Home>Technology>Smart Home Devices>How Do You Make 3D Printer Files

Smart Home Devices

How Do You Make 3D Printer Files

Modified: August 20, 2024

Learn how to create 3D printer files for smart home devices with our comprehensive guide. Start printing your designs today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

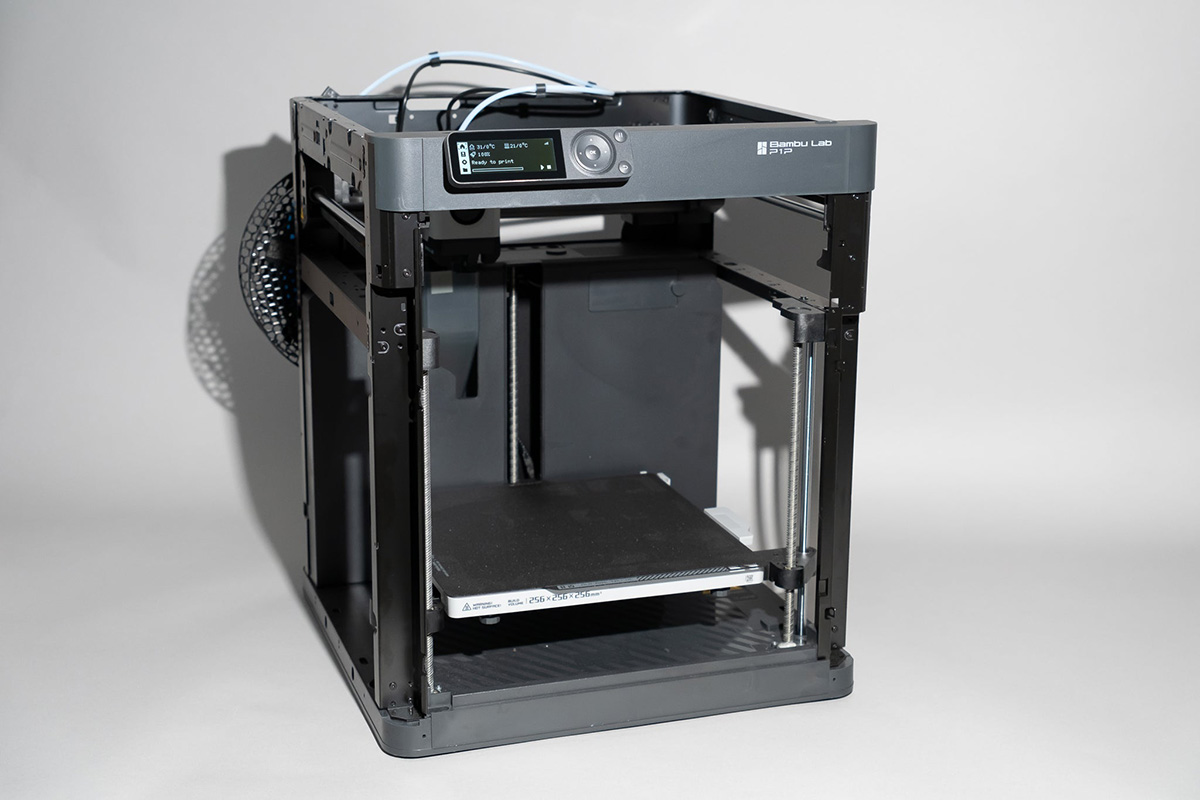

Welcome to the fascinating world of 3D printing! Whether you are a hobbyist, an artist, a designer, or an engineer, the ability to create physical objects from digital designs is an incredibly empowering and innovative endeavor. At the heart of 3D printing lies the 3D printer file, a digital blueprint that guides the printer in constructing the desired object layer by layer.

In this comprehensive guide, we will delve into the intricacies of 3D printer files, exploring how they work, how to create and edit them, and the process of converting files for seamless 3D printing. By the end of this journey, you will have a deep understanding of 3D printer files and the tools at your disposal to unleash your creativity in the realm of 3D printing.

So, grab your imagination and let's embark on this enlightening exploration of 3D printer files!

Key Takeaways:

- Understanding 3D printer files is crucial for creating precise digital blueprints that bring designs to life through 3D printing. Different file formats offer unique features and compatibility, empowering creators to optimize their designs for efficient and high-quality printing.

- Creating, editing, and converting 3D printer files requires meticulous attention to detail and iterative refinement. By embracing creativity, precision, and specialized software, creators can sculpt digital designs into refined and optimized files ready for seamless translation into physical form.

Read more: How Do You Use A 3D Printer

Understanding 3D Printer Files

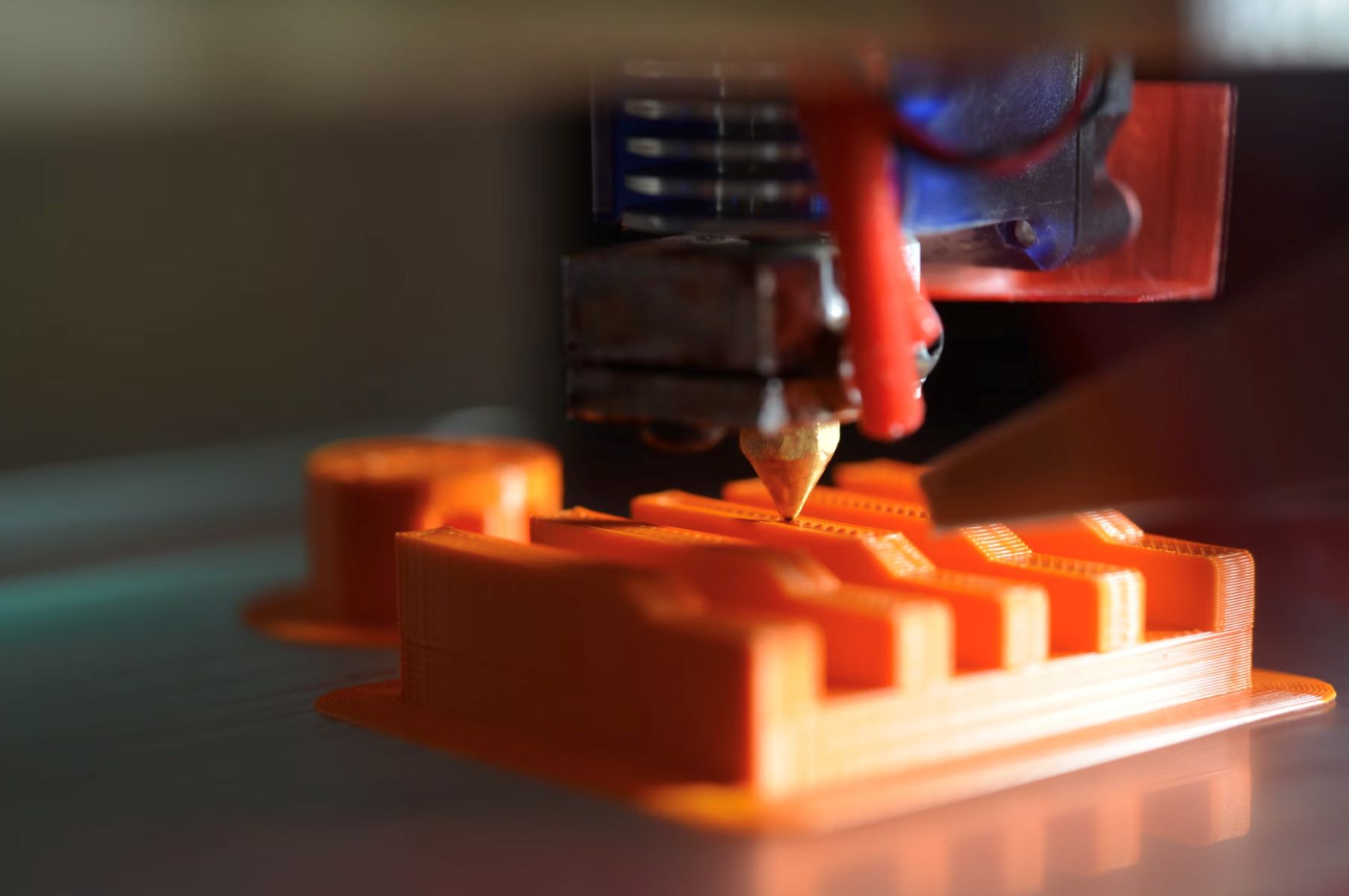

Before diving into the creation and manipulation of 3D printer files, it’s essential to grasp the fundamental concepts behind these digital blueprints. At the core of 3D printing is the concept of additive manufacturing, where objects are built layer by layer from the bottom up. This process is guided by 3D printer files, which contain the precise instructions for the printer to execute.

There are several file formats commonly used in 3D printing, each with its own unique features and compatibility with different printers. The STL (stereolithography) file format is one of the most widely used formats due to its simplicity and compatibility with a wide range of 3D printers. It represents 3D surfaces as a collection of interconnected triangles, providing a basic yet effective means of conveying the geometry of the object.

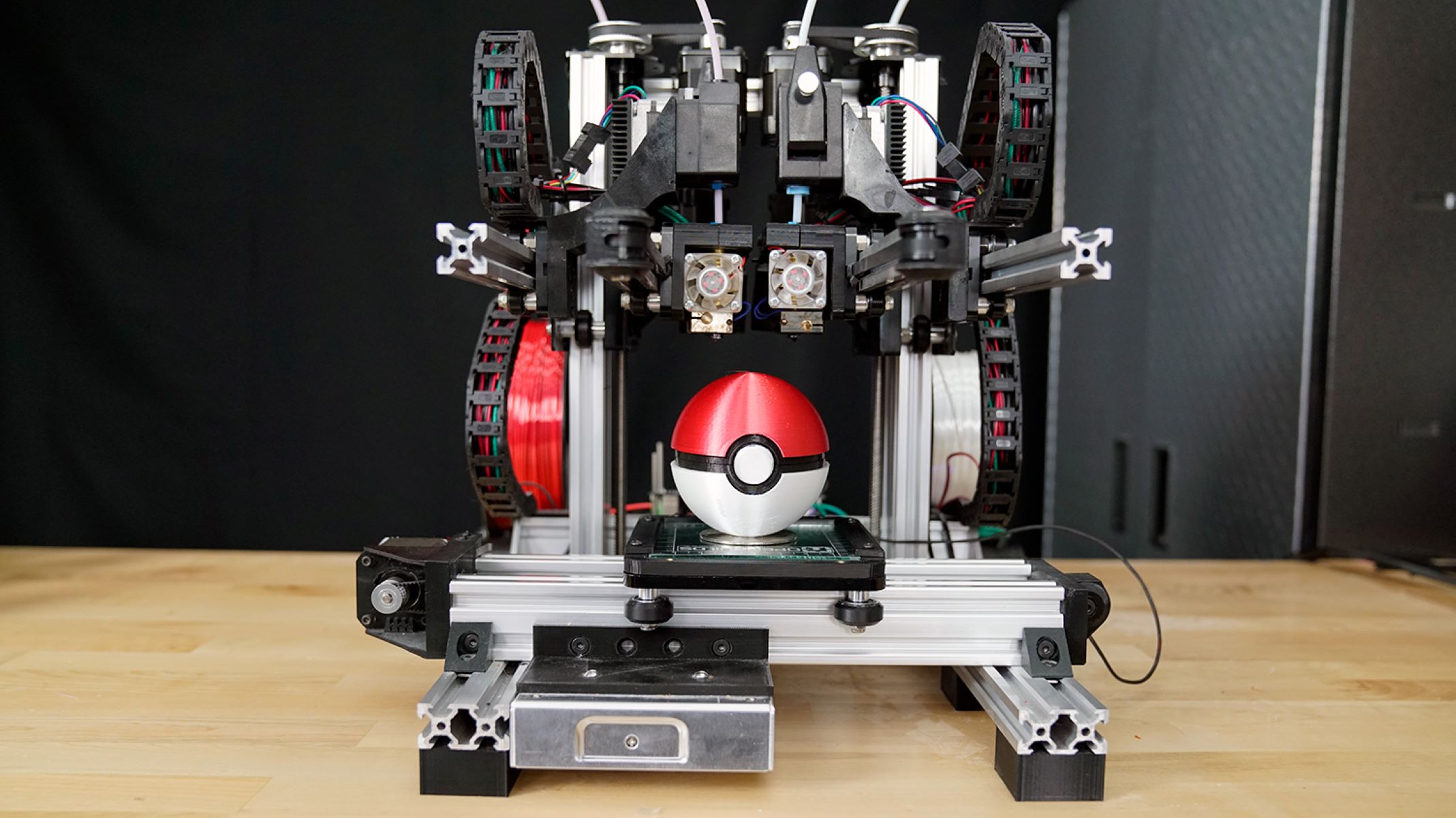

Another popular file format is the OBJ (object) format, which supports more complex geometry and can store color information, making it suitable for more intricate and visually detailed designs. Additionally, the AMF (additive manufacturing file format) has gained traction for its ability to convey not only geometry but also material properties and color, offering a more comprehensive representation of the intended object.

Understanding the intricacies of these file formats empowers creators to select the most suitable format for their designs, considering factors such as complexity, color requirements, and printer compatibility. Moreover, comprehending the structure of these files enables users to optimize their designs for efficient and high-quality 3D printing.

As we venture further, we will explore the process of creating and editing 3D printer files, equipping you with the knowledge and skills to bring your digital designs to life through 3D printing.

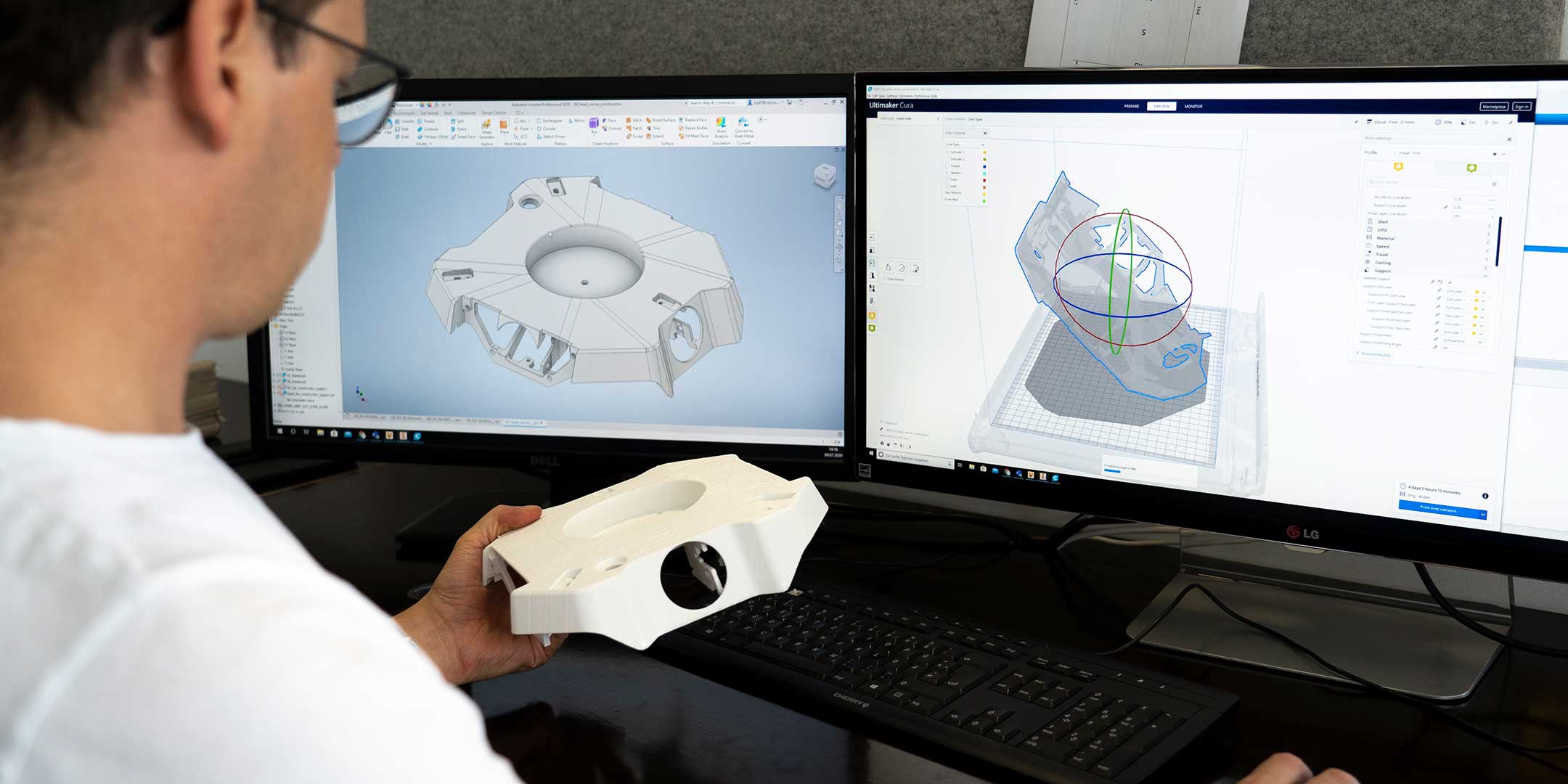

Creating 3D Printer Files

Embarking on the journey of creating 3D printer files is an exhilarating endeavor that allows individuals to transform their imaginative concepts into tangible objects. The process begins with the use of computer-aided design (CAD) software, which provides a platform for crafting and refining the digital blueprint of the intended object.

When creating 3D printer files, meticulous attention to detail is paramount. The design must be structurally sound, with considerations for appropriate wall thickness, support structures, and overall geometry to ensure successful printing. CAD software offers a plethora of tools for shaping and manipulating the digital model, allowing creators to unleash their creativity while adhering to the principles of effective 3D printing.

One of the key considerations during the creation phase is the choice of dimensions and scale. Ensuring that the digital model is accurately scaled to the desired real-world dimensions is crucial for achieving the intended size and functionality of the printed object. Additionally, incorporating precise measurements and clearances within the design is essential for seamless assembly and functionality post-printing.

Furthermore, the incorporation of intricate details and intricate features within the digital model requires careful consideration of the printer’s capabilities and the chosen printing materials. Understanding the limitations and capabilities of the 3D printer is essential for optimizing the design to achieve the desired level of detail and structural integrity.

Throughout the creation process, it’s important to maintain an iterative approach, refining the design based on simulations, prototypes, and feedback to ensure the viability and quality of the 3D printer file. This iterative refinement process is instrumental in honing the design to perfection before initiating the 3D printing process.

By harnessing the capabilities of CAD software and embracing a meticulous design approach, creators can craft 3D printer files that embody their vision with precision and artistry, setting the stage for the transformative journey from the digital realm to the physical world.

When creating 3D printer files, use design software like Tinkercad or Fusion 360 to create a 3D model. Save the file in a format compatible with your 3D printer, such as .STL or .OBJ.

Editing 3D Printer Files

Once a 3D printer file has been created, the journey of refinement and optimization often continues through the process of editing. Whether it involves fine-tuning the geometry, adjusting tolerances, or optimizing supports, editing 3D printer files is a crucial step in ensuring the successful realization of the digital design in physical form.

When delving into the realm of editing 3D printer files, the utilization of specialized software tailored for 3D modeling and printing is indispensable. These software solutions offer an array of tools and features that empower creators to modify and enhance their designs with precision and efficiency.

One of the primary considerations during the editing phase is the optimization of the design for 3D printing. This involves inspecting the model for potential issues such as overhangs, unsupported regions, or intricate features that may require additional support structures. By strategically adding or adjusting supports within the design, creators can mitigate printing challenges and ensure the integrity of the final printed object.

Furthermore, editing 3D printer files encompasses the refinement of surface textures, the adjustment of wall thickness, and the optimization of intricate details to align with the capabilities of the chosen 3D printing technology. This meticulous refinement process contributes to the enhancement of printability and the overall quality of the printed object.

Another pivotal aspect of editing 3D printer files involves the validation of the design through simulation and analysis tools integrated within the editing software. These tools enable creators to assess the structural integrity of the design, identify potential weak points, and simulate the printing process to anticipate and address any challenges that may arise.

Throughout the editing journey, embracing an iterative approach is essential, allowing creators to refine and optimize the design based on feedback, simulations, and real-world testing. This iterative refinement process plays a pivotal role in elevating the 3D printer file to a state of readiness for seamless and successful 3D printing.

By harnessing the capabilities of specialized 3D modeling and printing software, creators can embark on a transformative editing journey, sculpting their digital designs into refined and optimized 3D printer files that embody precision, functionality, and aesthetic appeal.

Converting Files for 3D Printing

As the digital landscape of 3D printer files continues to evolve, the process of converting these files for seamless 3D printing has become increasingly streamlined and versatile. The conversion phase plays a pivotal role in preparing the digital design for translation into physical form, aligning the file with the specific requirements of the chosen 3D printing technology and materials.

One of the key considerations during the file conversion process is the selection of the appropriate file format for 3D printing. While the initial design may have been created and edited in a specific file format, the conversion phase may involve translating the design into a format that is optimized for the target 3D printer and its associated software.

Moreover, the conversion process encompasses the preparation of the 3D printer file for the specific material that will be used during printing. This involves configuring parameters such as infill density, layer height, and support structures to align with the characteristics and behavior of the chosen printing material, whether it be filament, resin, or powder-based.

Furthermore, the conversion phase involves inspecting the 3D printer file for potential issues such as non-manifold geometry, overlapping surfaces, or other anomalies that may hinder the printing process. Addressing these issues during the conversion stage is essential for ensuring a smooth and successful printing experience.

Additionally, the process of converting files for 3D printing may involve the utilization of slicing software, which segments the 3D model into individual layers and generates the set of instructions that the 3D printer will follow during the printing process. This pivotal step in the conversion process optimizes the model for layer-by-layer construction, taking into account factors such as print speed, cooling, and structural integrity.

Throughout the conversion journey, it’s imperative to leverage the capabilities of specialized software that facilitates seamless file preparation for 3D printing. These software solutions offer a suite of tools for inspecting, optimizing, and refining the 3D printer file, culminating in a digital blueprint that is primed for successful translation into physical form.

By embracing the intricacies of file conversion for 3D printing, creators can ensure that their digital designs are meticulously prepared and tailored for a harmonious transition from the digital realm to the tangible world, where creativity and innovation converge through the transformative medium of 3D printing.

Read more: What Can You Make With A 3D Printer

Conclusion

Congratulations on embarking on this enlightening journey through the realm of 3D printer files! As we conclude our exploration, it’s evident that these digital blueprints serve as the linchpin of the transformative process that brings digital designs to life through the captivating medium of 3D printing.

From understanding the intricacies of 3D printer file formats to the meticulous process of creating, editing, and converting these files, we have unveiled the essential steps and considerations that underpin the seamless transition from digital design to physical object.

Throughout this journey, we have witnessed the pivotal role of creativity, precision, and iterative refinement in sculpting 3D printer files that embody not only the vision of the creator but also the functionality and aesthetic appeal that define the essence of 3D printing.

As you continue to explore the boundless possibilities of 3D printing, remember that the journey of crafting 3D printer files is a dynamic and evolving endeavor. Embrace the iterative refinement process, leverage the capabilities of specialized software, and immerse yourself in the artistry of digital design to unlock the full potential of 3D printing.

Whether you are a hobbyist, an artist, a designer, or an engineer, the realm of 3D printer files invites you to unleash your creativity, innovate with precision, and embark on a transformative journey where digital designs transcend into tangible manifestations.

So, with your newfound understanding and the tools at your disposal, venture forth with confidence, curiosity, and a passion for creation, as you continue to shape the future through the captivating art and science of 3D printing.

May your endeavors in the realm of 3D printer files be filled with inspiration, innovation, and the joy of witnessing your digital designs materialize into remarkable physical objects that enrich and inspire the world around you.

Frequently Asked Questions about How Do You Make 3D Printer Files

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Do You Make 3D Printer Files”