Home>diy>Architecture & Design>What Jobs Use CAD

Architecture & Design

What Jobs Use CAD

Modified: January 9, 2024

Discover the top jobs in architecture and design that utilize CAD software, providing endless opportunities to showcase your creativity and technical skills.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Computer-Aided Design (CAD) has revolutionized the way we design and create in various industries. From architecture to engineering, manufacturing to healthcare, CAD has become an essential tool for professionals across different domains. It offers a range of benefits, including increased efficiency, improved accuracy, and enhanced visualization.

In this article, we will explore the diverse fields where CAD is extensively utilized. We’ll delve into the specific applications and job roles that rely on CAD, highlighting the importance of this technology in shaping the modern world.

So, whether you’re an architecture enthusiast or interested in product design, let’s dive into the fascinating world of CAD and discover the exciting jobs it encompasses.

Key Takeaways:

- CAD is a versatile tool used in architecture, engineering, product design, civil engineering, and more. It enhances visualization, collaboration, and precision, revolutionizing various industries and shaping the modern world.

- From robotics to healthcare, CAD revolutionizes design, simulation, and customization. It empowers professionals to create innovative solutions, improve patient care, and optimize mechanical systems, driving progress and excellence in diverse fields.

Read more: How To Get A CAD Job

Architecture and Engineering

In the field of architecture and engineering, CAD has become an indispensable tool for design, visualization, and documentation. Architects and engineers utilize CAD software to create precise and detailed blueprints, 3D models, and construction drawings.

With CAD, architects can efficiently draft floor plans, elevations, and sections, allowing for accurate measurements and easy modifications. These digital representations help architects visualize the final product before construction, enabling them to make necessary adjustments to the design.

Structural engineers also heavily rely on CAD to analyze and design complex structures such as bridges and skyscrapers. Using specialized CAD software, engineers can create detailed structural models, perform simulations, and calculate load-bearing capacities. CAD enables engineers to ensure the safety and stability of structures, minimizing the risk of failure.

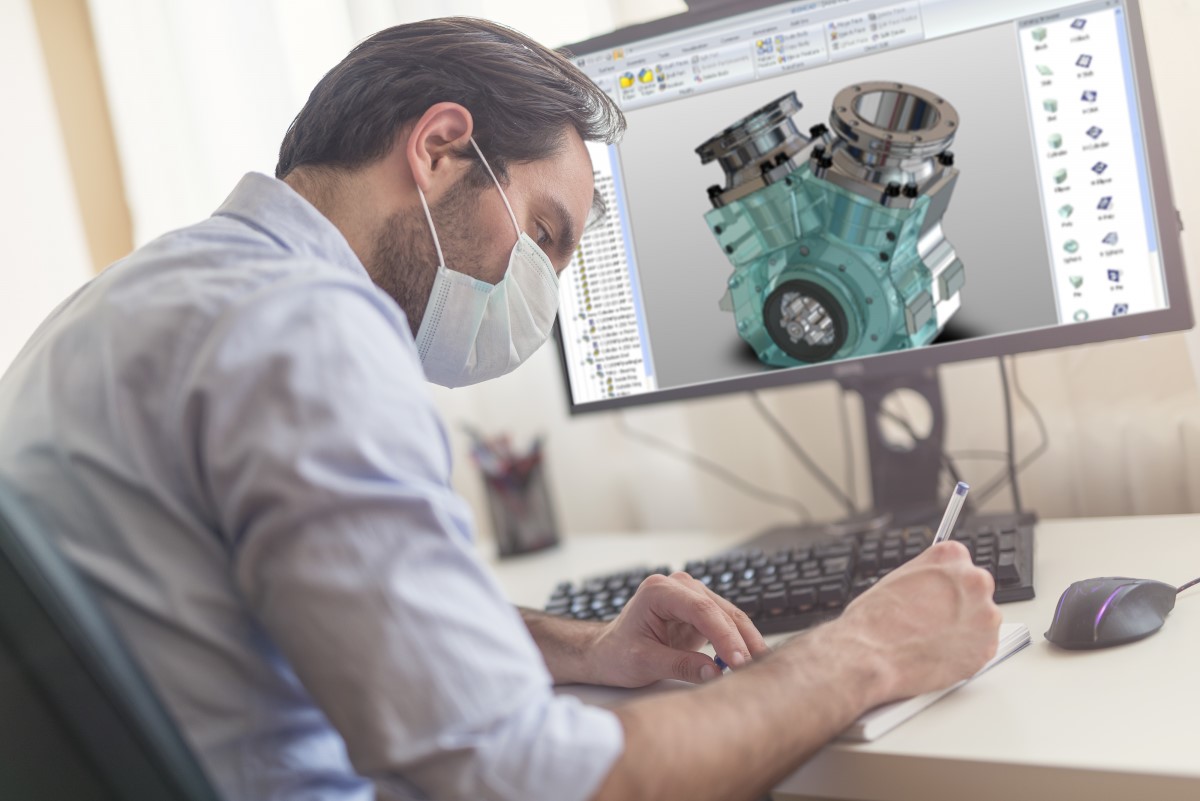

CAD software also plays a crucial role in the field of mechanical engineering. Mechanical design engineers use CAD to design components and assemblies for machines, vehicles, and industrial equipment. By creating 3D models, engineers can assess the functionality, clearance, and interference of moving parts, optimizing their designs for performance and manufacturability.

Overall, CAD empowers architects and engineers with the ability to visualize, analyze, and communicate their designs effectively. It brings efficiency and accuracy to the design process, saving time and resources and ensuring the successful execution of architectural and engineering projects.

Product Design and Manufacturing

Product design and manufacturing industries heavily rely on CAD software to bring innovative ideas to life. CAD plays a pivotal role in the entire product development process, from conceptualization and prototyping to production and quality control.

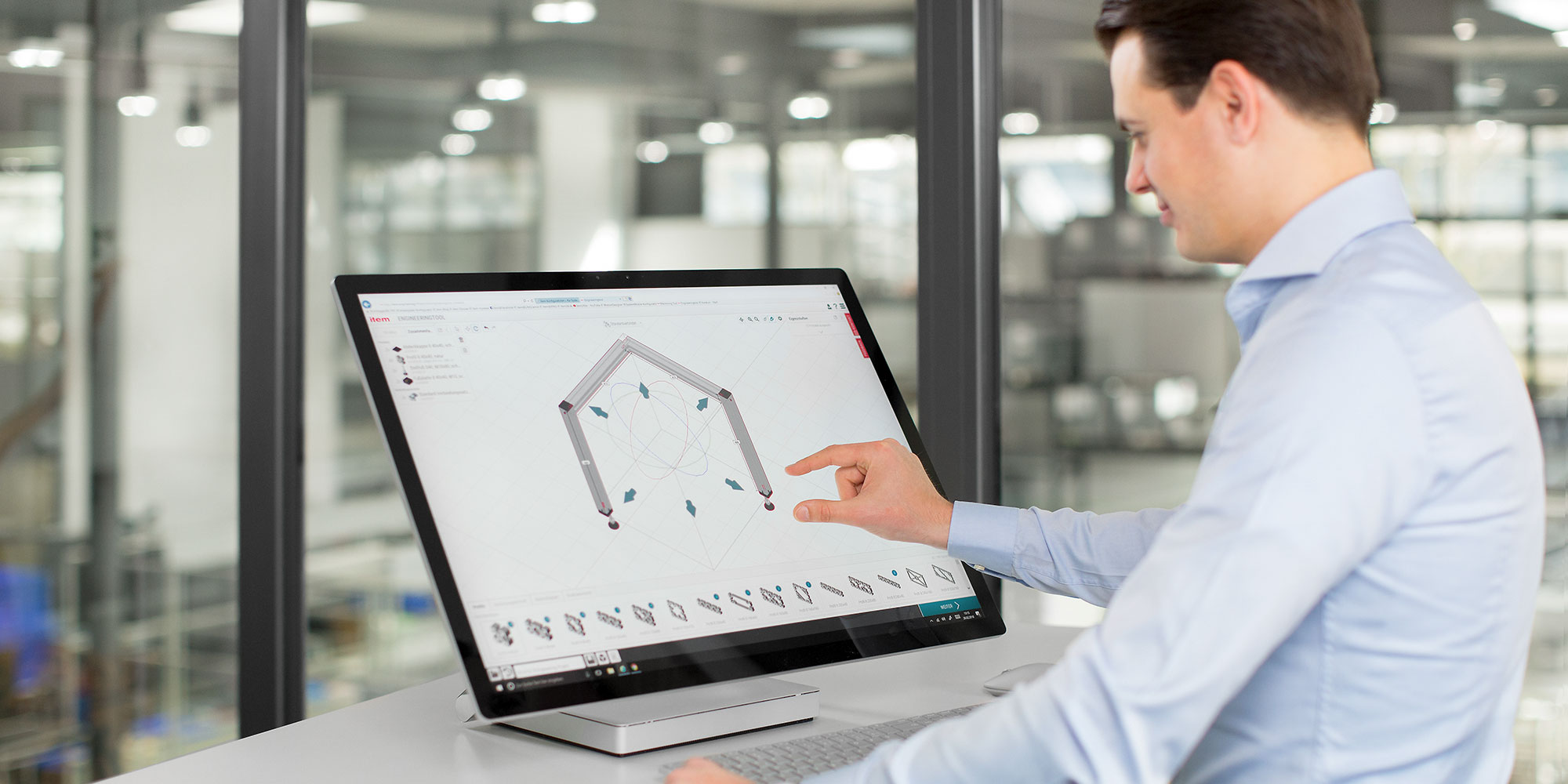

Product designers leverage CAD tools to create detailed 3D models of their envisioned products. These models allow designers to explore different design iterations, manipulate shapes and forms, and test various functionalities. CAD software provides features such as parametric modeling and assembly design, enabling designers to easily modify and refine their designs as needed.

Once the design is finalized, CAD models serve as the basis for creating accurate and precise manufacturing documentation. Engineers and manufacturers utilize these CAD models to generate specifications for tooling and machining processes. This ensures that every component is manufactured to exact specifications, resulting in consistent and high-quality products.

CAD also facilitates the creation of prototypes through technologies like 3D printing and CNC machining. Designers can convert their CAD models into physical prototypes, allowing them to assess the form, fit, and function of the product before mass production. This iterative process saves time and resources by identifying and addressing design flaws early on.

Furthermore, CAD software enhances collaboration between design teams, engineers, and manufacturers. Through cloud-based CAD platforms, multiple stakeholders can access and work on the same design files simultaneously. This streamlines communication, accelerates decision-making, and ensures everyone is on the same page throughout the product development cycle.

In summary, CAD revolutionizes product design and manufacturing by providing powerful tools for designing, prototyping, and producing innovative products. It enables designers to iterate quickly, engineers to optimize manufacturability, and manufacturers to produce high-quality products efficiently.

Civil Engineering and Construction

In the realm of civil engineering and construction, CAD is an essential tool for designing and planning infrastructures such as buildings, bridges, roads, and dams. It allows civil engineers to create precise and detailed drawings, perform simulations, and optimize construction processes.

CAD software provides civil engineers with the ability to create 2D and 3D models of proposed structures. With accurate measurements and realistic visualizations, engineers can analyze the structural integrity, load distribution, and overall performance of the design. They can also simulate various scenarios to assess the impact of external factors such as earthquakes or environmental conditions.

Construction professionals utilize CAD for site planning and layout, optimizing the placement of different components and ensuring efficient use of space. It helps in visualizing the construction process, identifying potential clashes or conflicts, and streamlining the scheduling and sequencing of tasks.

Furthermore, CAD software enables civil engineers to generate construction documents and drawings that accurately represent the details and specifications of the project. These documents serve as a communication tool between engineers, architects, contractors, and other stakeholders, ensuring everyone is aligned on the design and construction requirements.

During the construction phase, CAD can be utilized for quantity takeoffs and material estimation, helping in cost estimation and procurement planning. It can also aid in project management by visualizing the progress of work, tracking changes, and facilitating collaboration between different teams.

The use of CAD in civil engineering and construction yields numerous benefits, including improved accuracy, reduced errors, enhanced efficiency, and ultimately, successful project execution. It has revolutionized the industry by enabling engineers and construction professionals to design and build structures with precision and confidence.

Electrical and Electronics Engineering

CAD plays a vital role in electrical and electronics engineering, facilitating the design, analysis, and optimization of various electrical systems and electronic devices. With CAD software, electrical engineers can create detailed schematics, circuit designs, and PCB layouts.

One of the key benefits of CAD in this field is the ability to create and modify electrical schematics. Engineers can use CAD tools to design, label, and connect components in a schematic diagram, creating a visual representation of the electrical system. This helps in identifying potential issues or errors in the circuit design and ensures efficient and accurate wiring during the manufacturing process.

CAD software also enables engineers to design and simulate circuits before implementing them in the physical world. Through virtual prototyping, engineers can analyze the behavior of the circuit, test different configurations, and optimize its performance. This saves time and resources by identifying and resolving potential design flaws early on in the development process.

When it comes to PCB (Printed Circuit Board) design, CAD software provides powerful tools for creating layout designs and arranging components. Engineers can create multi-layered PCBs, define the routing paths, and ensure proper placement of components to minimize signal interference. CAD software also assists in generating manufacturing files and documentation for the production of PCBs.

In addition, CAD software facilitates the integration of electrical systems with mechanical components. Through collaboration between electrical and mechanical engineers, CAD allows for the design and visualization of enclosures, cable routing, and the overall integration of electrical hardware into larger systems.

Overall, CAD plays a crucial role in electrical and electronics engineering, enabling engineers to design, analyze, and optimize electrical systems and electronic devices. It improves the accuracy and efficiency of the design process, resulting in reliable and well-performing electrical and electronic systems.

Read more: What Is CAD Used For

Automotive and Aerospace Engineering

In the fields of automotive and aerospace engineering, CAD technology has revolutionized the design and development of vehicles and aircraft. From concept design to manufacturing, CAD software plays a pivotal role in creating innovative and efficient transportation systems.

Automotive engineers utilize CAD tools to design and model various vehicle components. They can create precise 3D models of engine components, chassis structures, and body panels, allowing for accurate analysis of performance, aerodynamics, and safety. CAD software also enables engineers to simulate different driving conditions and test the vehicle’s response and stability.

These 3D models serve as the basis for generating manufacturing drawings and specifications. By providing detailed information on dimensions, tolerances, and material requirements, CAD software ensures that each component can be manufactured to the desired specifications. Additionally, CAD facilitates the creation of assembly instructions, aiding in the efficient and accurate assembly of vehicles on the production line.

Aerospace engineers leverage CAD technology to design and optimize aircraft components and systems. They can create complex 3D models of wings, fuselages, and propulsion systems, allowing for structural analysis, weight optimization, and aerodynamic simulations. CAD software also assists in generating precise manufacturing data for the production of aircraft parts, ensuring exact tolerances and high-quality standards.

CAD software also plays a significant role in the prototyping and testing phases of automotive and aerospace engineering. Engineers can convert their CAD models into physical prototypes using techniques like 3D printing or CNC machining. These prototypes allow for physical testing, verification of design performance, and identification of potential improvements before mass production.

Overall, CAD technology greatly accelerates the design and development process in automotive and aerospace engineering. It enables engineers to create more efficient and safer vehicles and aircraft by providing accurate design visualization, simulation capabilities, and precise manufacturing documentation.

Tip: Many industries use CAD, including architecture, engineering, manufacturing, and construction. Look for job opportunities in these fields to utilize your CAD skills.

3D Modeling and Animation

3D modeling and animation rely heavily on CAD software to create lifelike and visually stunning computer-generated imagery (CGI). Whether it’s for movies, video games, architectural visualization, or product rendering, CAD plays a crucial role in bringing virtual creations to life.

CAD software provides powerful tools for creating detailed 3D models of objects, characters, and environments. Artists and designers can sculpt digital models, define surfaces and textures, and manipulate lighting and camera angles to achieve the desired visual effect. CAD allows for precise control over every aspect of the modeling process, ensuring accuracy and realism.

Once the 3D models are created, CAD software enables artists to animate them by defining movements, interactions, and behaviors. From simple character animations to complex simulations of physics and dynamics, CAD allows for the creation of captivating and realistic motion. Artists can also apply various effects, such as particle systems and fluid simulations, to enhance the visual impact of their creations.

CAD software is also used in architectural visualization, allowing architects and designers to create photorealistic renderings of buildings and interior spaces. By accurately modeling the architectural elements and applying realistic materials and lighting, CAD enables the creation of immersive visualizations that help clients and stakeholders visualize the finished project.

Furthermore, CAD software facilitates the integration of 3D models into virtual reality (VR) and augmented reality (AR) experiences. Through CAD, designers can create interactive and immersive environments that users can explore and interact with, enhancing the visualization and communication of ideas and concepts.

In summary, CAD has transformed the field of 3D modeling and animation by providing intuitive and powerful tools for creating lifelike and visually appealing CGI. It empowers artists and designers to unleash their creativity and bring their imaginative ideas to life in a virtual world.

Interior Design

In the world of interior design, CAD has become an invaluable tool for envisioning, planning, and executing stunning living spaces. Interior designers utilize CAD software to create accurate floor plans, visualize design concepts, and communicate their ideas with clients and contractors.

CAD software allows interior designers to accurately depict the layout and dimensions of a space through 2D floor plans. These plans serve as the foundation for designing functional and aesthetically pleasing interiors. With CAD, designers can easily experiment with different furniture arrangements, room divisions, and spatial configurations, ensuring optimal use of space.

Interior designers also utilize CAD to create 3D visualizations of their design concepts. By accurately modeling the interior elements such as furniture, lighting fixtures, and decorative objects, CAD software provides a realistic representation of how the final space will look. This enables designers to showcase their vision to clients, helping them make informed decisions and visualize the end result.

CAD software also assists in material selection and customization. Designers can apply various textures, finishes, and colors to surfaces within the 3D model, allowing clients to see how different materials will look in the space. CAD software also offers the ability to generate accurate material and furniture schedules, facilitating the procurement process and ensuring a cohesive design concept.

Collaboration is enhanced through the use of CAD software in interior design. Designers can easily share their 3D models with clients and contractors, allowing for effective communication and eliminating any misunderstandings. Changes can be made and visualized in real-time, ensuring that all parties are aligned and on the same page throughout the design process.

In summary, CAD software greatly enhances the field of interior design by providing precise and realistic visualizations of spaces. It enables designers to efficiently plan and execute their design concepts, resulting in beautifully crafted interiors that meet the needs and preferences of clients.

Robotics and Automation

Robotics and automation industries heavily rely on CAD technology to design, simulate, and optimize robotic systems and automated processes. CAD software enables engineers to create precise 3D models of robots, manipulate their movements and interactions, and simulate their behavior in various scenarios.

CAD software allows engineers to design and visualize robotic systems, incorporating components such as robotic arms, grippers, and sensors. Engineers can accurately model the mechanical structure of the robot, define kinematic constraints, and simulate its range of motion. CAD software also enables the integration of electrical components and interfaces, ensuring seamless communication and control of the robot.

Simulation is a critical aspect of robotics and automation design, and CAD software plays a vital role in this process. Engineers can define the behavior and operations of the robot in a simulated environment, test different algorithms, and optimize its performance. Simulation allows for the identification of potential issues, clashes, or bottlenecks, helping engineers refine the design before physical implementation.

CAD software also aids in the optimization of automated processes and workflows. By accurately modeling the manufacturing or assembly process, engineers can identify inefficiencies, improve cycle times, and optimize the placement and movement of robotic systems. CAD makes it possible to conduct virtual simulations to ensure seamless integration and collision avoidance in real-world scenarios.

Furthermore, CAD software facilitates the creation of accurate manufacturing documentation for the production of robotic systems. It provides detailed information on tolerances, material specifications, and assembly instructions, ensuring that every component is manufactured to the desired specifications. CAD software also aids in the generation of code for programming the robot, simplifying the implementation process.

In summary, CAD plays a crucial role in robotics and automation by facilitating the design, simulation, and optimization of robotic systems and automated processes. It enables engineers to create efficient and reliable systems, ensuring seamless integration and improving productivity in various industries.

Read more: How To Use CAD

Industrial Design

Industrial design entails creating aesthetically pleasing and functional products that meet the needs of consumers. CAD software is an essential tool in the field of industrial design, enabling designers to bring their concepts to life and streamline the product development process.

CAD software allows industrial designers to create detailed 3D models of their product concepts. From consumer electronics to household appliances, CAD helps designers visualize and refine the product’s form, shape, and ergonomics. Designers can explore different design options, make precise modifications, and test the functionality of the product virtually.

With CAD, designers can easily incorporate complex design features, such as curves, fillets, and grooves, into their 3D models. The software provides intuitive tools to manipulate these features, ensuring the visual appeal and manufacturability of the final product. CAD software also enables designers to apply various surface finishes and textures, giving a realistic representation of the product’s appearance.

Additive manufacturing, such as 3D printing, is a common technique used in industrial design prototyping. CAD software plays a crucial role in preparing 3D models for 3D printing, ensuring that the design is optimized for the chosen manufacturing process. Designers can fine-tune details, validate dimensions, and create prototypes without the need for expensive and time-consuming traditional manufacturing methods.

CAD software also facilitates the collaboration between industrial designers and engineers. By sharing CAD files, designers can communicate their design intent to engineers and work together to optimize the product for manufacturing. Design changes can be quickly incorporated into the CAD model and shared with the entire development team, streamlining the design iteration process.

Moreover, CAD software is instrumental in generating manufacturing documentation. It provides precise measurements, tolerances, and material specifications required for production. This ensures accurate replication of the design during the manufacturing process and minimizes errors and discrepancies.

In summary, CAD software significantly enhances the industrial design process by providing powerful tools for concept visualization, design refinement, and collaboration. It enables designers to create innovative and appealing products while optimizing manufacturability and reducing time to market.

Mechanical Engineering

Mechanical engineering relies heavily on CAD software for designing, analyzing, and optimizing mechanical systems and components. From complex machinery to intricate mechanical parts, CAD plays a crucial role in the field of mechanical engineering.

CAD software provides powerful tools for creating detailed 2D and 3D models of mechanical components and assemblies. Engineers can accurately define the dimensions, shapes, and features of each part, allowing for precise manufacturing and assembly. CAD software also enables the creation of exploded views and animations, making it easier to understand the functionality and assembly process of the mechanical system.

One of the key benefits of CAD software in mechanical engineering is the ability to perform simulations and analyze the performance of mechanical systems. Engineers can conduct stress and strain analysis, thermal analysis, and fluid flow simulations to ensure that designs meet performance requirements. This enables engineers to optimize the design, identify potential issues, and enhance the reliability and efficiency of the mechanical system.

CAD software also aids in the generation of manufacturing documentation. Engineers can easily create detailed drawings, bill of materials, and specifications that are essential for the production of mechanical components and assemblies. CAD software ensures accurate dimensions, tolerances, and annotations, simplifying the manufacturing process and minimizing errors.

Furthermore, CAD software facilitates the integration of mechanical systems with other disciplines, such as electrical and control engineering. Through collaborative design, engineers can design and visualize the integration of mechanical and electrical components, ensuring seamless communication and functionality.

In addition to designing new systems, CAD software is also used in reverse engineering. By accurately capturing the geometry of existing components using specialized scanning or measurement techniques, CAD allows engineers to recreate the components digitally. This is useful in situations where a product needs to be replicated, modified, or improved.

In summary, CAD software revolutionizes the field of mechanical engineering by providing powerful tools for design, simulation, and documentation. It enables engineers to create and optimize mechanical systems, ensuring accuracy, reliability, and performance in various industries.

Medical and Healthcare

Medical and healthcare industries have increasingly embraced the use of CAD software to revolutionize patient care, medical device design, and surgical planning. CAD plays a critical role in creating precise and customized solutions that improve diagnosis, treatment, and overall patient outcomes.

CAD software enables medical professionals to generate accurate 3D models from medical imaging data such as CT scans, MRI scans, and ultrasounds. These models provide detailed visualizations of anatomical structures, allowing healthcare providers to better understand patient-specific conditions and plan interventions accordingly.

With this technology, medical device designers can create patient-specific implants and prosthetics. CAD software allows designers to accurately model and simulate the implant or prosthetic, ensuring proper fit and functionality. This customization ensures optimal patient comfort and functionality, improving patient quality of life.

In addition to customizations, CAD software assists in surgical planning and simulation. Surgeons can simulate procedures in a virtual environment using CAD models, allowing them to practice complex surgeries and identify potential challenges or complications. This enhances surgical precision and reduces the risk of errors during the actual procedure.

CAD software also aids in the design and development of medical equipment and instruments. Engineers can create detailed 3D models of medical devices such as surgical tools, monitoring equipment, and diagnostic devices. CAD software allows for the analysis of ergonomics, range of motion, and mechanical properties of these devices, optimizing their design and functionality.

Furthermore, CAD software plays a significant role in the field of medical research. Researchers can use CAD models to create realistic simulations of physiological systems and study the impact of various treatments or interventions. This allows for the advancement of medical knowledge and the development of new treatment approaches.

In summary, CAD software has transformed the medical and healthcare industries by providing precise and customizable solutions. It enhances diagnostic accuracy, facilitates the development of medical devices, improves surgical planning, and contributes to medical research, ultimately improving patient care and outcomes.

Frequently Asked Questions about What Jobs Use CAD

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Jobs Use CAD”