Articles

How To Check Compressor On Refrigerator

Modified: January 19, 2024

Learn how to check the compressor on your refrigerator with this helpful article. Discover step-by-step instructions and troubleshooting tips to ensure optimal performance and efficiency.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

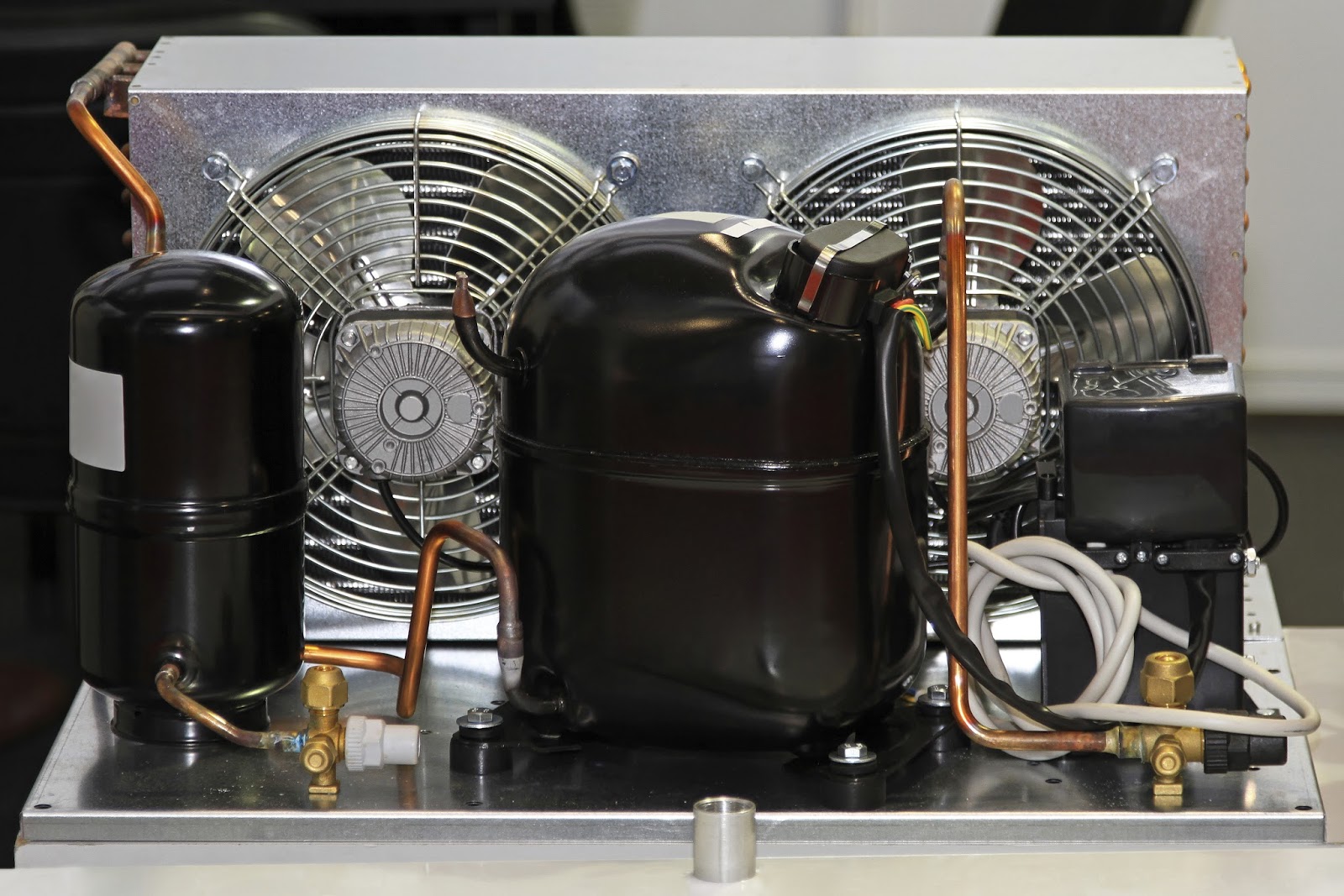

When it comes to keeping your refrigerator running smoothly, the compressor plays a key role. It is responsible for compressing the refrigerant gas, which helps the fridge maintain its cool temperature. However, over time, the compressor can experience issues that may affect its performance.

Identifying problems with the compressor early on can save you from expensive repairs or having to replace the entire appliance. By performing a thorough check on the compressor, you can diagnose issues and take appropriate measures to resolve them.

In this article, we will guide you through the steps of checking the compressor on your refrigerator. By following these steps, you can gain valuable insights into the condition of your compressor and potentially avoid more significant problems down the line.

Key Takeaways:

- Regularly checking the compressor on your refrigerator is crucial for identifying potential issues early and ensuring the longevity of your appliance. Safety precautions, visual inspections, and professional consultations are key steps in maintaining optimal performance.

- Listening for unusual sounds, testing the compressor windings, and evaluating the capacitor and compressor relay provide valuable insights into the electrical and refrigerant systems. When in doubt, always seek the expertise of a professional technician to accurately diagnose and address any compressor issues.

Read more: How To Check HVAC Compressor

Step 1: Safety Precautions

Before you start inspecting the compressor on your refrigerator, it is crucial to prioritize safety. Keep in mind that the compressor and other components of the appliance may be under high voltage, so taking the necessary precautions is essential to prevent any accidents or injuries.

Here are some safety measures to follow:

- Unplug the refrigerator from the power source to ensure you are not working with live electricity.

- Wear protective gloves and safety glasses to safeguard your hands and eyes from any potential hazards.

- Keep the area well-lit to have a clear view of the compressor and its surroundings.

- Avoid touching any exposed wires or electrical connections while conducting the inspection.

- Make sure the refrigerator is placed on a stable surface to prevent any accidents or damage.

Once you have taken these safety precautions, you can proceed with confident and peace of mind to the next steps of inspecting the compressor on your refrigerator. Remember, safety should always be a top priority when working with electrical appliances.

Step 2: Accessing the Compressor

Now that you have taken the necessary safety precautions, the next step is to gain access to the compressor. The location of the compressor may vary depending on the make and model of your refrigerator, but it is usually located at the back of the fridge.

Follow these steps to access the compressor:

- Unplug the refrigerator and ensure you have disconnected it from the power source.

- If there is a rear panel or cover, remove it carefully. You may need to use a screwdriver or socket wrench to take out the screws or fasteners holding the panel in place.

- Once the panel is removed, you should have a clear view of the compressor. Take a moment to familiarize yourself with the different components surrounding the compressor.

By accessing the compressor, you can now proceed to visually inspect it and check for any potential issues. Having a clear view of the compressor and its surroundings is crucial for a thorough inspection.

However, if you are unsure or uncomfortable with removing the rear panel or accessing the compressor yourself, it is always recommended to consult a professional technician who can safely perform the inspection for you.

Step 3: Visual Inspection

With access to the compressor achieved, it’s time to perform a visual inspection to identify any visible signs of damage or issues. A visual inspection can give you valuable clues about the condition of the compressor.

Here’s how to conduct a visual inspection of the compressor:

- Observe the exterior of the compressor for any signs of wear, corrosion, or physical damage. Look for rust, cracks, or dents.

- Inspect the refrigerant lines connected to the compressor. Check for any signs of leakage such as oil stains or excessive moisture.

- Examine the electrical connections and wires leading to the compressor. Ensure there are no loose or frayed wires that could affect its performance.

- Inspect the compressor fan to ensure it is clean and free from debris such as dust or lint.

- Take note of any unusual or out-of-place components or parts near the compressor. This could indicate a potential issue that needs further investigation.

A visual inspection can provide important clues about the overall condition of the compressor. If you notice any significant damage or suspect any issues during the visual inspection, it is recommended to contact a professional technician for further assessment and repairs.

However, remember that a visual inspection may not reveal all underlying problems with the compressor, so additional tests and checks may be necessary to determine its functionality accurately.

Step 4: Listening for Unusual Sounds

In addition to visual inspection, listening for unusual sounds can provide valuable insights into the condition of the compressor. Unusual noises coming from the compressor can indicate potential issues that need attention.

Follow these steps to listen for any unusual sounds:

- Ensure the refrigerator is plugged in and turned on, allowing the compressor to run.

- Position yourself near the back of the refrigerator, close to the compressor.

- Listen carefully for any abnormal sounds coming from the compressor. Common sounds to be aware of include buzzing, rattling, hissing, or clicking noises.

- If you hear a loud knocking or banging sound, it could indicate a problem with the compressor motor or internal components.

- Prolonged or continuous loud noises could be a sign of a failing compressor, and it is advisable to consult a professional technician for further diagnosis.

Listening for unusual sounds can provide valuable information about the condition of the compressor. If you notice any concerning noises, it is best to address the issue promptly to avoid further damage to the compressor or other components of the refrigerator.

Remember, attempting to repair or replace the compressor yourself can be dangerous and may void any warranties. It is recommended to seek the help of a professional technician with experience in appliance repair to address any identified issues.

Read more: How To Check An Air Conditioner Compressor

Step 5: Checking the Temperature

Another important step in checking the compressor on your refrigerator is to monitor the temperature inside the appliance. The temperature can provide valuable insights into the performance of the compressor and the overall cooling system.

Here’s how you can check the temperature:

- Ensure the refrigerator has been running for a few hours to stabilize the temperature.

- Open the refrigerator door and place a thermometer in a central location, such as on a shelf in the middle of the fridge.

- Note down the temperature reading displayed by the thermometer.

- Check the temperature in the freezer compartment as well, using a separate thermometer if necessary.

- Compare the recorded temperatures with the recommended range for your refrigerator, typically between 35°F (1.7°C) and 38°F (3.3°C) for the refrigerator section, and between 0°F (-18°C) and 5°F (-15°C) for the freezer section.

If you notice that the temperature in either the refrigerator or freezer section is consistently higher than the recommended range, it could indicate an issue with the compressor or the cooling system. In this case, it is advisable to seek professional assistance to diagnose and resolve the problem.

Keep in mind that temperature fluctuations can occur due to various factors, such as frequent door openings or a high load of food items. However, if the temperature remains consistently outside the recommended range, it is best to address the issue to ensure the longevity and efficiency of your refrigerator.

To check the compressor on a refrigerator, listen for a humming sound. If the compressor is running but the fridge is not cooling, it may be a sign of a malfunction.

Step 6: Testing the Compressor Windings

Testing the compressor windings can help determine if there are any electrical issues affecting the performance of the compressor. The windings are the copper coils inside the compressor that generate the electric motor’s magnetic field. By testing these windings, you can get a better understanding of the compressor’s electrical condition.

Follow these steps to test the compressor windings:

- Make sure the refrigerator is unplugged from the power source to avoid any electrical accidents.

- Locate the compressor terminal cover or access panel on the back of the refrigerator.

- Remove the cover or panel to reveal the compressor terminals.

- Identify the common, start, and run terminals on the compressor. These terminals are usually labeled, but refer to the manufacturer’s manual for specific instructions.

- Using a multimeter set to the resistance or ohms setting, touch one probe to the common terminal and the other probe to the start terminal. Take note of the resistance reading displayed on the multimeter.

- Next, touch one probe to the common terminal and the other probe to the run terminal. Record the resistance reading.

- Compare the resistance readings with the manufacturer’s specifications. If your readings deviate significantly from the recommended range, it could indicate a problem with the compressor windings.

If you find that the resistance readings are significantly different from the manufacturer’s specifications or if there is an open circuit (infinite resistance), it is likely that the compressor windings are faulty. In such cases, it is best to contact a professional technician to further diagnose and address the issue.

Testing the compressor windings requires some technical knowledge and the use of specialized equipment. If you are not confident in performing this test, it is always recommended to seek professional assistance to avoid causing further damage or injury.

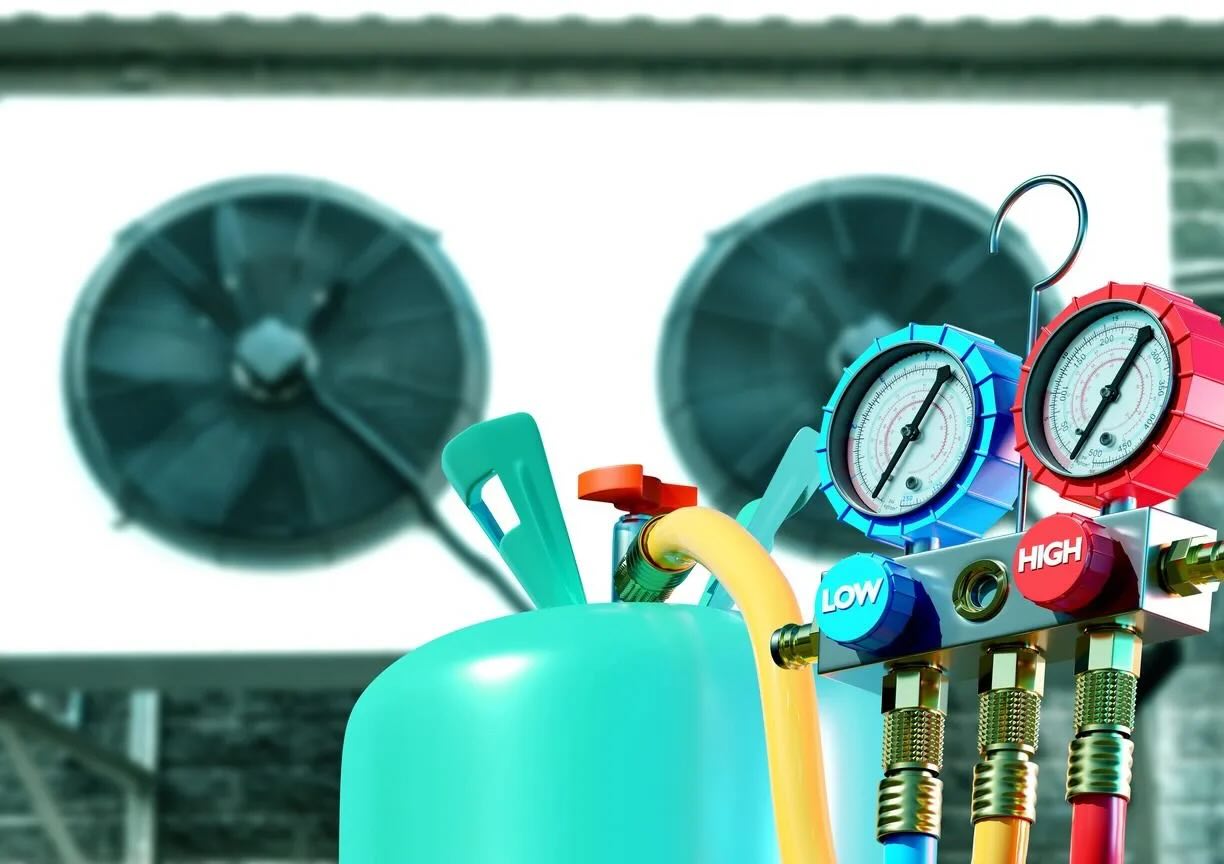

Step 7: Checking for Leaks

One of the vital aspects of checking the compressor on your refrigerator is to inspect for any leaks in the refrigerant system. Leaks can lead to a decrease in cooling efficiency and can even result in a complete breakdown of the compressor if not addressed promptly.

Here’s how you can check for leaks:

- Ensure the refrigerator is unplugged and turned off.

- Carefully inspect the refrigerant lines, joints, and connections near the compressor for any signs of leakage.

- Look for oil stains or wet spots around the area, as this could be an indication of a refrigerant leak.

- You can also use a leak detection solution or a UV light to help detect any leaks. These can reveal fluorescent dye that is added to the refrigerant system for leak detection purposes.

- If you notice any leaks or suspect a refrigerant leak, it is important to contact a professional technician who can safely repair the leak and recharge the refrigerant system.

Refrigerant leaks can be hazardous and require proper equipment and expertise to rectify. It is best to leave the repair of refrigerant leaks to professionals who are trained in handling refrigerant systems safely.

Regularly checking for leaks and promptly addressing them can help maintain the efficiency and longevity of your refrigerator’s compressor and cooling system.

Note: Refrigerant handling and repair should only be performed by licensed professionals in accordance with local regulations and safety guidelines.

Step 8: Testing the Capacitor

Testing the capacitor is another crucial step in checking the compressor on your refrigerator. The capacitor plays a vital role in providing the necessary electrical boost to start the compressor motor. A malfunctioning capacitor can lead to compressor issues and cause the refrigerator to fail in maintaining the desired temperature.

Here’s how to test the capacitor:

- Ensure that the refrigerator is unplugged from the power source.

- Locate the capacitor, which is usually cylindrical in shape and located near the compressor.

- Take a closer look at the capacitor for any signs of physical damage, such as bulging or leaking. If you notice any visible damage, it is likely that the capacitor needs to be replaced.

- If there are no visible signs of damage, you can proceed to test the capacitor using a digital multimeter.

- Set the multimeter to the capacitance setting and ensure it is within the appropriate range for the capacitor being tested.

- With the multimeter probes, touch the terminals of the capacitor, making sure to connect the positive probe to the positive terminal and the negative probe to the negative terminal.

- Observe the multimeter reading. It should slowly increase and then stabilize, indicating the capacitance value of the capacitor. If the reading remains at “0” or does not match the capacitance rating on the capacitor, it is likely defective and needs to be replaced.

If the capacitor is defective or not functioning within the expected range, it is recommended to consult a professional technician for further evaluation and replacement.

Testing the capacitor requires knowledge of electrical safety and the use of a multimeter. If you are not confident in performing this test, it is best to seek the assistance of a qualified technician to avoid any potential risks or damage.

Read more: How To Replace A Refrigerator Compressor

Step 9: Evaluating the Compressor Relay

The compressor relay is an electrical component that controls the supply of power to the compressor motor. A malfunctioning relay can lead to compressor issues and cause the refrigerator to stop cooling properly. Therefore, it is important to evaluate the compressor relay as part of the overall inspection process.

Here’s how to evaluate the compressor relay:

- Make sure the refrigerator is unplugged and turned off.

- Locate the compressor relay, which is typically located near the compressor or on the side of the refrigerator.

- Carefully inspect the relay for any signs of damage, such as burnt spots, melted plastic, or loose connections.

- If the relay appears to be damaged, it is likely that it needs to be replaced.

- If there are no visible signs of damage, you can proceed to test the compressor relay using a multimeter.

- Set the multimeter to the resistance or ohms setting.

- With the multimeter probes, touch the relay terminals associated with the compressor motor. Refer to the manufacturer’s manual for specific instructions on identifying these terminals.

- Observe the multimeter reading. A functional relay should display a low resistance reading, indicating continuity. If the multimeter reading shows infinite resistance or no continuity, it is likely that the relay is faulty and needs to be replaced.

If you suspect that the compressor relay is defective or not functioning correctly based on your evaluation, it is recommended to consult a professional technician. They can further assess the relay and determine if it needs to be replaced to restore proper functionality to the compressor.

Testing and evaluating the compressor relay require electrical knowledge and the use of a multimeter. If you are unsure or uncomfortable with performing these tests, it is advised to seek professional assistance to prevent any electrical accidents or further damage to the refrigerator.

Step 10: Consulting with a Professional

After conducting the necessary checks and inspections on the compressor of your refrigerator, if you are still uncertain or unable to diagnose the issue, it is highly recommended to consult with a professional technician. They have the expertise and experience to accurately assess the condition of the compressor and provide appropriate solutions.

Here’s why consulting with a professional is important:

- Expertise: Professional technicians are trained in diagnosing and repairing various issues with refrigerators, including compressor problems. They have a deep understanding of the inner workings of the appliance and can identify the root cause of the issue.

- Specialized Tools and Equipment: Professionals have access to specialized tools and equipment that are necessary for a comprehensive evaluation of the compressor. These tools enable them to perform more accurate tests and measurements, leading to an accurate diagnosis.

- Safety: Dealing with electrical appliances can be dangerous, especially when it involves components like the compressor. Professional technicians are well-versed in safety protocols and can handle the repair or replacement process safely and effectively.

- Warranty and Guarantees: If your refrigerator is still under warranty, attempting to repair or replace the compressor yourself may void the warranty. Consulting with a professional ensures that the repair work is done in accordance with the manufacturer’s guidelines and maintains the warranty coverage.

- Time and Cost Efficiency: With their knowledge and experience, professional technicians can efficiently diagnose and resolve compressor issues. This saves you from potential trial-and-error attempts that could waste time and money.

When consulting with a professional technician, provide them with all the information gathered during your own inspection. This will help them to better understand the problem and perform a more accurate diagnosis.

Remember, attempting complex repairs without the necessary knowledge and expertise may cause further damage to the refrigerator and put your safety at risk. It is always wise to rely on the expertise of qualified professionals to ensure the best outcome for your appliance.

Conclusion

Checking the compressor on your refrigerator is an essential task to ensure its proper functioning and longevity. By following the steps outlined in this guide, you can perform a thorough inspection of the compressor and identify any potential issues. Remember, safety should always be a priority when working with electrical appliances, so be sure to follow the necessary safety precautions.

From visually inspecting the compressor for any visible damage to listening for unusual sounds and checking the temperature, each step plays a crucial role in assessing the compressor’s condition. Testing the compressor windings, evaluating the capacitor and compressor relay, as well as checking for leaks, provide insight into the compressor’s electrical and refrigerant systems.

While these DIY steps can help you diagnose certain issues, it is important to know your limitations. If you are unsure or uncomfortable with any step of the inspection process, it is recommended to consult with a professional technician. They have the expertise and specialized tools to accurately diagnose and repair any issues with your refrigerator’s compressor.

Maintaining the optimal performance of the compressor not only ensures the proper cooling of your refrigerator but also extends its lifespan. Regular inspections and timely repairs can save you from expensive repairs or the need to replace the entire appliance.

Remember to consult the manufacturer’s manual or reach out to the manufacturer if you have any specific questions or concerns regarding your refrigerator’s compressor. With proper care and attention, your refrigerator can continue to provide reliable cooling for years to come.

Frequently Asked Questions about How To Check Compressor On Refrigerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Check Compressor On Refrigerator”