Home>Home Maintenance>How To Clean Mold On Styrofoam In An Air Conditioner

Home Maintenance

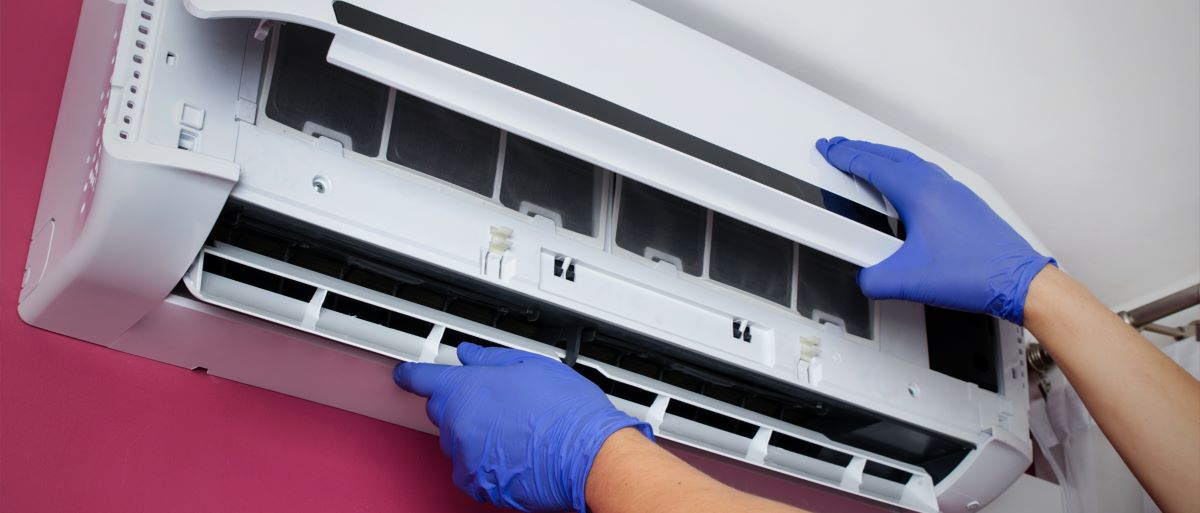

How To Clean Mold On Styrofoam In An Air Conditioner

Modified: January 24, 2024

Learn effective home maintenance tips for cleaning mold on styrofoam in your air conditioner. Follow our expert guide to keep your home environment healthy and mold-free.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Air conditioners play a crucial role in maintaining a comfortable indoor environment, especially during scorching summers. However, the presence of mold in air conditioning systems can pose significant health risks and affect the efficiency of the unit. In particular, mold growth on Styrofoam components within an air conditioner can be a cause for concern.

Mold is a type of fungus that thrives in moist environments, making air conditioners an ideal breeding ground. When mold grows on the Styrofoam components of an air conditioner, it can compromise the air quality and impact the overall performance of the unit. As a result, it is essential to address mold growth promptly and effectively.

In this article, we will explore the risks associated with mold in air conditioners, identify the signs of mold on Styrofoam components, outline safety precautions for cleaning mold, and provide step-by-step instructions for effectively removing mold from Styrofoam in an air conditioner. Additionally, we will discuss preventive measures to inhibit future mold growth, ensuring the long-term efficiency and safety of your air conditioning system.

By understanding the potential hazards of mold in air conditioners and learning how to mitigate its impact, you can safeguard your indoor air quality and prolong the lifespan of your air conditioning unit. Let's delve into the essential steps for addressing mold on Styrofoam in an air conditioner, empowering you to maintain a healthy and comfortable living environment.

Key Takeaways:

- Keep your air conditioner mold-free by regularly inspecting and cleaning Styrofoam components. This helps maintain indoor air quality and prevents health risks and operational inefficiencies.

- Prevent mold growth in air conditioners by monitoring humidity levels, promptly addressing leaks, and implementing regular maintenance. These proactive measures ensure a healthier indoor environment and sustained efficiency.

Read more: How To Clean Black Mold In Air Conditioner

Understanding the Risks of Mold in Air Conditioners

Mold growth in air conditioners poses various risks, ranging from health concerns to operational inefficiencies. When mold proliferates within an air conditioning system, it can release spores into the air, leading to respiratory issues, allergies, and other health complications. Individuals with pre-existing respiratory conditions, such as asthma, may experience exacerbated symptoms when exposed to mold-contaminated air.

Furthermore, mold can compromise the efficiency of the air conditioner, hindering its ability to regulate temperature and humidity effectively. As mold accumulates on components such as Styrofoam insulation, it can impede airflow and heat exchange, diminishing the unit’s performance and increasing energy consumption. This not only leads to higher utility bills but also accelerates wear and tear on the system, potentially necessitating costly repairs or premature replacement.

Moreover, the presence of mold in air conditioners can result in musty odors permeating the indoor environment, diminishing air quality and creating an unpleasant living or working space. As a result, addressing mold growth in air conditioners is crucial for maintaining a healthy indoor environment and optimizing the functionality of the cooling system.

By recognizing the risks associated with mold in air conditioners, individuals can prioritize proactive measures to mitigate its impact. Regular inspection, maintenance, and cleaning of air conditioning components, particularly those susceptible to mold growth such as Styrofoam insulation, are essential for safeguarding both the health of occupants and the longevity of the air conditioning system.

Next, we will delve into the process of identifying mold on Styrofoam components in an air conditioner, empowering you to detect and address mold growth in a timely manner.

Identifying Mold on Styrofoam in an Air Conditioner

Identifying mold on Styrofoam components within an air conditioner is vital for prompt remediation. Mold on Styrofoam may appear as discolored patches, often green, black, or brown in color, and can have a fuzzy or slimy texture. These patches may develop in areas where moisture accumulates, such as near the evaporator coils, air ducts, or other insulated surfaces.

Musty odors emanating from the air conditioner can also indicate the presence of mold on Styrofoam components. If you notice a persistent musty smell when the air conditioner is running, it is advisable to inspect the unit for mold growth promptly.

In some cases, visible condensation or water droplets on the Styrofoam insulation may signal excessive moisture, creating an environment conducive to mold growth. Additionally, if the air conditioner has been inactive for a prolonged period or has experienced water leakage, the likelihood of mold development on Styrofoam surfaces increases.

Regular visual inspections of the air conditioner, particularly the Styrofoam insulation and surrounding components, can aid in early detection of mold growth. By promptly identifying mold on Styrofoam in an air conditioner, you can take the necessary steps to mitigate its impact and prevent further proliferation.

Now that you are equipped with the knowledge to identify mold on Styrofoam in an air conditioner, we will explore essential safety precautions to observe before initiating the cleaning process.

Safety Precautions Before Cleaning Mold

Prior to addressing mold on Styrofoam in an air conditioner, it is imperative to prioritize safety precautions to mitigate potential health risks associated with mold exposure. Mold remediation requires careful handling to prevent the dispersal of spores and minimize direct contact with mold-infested surfaces.

First and foremost, ensure proper ventilation in the area where the air conditioner is located. Open windows and doors to facilitate air circulation, reducing the concentration of airborne mold spores. If possible, use fans to promote airflow and minimize the spread of mold during the cleaning process.

Wearing personal protective equipment (PPE) is essential when dealing with mold. This includes wearing a respirator or mask designed to filter mold spores, as well as gloves and eye protection to prevent skin and eye irritation from mold exposure. Additionally, wearing old clothing that can be laundered or discarded after the cleaning process is advisable to prevent cross-contamination of mold spores.

Prior to initiating the cleaning process, it is recommended to isolate the air conditioner from the rest of the indoor environment. This can be achieved by sealing off the area around the air conditioner with plastic sheeting and duct tape to contain any dislodged mold spores and prevent their dispersion to other areas of the building.

Furthermore, it is crucial to address the root cause of the mold growth, which often involves identifying and rectifying sources of moisture. Whether it is a leaking condensate drain line, improper insulation, or other water intrusion issues, resolving these underlying factors is essential to prevent future mold recurrence.

By adhering to these safety precautions before cleaning mold on Styrofoam in an air conditioner, you can minimize health risks and ensure a more effective remediation process. With these measures in place, you are better equipped to proceed with the cleaning process, which we will outline in the following section.

Mix equal parts of white vinegar and water in a spray bottle. Spray the solution onto the moldy areas of the styrofoam in the air conditioner and let it sit for 10-15 minutes. Then, scrub the mold with a brush and wipe it clean with a damp cloth.

Steps to Clean Mold on Styrofoam in an Air Conditioner

When addressing mold on Styrofoam components within an air conditioner, it is essential to follow a systematic approach to ensure thorough remediation while minimizing the dispersal of mold spores. The following steps outline a comprehensive process for effectively cleaning mold from Styrofoam in an air conditioning unit:

- Turn Off the Air Conditioner: Begin by powering off the air conditioning unit to prevent the circulation of air and dispersal of mold spores during the cleaning process. This step is crucial in minimizing the risk of exposure to airborne mold particles.

- Wear Personal Protective Equipment (PPE): Prior to initiating the cleaning process, don appropriate personal protective equipment, including a respirator or mask, gloves, and eye protection to safeguard against mold exposure.

- Isolate the Work Area: Seal off the area surrounding the air conditioner with plastic sheeting and duct tape to contain any dislodged mold spores, preventing their spread to other parts of the building.

- Clean Visible Mold: Using a mild detergent or commercial mold cleaner and a soft-bristled brush, gently scrub the visible mold on the Styrofoam surfaces. Avoid using harsh abrasives that could damage the insulation material.

- Thoroughly Dry the Area: After cleaning the mold-infested surfaces, ensure thorough drying to eliminate residual moisture. Use fans and dehumidifiers to expedite the drying process and inhibit the regrowth of mold.

- Inspect for Remaining Mold: Conduct a meticulous inspection of the Styrofoam insulation and surrounding components to ensure that all mold growth has been effectively removed. Address any remaining mold promptly to prevent recurrence.

- Address Underlying Issues: Identify and rectify any underlying sources of moisture that contributed to mold growth, such as condensate leaks, inadequate insulation, or drainage issues. Resolving these factors is crucial for preventing future mold infestations.

- Perform Regular Maintenance: Implement a routine maintenance schedule for the air conditioner, including periodic inspections of Styrofoam components and proactive measures to inhibit mold growth, such as cleaning or replacing filters, and ensuring proper drainage and insulation.

By following these steps diligently, individuals can effectively clean mold on Styrofoam in an air conditioner, mitigate health risks, and restore the unit’s functionality. Additionally, implementing preventive measures can help safeguard against future mold growth, ensuring long-term air conditioning efficiency and indoor air quality.

Preventing Future Mold Growth in Air Conditioners

Preventive measures are instrumental in inhibiting future mold growth in air conditioners, promoting optimal indoor air quality and the sustained efficiency of the cooling system. By implementing proactive strategies, individuals can mitigate the risk of mold proliferation and maintain a healthy living or working environment. The following preventive measures are essential for preventing future mold growth in air conditioners:

- Regular Maintenance: Establish a routine maintenance schedule for the air conditioner, including inspections of Styrofoam components, air filters, and drainage systems. Regular maintenance helps detect and address potential issues before they escalate, reducing the likelihood of mold growth.

- Monitor Humidity Levels: Maintain indoor humidity levels between 30-50% to discourage mold growth. Using dehumidifiers in humid climates or moisture-prone areas can help regulate indoor humidity, inhibiting the conditions conducive to mold proliferation.

- Proper Insulation: Ensure proper insulation of air conditioning components, including Styrofoam insulation, to prevent condensation and moisture buildup. Proper insulation reduces the likelihood of mold-friendly environments within the air conditioning system.

- Promptly Address Leaks: Address any water leaks or condensation issues promptly. Whether it is a leaking condensate drain line or water intrusion from external sources, swift resolution of leaks prevents moisture accumulation that fuels mold growth.

- Regular Filter Replacement: Replace air filters at regular intervals to maintain optimal airflow and reduce the accumulation of dust and debris, which can contribute to mold growth. Clean or replace filters according to the manufacturer’s recommendations.

- Enhance Ventilation: Promote adequate ventilation in the indoor environment to facilitate air circulation and reduce moisture buildup. Proper ventilation helps mitigate humidity levels and discourages mold development.

- Professional Inspections: Periodically engage professional HVAC technicians to conduct comprehensive inspections of the air conditioning system, including Styrofoam components, to identify and address potential issues that could lead to mold growth.

- Educate Occupants: Educate occupants about the importance of maintaining a clean and moisture-free environment. Encouraging responsible practices, such as promptly reporting leaks or moisture issues, fosters a collective effort in preventing mold growth.

By integrating these preventive measures into your air conditioning maintenance regimen, you can fortify the system against mold infestations, ensuring sustained efficiency and a healthier indoor environment. Proactive maintenance and vigilant monitoring are key to preventing future mold growth in air conditioners, ultimately contributing to enhanced air quality and operational longevity.

Conclusion

Mold growth on Styrofoam components within air conditioners presents multifaceted risks, encompassing health concerns, operational inefficiencies, and indoor air quality degradation. By understanding the implications of mold in air conditioning systems and equipping oneself with the knowledge to identify, remediate, and prevent mold growth, individuals can safeguard their living or working environment and optimize the functionality of their air conditioning units.

Recognizing the signs of mold on Styrofoam, such as discoloration, musty odors, and moisture accumulation, empowers individuals to detect and address mold growth in a timely manner. Prioritizing safety precautions, such as proper ventilation, personal protective equipment, and isolation of the work area, is crucial before embarking on the mold remediation process.

Following a systematic approach to clean mold from Styrofoam in an air conditioner, including thorough drying, inspection, and addressing underlying issues, is essential for comprehensive remediation. Moreover, implementing preventive measures, such as regular maintenance, humidity control, proper insulation, and prompt leak resolution, is instrumental in inhibiting future mold growth in air conditioners.

By adhering to these guidelines and integrating proactive strategies into air conditioning maintenance, individuals can foster a mold-resistant environment, promoting sustained air quality and the longevity of their cooling systems. Furthermore, fostering awareness about responsible practices among occupants contributes to a collective effort in preventing mold proliferation and maintaining a healthy indoor environment.

In conclusion, addressing mold on Styrofoam in air conditioners requires a holistic approach encompassing identification, remediation, and prevention. By prioritizing these aspects, individuals can mitigate the risks associated with mold, ensuring optimal air quality, energy efficiency, and the prolonged functionality of their air conditioning systems.

Armed with this knowledge, individuals are empowered to proactively manage mold growth in air conditioners, fostering a healthier and more comfortable indoor environment for themselves and those around them.

Frequently Asked Questions about How To Clean Mold On Styrofoam In An Air Conditioner

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.