Articles

How To Make An Electric Motor Variable Speed

Modified: December 7, 2023

Learn how to make an electric motor variable speed with our informative articles. Discover step-by-step instructions and expert tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors are a critical component in various industries and applications, serving as the driving force behind machinery and equipment. They are used in everything from manufacturing processes to transportation systems, making them an essential part of our daily lives.

One important aspect of electric motors is their speed. The ability to control and adjust the speed of a motor is crucial in many applications, as it allows for efficient operation and optimal performance. This is where the concept of variable speed comes into play.

In this article, we will delve into the world of electric motors and explore the importance of variable speed. We will also discuss different methods to make an electric motor variable speed, providing insights into the benefits and considerations of each approach.

Key Takeaways:

- Variable speed control in electric motors offers benefits such as energy efficiency, precise process control, extended motor life, noise reduction, and improved safety, making it a crucial feature for optimal performance in various applications.

- When choosing a method to make an electric motor variable speed, factors such as motor type, precision requirements, compatibility, energy efficiency, cost, system complexity, and application-specific factors must be carefully considered to ensure optimal performance and efficiency.

Understanding Electric Motors

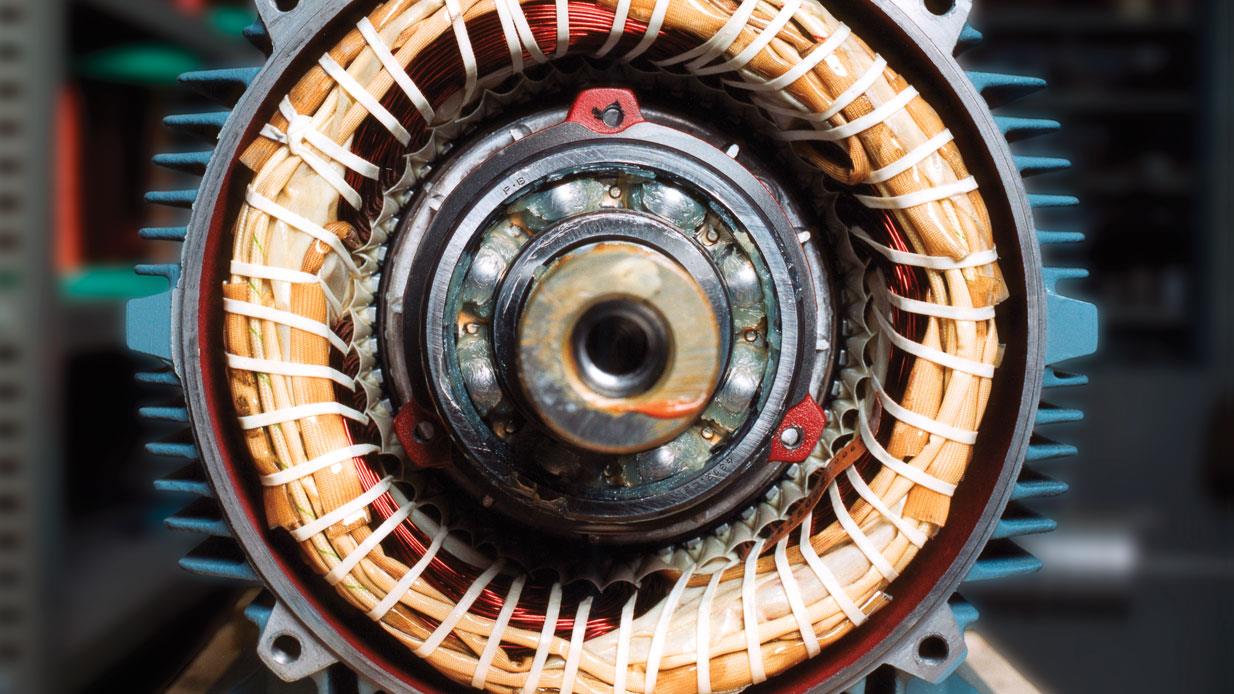

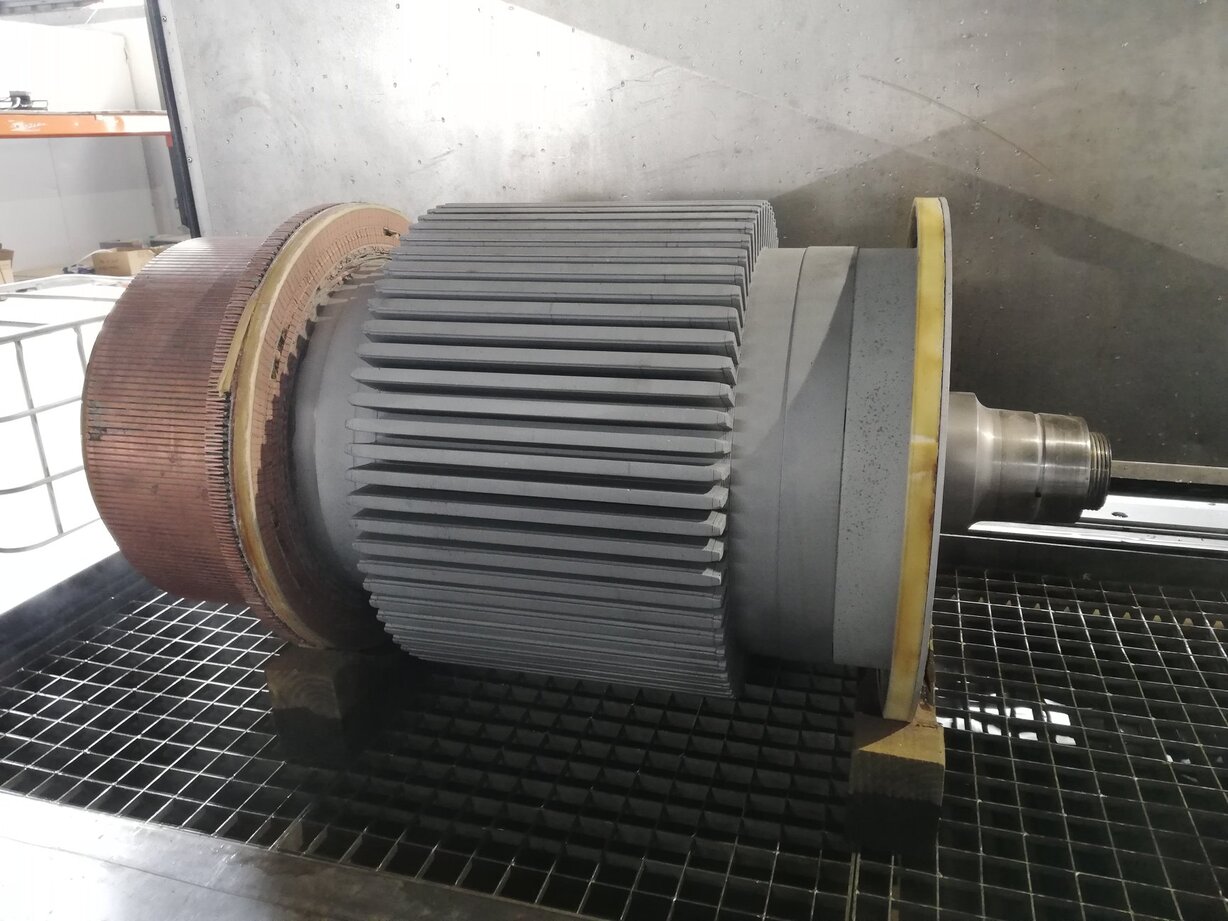

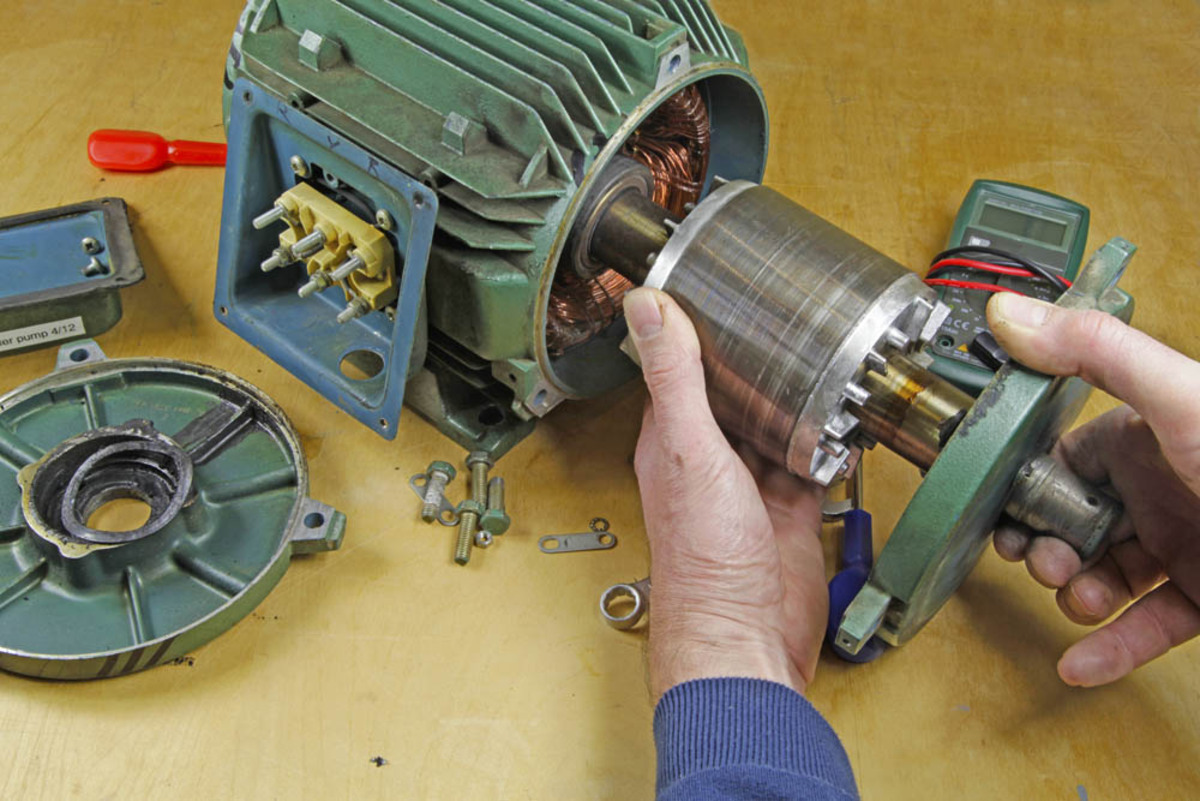

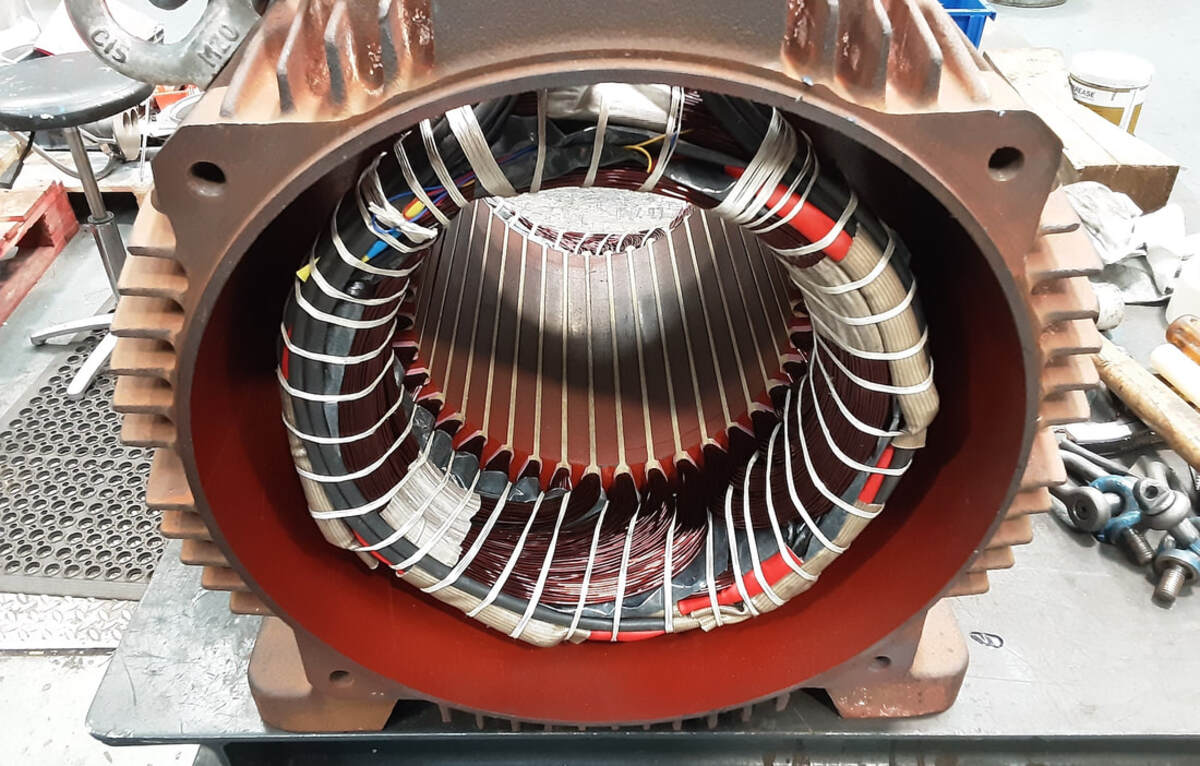

Before we dive into the topic of variable speed, let’s first gain a basic understanding of electric motors. At their core, electric motors are devices that convert electrical energy into mechanical energy. They consist of a rotor and a stator, with the rotor being the rotating part and the stator being the stationary part.

The operation of an electric motor is based on the principle of electromagnetic induction. When an electric current passes through the stator windings, a magnetic field is created. This magnetic field interacts with the rotor, causing it to rotate. The rotational movement of the rotor is what generates mechanical power.

Electric motors come in different types, including AC (alternating current) motors and DC (direct current) motors. AC motors are widely used in residential, commercial, and industrial applications, while DC motors are commonly found in battery-operated devices and automotive systems.

AC motors can further be categorized into induction motors and synchronous motors. Induction motors are the most common type and work based on the induction principle. They are reliable, cost-effective, and easy to maintain. Synchronous motors, on the other hand, operate at a fixed speed and are commonly used in applications where precise speed control is required.

DC motors, as the name implies, operate on direct current. They are known for their ability to provide high starting torque and precise speed control. DC motors are widely used in robotics, automation systems, and various industrial applications.

As we can see, electric motors are the lifeblood of many industries, and their proper functioning and control are vital for efficient operation. This brings us to the importance of variable speed in electric motors.

Importance of Variable Speed in Electric Motors

Variable speed control is a crucial feature in electric motors due to its numerous advantages and benefits. Let’s explore why variable speed is so important in electric motor applications:

- Energy Efficiency: One of the primary benefits of variable speed control is improved energy efficiency. By adjusting the motor’s speed to match the specific requirements of the application, energy wastage is minimized. Motors operating at lower speeds consume less power, resulting in significant energy savings over time. This is particularly beneficial in applications where the motor operates for extended periods or in processes where the load varies.

- Precise Process Control: Variable speed control allows for precise process control, enabling operators to fine-tune the speed to match specific production needs. For instance, in a manufacturing setting, different stages of production may require different motor speeds. By adjusting the motor’s speed accordingly, operators can optimize product quality, reduce errors, and enhance overall efficiency.

- Extended Motor Life: Running a motor at a fixed speed that is higher than necessary can lead to increased wear and tear, resulting in reduced motor life. With variable speed control, the motor can be operated at the optimal speed for a given application, reducing stress on the motor and prolonging its lifespan. This translates to lower maintenance costs, decreased downtime, and increased productivity.

- Noise Reduction: Electric motors running at high speeds can generate significant noise levels, leading to a noisy working environment. By operating the motor at lower speeds when possible, noise levels can be reduced, creating a quieter and more comfortable workspace for employees.

- Improved Safety: Some applications may require varying motor speeds to ensure safe operation. For example, in conveyor systems, sudden changes in load or product jamming can occur. By using variable speed control, the motor’s speed can be adjusted to prevent accidents, improve safety, and mitigate potential damage to equipment.

These are just a few examples of the importance of variable speed control in electric motors. It offers significant benefits in terms of energy efficiency, process control, motor life, noise reduction, and safety. Now, let’s explore the methods used to make an electric motor variable speed.

Methods to Make an Electric Motor Variable Speed

There are several methods to make an electric motor variable speed, each with its own advantages and considerations. Let’s explore three common methods:

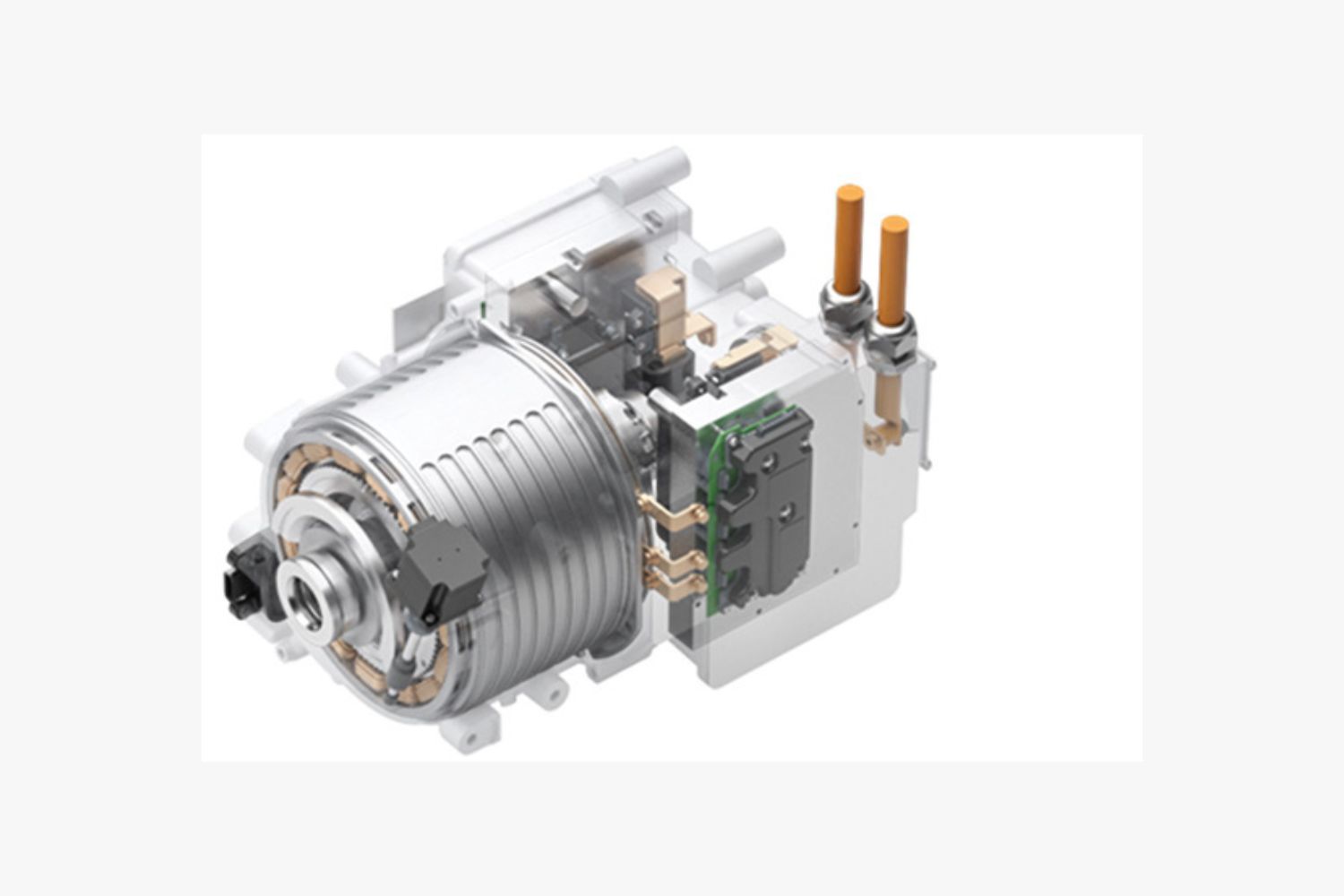

- Method 1: Using a Variable Frequency Drive (VFD): A Variable Frequency Drive, also known as VFD or AC Drive, is a device that converts the incoming power supply frequency into the desired frequency to control the motor speed. It regulates the motor’s electrical input, adjusting the frequency and voltage to achieve the desired speed. VFDs provide precise and smooth control, allowing for a wide range of speed adjustment. They are commonly used in industrial applications where motor control and energy efficiency are vital.

- Method 2: Using a Variable Voltage Power Supply: Another method to achieve variable speed control is by using a variable voltage power supply. By adjusting the voltage supplied to the motor, the speed can be controlled. This method is commonly used in small-scale applications or older motor systems that may not be compatible with VFDs. However, it is important to note that varying the voltage can impact the motor’s performance and efficiency, and it may not provide as precise speed control as other methods.

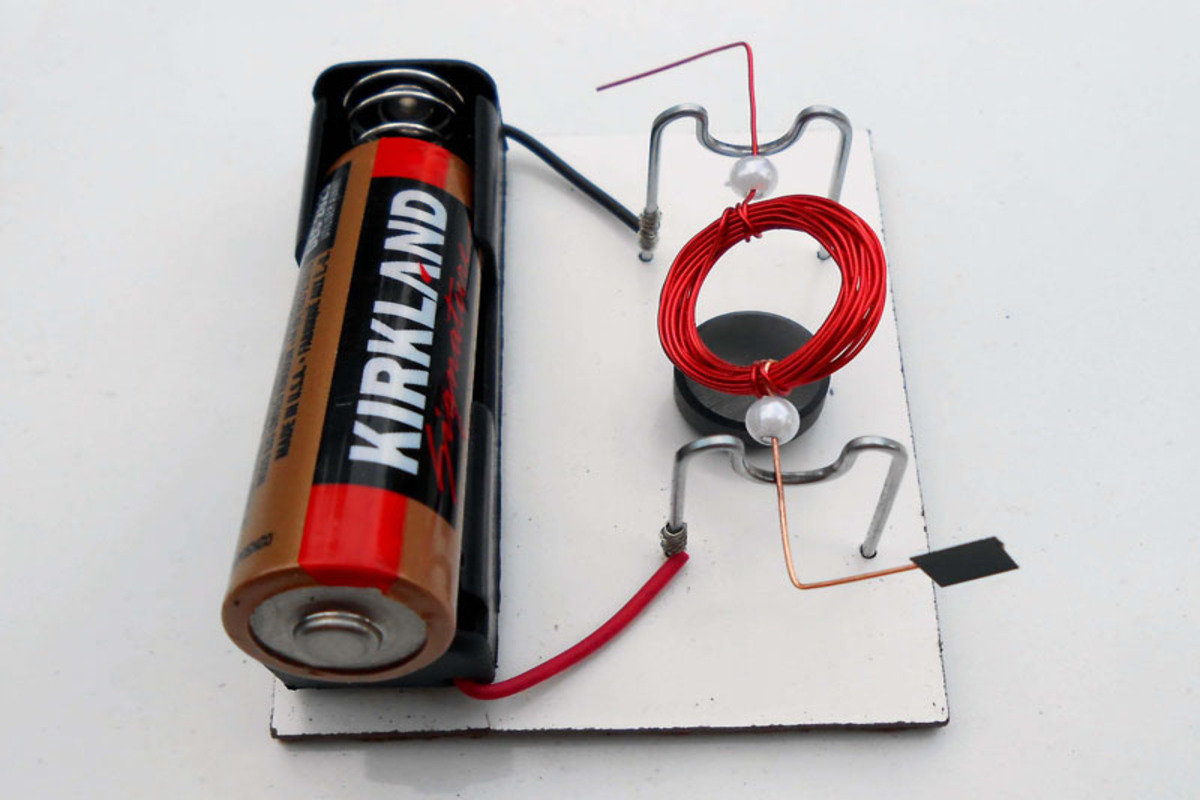

- Method 3: Using a Pulse Width Modulation (PWM) Controller: Pulse Width Modulation is a technique that involves rapidly switching the power supplied to the motor on and off. By adjusting the width of the pulses, the effective voltage and thus the motor speed can be controlled. PWM controllers are commonly used in DC motor applications and offer precise speed control, low power consumption, and minimal heat generation. However, they may introduce electronic noise and require proper shielding and filtering.

When considering which method to use for making an electric motor variable speed, it is essential to evaluate factors such as cost, compatibility, control precision, maintenance requirements, and overall system requirements. Consulting with a knowledgeable expert can help in determining the most suitable method for a specific application.

Remember, the selected method should not only provide the desired variable speed control but also ensure the motor’s safety, efficiency, and longevity. Proper installation, setup, and regular maintenance are crucial to maximize the benefits of variable speed control and ensure optimal motor performance.

Now that we have explored the different methods to achieve variable speed control, let’s discuss how to choose the right method for your electric motor application.

Method 1: Using a Variable Frequency Drive (VFD)

A Variable Frequency Drive (VFD), also known as an AC Drive, is a common method used to make an electric motor variable speed. It operates by adjusting the frequency of the power supply to the motor, thus controlling its speed. Here’s an overview of how VFDs work and the benefits they offer:

Working Principle: VFDs consist of three main components: a rectifier, an inverter, and a control unit. The rectifier converts the incoming AC power supply into DC power, while the inverter converts the DC power back into variable-frequency AC power. The control unit monitors and adjusts the frequency and voltage of the output power to achieve the desired motor speed. By varying the frequency and voltage, the speed of the motor can be precisely controlled.

Benefits of VFDs: Using a VFD to make an electric motor variable speed offers several benefits:

- Precise Speed Control: VFDs provide precise speed control, allowing operators to set the motor speed to match specific application requirements. This level of control is crucial in applications where different speeds are needed for different stages of operation.

- Energy Efficiency: VFDs optimize energy consumption by adjusting the motor’s speed according to the load demand. By running the motor at lower speeds when possible, energy wastage is minimized, resulting in significant energy savings and reduced operating costs.

- Soft Start and Stop: VFDs offer soft start and stop functionality, gradually ramping up or down the motor’s speed instead of abrupt starts and stops. This reduces mechanical stress and extends the motor’s lifespan, resulting in reduced maintenance and replacement costs.

- Overload Protection: VFDs provide built-in protection features that monitor the motor’s performance and automatically adjust the power supply to prevent overloading. This helps to protect the motor from damage and enhances safety in the working environment.

- Reduced Wear and Tear: By controlling the motor’s speed based on the actual load requirements, VFDs reduce unnecessary wear and tear on the motor and associated mechanical components. This leads to longer equipment life and decreased downtime due to maintenance and repairs.

Overall, using a VFD to make an electric motor variable speed provides significant advantages in terms of precise control, energy efficiency, soft start/stop functionality, overload protection, and reduced wear and tear. However, it should be noted that VFDs may have higher initial costs and require professional installation and setup. It is essential to consult with experts and consider the specific application requirements before implementing a VFD solution.

Now that we have explored the first method for making an electric motor variable speed using a VFD, let’s move on to the next method.

To make an electric motor variable speed, use a variable frequency drive (VFD) to control the motor’s speed by adjusting the frequency of the electrical supply. This allows for precise speed control and energy savings.

Read more: How To Reduce The Speed Of An Electric Motor

Method 2: Using a Variable Voltage Power Supply

Another method to make an electric motor variable speed is by using a variable voltage power supply. This method involves adjusting the voltage supplied to the motor, which in turn affects its speed. Here’s an overview of how this method works and its considerations:

Working Principle: The motor’s speed is directly proportional to the voltage supplied to it. By varying the voltage, the speed can be controlled. This can be achieved using a variable voltage power supply, which allows for adjusting the output voltage to the motor. By increasing or decreasing the voltage, the motor’s speed can be increased or decreased accordingly.

Considerations: While using a variable voltage power supply is a simple and cost-effective method for achieving variable speed control, there are some important considerations to keep in mind:

- Motor Compatibility: Not all motors can be operated at variable voltages, so it is essential to ensure that the motor is compatible with this method. Check the motor’s specifications and consult the manufacturer or an expert to determine if it can be safely operated with a variable voltage power supply.

- Control Precision: Unlike more advanced methods like VFDs, a variable voltage power supply may not offer the same level of precise control over the motor’s speed. Adjusting the voltage directly affects the motor’s speed, but the control may not be as fine-tuned as with other methods.

- Efficiency and Power Consumption: Varying the voltage supplied to the motor can affect its efficiency. Running the motor at lower voltages can result in reduced performance and efficiency. Additionally, it is important to consider the power consumption and potential energy savings when using a variable voltage power supply.

- Application Limitations: This method may not be suitable for all types of applications. In some cases, maintaining a constant motor speed may be critical, and varying the voltage may not be ideal. Evaluate the specific requirements of the application and consult with experts to determine the best approach.

Although using a variable voltage power supply is a relatively straightforward method for achieving variable speed control, it may have limitations in terms of control precision and motor compatibility. It is essential to carefully consider the motor specifications, control requirements, and overall application demands before implementing this method.

Now that we have explored the second method for making an electric motor variable speed using a variable voltage power supply, let’s move on to the third and final method.

Method 3: Using a Pulse Width Modulation (PWM) Controller

Using a Pulse Width Modulation (PWM) controller is another method to make an electric motor variable speed. PWM controllers manipulate the power supply by rapidly switching it on and off at varying intervals, effectively controlling the motor’s speed. Here’s an overview of how this method works and its benefits:

Working Principle: PWM controllers operate by adjusting the width of the pulses in the power signal sent to the motor. By varying the width of the pulses, the effective voltage and thus the motor speed can be controlled. This is achieved by rapidly switching the power on and off, creating an average voltage that is equivalent to the desired speed. The controller adjusts the pulse width based on the desired speed setting.

Benefits of PWM Controllers: Using a PWM controller to achieve variable speed control offers several benefits:

- Precise Speed Control: PWM controllers provide precise speed control by allowing for fine adjustments to the pulse width. This level of control enables operators to set the motor speed with accuracy, matching the specific requirements of the application.

- Low Power Consumption: PWM controllers are highly efficient in terms of power consumption. By rapidly switching the power supply on and off, energy wastage is minimized, resulting in lower power consumption and potentially significant energy savings.

- Minimal Heat Generation: The rapid switching of the power signal in PWM controllers reduces heat generation compared to other methods. This is beneficial in terms of both motor performance and overall system safety.

- Noise Reduction: PWM controllers can alleviate noise issues associated with electric motors. The rapid switching of the power signal reduces the noise generated by the motor, resulting in a quieter operating environment.

- Compact and Cost-Effective: PWM controllers are relatively compact and cost-effective compared to other variable speed control methods. They are widely used in DC motor applications and offer an affordable solution for achieving speed control.

While PWM controllers offer precise speed control and energy-efficient operation, there are a few considerations to keep in mind:

- EMI/RFI Interference: The rapid switching of power signals in PWM controllers can introduce electromagnetic interference (EMI) or radio frequency interference (RFI) in some cases. Proper shielding and filtering may be required to mitigate these issues.

- Compatibility: PWM controllers are primarily used in applications that involve direct current (DC) motors. Ensure that the motor is compatible with PWM control before implementing this method.

- System Design: Proper system design is crucial when using PWM controllers. Factors such as motor ratings, power supply requirements, and controller specifications need to be considered to ensure safe and efficient operation.

Considering the benefits of precise speed control, low power consumption, minimal heat generation, and noise reduction, PWM controllers are a viable method to achieve variable speed control in DC motor applications. Careful consideration of system design and potential interference issues is essential to maximize the benefits of this method.

Now that we have explored the third method for making an electric motor variable speed using a PWM controller, let’s discuss how to choose the right method for your electric motor application.

Choosing the Right Method for Your Electric Motor

When it comes to making an electric motor variable speed, it is crucial to choose the right method that best suits your specific application requirements. Consider the following factors when selecting the appropriate method:

- Type of Motor: Consider the type of motor you are working with. AC motors typically use Variable Frequency Drives (VFDs) for variable speed control, while DC motors can utilize both variable voltage power supplies and Pulse Width Modulation (PWM) controllers.

- Precision: Determine the level of precision in speed control that your application requires. If precise speed adjustment is critical, methods like VFDs and PWM controllers offer more accurate control compared to variable voltage power supplies.

- Compatibility: Ensure that the chosen method is compatible with your motor. Some motors may have limitations or specific requirements for variable speed control. Refer to the motor’s specifications or consult with the manufacturer or an expert to ensure compatibility.

- Energy Efficiency: Consider the energy efficiency aspect of the chosen method. Variable frequency drives (VFDs) are known for their energy-saving capabilities, while PWM controllers can provide efficient operation for DC motors. Evaluate the potential energy savings and long-term cost considerations for your application.

- Cost and Budget: Assess your budget and the cost implications of each method. Variable frequency drives (VFDs) and PWM controllers may have higher upfront costs compared to variable voltage power supplies. Consider the long-term benefits and return on investment when making your decision.

- System Complexity: Evaluate the complexity of your system and the associated installation and setup requirements. Some methods may require professional installation and expertise, while others may be simpler to implement.

- Application-Specific Factors: Take into account any specific factors related to your application, such as safety requirements, maintenance considerations, noise reduction needs, and space limitations. Each method may have its own advantages and limitations in addressing these factors effectively.

Consulting with experts in the field or discussing your requirements with motor manufacturers can provide valuable insight and guidance in selecting the most suitable method for your electric motor. They can assess your specific needs and recommend the best approach to achieve optimal variable speed control.

By carefully considering these factors and weighing the benefits and considerations of each method, you can make an informed decision and choose the method that will meet your needs and provide efficient, reliable, and adaptable variable speed control for your electric motor application.

Now that we have explored the considerations for choosing the right method, let’s wrap up our discussion.

Conclusion

Variable speed control is a critical feature in electric motors, offering numerous benefits in terms of energy efficiency, precise process control, extended motor life, noise reduction, and improved safety. Having the ability to adjust the speed of an electric motor allows for optimal performance, reduced energy consumption, and enhanced productivity in various applications.

In this article, we explored three common methods to make an electric motor variable speed: using a Variable Frequency Drive (VFD), a variable voltage power supply, or a Pulse Width Modulation (PWM) controller. Each method has its own advantages, considerations, and application suitability.

A Variable Frequency Drive (VFD) provides precise speed control, energy efficiency, soft start/stop functionality, overload protection, and reduced wear and tear. It is commonly used in industrial applications where motor control and energy savings are crucial.

A variable voltage power supply allows for direct control of the motor’s speed by adjusting the voltage supplied to it. While it is a cost-effective method, it may lack the same level of precision as other methods and requires careful consideration of motor compatibility and control requirements.

A Pulse Width Modulation (PWM) controller offers precise speed control, low power consumption, minimal heat generation, and noise reduction. It is commonly used in DC motor applications and provides an affordable solution for achieving variable speed control.

When choosing the right method for making an electric motor variable speed, factors such as motor type, precision requirements, compatibility, energy efficiency, cost, system complexity, and application-specific factors must be taken into account. Consulting with experts and considering the specific needs of your application will help determine the most suitable method.

By implementing the appropriate method for variable speed control, you can optimize your electric motor’s performance, increase energy efficiency, reduce maintenance costs, and enhance overall system productivity.

Remember, proper installation, setup, and regular maintenance are crucial for maximizing the benefits of variable speed control and ensuring the longevity and smooth operation of your electric motor.

With the right method in place, you can take full advantage of the flexibility and efficiency that variable speed control offers, leading to improved productivity, cost savings, and enhanced performance in your electric motor applications.

Frequently Asked Questions about How To Make An Electric Motor Variable Speed

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make An Electric Motor Variable Speed”