Articles

How Does A Refrigerator Ice Maker Work

Modified: May 6, 2024

Discover how a refrigerator ice maker works with this informative article. Learn about the inner workings and functions of this essential appliance feature.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Refrigerator ice makers have become an essential feature in modern households, providing a convenient and constant supply of ice for all your cooling needs. But have you ever wondered how these ice makers actually work? In this article, we will delve into the fascinating mechanism behind refrigerator ice makers and explore the step-by-step process of how they produce those refreshing ice cubes.

Ice makers are typically located in the freezer compartment of the refrigerator and are connected to the water supply. Once activated, they go through a series of processes to transform water into perfectly formed ice cubes. Understanding the inner workings of these ice makers can help you appreciate the engineering marvel behind their operation.

So, let’s dive into the world of refrigerator ice makers and explore the intriguing mechanism that brings the cold comfort of ice into our lives!

Key Takeaways:

- Refrigerator ice makers work by filling a mold with water, freezing it, then harvesting and dispensing the ice cubes. The process involves precise water control, freezing temperatures, and innovative mechanisms for efficient ice production.

- Understanding the intricate process behind refrigerator ice makers allows us to appreciate the engineering marvel that brings the convenience of ice cubes into our lives. From water supply to ice dispensing, each step is carefully orchestrated to ensure a constant supply of refreshing ice.

Read more: How Does An Ice Maker Work In A Refrigerator

Understanding the Ice Maker Mechanism

Before we delve into the detailed steps of how a refrigerator ice maker works, it’s important to grasp the fundamental components that make up its mechanism. The key elements of an ice maker include the water supply, water valve, ice mold, freezer temperature control, and ice dispenser. Each of these components plays a crucial role in the ice-making process.

The ice maker operates under the principle of freezing water in a specifically designed mold and then harvesting the ice cubes. It involves a combination of mechanical and electrical processes that work in harmony to produce ice cubes efficiently and continuously.

The process begins by supplying water to the ice mold. The water is controlled by a water valve, which opens and closes to let the right amount of water into the mold. Once the mold is filled, it is then placed inside the freezer, where the temperature is maintained at a freezing point.

The freezing process occurs when the mold comes into contact with the extremely low temperatures inside the freezer. The water gradually freezes, transforming into solid ice cubes. This freezing process is accelerated by the presence of refrigerant tubes or coils, which actively cool the mold.

Once the ice is completely frozen and ready to be harvested, the ice maker initiates the harvest cycle. This involves heating the mold slightly or using mechanical devices to separate the ice cubes from the mold. The ice cubes are then released into a storage bin or passed through a dispenser chute to be readily available for use.

All of these processes are carefully controlled by various sensors, timers, and electrical circuits within the ice maker. These components work together to ensure that the production and harvesting of ice cubes occur smoothly, maintaining a constant supply of ice for your convenience.

Now that we have a basic understanding of the ice maker mechanism, let’s explore each step of the process in more detail to get a comprehensive understanding of how it all comes together.

Step 1: Water Supply

The first step in the ice-making process is the water supply. A refrigerator ice maker is connected to the main water supply of your home or directly to a water line. This ensures a constant flow of water to the ice maker, allowing it to produce ice whenever needed.

When you activate the ice maker, either manually or through an automatic sensor, it sends a signal to the water valve to open. The water valve is responsible for controlling the flow of water to the ice maker. It is typically located at the back of the refrigerator and connected to the water supply line.

Upon receiving the signal, the water valve opens, allowing water to enter the ice maker. The amount of water is controlled by the ice maker’s internal mechanisms, ensuring that the correct amount is dispensed into the ice mold. This precise measurement of water is crucial for producing properly sized ice cubes.

Depending on the specific ice maker design, the water supply may be regulated by a timer or a sensor. For timers, a predetermined duration of water flow is set, ensuring that the mold is adequately filled. Sensors, on the other hand, can detect the level of water in the mold and stop the flow once it reaches the desired level.

It’s important to note that the water used for making ice should be clean and free from contaminants. Many ice makers are equipped with filters to remove impurities and provide high-quality, pure ice cubes. Regularly cleaning and maintaining these filters will help ensure the purity and taste of your ice.

With the water supply stage complete, the ice maker moves on to the next step: filling the ice mold with the correct amount of water. We will explore this process in detail in the next section.

Step 2: Water Valve

The water valve plays a crucial role in the ice-making process by controlling the flow of water to the ice maker. It ensures that the ice mold receives the correct amount of water to produce properly sized ice cubes.

The water valve is typically located at the back of the refrigerator, near the water supply line. It consists of a solenoid, which is an electromechanical device that controls the flow of water through the valve. When the ice maker sends a signal to open the water valve, the solenoid is activated and allows water to flow into the ice maker.

The activation of the water valve can be triggered manually or automatically. In manual activation, you can use a lever or push button on the front of the refrigerator to open the water valve and initiate the ice-making process. Automatic activation occurs when the ice maker’s internal mechanisms detect the need for more ice and send a signal to the water valve to open.

The water valve is designed to dispense the correct amount of water required for each ice-making cycle. It ensures that the ice mold is adequately filled without overflow or underfill. This precise control is important for producing consistent and properly sized ice cubes.

In some ice makers, the water valve may also have a secondary function of controlling the flow of water to other parts of the refrigerator, such as a water dispenser or a cold water line. This versatility allows for convenient access to both ice and cold water from the same appliance.

It is worth noting that the durability and reliability of the water valve are important factors for the overall performance of the ice maker. A faulty valve can lead to water leakage, inconsistent ice production, or even damage to the refrigerator. Regular maintenance and inspection of the water valve are essential to ensure its proper functioning.

With the water valve controlling the flow of water, the ice maker proceeds to the next step: filling the ice mold with water. We will explore this process in detail in the following section.

Step 3: Filling the Ice Mold

After the water valve has opened to allow water into the refrigerator ice maker, the next step is to fill the ice mold. The ice mold is a specially designed container where the water is poured and transformed into ice cubes.

The ice mold is typically made of durable plastic and has multiple compartments or slots. These compartments determine the shape and size of the ice cubes that will be produced. Common shapes include square, rectangular, or cylindrical cubes.

When the water valve opens, water flows into the ice maker and is directed into the ice mold. The amount of water is carefully controlled by the ice maker’s internal mechanisms to ensure that each compartment of the mold receives the correct amount of water.

The water level in the ice mold is crucial for producing properly sized ice cubes. If the mold is underfilled, the resulting ice cubes will be small and may melt quickly. Conversely, if the mold is overfilled, the ice cubes may be too large and cause problems during the harvesting process.

Some ice makers employ sensors to monitor the water level in the mold, ensuring accuracy and consistency. These sensors detect when the water reaches the desired level and notify the ice maker to stop the water flow. Other ice makers rely on timers, where a predetermined duration of water flow is set to achieve the desired water level.

Once the ice mold has been filled with the correct amount of water, the ice maker proceeds to the next step: freezing the water to transform it into solid ice. We will explore this freezing process in more detail in the following section.

Regularly cleaning and maintaining the ice maker and its components, such as the water filter and ice bin, can help ensure efficient and clean ice production.

Read more: How Does An Ice Maker Work?

Step 4: Freezing the Ice

After the ice mold has been properly filled with water, the freezing process begins in the refrigerator ice maker. The goal of this step is to transform the water into solid ice cubes through the application of low temperatures.

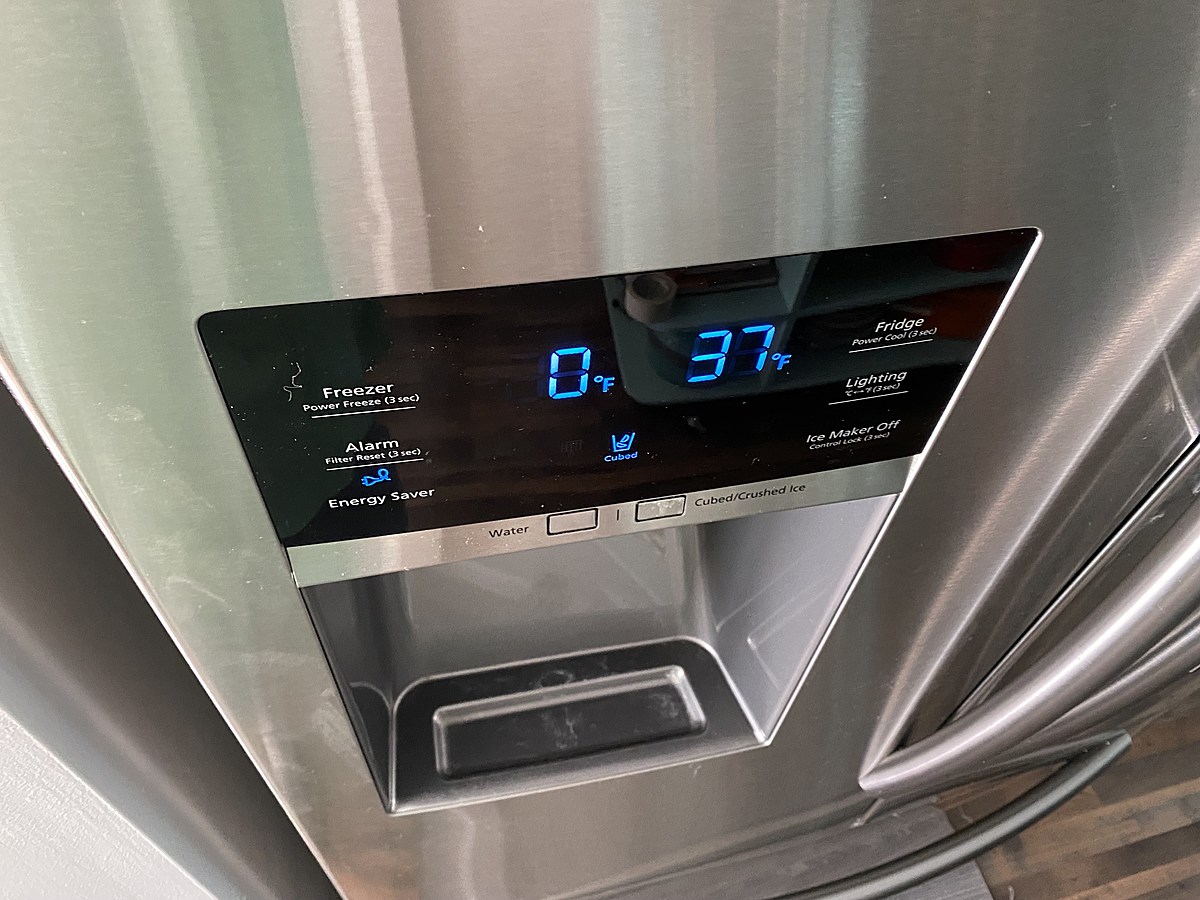

Inside the freezer compartment of the refrigerator, the temperature is maintained at a freezing point. This is typically around 0 degrees Fahrenheit (-18 degrees Celsius), ensuring that the water in the ice mold freezes rapidly and efficiently.

The freezing process is accelerated by the presence of refrigerant tubes or coils in close proximity to the ice mold. These tubes contain a refrigerant gas that is cooled to extremely low temperatures. When the air in the freezer comes into contact with these cold coils or tubes, it is rapidly cooled, creating a frosty environment.

As the water-filled ice mold is exposed to the freezing air in the freezer, heat is transferred from the water to the cold air. This causes the water to gradually freeze, starting from the edges of the mold and gradually working its way inward.

The time it takes for the water to freeze and solidify into ice cubes depends on various factors, including the ambient temperature, the temperature settings of the freezer, and the design of the ice maker. In most cases, it takes a few hours for the water to completely freeze and form solid ice cubes.

During the freezing process, it is important for the ice maker to maintain a consistent temperature. Fluctuations in temperature can affect the quality and integrity of the ice cubes. Modern ice makers are equipped with sensors and temperature control mechanisms to ensure that the freezing process occurs under optimal conditions.

Once the water in the ice mold has completely frozen, the ice maker moves on to the next step: harvesting the ice cubes. We will explore this fascinating process in detail in the following section.

Step 5: Harvesting the Ice

Once the water in the ice mold has frozen and transformed into solid ice cubes, the refrigerator ice maker moves on to the next step: harvesting the ice. During this step, the ice cubes are released from the mold and prepared for dispensing or storage.

To initiate the harvest cycle, the ice maker employs various methods depending on its design. One common method involves heating the ice mold slightly to loosen the ice cubes. This is achieved by activating a heating element positioned around the mold. The heat melts the surface of the ice cubes just enough to allow them to be easily released.

Alternatively, some ice makers use mechanical devices to separate the ice cubes from the mold. These devices may include rotating blades, rakes, or even vibrating mechanisms that help loosen the ice cubes and dislodge them from the mold.

Once the ice cubes are released, they either fall into a storage bin located underneath the ice maker or are directed towards an ice dispenser. The storage bin collects the ice cubes and keeps them frozen until they are ready to be used.

In ice makers with built-in ice dispensers, the harvested ice cubes are guided through a dispenser chute and are ready to be dispensed on demand. The dispensing mechanism is typically activated by pressing a button or lever, allowing the ice cubes to be easily accessed without opening the refrigerator door.

It’s worth noting that some ice makers employ sensors or mechanisms to ensure that the storage bin doesn’t overfill with ice. These sensors can detect the level of ice in the bin and may temporarily pause the ice-making process if the bin is full. This prevents the ice maker from wasting water and energy on producing excess ice.

The harvesting of the ice cubes marks the final step of the ice-making process. The ice maker has successfully transformed water into solid ice, and the ice cubes are now ready to be used for cooling drinks or other purposes. With the ice cubes harvested, the ice maker enters a standby mode until more ice is needed or until it is manually activated again.

Step 6: Ice Dispensing

After the ice cubes have been harvested and stored, the refrigerator ice maker offers the convenience of easy ice dispensing. This final step allows you to access the ice cubes whenever you need them, without the hassle of manually removing them from the storage bin.

In ice makers with built-in ice dispensers, the ice cubes are guided through a dispenser chute or ice chute towards a designated area. This area is typically accessible from the front of the refrigerator, allowing you to conveniently retrieve the ice cubes.

To dispense the ice cubes, you can use a control panel on the front of the refrigerator. This control panel usually features buttons or levers that activate the ice dispensing mechanism. When you press or activate the appropriate button or lever, the ice cubes are released from the storage bin and directed towards the dispensing area.

Some ice dispensers offer the option to dispense ice in different forms, such as ice cubes, crushed ice, or even chilled water. This versatility allows you to choose the desired form based on your preferences and needs.

Once the ice cubes are dispensed, they can be collected in a glass, container, or directly added to drinks or beverages. The dispenser chute directs the ice cubes with controlled force to ensure minimal splatter and easy collection.

Within the dispenser chute, there is often a mechanism that prevents the ice cubes from clumping together. This mechanism, such as an agitator or rotating paddle, ensures that the ice cubes remain loose and separate, making it easier for them to be dispensed smoothly.

It’s important to note that regular cleaning and maintenance of the ice dispenser are essential to ensure its proper functioning. This includes wiping down the dispenser area, removing any ice buildup or residue, and periodically inspecting the dispensing mechanism for any signs of wear or damage.

With the ice dispenser providing convenient access to ice cubes, the ice-making process is complete. The refrigerator ice maker has successfully produced, harvested, and dispensed the ice cubes for your cooling needs!

Conclusion

Refrigerator ice makers have revolutionized the way we enjoy cold beverages and keep our food fresh. Understanding the mechanism behind these ice makers allows us to appreciate the intricate processes involved in transforming water into ice cubes with just the push of a button.

From the water supply and the water valve to the filling of the ice mold, the freezing process, and the harvesting and dispensing of the ice cubes, each step is carefully orchestrated to ensure the production of high-quality ice. The precise control of water flow and temperature, along with the use of innovative mechanisms, guarantees a constant supply of refreshing ice cubes whenever we need them.

Modern ice makers are equipped with advanced features like sensors, timers, and temperature controls to optimize the ice-making process. They also offer the convenience of built-in ice dispensers, allowing for easy access to ice cubes without opening the refrigerator door.

Regular maintenance and cleaning are important for maintaining the performance and longevity of your refrigerator ice maker. This includes ensuring a clean water supply, changing filters as needed, and regularly inspecting and cleaning the ice mold and dispenser area.

Whether it’s for cooling beverages, alleviating summer heat, or hosting gatherings, a refrigerator ice maker is a valuable addition to any modern kitchen. The constant supply of ice cubes ensures that you never run out, providing convenience and comfort year-round.

So the next time you enjoy a refreshing drink with ice cubes, take a moment to appreciate the fascinating mechanism behind your refrigerator ice maker. It’s the small details that make our lives more enjoyable, and having a reliable ice maker is certainly one of them.

Now that you've mastered how refrigerator ice makers operate, maintaining this appliance is crucial for its longevity and efficiency. If you're curious about keeping yours clean and fully functional, our guide on refrigerator maintenance offers practical tips for keeping ice makers spotless. Should you encounter any hitches with your device, our detailed instructions on ice maker repair will help you fix common issues quickly and effectively. Both articles provide valuable insights to ensure your ice maker stays in top condition!

Frequently Asked Questions about How Does A Refrigerator Ice Maker Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does A Refrigerator Ice Maker Work”