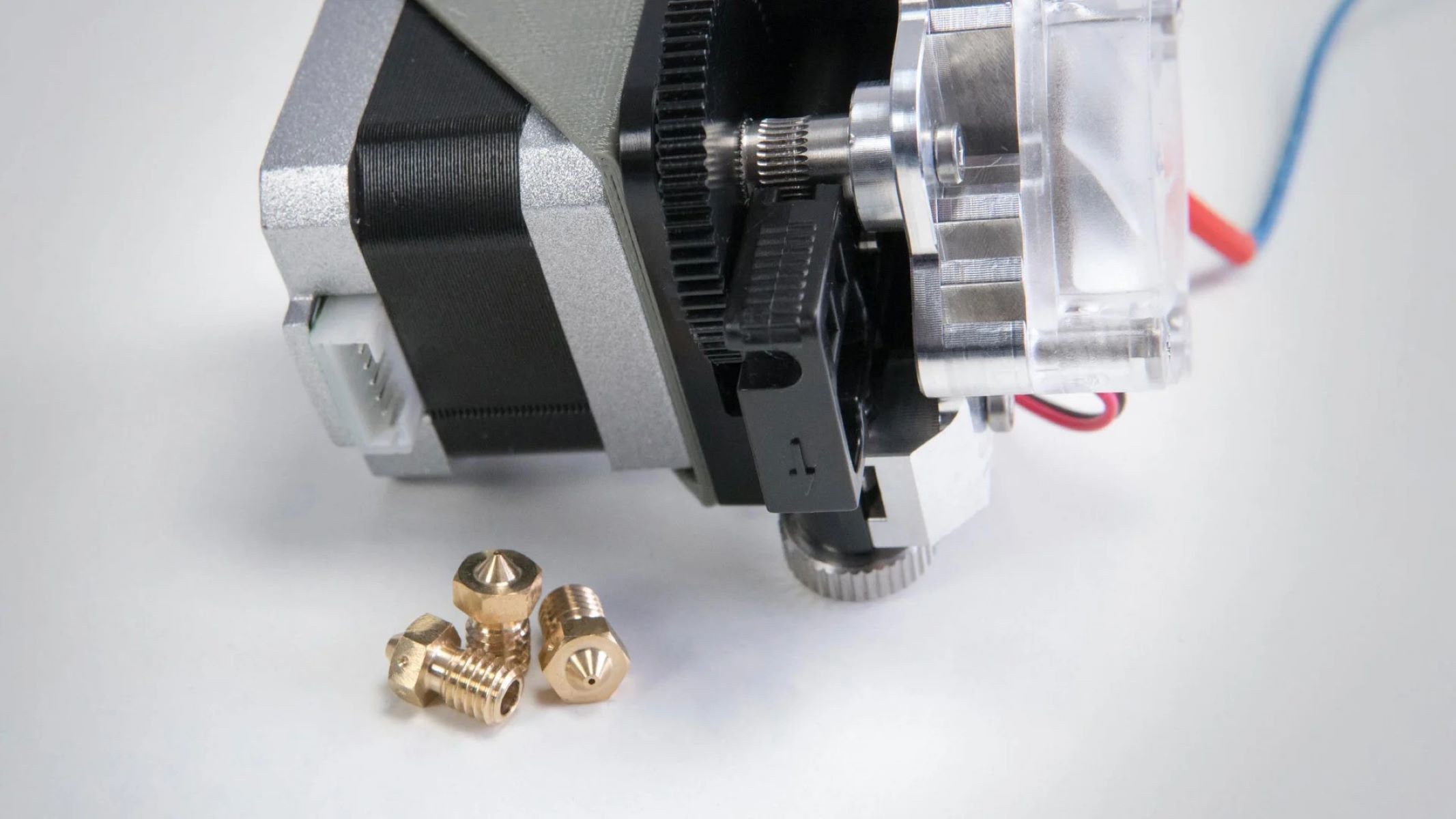

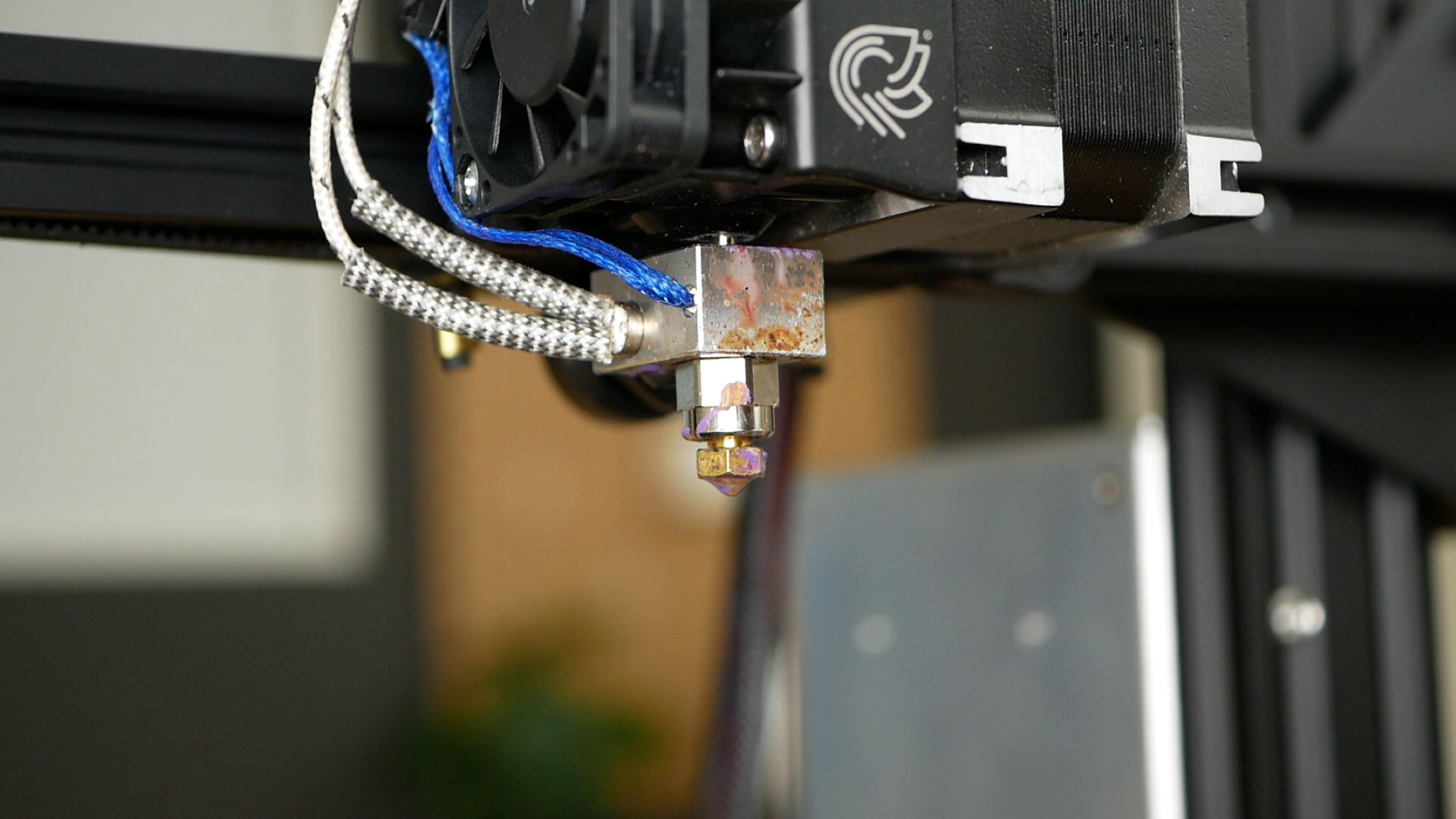

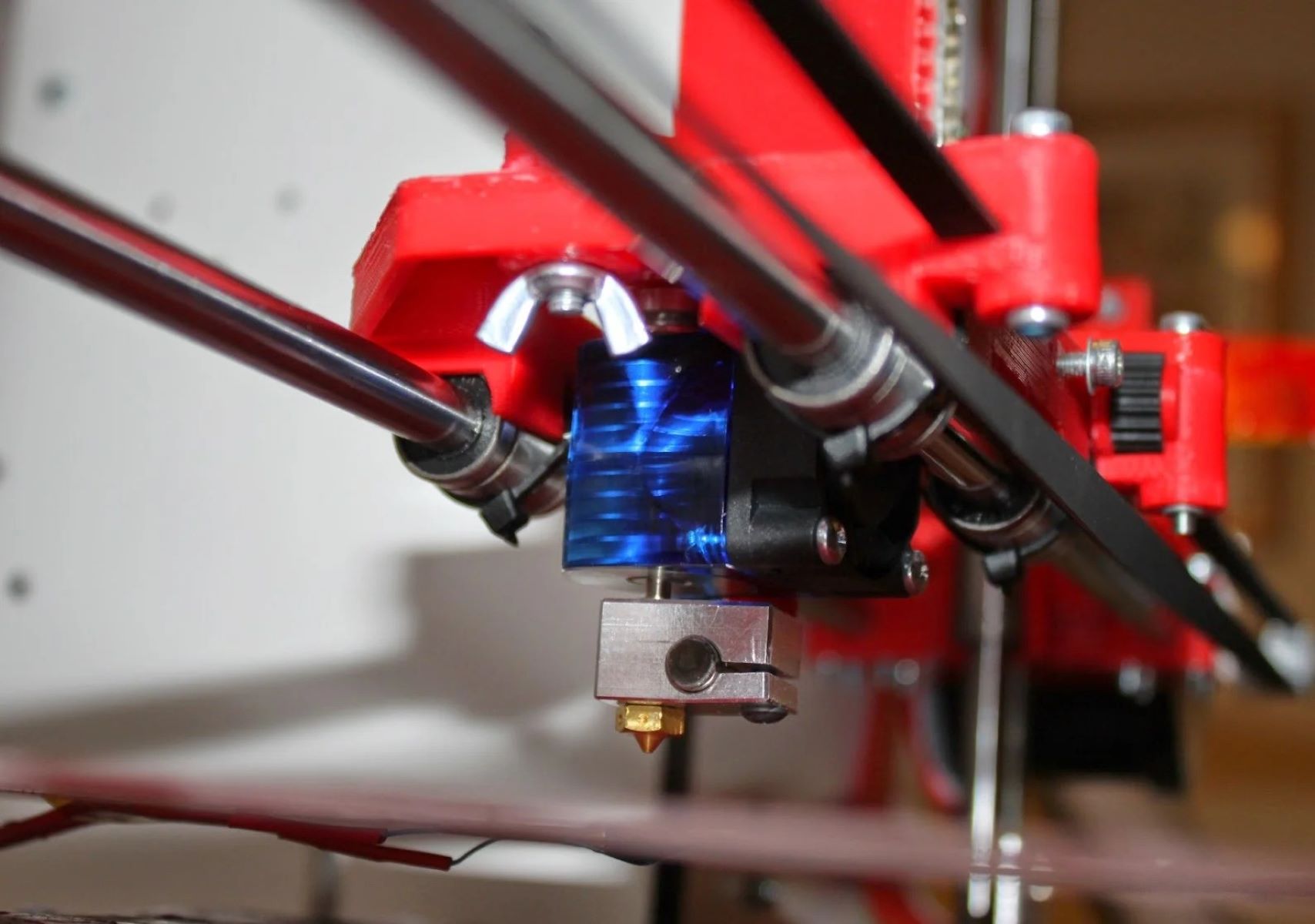

3D printers utilize plastic filament by heating it to a precise temperature, allowing it to melt and be extruded layer by layer to form the desired object. The versatility of plastic filament extends to specialized variations such as flexible filaments, which are ideal for producing rubber-like objects, and composite filaments infused with materials like wood or metal particles, adding unique textures and properties to the printed objects.

Whether you’re crafting intricate jewelry, engineering prototypes, or vibrant artistic creations, plastic filament empowers 3D printing enthusiasts and professionals to bring their visions to life with precision and creativity. Its accessibility and adaptability make it a foundational material in the world of additive manufacturing, driving innovation and pushing the boundaries of what is possible.

Resin

Resin, a versatile and rapidly evolving material, has significantly expanded the horizons of 3D printing, particularly in the realm of high-detail, intricate, and smooth-surface objects. Utilizing a process known as stereolithography, resin-based 3D printers selectively cure liquid resin using a UV light source, layer by layer, to create precise and intricate objects with remarkable surface quality.

One of the key advantages of resin-based 3D printing is the ability to produce objects with fine details and intricate geometries, making it an ideal choice for jewelry, dental appliances, and figurines. The resin’s ability to capture intricate details and produce smooth surfaces elevates the quality and visual appeal of the printed objects, setting it apart from traditional filament-based 3D printing.

Resins come in various formulations, each tailored to specific applications and desired characteristics. Standard resins offer a balance of strength and detail, catering to a wide range of applications, while specialized resins, such as flexible, tough, or castable resins, cater to specific needs, from functional prototypes to investment casting patterns.

Furthermore, the evolution of resin materials has led to the development of engineering-grade resins with exceptional mechanical properties, heat resistance, and chemical resistance, expanding the scope of 3D printing to functional end-use parts in industries such as aerospace, automotive, and healthcare.

As the capabilities of resin-based 3D printing continue to advance, the material’s potential for producing high-precision, detailed, and functional objects grows exponentially, opening new doors for innovation and customization across diverse industries.

Metal

3D printing with metal materials has revolutionized the manufacturing landscape, enabling the production of complex, high-strength, and precise metal components with unparalleled design freedom. The process, known as metal additive manufacturing or direct metal laser sintering, involves selectively fusing metal powder particles layer by layer using a high-powered laser or electron beam, resulting in fully dense metal parts with intricate geometries.

One of the defining attributes of metal 3D printing is the ability to work with a wide range of metals, including titanium, aluminum, stainless steel, and nickel-based superalloys, each offering unique mechanical properties, corrosion resistance, and heat resistance. This versatility allows for the creation of functional prototypes, customized medical implants, aerospace components, and intricate jewelry, among other applications.

Metal 3D printing offers unparalleled design freedom, enabling the production of complex geometries, lattice structures, and internal channels that are challenging or impossible to achieve through traditional manufacturing methods. This capability has spurred innovation in industries such as aerospace, where lightweight and high-strength components are essential, and healthcare, where patient-specific implants and surgical instruments can be tailored with precision.

Furthermore, the exceptional mechanical properties of metal parts produced through 3D printing, including high tensile strength, fatigue resistance, and thermal conductivity, have positioned metal additive manufacturing as a disruptive force in the production of end-use parts for critical applications.

As the technology continues to advance, with developments in multi-material printing, in-situ alloying, and post-processing techniques, the potential for metal 3D printing to transform industries, drive innovation, and unlock new possibilities for design and engineering is boundless.

A 3D printer uses various materials such as plastic, metal, resin, and even food ingredients to create 3D objects. These materials are heated and then deposited layer by layer to form the final product.

Ceramic

3D printing with ceramic materials has emerged as a transformative force in the realm of advanced manufacturing, offering the ability to produce intricate ceramic components with precision, complexity, and customization. Ceramic 3D printing, also known as additive manufacturing of ceramics, harnesses the unique properties of ceramics, including high-temperature resistance, electrical insulation, and biocompatibility, to create a diverse array of functional and aesthetic objects.

One of the key advantages of ceramic 3D printing is the ability to produce complex geometries and intricate structures that are challenging to achieve through traditional ceramic forming methods. This capability has unlocked new possibilities in the production of ceramic components for aerospace, electronics, biomedical devices, and architectural applications.

The materials used in ceramic 3D printing encompass a wide range of ceramic powders, including alumina, zirconia, silicon carbide, and specialized formulations tailored to specific applications. These powders are selectively deposited and fused using techniques such as binder jetting or stereolithography, resulting in fully dense ceramic parts with exceptional mechanical properties and surface finishes.

Furthermore, the customization potential of ceramic 3D printing has paved the way for the production of patient-specific medical implants, intricate ceramic art pieces, and functional ceramic components with tailored thermal and electrical properties. The ability to create intricate lattice structures and internal channels within ceramic parts has further expanded the scope of applications, from lightweight aerospace components to efficient heat exchangers.

As the technology continues to evolve, with advancements in multi-material printing, post-processing techniques, and the integration of ceramic composites, the potential for ceramic 3D printing to drive innovation, sustainability, and performance across diverse industries is poised to redefine the boundaries of ceramic manufacturing.

Read more: What Is An Extruder On A 3D Printer

Food

3D printing has transcended traditional manufacturing domains and ventured into the culinary world, where it has redefined the art of food creation and presentation. Food 3D printing, also known as digital gastronomy, utilizes edible ingredients to craft intricate and customized culinary creations, ranging from decorative confections and intricate pastries to personalized nutrition and innovative culinary experiences.

One of the key advantages of food 3D printing is the ability to precisely control the composition, texture, and appearance of food, enabling chefs, food designers, and nutritionists to unleash their creativity and cater to diverse dietary needs. Edible ingredients such as chocolate, sugar, dough, purees, and even plant-based proteins are transformed into printable pastes or gels, allowing for the creation of visually stunning and flavorful dishes.

Food 3D printers, equipped with specialized extrusion nozzles and precise control systems, deposit edible materials layer by layer to build intricate shapes, textures, and structures that are challenging to achieve through traditional culinary techniques. This capability has opened new avenues for artistic expression, personalized nutrition, and culinary innovation.

From creating intricate chocolate sculptures and decorative cake toppers to crafting personalized nutrition bars and visually striking desserts, food 3D printing has empowered chefs and food enthusiasts to push the boundaries of culinary artistry. Furthermore, the technology has the potential to address dietary restrictions, food sustainability, and personalized nutrition by tailoring the composition and presentation of food to individual needs.

As the field of food 3D printing continues to evolve, with ongoing research into novel edible materials, flavor encapsulation techniques, and multi-material printing capabilities, the potential for 3D printing to revolutionize the culinary landscape, redefine dining experiences, and cater to diverse dietary needs is poised to transform the way we perceive and interact with food.

Conclusion

As we conclude our exploration of the diverse materials utilized in 3D printing, it becomes evident that this revolutionary technology has transcended traditional manufacturing boundaries, opening new frontiers of creativity, innovation, and customization across a multitude of industries. From plastic filament and resin to metal, ceramic, and even food, each material has contributed to the transformative power of 3D printing, enabling the production of intricate prototypes, functional components, personalized medical devices, culinary delights, and artistic creations.

Plastic filament, with its versatility and accessibility, has fueled the creativity of makers, designers, and engineers, offering a broad spectrum of colors, properties, and applications. Resin, with its ability to capture fine details and produce high-quality surfaces, has elevated the precision and visual appeal of 3D-printed objects, particularly in jewelry, dental, and specialized applications. Metal 3D printing has redefined the production of high-strength, complex components, offering unparalleled design freedom and functional capabilities across aerospace, healthcare, and beyond.

Furthermore, ceramic 3D printing has unlocked new dimensions in advanced manufacturing, harnessing the unique properties of ceramics to produce intricate, functional components with tailored thermal, electrical, and aesthetic characteristics. Lastly, food 3D printing has ventured into the culinary realm, revolutionizing the art of food creation, presentation, and personalized nutrition, offering chefs and food enthusiasts the ability to craft visually stunning and flavorful dishes with precision and creativity.

As the capabilities of 3D printing continue to evolve, with ongoing advancements in material science, printing technologies, and post-processing techniques, the potential for 3D printing to drive innovation, sustainability, and customization across diverse industries is boundless. Whether it’s the production of intricate aerospace components, personalized medical implants, culinary masterpieces, or artistic creations, 3D printing has proven to be a transformative force, reshaping the way we design, create, and interact with the world around us.

Join us in embracing the limitless possibilities of 3D printing, where imagination meets technology to bring digital concepts to life, one layer at a time.

Frequently Asked Questions about What Does A 3D Printer Use For Material

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does A 3D Printer Use For Material”