Home>Technology>Smart Home Devices>What Is Thermal Runaway In A 3D Printer

Smart Home Devices

What Is Thermal Runaway In A 3D Printer

Modified: August 20, 2024

Learn about thermal runaway in 3D printers and how it can be prevented. Discover essential tips for smart home device safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of 3D printing! As the popularity of 3D printers continues to soar, enthusiasts and professionals alike are delving into the intricacies of this innovative technology. However, amidst the excitement of creating intricate designs and functional prototypes, it is crucial to understand potential risks associated with 3D printing, such as thermal runaway.

In this comprehensive guide, we will explore the concept of thermal runaway in the context of 3D printers. By shedding light on its causes, consequences, and preventive measures, we aim to equip you with the knowledge to ensure safe and efficient 3D printing experiences. So, let's embark on this enlightening journey to unravel the mysteries of thermal runaway in 3D printers!

Key Takeaways:

- Thermal runaway in 3D printers can lead to dangerous temperature spikes, fire hazards, and print quality issues. Preventive measures like regular maintenance and overheat protection are crucial for a safe printing environment.

- Factors like malfunctioning heating elements, environmental variations, and software glitches can trigger thermal runaway. Understanding these causes and implementing quality components and emergency protocols is essential for safe 3D printing.

Read more: What Is An Extruder On A 3D Printer

Understanding Thermal Runaway

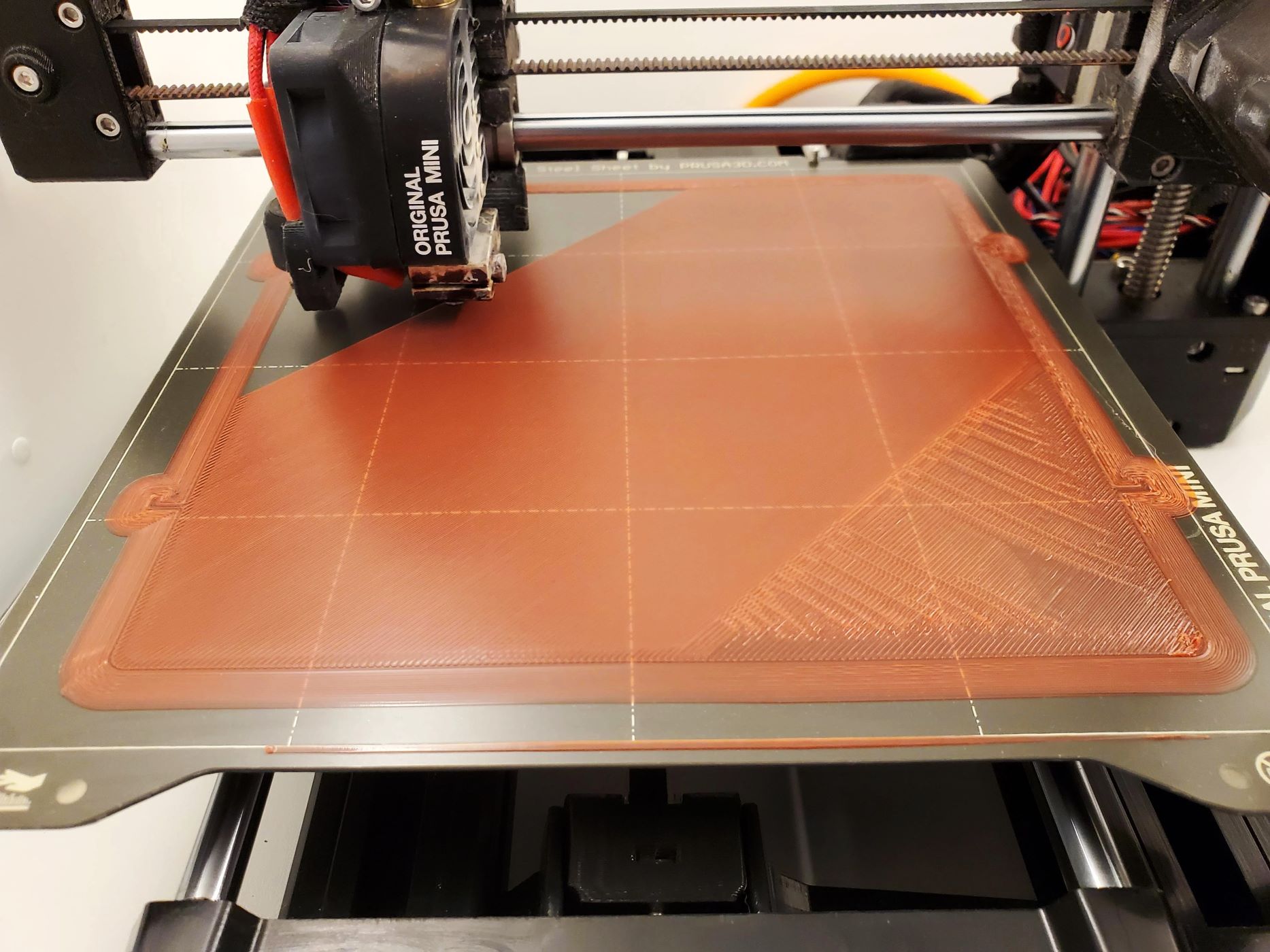

Thermal runaway in the realm of 3D printing refers to a potentially hazardous scenario in which the temperature of the print head or heated bed of a 3D printer spirals out of control, leading to a cascade of detrimental effects. This phenomenon can result in a range of issues, from print quality degradation to the risk of fire and damage to the printer itself.

At the core of thermal runaway is the inability of the printer’s heating system to maintain the desired temperature within a safe range. This can occur due to various factors, such as malfunctioning components, environmental influences, or software glitches. When left unchecked, thermal runaway can pose serious safety hazards and compromise the integrity of the printed objects.

Essentially, thermal runaway is a situation where the printer’s heating elements continue to generate heat beyond the set parameters, leading to an uncontrolled rise in temperature. This runaway effect can rapidly escalate, potentially reaching levels that pose a fire risk and endanger the surrounding environment.

Understanding the dynamics of thermal runaway is pivotal for 3D printing enthusiasts and professionals. By grasping the intricacies of this phenomenon, individuals can implement proactive measures to mitigate its occurrence and safeguard their printing endeavors.

Causes of Thermal Runaway in 3D Printers

Several factors can contribute to the onset of thermal runaway in 3D printers, each presenting unique challenges that necessitate careful consideration and proactive management. Understanding these potential causes is instrumental in implementing effective preventive strategies and maintaining a safe 3D printing environment.

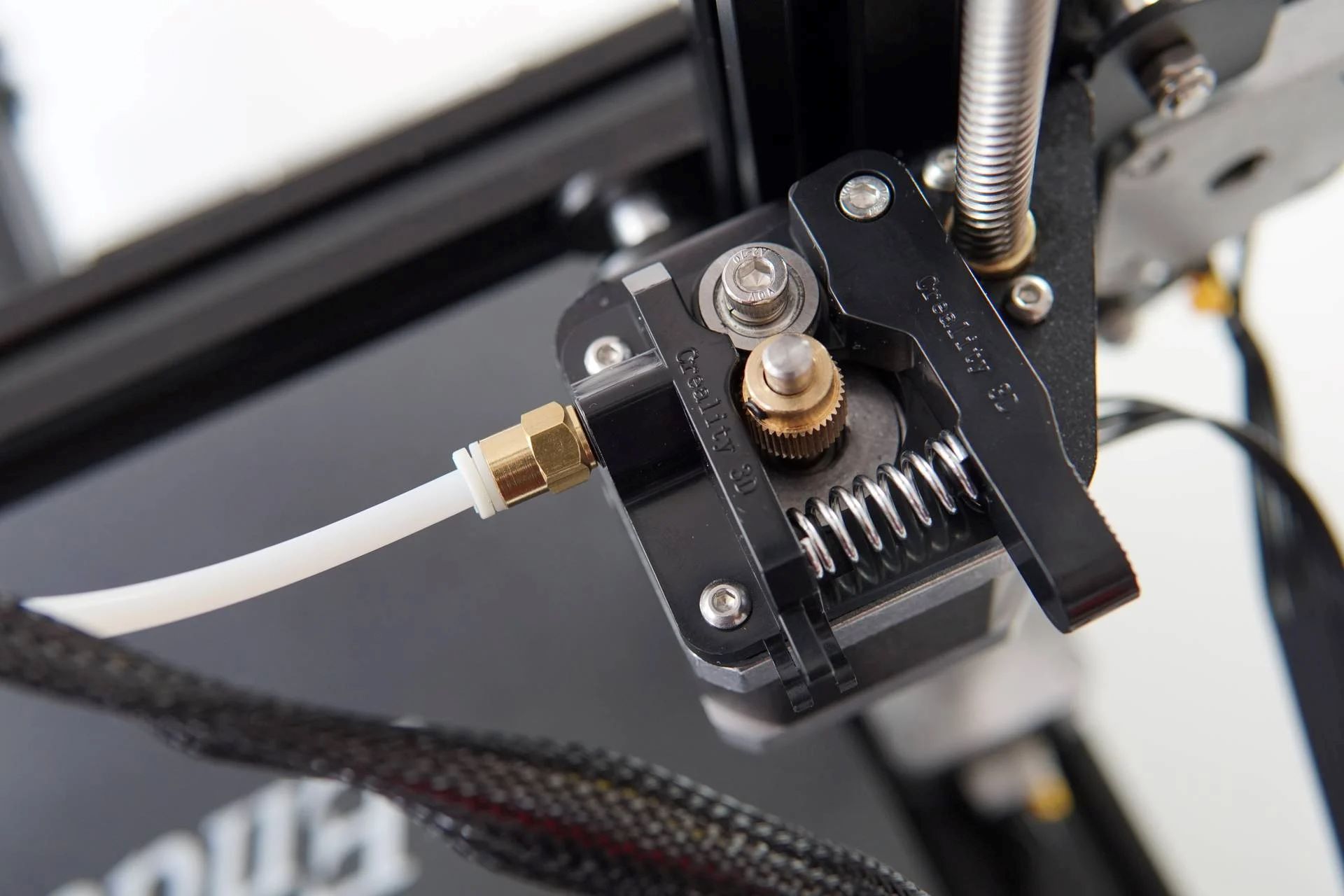

- Malfunctioning Heating Elements: One of the primary culprits behind thermal runaway is the malfunction of the heating elements within the 3D printer, including the print head and heated bed. This can stem from wear and tear, electrical issues, or substandard components, leading to erratic temperature regulation and the risk of runaway.

- Environmental Variations: Fluctuations in ambient temperature and humidity levels can exert a significant influence on the thermal stability of a 3D printer. Sudden environmental shifts can disrupt the heat dissipation process, potentially triggering thermal runaway if not adequately managed.

- Software Glitches: The software controlling the 3D printer’s heating system plays a pivotal role in maintaining temperature parameters. However, software malfunctions, bugs, or compatibility issues can compromise the accuracy of temperature regulation, paving the way for thermal runaway incidents.

- Insufficient Cooling Mechanisms: Inadequate cooling mechanisms, such as malfunctioning fans or clogged ventilation channels, can impede the dissipation of heat generated by the printer’s components. This impediment to heat dissipation can exacerbate the risk of thermal runaway.

- Electrical Anomalies: Electrical irregularities, including power surges, voltage fluctuations, or faulty connections, can disrupt the stable operation of the 3D printer’s heating system, potentially leading to uncontrolled temperature spikes and thermal runaway.

By identifying and comprehending these potential causes, 3D printing enthusiasts and professionals can proactively address vulnerabilities within their printing setups, bolstering the resilience of their systems against thermal runaway.

Always monitor your 3D printer while it’s running to prevent thermal runaway. Check for any unusual smells, smoke, or excessive heat. Regular maintenance and cleaning can also help prevent issues that could lead to thermal runaway.

Consequences of Thermal Runaway

The ramifications of thermal runaway in a 3D printing environment can be far-reaching, encompassing a spectrum of adverse effects that compromise the safety, quality, and functionality of the printing process. Understanding these consequences is pivotal in emphasizing the urgency of preventive measures and the imperative need for vigilance when operating 3D printers.

- Print Quality Degradation: Thermal runaway can manifest in the form of inconsistent and flawed print quality, characterized by irregularities and deformities in the printed objects. Uncontrolled temperature fluctuations can disrupt the extrusion process, resulting in structural weaknesses and surface imperfections.

- Fire Hazard: Perhaps the most alarming consequence of thermal runaway is the heightened risk of fire. As the temperature spirals out of control, the accumulation of heat can ignite flammable materials within the printer or its vicinity, posing a grave hazard to the surroundings.

- Component Damage: The sustained exposure to excessively high temperatures during a thermal runaway event can inflict damage on vital components of the 3D printer, including the print head, heated bed, wiring, and electronic circuitry. This can necessitate costly repairs and jeopardize the printer’s operational integrity.

- Safety Risks: Thermal runaway poses inherent safety risks to individuals in the vicinity of the 3D printer, as well as the broader environment. The potential for fire outbreaks and exposure to hazardous fumes underscores the critical need for preemptive measures to avert such perils.

- Operational Disruption: In addition to the immediate hazards, thermal runaway can disrupt the seamless operation of 3D printers, leading to production delays, material wastage, and interruptions in project timelines.

By comprehending the multifaceted consequences of thermal runaway, 3D printing practitioners can appreciate the gravity of this phenomenon and prioritize the implementation of robust preventive strategies to mitigate its potential impact.

Preventing Thermal Runaway

Effectively mitigating the risk of thermal runaway in 3D printers necessitates a proactive approach that encompasses a spectrum of preventive measures, encompassing hardware, software, and operational protocols. By integrating these strategies, individuals can fortify the resilience of their 3D printing setups and cultivate a safe and reliable printing environment.

- Regular Maintenance: Conducting routine maintenance checks on the 3D printer’s heating elements, cooling systems, and electrical connections is imperative for identifying and rectifying potential vulnerabilities that could precipitate thermal runaway.

- Quality Components: Investing in high-quality heating elements, such as reliable print heads and heated beds, can bolster the stability and longevity of the 3D printer’s heating system, minimizing the risk of malfunctions that culminate in thermal runaway.

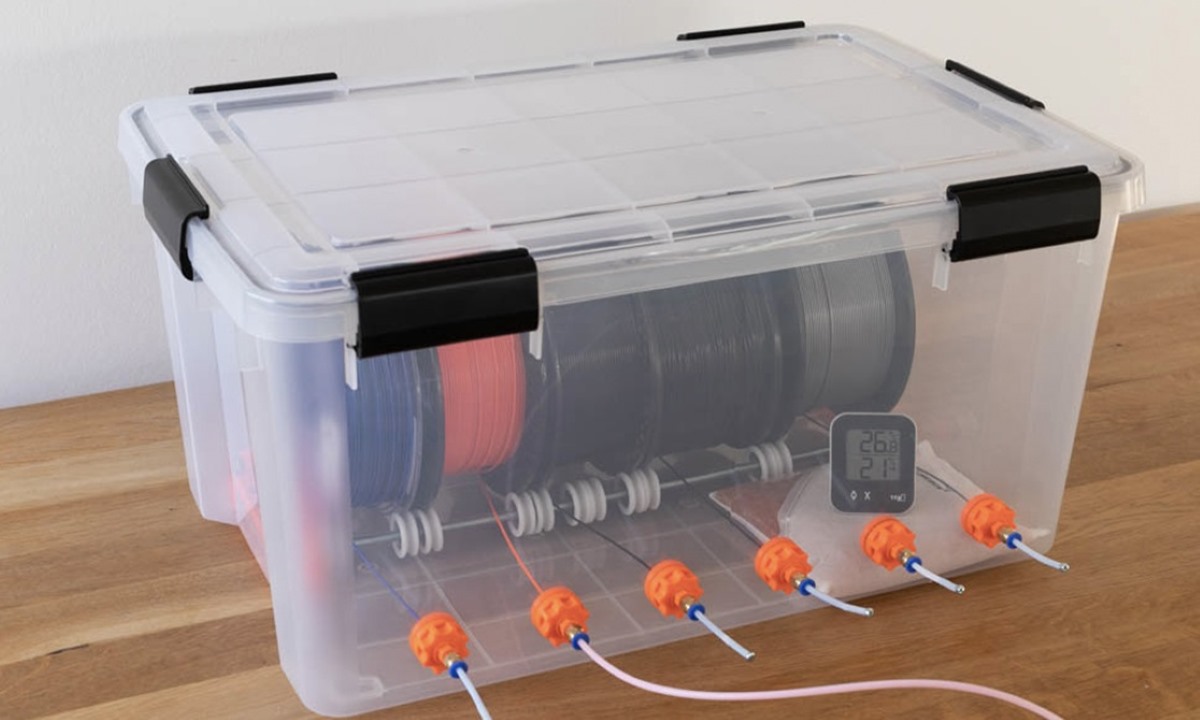

- Environmental Control: Maintaining a stable and conducive printing environment, characterized by controlled temperature and humidity levels, can mitigate the impact of environmental variations on the printer’s thermal regulation, reducing the likelihood of thermal runaway.

- Software Vigilance: Keeping the 3D printing software updated and ensuring compatibility with the printer’s hardware is essential for optimizing temperature control and preempting software-related glitches that could precipitate thermal runaway.

- Overheat Protection: Implementing overheat protection mechanisms, such as thermal fuses and temperature sensors, provides an additional layer of defense against thermal runaway by triggering automatic shutdowns in the event of temperature anomalies.

- Emergency Protocols: Establishing clear protocols for responding to potential thermal runaway incidents, including fire safety measures and printer shutdown procedures, is crucial for mitigating the impact of such emergencies and safeguarding individuals and property.

By embracing a holistic approach to preventive measures, 3D printing enthusiasts and professionals can fortify their defenses against thermal runaway, fostering a secure and productive printing environment that prioritizes safety and operational continuity.

Read more: What Is A Resin 3D Printer

Conclusion

As we conclude our exploration of thermal runaway in 3D printers, it is evident that this phenomenon embodies a significant risk that demands conscientious attention and proactive measures from the 3D printing community. The intricate interplay of hardware, software, and environmental factors underscores the multifaceted nature of thermal runaway, emphasizing the imperative need for a comprehensive approach to risk mitigation.

By comprehending the causes and consequences of thermal runaway, individuals can cultivate a heightened awareness of the potential vulnerabilities within their 3D printing setups. This awareness serves as a catalyst for the implementation of robust preventive strategies, ranging from regular maintenance and quality component selection to the integration of overheat protection mechanisms and emergency protocols.

Furthermore, the emphasis on environmental control and software vigilance underscores the interconnectedness of various elements in safeguarding against thermal runaway. As the 3D printing landscape continues to evolve, it is paramount for practitioners to remain vigilant, adaptable, and informed, continuously refining their preventive measures to align with emerging technologies and best practices.

Ultimately, by prioritizing safety, operational continuity, and the preservation of print quality, individuals can navigate the realm of 3D printing with confidence, leveraging their understanding of thermal runaway to fortify their printing environments and cultivate a culture of responsible and secure 3D printing practices.

Armed with this knowledge, we embark on our 3D printing endeavors with a steadfast commitment to mitigating the risks posed by thermal runaway, fostering a harmonious convergence of innovation, safety, and excellence within the captivating realm of 3D printing.

Frequently Asked Questions about What Is Thermal Runaway In A 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Thermal Runaway In A 3D Printer”