Home>Home Appliances>Laundry Appliances>Why Won’t My Washing Machine Agitate

Laundry Appliances

Why Won’t My Washing Machine Agitate

Modified: March 2, 2024

Discover common reasons why your washing machine won't agitate and how to troubleshoot the issue. Get expert tips for fixing laundry appliances.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Common Reasons for Washing Machine Agitation Issues

When your trusty washing machine fails to agitate as expected, it can throw a wrench into your laundry routine. Understanding the common reasons behind this agitation malfunction can help you troubleshoot the issue effectively. Here are some prevalent culprits to consider:

-

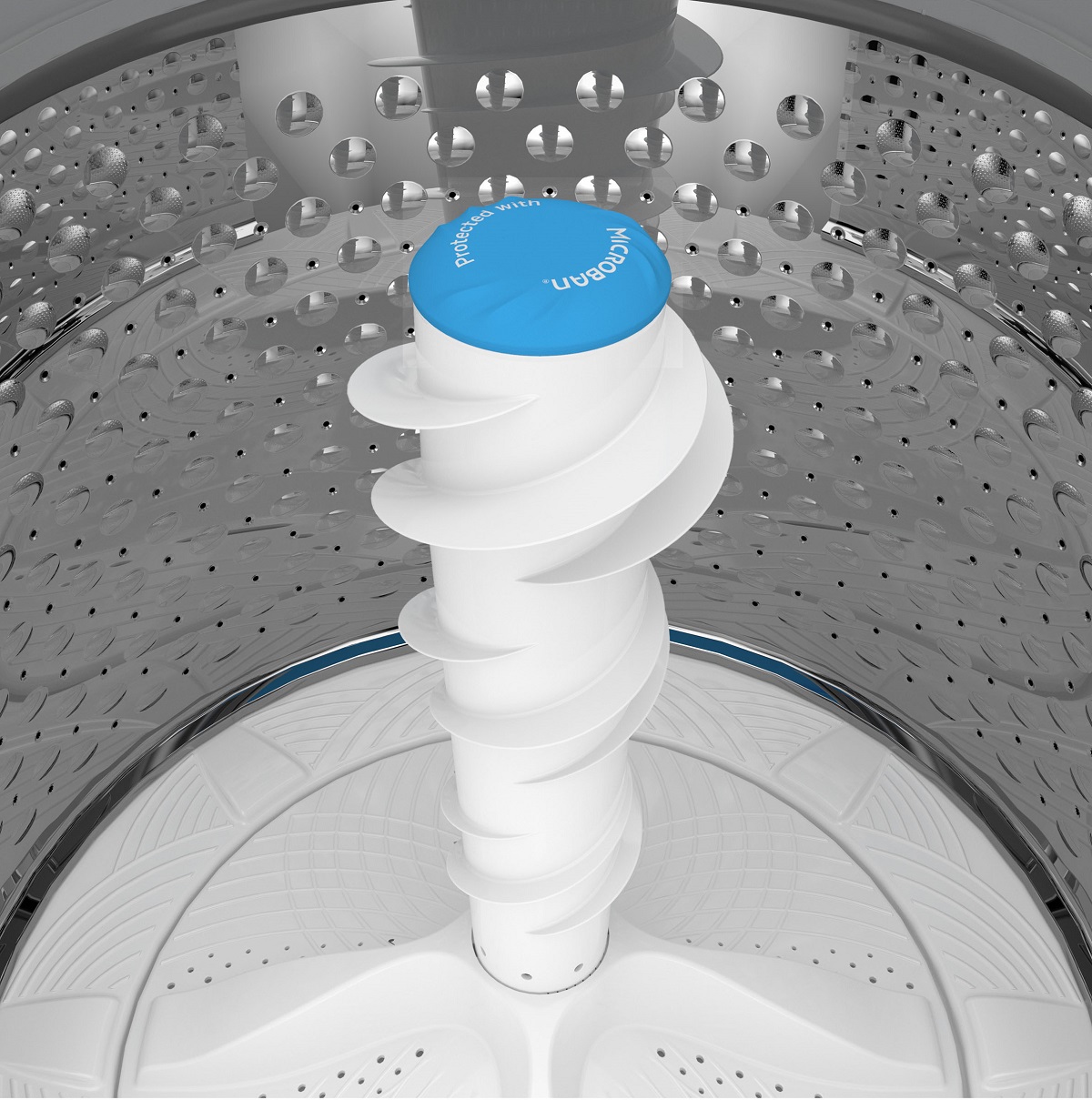

Faulty Agitator Dogs: Within the agitator, there are small plastic components known as agitator dogs. Over time, these can wear out or break, leading to a loss of agitation function. If you notice a weak or inconsistent agitation motion, these agitator dogs may be the root cause.

-

Worn Agitator Cam: The agitator cam assembly is responsible for generating the back-and-forth motion during the wash cycle. If this component becomes worn or damaged, it can hinder the agitator's ability to function properly, resulting in agitation issues.

-

Malfunctioning Agitator Cogs: Another potential culprit for agitation problems is the agitator cogs. These cogs engage with the agitator cam, facilitating the desired agitation motion. If they become worn or broken, the agitator's ability to move as intended can be compromised.

-

Defective Agitator Repair Kit: In some cases, the agitator repair kit itself may be the source of agitation troubles. Whether it's due to worn-out components or improper installation, a faulty repair kit can impede the agitator's performance.

-

Worn Agitator Pulley and Splutch Assembly: The agitator pulley and splutch assembly play a crucial role in driving the agitator's motion. If these components wear out or sustain damage, the agitation function can be adversely affected.

Understanding these common reasons for washing machine agitation issues can empower you to identify and address the underlying problems. By delving into the specifics of each potential issue, you can take targeted steps to restore your washing machine's agitation capabilities, ensuring that your laundry chores proceed without a hitch.

Key Takeaways:

- Don’t let a non-agitating washing machine ruin your laundry day! Look out for worn agitator parts and faulty repair kits to keep your machine running smoothly.

- Keep your washing machine in top shape by checking the drive belt and motor coupling for wear and tear. A little maintenance goes a long way in preventing agitation issues.

Read more: Why Wont My Washer Turn On

Checking the Agitator for Problems

When your washing machine exhibits agitation issues, one of the primary areas to inspect is the agitator. This central component is responsible for creating the back-and-forth motion that facilitates the washing process. To effectively troubleshoot agitation problems, it's crucial to conduct a thorough examination of the agitator and its associated parts.

Inspecting the Agitator Dogs

The agitator dogs, small plastic components located within the agitator, are pivotal in generating the agitation motion. Over time, these dogs can wear out or break, leading to a weakened or erratic agitation function. To check for this issue, carefully remove the agitator and examine the condition of the agitator dogs. If they appear worn or damaged, replacing them can often restore the agitator's effectiveness.

Assessing the Agitator Cam Assembly

Another critical element to scrutinize is the agitator cam assembly. This component is integral to producing the back-and-forth movement during the wash cycle. If the agitator cam becomes worn or damaged, it can impede the agitator's ability to function optimally. By inspecting the condition of the agitator cam assembly, you can determine whether it requires replacement to resolve the agitation issues.

Examining the Agitator Cogs

The agitator cogs, which engage with the agitator cam to facilitate the desired agitation motion, are susceptible to wear and breakage. If these cogs are compromised, the agitator's ability to move as intended can be hindered. Carefully examining the condition of the agitator cogs is essential in identifying whether they are contributing to the agitation problems. If necessary, replacing the agitator cogs can help restore the agitator's functionality.

Read more: Why Wont My GE Washer Spin

Verifying the Agitator Repair Kit

In some instances, agitation issues may stem from a faulty agitator repair kit. Whether due to worn-out components or improper installation, a defective repair kit can impede the agitator's performance. By verifying the condition and installation of the agitator repair kit, you can determine if it is contributing to the agitation problems. Replacing the repair kit, if necessary, can rectify the issues and restore the agitator's functionality.

By meticulously checking the agitator and its associated components for problems, you can pinpoint the underlying issues contributing to the washing machine's agitation malfunction. This thorough inspection empowers you to take targeted measures to address the specific concerns affecting the agitator, ultimately restoring its optimal performance and ensuring seamless laundry cycles.

Examining the Drive Belt for Wear and Tear

The drive belt in a washing machine plays a pivotal role in facilitating the transmission of power from the motor to the drum, enabling the various functions of the appliance. When encountering agitation issues, it is essential to thoroughly examine the drive belt for signs of wear and tear, as this component directly impacts the machine's ability to agitate effectively.

To commence the inspection, it is imperative to disconnect the washing machine from its power source and ensure that it is in a stable, accessible position. Once this is confirmed, carefully remove the access panel or the rear panel, depending on the machine's design, to gain visibility of the drive belt. The drive belt is typically situated around the motor pulley and the drum's drive pulley, forming a crucial connection that enables the transfer of rotational force.

Upon visual inspection, any fraying, stretching, or visible damage to the drive belt indicates a need for replacement. Additionally, the belt should be assessed for proper tension. A loose or overly tight drive belt can impede the smooth operation of the washing machine, potentially leading to agitation issues. It is advisable to press down on the belt at the center point between the motor and the drum pulleys to ascertain the appropriate tension. The belt should depress by approximately half an inch, indicating optimal tension for efficient operation.

Furthermore, the drive belt's alignment is a critical aspect to evaluate during the inspection. Misalignment can result in uneven wear and compromise the belt's functionality, ultimately affecting the washing machine's agitation performance. By observing the positioning of the drive belt on the pulleys, any deviations from the intended alignment can be identified and rectified.

In addition to visual and tension assessments, it is essential to examine the drive belt for any foreign objects or debris that may have become lodged within its mechanism. Foreign materials can disrupt the smooth movement of the belt, leading to irregular operation and potential agitation issues. Thoroughly clearing any obstructions from the drive belt ensures unhindered functionality and contributes to the overall smooth operation of the washing machine.

By meticulously examining the drive belt for wear, tension, alignment, and the presence of foreign objects, potential issues impacting the washing machine's agitation capabilities can be identified and addressed effectively. This comprehensive inspection empowers users to take targeted measures, such as belt replacement or realignment, to restore the optimal functionality of the drive belt and ensure seamless agitation during laundry cycles.

Inspecting the Motor Coupling for Damage

The motor coupling in a washing machine serves as a vital component that facilitates the transmission of power from the motor to the transmission and agitator. When encountering agitation issues, it is imperative to conduct a thorough inspection of the motor coupling to identify potential damage or wear that may be impeding the machine's functionality.

To commence the inspection, it is essential to ensure the washing machine is disconnected from its power source and positioned in a stable and accessible manner. Once this is confirmed, gaining access to the motor coupling typically involves removing the washer's cabinet or accessing the component through the machine's rear panel, depending on the specific model and design.

Upon gaining visibility of the motor coupling, a visual assessment is conducted to identify any visible signs of damage or wear. Cracks, fractures, or excessive wear on the coupling indicate potential issues that can hinder its ability to effectively transfer power. Additionally, any signs of misalignment or irregularities in the coupling's positioning warrant further investigation to determine the extent of the damage.

In addition to visual inspection, the motor coupling's flexibility and resilience are evaluated by gently maneuvering the component. Any excessive play, stiffness, or resistance during movement can signify underlying damage or deterioration, potentially contributing to agitation problems. The coupling should exhibit a degree of flexibility while maintaining structural integrity, enabling it to effectively transmit power without impedance.

Furthermore, the motor coupling's connection points to the motor and transmission are scrutinized to ensure secure attachment and proper alignment. Any looseness or misalignment at these connection points can disrupt the smooth transmission of power, leading to agitation issues and overall operational inefficiencies.

It is also crucial to examine the motor coupling for the presence of any foreign objects or debris that may have become lodged within its mechanism. Foreign materials can impede the coupling's movement and compromise its functionality, potentially contributing to agitation problems. Thoroughly clearing any obstructions from the motor coupling ensures unhindered power transmission and contributes to the overall smooth operation of the washing machine.

By meticulously inspecting the motor coupling for damage, misalignment, flexibility, and the presence of foreign objects, potential issues impacting the washing machine's agitation capabilities can be identified and addressed effectively. This comprehensive inspection empowers users to take targeted measures, such as coupling replacement or realignment, to restore the optimal functionality of the motor coupling and ensure seamless agitation during laundry cycles.

Troubleshooting the Lid Switch for Malfunctions

The lid switch in a washing machine serves a crucial safety function, ensuring that the appliance operates only when the lid is securely closed. When encountering agitation issues, it is essential to thoroughly troubleshoot the lid switch to identify potential malfunctions that may be impacting the machine's functionality.

To initiate the troubleshooting process, it is imperative to disconnect the washing machine from its power source and ensure that it is in a stable and accessible position. Once this is confirmed, gaining access to the lid switch typically involves removing the washer's cabinet or accessing the component through the machine's rear panel, depending on the specific model and design.

Upon gaining visibility of the lid switch, a comprehensive assessment is conducted to identify any signs of damage, wear, or misalignment. Visual inspection is crucial in determining the overall condition of the switch, including the integrity of its housing and the functionality of its internal components. Any visible damage or irregularities warrant further investigation to ascertain the extent of the malfunctions.

Furthermore, the lid switch's electrical connections are meticulously examined to ensure secure attachment and proper conductivity. Loose or corroded connections can impede the switch's ability to communicate with the washing machine's control system, potentially leading to agitation issues and operational inefficiencies. By verifying the integrity of the electrical connections, potential electrical malfunctions can be identified and addressed effectively.

In addition to visual and electrical assessments, the functionality of the lid switch is evaluated by simulating the closing and opening of the lid. This involves manually activating the switch to mimic the engagement that occurs when the lid is closed during a regular washing cycle. Any resistance, inconsistency, or failure to engage and disengage as intended indicates potential malfunctions that may be contributing to agitation problems.

Moreover, the continuity of the lid switch is tested using a multimeter to measure its electrical conductivity. This diagnostic step helps determine whether the switch is effectively transmitting the necessary signals to the washing machine's control system. Any disruptions in continuity or irregularities in electrical conductivity signify underlying malfunctions that require attention.

By meticulously troubleshooting the lid switch for malfunctions, potential issues impacting the washing machine's agitation capabilities can be identified and addressed effectively. This comprehensive diagnostic process empowers users to take targeted measures, such as switch replacement or repair, to restore the optimal functionality of the lid switch and ensure seamless agitation during laundry cycles.

Frequently Asked Questions about Why Won't My Washing Machine Agitate

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Won’t My Washing Machine Agitate”